The demand for rapid access and maintenance in high-performance motorcycles has led to the adoption of 1/4 turn screw fasteners, also known as quick-release fasteners. These fasteners play a critical role in the motorcycle industry, especially for racing and performance models, where every second counts. This article delves into the comprehensive utility of 1/4 turn screw fasteners, examining their design, technical specifications, and real-world applications. Additionally, market trends and the availability of these fasteners will be explored. Understanding these elements provides a roadmap for motorcycle businesses to enhance maintenance efficiency and racing performance, ultimately contributing to customer satisfaction and enhanced user experiences.

Turning Speed into Precision: The Craft and Engineering of 1/4-Turn Fasteners for Motorcycle Fairings

The skin of a motorcycle, especially when it wears racing-grade bodywork, is more than just a shell. It is a carefully engineered interface between the air, the rider, and the machine’s performance. In that interface, the fasteners that hold the fairings together play a crucial, if quiet, role. Among the most transformative tools in the rider’s toolkit are 1/4-turn screw fasteners. Known in the paddock as quick-release fasteners or quarter-turn fasteners, these small devices compress and align panels with a speed and reliability that can feel almost systemic. The essence of their value lies in the simple geometry of a 90-degree turn. A quarter turn locks the fastener, holds the panel secure, and offers a predictable release path for maintenance or aerodynamic changes. When every millisecond counts, and when the bike must be prepped for a hot track session in a morning chill, such devices prove their worth in practical, tangible ways. They minimize downtime and maximize uptime, turning what could be an hour-long panel swap into a brief interlude between practice runs. The beauty of the system is not merely about speed; it is about repeatable, robust function under the relentless stresses of racing, where vibes, wind, and the vibrations of the engine all conspire to loosen less purposeful hardware.

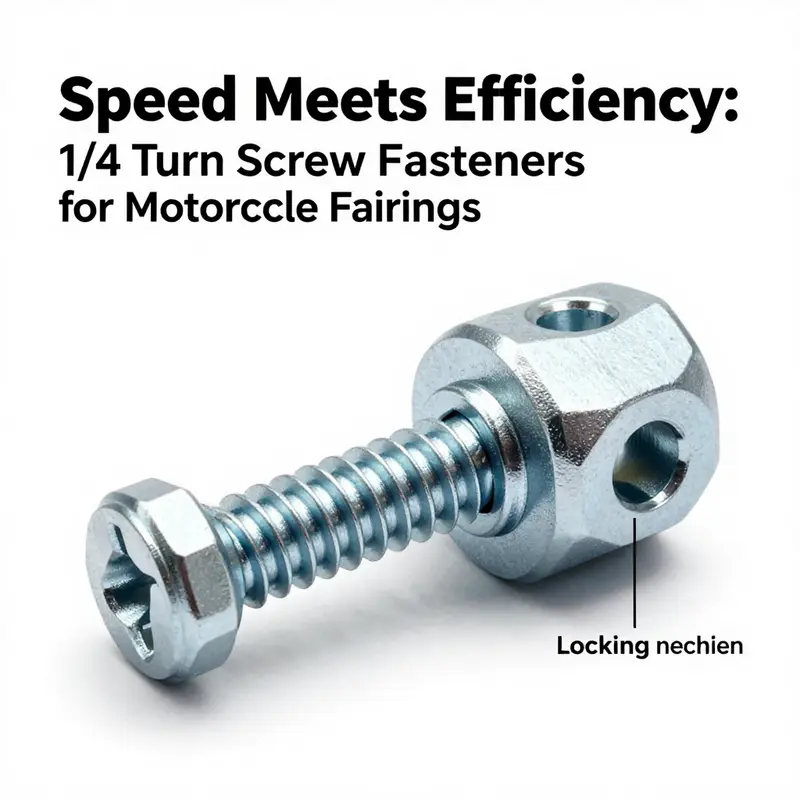

The mechanism is deceptively simple. A stud is mounted into the fairing or sometimes into the frame, and a corresponding clip or retainer threads onto the stud. When the two pieces engage, a 90-degree twist draws the two halves together. The design provides a strong clamping force without the need for power tools or complicated torque sequences. That simplicity is its strength: fewer moving parts, fewer steps, and less risk of cross-threading during hurried pit times. For the rider, this translates into confidence. You know that a fairing will seat correctly, that the panel alignment will be consistent, and that the finish will not be marred by a missing screw or a misaligned clip at the edge of a wind-cut line.

