The 01 Aprilia Motorcycle SL1000 Falco is a beloved model among performance enthusiasts, admired not just for its speed but also for its sleek aesthetics. As a motorcycle business owner, understanding the importance of race fairings can elevate your offerings. This guide delves into the market for these components, their technical specifications, performance enhancements, cost considerations, and how they compare to other models in the sports category. Each chapter builds on the previous one to provide a comprehensive understanding of why race fairings are a worthwhile investment.

Racing Armor on the Marketplace: Navigating 01 Model Year Fairings for a Classic Italian Sportbike

Fairings are more than skin on a bike; they are the frontline of aerodynamics, protection, and identity. For a classic, late-90s to early-2000s sportbike from a renowned Italian maker, the 01 model year era represents a moment when race-inspired bodywork was still a user-serviceable, collectible commodity. As with many aging performance machines, the availability of genuine race fairings for this generation is a mix of aging stock—new old stock where it exists—and a broader, sometimes patchy market of replacements and replicas. The bigger truth behind the market: these pieces are finite enough that a rider-restorer or race-day builder must learn to read listings carefully, verify fit, and still expect a few tradeoffs between price, condition, and accuracy.

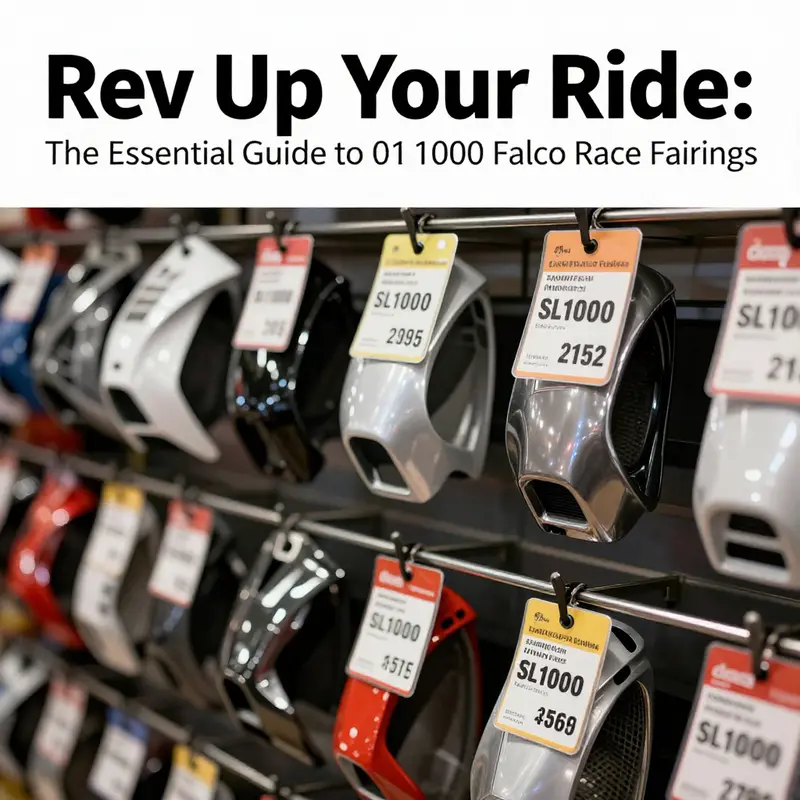

In practice, the search begins with the recognition that the bike’s original panels and race-oriented variants were produced in limited runs and then dispersed through a mix of dealers, private sellers, and specialty outlets. You will encounter listings that present the parts as new or as lightly used, with an emphasis on specific components like the upper and lower side panels, the front fairing, and the right- or left-hand pieces that carry integral indicators. A typical catalog scan from the market shows an example described as a gray lower panel belonging to this generation, advertised with a purchase price near eighty-two dollars and a separate shipping charge that can be in the neighborhood of fifty dollars. These numbers illustrate a broader trend: the parts are affordable to acquire by weight if you catch a good listing, but the total landed cost quickly climbs once you factor in the shipping, the potential for imperfect finishes, and the inspection needed to confirm the part’s compatibility with a given bike’s frame and electrical harness.