Materials play a fundamental role in the reliability of these fasteners. Stainless steel and other corrosion-resistant alloys are common, chosen for both their strength and their resistance to environmental exposure. In a sport environment, where rain, mud, brake dust, and road spray are daily companions, the longevity of these fasteners matters as much as their lock integrity. Anti-vibration features further enhance reliability. Well nuts, designed to compress and seal while accommodating panel movement, help absorb vibration without loosening the fastener. Anti-vibration washers are another pragmatic addition, reducing micro-movements that can degrade the clamping force over time. These little details, frequently overlooked by casual observers, are precisely the kind of engineering nuance that separates a dependable high-performance fairing system from a fragile one.

The typical installation set is a compact orchestra of parts. You’ll find threaded studs—commonly in M5 or M6 for the small to mid-size panels—paired with clips or nuts that screw onto the stud. Lengths vary to accommodate different panel thicknesses and fairing structures, with 16 mm, 20 mm, and 25 mm lengths among the usual options. The kits often include a selection of bolts, washers, and sometimes well nuts to provide a watertight seal at critical junctures. Basic tool access is intentionally minimal, and many setups are designed to be hand-operated, with the option of a tiny hex key for final tensioning. The result is a fastening system that is both precise and forgiving: you can snug a panel without over-tightening, and you can remove it quickly without hunting for the right screwdriver or torque spec in the pit lane.

What makes 1/4-turn fasteners particularly compelling for racing fairings is their balance of strength, weight, and accessibility. The fasteners themselves are compact, contributing little to the overall mass of the bodywork, yet they carry the load of the entire panel and maintain alignment under distortion from air loads and rider movements. The 90-degree action creates a defined engagement; the components are designed to resist back-off under vibration, but they remain capable of being released in a controlled way when necessary. This interplay between secure engagement and quick disengagement underpins the practical essence of the system. For riders who routinely swap fairings to experiment with winglets, canard configurations, or different air intakes, the ability to reconfigure the bodywork without a full toolbox is more than convenience—it’s an enabler of iterative design.

In real-world use, the ease of use translates into consistent aesthetics as well. A fairing set that is cleanly fastened looks pristine. The panels align with precision, gaps are even, and the overall surface looks intentional rather than jury-rigged. The absence of visible, protruding screws on some race fairings is not merely cosmetic. It reduces parasitic drag and helps maintain the unbroken lines that teams chase for aero efficiency. It also reduces the chance of snagging in grass or during pit-side work, where a protruding head or accidentally loosened fastener can cause more problems than it solves. The visual discipline of a well-fastened fairing—neat lines, uniform gaps, and a consistent finish—becomes part of the rider’s identity on the track.

The production and procurement of these fasteners reflect a culture of modularity and customization. They are widely available in various materials, with a spectrum of lengths and thread sizes to match the diverse needs of OEM and aftermarket fairings. Prices vary with material quality, brand, and quantity, but the underlying economics reflect the practicality of a modular approach: a kit can be tailored for specific panels, or purchased as a bulk set for multiple bikes or race entries. A typical kit in the track-ready category might include a mix of M6 and M5 bolts in short and mid-lengths, accompanied by several washers, a handful of well nuts, and a pair of hex wrenches to set and maintain the assembly. The availability of stainless steel variants ensures that buyers can balance strength with weight, achieving a robust hold without adding unnecessary mass to a machine that already operates with lean efficiency.