Another recurring item in the marketplace is the right-hand front fairing that includes an indicator. In recent listings, this component often appears with a modest asking price in the mid-fifties. The reminder here is straightforward: when you buy a shell that still houses an indicator, you are not simply purchasing a cosmetic piece. You’re obtaining a portion of a circuit, a connector geometry, and a mounting plan that must align with the bike’s frame geometry and the instrument wiring. The practical reality is that even when the outside looks sound, the internal attachment points may have been stressed through use, or the connector housings may have degraded with age. This is not only a matter of visual fit; it is a functional equation—will the indicator operate cleanly, and will the mounting tabs align with the bike’s mounting points without modification?

The market for these parts is, in essence, a negotiation between scarcity and desire. On one side, collectors and racers seek original pieces to preserve authenticity and maintain correct geometry. On the other side, riders who want to restore function—get back to a fairing kit that seals against wind and rain while protecting the battery, the ignition coils, and the delicate electronics—often turn to aftermarket or refurbished components. An important part of that negotiation is the part’s reference and its fitment notes. While a given listing may reference a year like 2003, the exact production run and the model’s sub-variants can differ in ways that affect mounting points, the curvature of the inner fairing’s contour, and even the alignment of the mounting pegs. In other words, the same general shape may come from slightly different tooling across production batches, and buyers should treat each listing as a potentially unique case study rather than a universal blueprint.

From a practical standpoint, the path to a successful acquisition is as much about due diligence as it is about price. Start with the year compatibility: confirm that the fairing piece is designed to fit the model’s front contour and frame offset, particularly if you intend to retain the stock indicators or integrate aftermarket lighting. Ask for clear photos of all mounting tabs, the integrity of the edge profiles, and the condition of the inner surfaces that mate to the bike’s subframes. Any listing that is light on pictures or offers vague language about fitment should be treated with suspicion. The risk of hidden cracks, torn mounting lugs, or warped contours is high with used parts, and those flaws can translate into costly installation headaches that cancel out any perceived savings.

Color and finish also play a crucial role in the restoration equation. The gray hues described for some lower panels mirror the period’s aesthetic, but color matching can be elusive after years of sun exposure and heat cycling. If you’re building toward a period-correct look, you may find yourself repainting panels or seeking a closer match from the same vintage palette. Paint matching is not merely cosmetic; it is a practical barrier to a clean overall install, especially when the rest of the bodywork has been preserved or restored with attention to original shading and gloss levels. Color tolerance matters because mismatched panels can draw attention in ways that even a well-fitted fairing cannot disguise. In this light, buyers should factor in potential repaint costs and the time needed to achieve an even, showroom-like finish across all fairing pieces.

As this market unfolds, the value proposition of a given part must be weighed against broader restoration goals. A right-hand front fairing with an indicator, for example, may be priced modestly, reflecting its functional state and cosmetic wear. A lower panel, with its own unique indexing and attachment points, might command a similar or slightly higher price depending on its condition and whether the surface shows stress lines or fading from sun exposure. The arithmetic is straightforward but the outcomes vary widely—sometimes a bargain panel arrives with flawless tabs and a pristine inner surface; other times the piece shows microfractures along mounting corners that will demand careful reinforcement or replacement entire sections. The buyer’s tolerance for risk—whether they are chasing a concours-standard restoration or a race-ready shell that will be bolted onto a bare frame—will guide the decision. In the end, the market’s mosaic of listings becomes a practical map for assembling a coherent package: one primary fairing shell, a compatible indicator assembly or an aftermarket stand-in, and the necessary hardware that survives the test of time.

For those who are newly entering this particular corner of vintage performance biking, a telling sign is the profile of available parts across markets. Some listings reflect a distribution channel that includes both private sellers and small parts houses that catalog parts by year ranges and model families. The advantage of working with a seller who can supply measurements, mounting diagrams, and a returns policy is clear: it reduces the probability of accruing misfit parts and the misalignment that leads to a half-install and a lot of adjustment. The trade-off, of course, is that such sellers can be price-competitive yet still must cover the overhead of sourcing and verifying vintage inventory. The balance between guaranteed compatibility and price convenience is the crux of the decision-making process for anyone looking to stitch together a complete set of fairings for this generation.

From a broader perspective, this market narrative mirrors the ongoing evolution of vintage performance components. As time passes, original tooling becomes rarer, and the availability of exact-fit race fairings grows more episodic. The resurgence of interest in classic configurations, both for track bikes and for show builds, sustains a lively, if uneven, ecosystem of parts. This is where the value of patient searching, cross-checking part numbers (even when they are not named in this discussion), and connecting with knowledgeable sellers becomes clear. The modern rider who treats a fairing acquisition as a small but meaningful project will benefit from a careful blend of price awareness, inspection discipline, and clear expectations about fit and finish. The result is not just a set of body panels, but a coherent path toward re-creating the bike’s lines, its aerodynamics, and its presence on the road or on the track.

External reference: For an explicit example of a current marketplace listing for a component from this generation, see the external resource linked here. It provides the description and price context that many buyers will encounter as they evaluate whether to pursue a particular piece in the hopes of a near-perfect restoration or a competitive rebuild. https://www.ebay.com/itm/Aprilia-SL1000-RH-Front-Fairing-with-Indicator-2003-SL1000-Falco-Ref-BK051/363987231942?hash=item54d3a2e3b6:g:ZmYAAOSwqyVfjFzC

How the 2001 Aprilia SL1000 Falco Race Fairings Were Engineered: Materials, Aerodynamics, and Fitment Insights

The race-style fairings developed for the 2001 Aprilia SL1000 Falco were created with a clear set of priorities: reduce aerodynamic drag, increase high-speed stability, protect critical components, and keep weight low. These goals shaped every design decision, from the curvature of the nose cone to the choice of inner reinforcements. While an exhaustive spec sheet from the factory is not widely available, what survives in parts listings, supplier notes, and enthusiast documentation paints a consistent technical picture grounded in performance-driven choices.

Aprilia’s approach to the Falco’s race fairings begins with geometry. The front end adopts a low-profile, pointed nose that narrows airflow and reduces frontal area. Side panels sweep rearward and tightly wrap the headlight and instrument area, forming a continuous surface that channels air toward the bike’s midsection. The rear tail unit is truncated and compact. This cut-off tail minimizes wake size behind the rider and seat, reducing turbulence at high speed. Integrated air intakes and channels are positioned to feed cooling airflow to the engine and brakes without disrupting the primary aerodynamic path.

Materials follow that same logic. Most race fairings offered for this model are molded from lightweight composites. Fiberglass was the common option for many OEM and aftermarket pieces, offering an economical balance of light weight and repairability. Higher-end variants and true track-spec bodies used carbon fiber or carbon-kevlar blends where stiffness and weight reduction were more critical. These composites yield a high stiffness-to-weight ratio. They also tolerate the heat and vibration characteristic of a 60–70 mph plus race environment. Inner surfaces often received local reinforcement where fasteners or mounting points concentrate loads. Such interior supports maintain alignment and prevent cracking under repeated track stress.

Mounting architecture is another important technical area. Race fairings for the SL1000 Falco were designed to interface with the bike’s original mounting bosses and subframe attachments where possible. However, because the fairings prioritize lightweight, some components trade integrated brackets for removable inserts or bolt-on plates. This allows racers to fit or remove fairings quickly and to use stronger steel or aluminum plates at stress points. Typical attachment points include the upper triple clamp region, lower engine cradle brackets, and several rear subframe anchors. Exact hole patterns and dimensions vary between OEM and third-party pieces; careful test-fitting is common practice. Enthusiast forums and parts suppliers recommend checking the alignment of all mounting points before cutting or trimming any fairing for fit.

Aerodynamic detail extends beyond simple shapes. Surface transitions are compressed and smoothed to avoid flow separation. Headlight areas feature contoured recesses or flush-fitting covers to reduce drag. Where cooling intakes exist, they are shaped to create pressure recovery and direct air precisely to radiators or brake ducts. The underside panels guide airflow around the engine and toward the tail, reducing lift at the front and promoting stability. On track-oriented kits, small ducts or louvres can be found near the lower panels to channel airflow for oil coolers or to vent hot air. The deliberate placement of these outlets helps manage underbody pressure and prevents high-temperature buildup in critical areas.