Beyond the hardware itself, the success of 1/4-turn fasteners hinges on a broader understanding of fit and finish. Panel thickness matters. If the fairing is too thin, a fastener might self-limit its clamping range, leading to premature loosening or panel flutter at high speeds. If the panel is too thick, the stud length will be insufficient to draw the panel tight, leaving gaps and eventually causing misalignment. In practice, this means that racers and builders often curate a small set of hardware that covers typical fairing architectures: thicker sections around the airbox, lighter sections around the tail, and intermediate densities for the sides. Anti-vibration washers and well nuts become not just optional accessories but core elements of a robust, durable setup. The right combination reduces the risk of fatigue failures in the fairing mounts and helps the panels stay locked in place during long sessions where the track’s heat adds another variable to the equation.

For those who crave tuning and customization, there is another layer of finesse: the compatibility matrix. While a 1/4-turn system provides a universal advantage for many competition contexts, the precise thread, length, and clip geometry must be matched to the fairing design and the underlying structure. In practice, this means verifying that the stud’s thread is compatible with the chosen clip, that the clip’s geometry applies uniform pressure across the panel, and that the overall assembly does not intrude on internal channels or electronics behind the fairing. In some cases, such as when working with race fairings that feature multi-part or composite constructions, practitioners might opt for a mixed hardware approach. They’ll use sturdy stainless studs in the primary load-bearing regions, with more lightweight hardware in non-structural positions. This strategic distribution further ensures reliability while keeping weight to a minimum.

A broader look at availability and procurement reveals a landscape shaped by both OEM-influenced design and aftermarket experimentation. Kits are widely offered in multiple configurations, often in packs of two or more, designed to suit different bike generations or race classes. The practical takeaway is simple: for a rider who values speed, repeatability, and a pristine finish, investing in a curated set of 1/4-turn fasteners makes sense. It allows rapid changes in response to evolving aero strategies, weather conditions, or track-specific requirements without sacrificing reliability. The cost-benefit calculus favors lightweight, corrosion-resistant options that deliver consistent clamping force over many cycles. The long game is straightforward: fewer tools, fewer delays, and more time on the track.

Amid the practicalities lies a subtle engineering philosophy. The 1/4-turn fastener system embodies a philosophy of modularity that aligns with how modern race engineering approaches optimization. Panels are viewed as replaceable, adjustable components of a larger aero strategy. The fasteners facilitate this philosophy by enabling quick, repeatable changes without compromising the integral strength of the attachment points. It is a philosophy that recognizes that fairings are not just cosmetic shells but functional contributors to aerodynamics, cooling, and rider comfort. The small, precise action of turning a fastener 90 degrees becomes a ritual of performance: a moment of ergonomic clarity in a paddock that often demands rapid decision-making under pressure.

To speak in practical terms about integrating these fasteners into a bike’s build or service routine, consider the sequence of steps that a typical track-day preparation might require. Start with a visual and tactile inspection of every panel. Look for signs of wear around the clips, check for any corrosion on the studs, and ensure that washers are not deformed. Replace any worn components before they fail. When reassembling, position the panel correctly, thread the clip onto the stud by hand, and then rotate to the 90-degree lock position. A firm, clean engagement is the goal, not overtightening. If a panel is stubborn, inspect the mating surfaces for dirt or paint buildup and clean gently. The idea is to keep the fairing assembly smooth and friction-free, so the rotation remains consistent across all latching points.

Finally, the broader ecosystem of equipment and knowledge that surrounds 1/4-turn fasteners is where riders and builders often find the most value. Resources that focus on fairing hardware, mounting strategies, and aero optimization provide a practical context for choosing between different materials and configurations. Online community discussions, mechanical catalogs, and kit documentation can illuminate subtle differences in the design of clips, nuts, and studs. As with any specialized modification, the aim is to harmonize speed, reliability, and finish. The result is a fairing system that looks disciplined and works predictably under the most demanding conditions.