Weight considerations are practical and strategic. Fiberglass lower panels commonly weigh notably more than carbon components, but they provide a good compromise between cost and durability—valuable for weekend racers and restoration projects. Carbon sets reduce mass further and can drop rotational and unsprung weight slightly when the kit includes lightweight inner panels and tail sections. Riders report that the difference in handling becomes more noticeable at sustained high speeds where decreased frontal area and lower mass translate into reduced rider fatigue and marginally quicker directional changes.

Structural integrity receives attention through inner supports and reinforcement plates. The rear fairing often incorporates an internal support section that maintains the tail unit’s shape and supports the rider’s weight if a solo seat is used. Listings for genuine parts mention interior pieces described as inner rear assemblies. These reinforce the outer shell and secure the tail to the subframe. Similarly, the belly pan or lower panel commonly includes ribs or channels on its inner face to resist flexing and to support the engine’s proximity to the fairing where contact risks are greater.

Thermal and environmental considerations are part of the design. Composite fairings resist fuel, oil, and coolant exposure fairly well, but heat shielding or venting is often used where proximity to headers or radiators might cause softening or discoloration. Race fairing kits frequently leave space for protective heat shields or include pre-formed cutouts that match the Falco’s exhaust path. Paint and surface finishes can affect thermal behavior too; darker finishes absorb more heat, while light gelcoats dissipate heat differently. For racers, the practical path is to leave inner surfaces unpainted where heat exposure is highest and to use heat-resistant coatings selectively.

Fitment variations exist between OEM race and aftermarket kits. Genuine parts are designed to conform closely to original frame and accessory layouts. Aftermarket alternatives sometimes require minor trimming at the edges or the use of adaptors for mounting points. This is especially true for lighting and instrumentation areas if the racer chooses to fit blanking plates or flush panels to achieve a cleaner nosecone. Adapters and universal mounting plates help when swapping turn-signal mounts, mirror brackets, or auxiliary sensors.

Maintenance and repair considerations shaped many of the manufacturing choices. Fiberglass allows for inexpensive repairs with standard resins and cloth. Carbon fiber repairs are stronger but require specialized epoxy systems and attention to prep work. Inner reinforcements and removable brackets make it possible to replace single damaged pieces without buying an entire kit. Fastener selection matters: stainless or zinc-coated hardware is typical to resist corrosion, and nylon washers or rubber bushings are used to isolate vibration where needed.

For exact dimensions, hole patterns, or material callouts, the most reliable path is to consult period service documentation or reputable parts suppliers that catalog genuine OEM items and their internal support pieces. Such listings often reference inner rear assemblies and lower panels by specific part codes. One supplier’s catalog entry for a rear fairing inner assembly confirms that the Falco’s race fairings incorporated internal reinforcement elements to preserve structural integrity under track use.

Those working to restore or upgrade an SL1000 Falco with race fairings should plan for a test-fit stage, account for potential trimming or adapter plates, and select materials that suit their budget and performance needs. Race fairings are more than cosmetic; they are an engineered system that balances aerodynamics, protection, and durability for spirited riding and track environments.

For enthusiasts seeking comparative options or kits inspired by classic sportbikes, a dedicated collection of period sportbike fairings can serve as a useful reference point: https://www.summitfairings.com/collections/yamaha-yzf-r1-fairings-2000-2001

For more specific part listings and a closer look at original inner support parts referenced above, consult archival parts suppliers that carry genuine components for the Falco: https://www.mth.co.uk/parts/motorcycle-parts/aprilia/74365-aprilia-sl-1000-falco-bj-01-rear-fairing-inside-rear-a158c.html

Aerodynamic Edge: Performance Enhancements from Race Fairings on an Early-2000s V-Twin Sport Bike

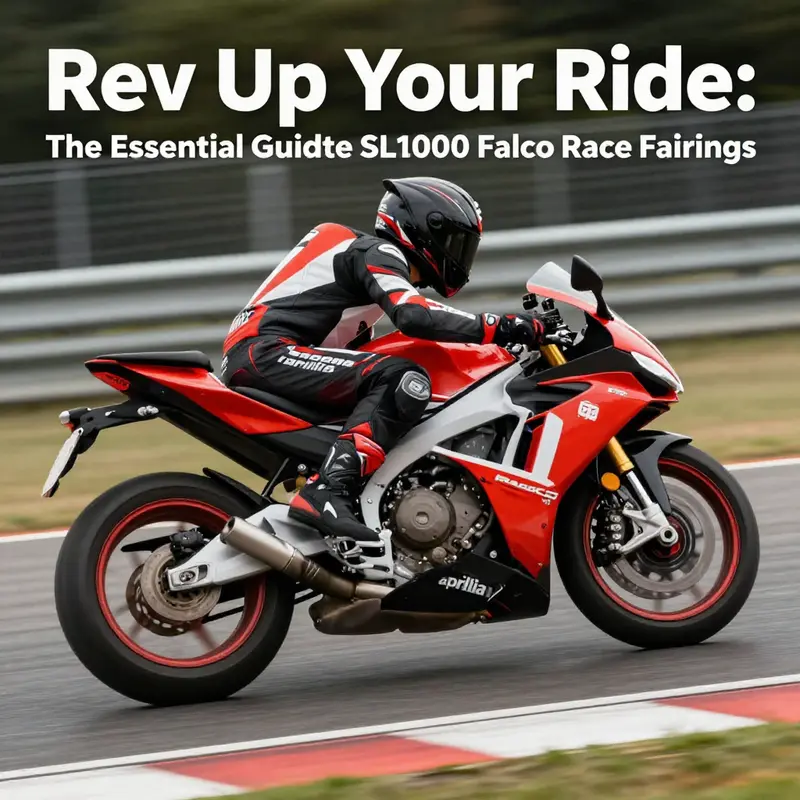

Fairings are more than cosmetic shells; they are precision tools that redefine how a motorcycle slices through air. When you search for race-oriented bodywork from the early 2000s, you encounter a class of components designed to streamline airflow, manage turbulence, and protect the rider and engine under the most demanding conditions. The chapter that follows looks beyond paint and badge to the core ways race fairings influence performance on a mid-weight, V-twin sport bike from that era. The discussion weaves together aerodynamics, engine cooling, handling stability, rider comfort, and the practical realities of sourcing and fitting these panels. The throughline is simple: the right fairings can unlock a meaningful, measurable uptick in how the bike behaves on the road and on the track, without compromising safety or reliability.

From the outset, the most evident impact of race fairings is aerodynamic efficiency. A well-designed fairing pair reduces the stubborn drag that resists forward motion at speed. By curving the upper surfaces to minimize flow separation and by shaping the sides to channel air smoothly around the rider and the engine, the bike experiences less pressure drag and less parasitic lift. The result is a cleaner pressure gradient along the bike’s profile, which translates to a higher effective top speed and a more stable ride at velocity. Aerodynamics here is not about a single trick—it’s about an integrated system where every contour contributes to how air flows around the bike in a range of lean angles, crosswinds, and rutty road sections. In practical terms, riders often report that a motorcycle equipped with race fairings feels more poised when racing toward the apex, especially as the speeds climb and the wind becomes a dominant teammate—or adversary.

A key aspect of this aerodynamic equation is airflow management around the engine and cooling pathways. The fairings guide air toward critical components in a controlled manner, sculpting streams that cool the engine, shed heat efficiently, and prevent hotspots during sustained riding. In performance riding, overheating is not a mere inconvenience; it can cap the engine’s power delivery as the temperature climbs. When the airflow is optimized, the engine is permitted to sustain higher revs for longer intervals without the thermal throttling that can dull acceleration. The same airflow management often helps maintain more even temperatures across oil and coolant circuits, contributing to consistent power output after aggressive laps or long highway stints.

The stability of a high-speed machine is deeply entwined with its aero profile. A well-executed fairing package reduces buffeting and yawing moments that can unsettle the rider at speed or in gusty conditions. The flow pattern around the rider’s torso and the rear section of the bike can be tuned to minimize turbulent wake that would otherwise reflect back into the cockpit and disturb steering feel. In practice, this translates into a sensation of smoother handling at the limit, where tiny changes in line and throttle input would previously provoke a noticeable twitch. For riders pushing toward the upper end of performance, that stability is itself a performance lever, allowing more precise control in corner entry, mid-corner stability, and late exit thrust as the throttle is rolled on aggressively.