For readers who want a concrete starting point for exploration, a visit to a curated collection of fairing components can be worthwhile. See the Honda fairings collection for a representative range of compatible panels and mounting hardware that reflect common construction practices across a variety of bikes. This resource offers a glimpse into how a well-rounded kit is arranged, what lengths and thread sizes are typically employed, and how fastener geometry translates to real-world performance on the track. Honda fairings collection

External reference: For additional context on practical product examples and component combinations, see this external listing that illustrates a typical quick-release fastener kit used in racing applications: https://www.amazon.com/dp/B08B3FZQ5R

Turning Speed into Security: The Subtle Mastery of 1/4-Turn Fasteners in Motorcycle Fairings

Across the spectrum of motorcycle design, from street-legal commuters to race-bred machines, the fairing system sits at the intersection of aerodynamics, access, and durability. The 1/4-turn screw fastener emerges as a quiet guardian of that intersection. Its quarter-turn action promises speed without sacrificing grip, inviting maintenance crews and track-day riders to swap panels, adjust cowlings, or swap minor aero tweaks with a confidence that wrenching in a pit stall could never match. This chapter follows that promise into the heart of the design, examining how the fasteners are built, how they behave under real-world stresses, and how the choices made at the factory translate into practical advantages for the rider who expects both quick access and resolute panel retention when the bike is perched on the edge of grip at 180 miles per hour in a fed-up wind. The story is not merely about hardware; it is about how a simple 90-degree twist can synchronize with the physics of the bike, the geometry of the fairing, and the rhythms of track testing so that every panel fits like a precise skin on a high-performance frame.

The defining feature of the 1/4-turn fastener is its rotation. A full rotation is not required to secure a panel; instead, a single quarter turn tightens or releases the connection. That 90-degree movement is designed to pull the panel snug against a mounting point or to disengage without the need for tools. In practice, the mechanism operates through a cam or a threaded stud that engages a matching clip or socket. When the stud enters the clip and the user rotates the head by a quarter turn, the cam or thread engages with the receptacle in the fairing or frame to lock the assembly in place. The advantage is immediate: the rider or technician can seal or expose a panel within moments, a capability that matters most when time is of the essence—whether at the start line, after a crash, or during a fast pit-side setup change.

A companion feature is the integrated clip system. The robust pairing of a threaded stud—often featuring a D-shaped ring or similar geometry—and a pre-installed clip on the mounting surface creates a dependable pairing. The clip is typically made from a durable engineering plastic or metal, chosen for its resistance to vibration, environmental exposure, and the repeated flex of fairing panels. The compatibility between the two pieces hinges on the precise engagement of the stud with the clip and the integrity of the quarter-turn lock. The system’s reliability rests on a careful balance: the clip must hold the stud firmly enough to prevent accidental release under load, yet allow an easy 90-degree twist by the operator without excessive force that could damage the plastic or strip the threads.

Material choice matters more here than with many other fasteners. The stud is usually constructed from corrosion-resistant stainless steel, chosen for its strength-to-weight characteristics and its endurance in spray, rain, sun, and road grime. The clip, meanwhile, is typically a high-performance engineering plastic or, in some cases, a lightweight metal piece that resists UV degradation, cracking, and fatigue under remounting cycles. This combination delivers a composite that is both rugged and forgiving: the metal provides the core strength, while the plastic absorbs vibration and mitigates galling between metal parts during repeated assembly and disassembly.

The thread interface is designed for standardization. Most commonly, the stud uses metric threads such as M6 or M8, paired with a corresponding tapped hole in the fairing substructure or frame. The choice of thread size aligns with typical mounting points spread across a wide range of models and fairing thicknesses. The pitch, usually 1.0 mm for M6 and around 1.25 mm for M8, ensures a predictable bite as the stud engages the clip. This predictability is essential when racing teams routinely interchange fairings, relying on a consistent pocket depth and thread engagement to preserve accuracy in panel alignment after a spin in the pit or a hard braking event.