Rider fatigue is often overlooked in the performance calculus, yet it matters just as much as top-end speed. Airflow around the rider’s body is a major contributor to fatigue over long sessions or endurance-style rides. Proper wind management with race fairings reduces the drag the rider must overcome simply to stay in a stable position. This is not just about comfort; reduced drag can preserve grip and hand strength over the duration of a race or a long session at speed. The rider’s ability to maintain form, keep shoulders relaxed, and focus on lines rather than wrestling with the wind translates into more consistent lap times and a more enjoyable riding experience overall.

Turbulence management sits at the heart of a race fairing’s behind-the-scenes performance. An integrated rear section, often designed to minimize wake turbulence behind the rider and the engine, complements the front-end aerodynamics. This rear-channeling effort reduces the drag produced by the rider’s body as it sits in the air, shifting more energy toward forward momentum and away from wasted turbulence. The effect, while subtle to the casual observer, can be meaningful in track conditions where every fraction of a second counts. It is the culmination of careful shaping: the fairing’s lower contours support smoother air currents beneath the bike, while the rear profile blends the rider’s silhouette with the bike’s geometry so that the wake remains more compact and efficient.

From a parts and procedure perspective, riders and technicians often discuss the distinction between OEM (original equipment manufacturer) components and aftermarket race fairings. OEM pieces are designed to fit the bike with factory tolerances and to preserve the bike’s integrity and safety margins. They ensure that mounting points, panel alignment, and internal recesses cooperate with the bike’s structural frame and electronics. Aftermarket fairings, by contrast, can offer a wider range of aesthetic choices and sometimes lighter material builds, with the trade-off of needing careful fitment and mounting to prevent vibration, rubbing, or misalignment under dynamic loads. The right approach respects both tracks of thought: secure fitment that preserves safety and fit, while recognizing the performance philosophy that a meticulously crafted shell can contribute to a more coherent aero package.

In this overlap between engineering and practical maintenance, the availability of authentic or compatible fairing sets matters. For enthusiasts seeking to restore or modernize a bike from this era, the priority is to locate panels that align with the frame geometry and the rider’s seating position. A precise fit ensures that the air channels perform as intended, that the mounting hardware does not interfere with cables, and that the fairings stay secure through high-speed transitions. The result is a consistent performance story: a package that not only looks purposeful but behaves predictably under load, with the expected improvements in aerodynamics, cooling, and comfort.

A broader glance at the fairing landscape shows a wide spectrum of styling and function. The catalog of modern fairings reflects the same design language that governs performance: shaping air to work with the bike rather than against it. For riders curious about the range of styling and fitment options, a quick look at a comprehensive catalog can illuminate the breadth of configurations available for different chassis geometries. In this spirit, it is useful to explore collections that focus on sport-bike fairings to understand common mounting schemes, material choices, and integration points with radiators, oil coolers, and subframes. An example of such a resource is the Honda fairings collection, a reference point for how a modern supplier frames fitment, dimensions, and compatibility across a family of bikes. This internal link provides a sense of how a well-organized catalog communicates the essential details that matter to a builder or rider chasing a cohesive aero upgrade: Honda fairings collection.

The practical steps to achieving the promised aero gains begin with an honest assessment of the bike’s current geometry and the rider’s stance. A fairing package must align with the rider’s height, posture, and riding style to maintain the intended airflow patterns. If the rider sits more upright, the fairing must still guide air efficiently over the torso, while not creating excessive pressure on the chest that would impede breathing or comfort. Conversely, a sportier crouch requires contours that sweep air smoothly past the shoulders and back, shaping a wake that reduces drag without bending the rider into an uncomfortable posture. The installation needs careful torqueing of bolts, verification of clearances near the brake lines and throttle cables, and sometimes trimming or adjusting edge gaps for a seamless look and reliable performance. The goal is to preserve a clean, balanced silhouette that the wind trusts, rather than a hasty assemblage of panels that rub, rattle, or flutter at speed.

As a broader takeaway, race fairings are a performance philosophy, not a single modification. They symbolize an engineering mindset: every contour is a choice about how air will move, where heat will escape, and how the rider will interface with the wind. The perceived gains—quieter wind at the rider’s helmet, steadier lines through corner entries, cooler engine bays, and reduced rider fatigue—are the tangible dividends of that philosophy. They are not universal miracles; rather, they are the result of careful design, precise manufacturing, proper fitment, and the rider who knows how to ride with the balance the new bodywork affords.

For readers who want to see how this thinking translates into practical sourcing and fitment, modern suppliers offer a spectrum of options that respect OEM interfaces while extending the aero envelope. The emphasis remains on compatibility, structural integrity, and a finish that ages gracefully with use. The best projects begin with a clear plan: identify the bike’s key airflow bottlenecks, select a fairing model that preserves or enhances clearance and protection for electronics, and proceed with careful mounting and testing. In the end, the upgrade is not merely about looking fast; it is about giving a motorcycle a coherent aerodynamic personality that responds to rider input with confidence, consistency, and a touch more pace when pushed into fast sections and demanding corners.

External resource for further physics-based context on racing aerodynamics can provide a deeper understanding of the principles behind these effects. See NASA’s educational overview of airflow and aircraft performance for a grounded explanation of drag, lift, and flow separation and how these principles apply to motorcycle aerodynamics: https://www.grc.nasa.gov/www/k-12/airplane/airplane.html

null

null

How the 2001 SL1000 Falco Race Fairings Stack Up: Design, Fit and Year-to-Year Differences

The 2001 SL1000 Falco race fairings occupy a particular place in the model’s lineage. They reflect a design philosophy that balanced aggressive sport styling with practical durability, and they still influence how owners choose replacements or upgrades today. When examining these race-style panels, the rear section—identified by the factory as component A158C—illustrates the era’s priorities: angular lines, clear attachment points, and a form shaped to integrate with the Falco’s existing bodywork rather than to radically redefine it. That approach produced a set of panels that look purposeful on the street and function reliably on track days, but the subtle differences between model years and variants mean fitment and performance can vary noticeably.

The physical characteristics of the 2001 rear fairing reveal why it’s distinct. The A158C rear section exhibits a pronounced, somewhat angular silhouette that ties visually to the bike’s front and mid-fairings. Its mounting points align with chassis brackets specific to that year, so the piece doesn’t simply clip onto later or earlier frame points without modification. This stresses a simple truth for Falco owners: matching the component to the model year matters. Even when shapes look similar, small changes in tab placement, depth of recesses, or the radius of a mounting hole can force adjustments that add time, cost, and uncertainty to an installation.

Styling is often the first thing riders notice. The 2001 panels have sharper creases and a more muscular posture than the smoother, softer lines introduced on later Falco iterations. Those later designs aimed to refine airflow and visual cohesion, producing panels that look more modern and integrate some aerodynamic smoothing not present in the 2001 pieces. For a rider who values the classic early-2000s sport look, the 2001 fairings deliver authenticity. For someone chasing marginal aerodynamic gains or a sleeker profile, later-year panels or race-only variants may be more appealing.

Aerodynamics and functional performance are important but sometimes overstated in everyday riding. The 2001 fairings were engineered with performance in mind, yet they lack some of the minute aerodynamic tweaks found on later models and dedicated race kits. Small changes introduced in subsequent years—subtle curvature adjustments, refined venting, and repositioned edges—reduce drag and improve stability at higher speeds. On long straights or during competitive track sessions, those refinements produce measurable benefits. For street riders and occasional track users, however, the 2001 fairings still provide secure airflow management and adequate protection for mechanical components.

Parts availability plays a decisive role when choosing whether to keep, repair, or replace original panels. Genuine, year-specific components still surface through specialist catalogs and salvage inventories, but scarcity increases as years pass. Because the 2001 fairings include unique mounting arrangements and contour details, direct interchangeability with 2003 or later Falco parts is limited. This reality affects repair strategy. Owners who want a straightforward drop-in replacement should pursue the exact year designation. Those open to modification, or who prefer aftermarket alternatives that mimic the 2001 look, must budget for fitting work such as relocating tabs, trimming inner edges, or adding reinforcing plates.