Among the technical specifics, the head-diameter dimension of the D-ring portion—commonly around 17 millimeters—plays a pivotal role in both usability and compatibility. A larger D-ring can improve hand torque, especially when operating with gloves on, while a smaller diameter might be preferred where space is tight or where the rider wants a lower profile under the fairing edge. The overall length of the fastener, from the base of the D-ring to the tip of the thread, is typically tuned between 15 and 30 millimeters. This range accommodates varying fairing thicknesses, bracket depths, and the sometimes complicated geometry of a race panel’s mounting backplane. These lengths guarantee a secure clamp beneath the cap while leaving enough thread engagement to avoid stripping under repeated loads.

Torque requirements, though modest, are not negligible. For optimal performance without damage to the clip or the plastic substrate, technicians typically work within a window around 5 to 10 Newton-meters. This is not a hard, universal rule, but a guideline that reflects the delicate balance of clamping force and part resilience. Over-tightening can crush the plastic clip, distort the mounting hole, or strip the thread entirely. Under-tightening invites panel flutter, wind-induced movement, and even rapid panel separation under gust loads. The 5–10 Nm range acknowledges both the need for a firm seal against rain, dust, and air pressure and the necessity of preserving the panel’s, and the fastener’s, longevity through many cycles of installation and removal.

Environmental resistance is more than a feature name; it is a practical requirement. Premium variants endure UV exposure, salt spray, temperature extremes, and the continual vibration that comes from high-speed aerodynamics and rough road surfaces. Stainless steel resists corrosion from road salts and moisture, while the clips must resist UV-induced embrittlement and cracking in sunlight with long service life. The overall package aims for a lightweight, weatherproof solution that does not add unnecessary mass to the nose or tail of a motorcycle yet still performs as a fail-safe that keeps the fairing from becoming a loose, fluttering liability at speed.

From a mounting philosophy standpoint, bulk kits have become ubiquitous in performance-oriented builds. A typical kit might include a mix of M6 and M5 bolts in several lengths, such as 16, 20, and 25 millimeters, alongside truss screws and speed clips. Washers contribute to even load distribution, while well nuts provide a softened interface against the panel’s soft underlayers, reducing the risk of crack propagation under repeated stress. In some configurations, the kit includes hex keys that enable quick tensioning, even in limited space, reinforcing the “tool-free” advantage without sacrificing the precision of a well-torqued assembly.

The practical implications reach well beyond the aesthetic and the quick-change advantage. Fairings must endure aerodynamic loads that shift with speed, wind direction, and the rider’s posture. When a panel is not perfectly aligned, even a small misalignment can alter airflow, increasing drag or causing buffeting that disrupts stability. The 1/4-turn fastener’s design addresses this by combining a secure clamp with repeatable, accountable release. When a panel is removed, the same quarter-turn action preserves the tool-free engineering a rider depends on during a mechanical check or a fast setup change for a track day. The reliability of the clamp, the retention of the clip, and the durability of the stud all contribute to predictable, repeatable assembly across repeated sessions of use.

Compatibility is broad by design. The underlying geometry accommodates a wide range of fairings, frames, and mounting backplanes, fitting everything from street-oriented plastics to race-oriented, high-strength composites. The fasteners have become a standard in many performance-oriented kits because their standardization reduces the number of distinct fastener types a rider or technician must carry. This universality matters, especially when a fairing panel is damaged mid-season; the ability to substitute compatible fasteners quickly in the paddock becomes a practical advantage rather than a logistical constraint.

In choosing or inspecting a kit, several practical considerations come into play beyond the core dimensions and materials. First, assess whether the kit includes a complete set of components that anticipate real-world use: a mix of M6 and M5 lengths, washers of multiple thicknesses, well nuts to accommodate panel thickness, and appropriate clips that are matched to the stud profile. It is also sensible to verify whether the kit provides installation aids, such as a small hex key or a simple alignment guide, because even with a quarter-turn design, precise alignment accelerates setup time and reduces the chance of cross-threading. For riders and teams installed in areas where weather exposure is frequent, corrosion resistance becomes a non-negotiable criterion; otherwise, a fastener that begins to seize or corrode will slow a team down more than any aerodynamic tweak ever could.

For riders looking to explore a broader ecosystem of fairing options, a broad Honda fairings collection offers panels that can accommodate quick-release fasteners and, more importantly, demonstrates how such fasteners fit into a complete system of mounting, sealing, and aerodynamics. Honda fairings collection serves as a practical reminder that the right panel and the right fasteners are part of a coherent approach to performance, where every mounting decision aligns with the overall geometry of the bike and the rider’s goals. The relevance of these choices becomes evident when you consider the paddock as a workshop on all dimensions—weight, stability, access, and repeatability—where a well-chosen fastener system can shorten service times without compromising panel integrity or rider safety.

The chapter’s examination of the 1/4-turn fastener would be incomplete without acknowledging the standards that govern fastener performance. The practical strength and reliability of these parts are supported by established mechanical-property guidelines that define how materials behave under load, how threads should behave under repeated assembly, and how the interfaces between metal and plastic should perform at different temperatures. In formal terms, standards related to fastener strength, material properties, and testing methodologies provide a framework that ensures interchangeability and reliability across manufacturers and models. An authoritative reference for these mechanical properties is found in ISO standards governing fasteners made from carbon steel and alloy steel, offering a foundational context for the strength, durability, and reliability that riders expect from every component involved in fairing mounting. For readers who want to dive deeper into the material science of fasteners, the external resource at the end of this chapter provides a thorough overview.

While the specifics of each model and year’s fairing can drive small differences in mounting depth or clip geometry, the overarching principles remain consistent. The quarter-turn mechanism, the integrated clip, the predictable thread engagement, and the careful balance of mechanical strength and environmental resistance together form a cohesive system. Properly selected, installed, and maintained, these fasteners allow riders to push performance without worrying about panel integrity at the limit, enabling quicker changes between aero configurations and more efficient routine servicing during long seasons. The result is a rider who spends less time under a fairing and more time focusing on the ride itself, with the confidence that the panels will stay aligned and secure when the track demands everything the machine can deliver.

As the narrative of fasteners continues to evolve with new materials, novel clip geometries, and lighter alloys, the core lesson remains: a well-engineered fastener system is a part of the bike’s aerodynamic identity. It governs how the bodywork behaves under wind and acceleration, how quickly a crew can perform essential maintenance, and how consistently a rider can reproduce a setup across sessions. The 1/4-turn family embodies this balance—a compact, robust connection that makes speed practical without sacrificing the enduring need for reliability. In the chapters to come, we will explore how these principles translate into specific field practices, including inspection routines, wear indicators, and how to reconcile race-specific requirements with street-ready demands, all while keeping the focus on the role of fasteners as both enablers and protectors of performance.

External reference for further technical standards and material properties: https://www.iso.org/standard/58548.html

Locking Aerodynamics: The Subtle Power of 1/4-Turn Fasteners in Modern Motorcycle Fairings

One of the quiet engines behind aerodynamic efficiency and rapid maintenance on modern sport and performance motorcycles is often overlooked: the fastener that holds the fairing panels in place. The 1/4-turn fastener, sometimes called a quick-release or Dzus-style fastener, exemplifies a design where speed and security coexist. These fasteners are not merely hardware; they are enablers of track-day readiness, field repairs, and nuanced aerodynamic tuning. In a world where fractions of a second matter, the ability to remove or reseat a front or side panel with a simple quarter turn can translate into faster setup times, quicker access to radiators, air intakes, or electronic control units, and reduced downtime during a race weekend. What makes them particularly compelling is not just the ease of use, but the careful engineering that ensures a repeatable, dependable grip under a spectrum of riding conditions—from the blistering heat of a sprint race to damp, rain-soaked street riding. The 1/4-turn mechanism locks with a crisp motion that feels almost intentional, a tactile reminder that the bike is designed for precision under pressure rather than for the uncertain ritual of standard bolt-and-screw fastening.