Beyond fitment, material considerations matter. Factory race-style panels typically prioritize a balance of weight and resilience. The original parts use moulded plastics formulated for impact resistance and shape retention. Aftermarket race fairings may trade some durability for lighter weight, using thinner laminates to shave ounces—an attractive proposition for track-focused riders but potentially less robust for road use. When selecting replacements, think about use case: frequent street commuting benefits from tougher stock-style panels; track-only machines perform better with lighter, race-specific kits even if they require more frequent repairs.

One practical advantage of the 2001 fairings is their visual compatibility with the Falco’s electrical and exhaust routing. Cable runs, mounting brackets for lights, and heat shielding all assume the geometry of that year’s panels. When installing a panel from a different year or a generic race shell, small mismatches often arise: indicator mounts sit slightly off, inner liners do not sit flush, or vents no longer align with cooling ducts. These are solvable problems, but they add complexity. Many owners opt to source inner panels and brackets at the same time as outer shells to ensure a cohesive fit.

Maintenance and repair considerations also favor retaining the original design when possible. Replacement panels that match the 2001 configuration make it easier to restore the bike to factory condition for resale or inspection. Conversely, swapping to a later or non-matching fairing set can complicate registrations in some jurisdictions or raise questions during safety checks. For enthusiasts who prize authenticity, finding a correct-year rear section often becomes a priority even when an aftermarket option is cheaper and lighter.

Cost is an unavoidable factor. Genuine, year-specific panels often command a premium because they are rarer and because their fitment reduces the time and labor costs associated with installation. Aftermarket alternatives offer more affordable options, sometimes in different colorways or prepped for custom paint. When comparing costs, factor in potential modification expenses. The least expensive shell on paper can become the most costly if substantial trimming, bracket fabrication, or reinforcement is required.

For owners considering cross-year swaps, the key is measurement and verification. Compare mounting tab spacing, depth of recesses for lights and indicators, and the overall curvature where panels meet along the spine and belly areas. Small differences in these dimensions translate to big hassles during installation. If possible, inspect the donor panels on a similar bike or request detailed dimension photos from sellers. That diligence often saves time and avoids surprises.

Finally, consider the broader aftermarket ecosystem. While parts for other makes and models are plentiful, options specific to this Falco year are more constrained. For riders who appreciate browsing compatible fairings across manufacturers, resources showcasing fairings for various sportbikes can spark ideas for custom work or adaptation. One useful reference for fairing shapes and fittings across different sportbikes is the collection of Yamaha YZF R1 fairings from 2002–2003, which illustrates how small design evolutions affect fit and function: https://www.summitfairings.com/collections/yamaha-yzf-r1-fairings-2002-2003.

For a precise match and long-term reliability, tracking down a rear fairing specified for the 2001 Falco—complete with its inner liners and original mounting hardware—is the most straightforward path. If exact parts are unavailable, deliberate modification and careful material selection can yield a successful result, but doing so requires time, tools, and a willingness to adapt. For anyone balancing authenticity, performance, and cost, the differences between the 2001 panels and later or alternate options illustrate a central truth: small design choices matter. They determine not just how a bike looks, but how it fits together, how it performs, and what it will take to keep it on the road or ready for the track. Additional technical details and part listings for the 2001 rear fairing inside (A158C) are available from archived parts catalogs and specialist listings: https://www.mthmotorcycles.com/parts/aprilia/sl1000/falco/2001/rear-fairing-inside-rear-a158c.html

Final thoughts

Understanding the 01 Aprilia Motorcycle SL1000 Falco race fairings can significantly improve your business offerings, enhance customer satisfaction, and potentially increase sales. By staying informed about the market, technical specifications, performance benefits, cost aspects, and competitive comparisons, you’ll position your business as a knowledgeable resource. Investing in quality race fairings is not just about aesthetics; it’s a strategic move to meet the high demands of motorcycle enthusiasts seeking that competitive edge.