The core idea behind these fasteners is simple in principle but rich in practical implication. A stud—mounted securely into the fairing or frame—plays host to a corresponding clip or nut. The fastener’s body, with a properly engineered latch, accepts the stud and then, with a 90-degree rotation, moves into a locked position. In that moment, the panel is pressed with a consistent clamping force, a repeatable actuation that minimizes panel flutter while maintaining a seal against moisture, dust, and debris. The typical family of sizes centers around common metric threads such as M5 and M6, with a range of lengths—from compact 16 millimeters to more robust 25 millimeters—chosen to accommodate a variety of fairing profiles and mounting depths. For installation, many kits include washers, well nuts, and hex keys, which not only simplify the build but also help ensure that the mating surfaces remain true and that the fasteners do not introduce undue stress into the plastic or composite panels.

A crucial consideration in the use of 1/4-turn fasteners is material choice. Aluminum is a frequent favorite, thanks to its balance of strength and lightness, and its corrosion resistance helps ensure longevity in exposed environments. Stainless steel offers greater hardness and resilience, particularly in scenarios where a panel might be subjected to vibration, grit, or grit-induced wear. Some performance-oriented assemblies even explore titanium Gr5 bolts for those seeking the lightest possible hardware without compromising strength—an option that aligns with the high-performance ethos of racing fairings. In many cases, the actual fastener interfaces employ a standard diameter around 17 millimeters, a dimension that provides a snug, vibration-minimizing engagement while remaining widely compatible with a broad spectrum of fairing designs. The result is a fastener system that feels predictable, enabling riders and technicians to work with confidence when the bike is hot, tired, or under the clock during a pit stop.

The appeal of these fasteners extends beyond their mechanical footprint. They are particularly well suited to the front fairing, side panels, and even rear spoilers that are integral to the bike’s aerodynamics and overall appearance. In front fairings, the panels frequently require quick secondary access for radiator checks, coolant reseals, or wiring harness reconfigurations. Side panels often need to come off for tech inspections or to access ECU interfaces and fuse boxes, and the quarter-turn action makes those tasks less of a staged procession and more of a focused, repeatable moment. Rear spoilers and tail sections, which contribute to stability at speed and to the bike’s aesthetic silhouette, benefit from the same reliability. The capability to change setups quickly—whether for a track session with different wing angles or for a street ride that prioritizes ease of maintenance—becomes a practical advantage rather than a mere convenience.

The benefits are especially pronounced in racing environments, where aerodynamic experimentation and rapid turnover are daily requirements. Teams can swap fairing configurations to evaluate how different panel alignments influence drag, downforce, and balance, while keeping downtime to a minimum. The 1/4-turn approach reduces the friction of maintenance, letting riders focus on lines, braking markers, and gearing without the interruption that traditional hardware often imposes. This is not about replacing the basics of torque and fatigue analysis; it is about translating those fundamentals into a procedure that can be repeated with a level of certainty that supports data-driven decisions on the track.

From a practical standpoint, the installation and maintenance routines around these fasteners deserve attention. The stud and clip system demands clean mounting surfaces and proper thread engagement. A well-executed pre-check involves inspecting the stud threads for any cross-threading or damage, confirming that the fasteners seat fully with a quarter-turn beyond the lock position, and ensuring that any accompanying washers or sealants contribute to a stable, moisture-resistant seal without creating binding. For riders who ride in wet or dusty conditions, the corrosion resistance of the chosen materials becomes a critical factor. Even the most robust fastener can become a liability if moisture accelerates galvanic corrosion between aluminum and harder metals, or if grit becomes wedged between the mating surfaces and compromises the panel’s alignment. Routine inspection is simple and powerful: a quick visual check of each fastener’s alignment, a tactile check to ensure a full quarter turn yields a firm bite, and a periodic lubrication protocol that uses a compatible, light anti-seize compound on the threads to ease future removal. The goal is not to create a byzantine maintenance ritual but to build a predictable pattern that keeps the fairings behaving as intended without inviting unwelcome surprises during a pit stop or a windy, high-speed stretch.

The landscape of hardware that accompanies these fasteners is as varied as the bikes they adorn. Kits often include a blend of M6 and M5 bolts in several lengths, such as 6 x 40 millimeters, 6 x 20 millimeters, and 5 x 16 millimeters, with additional pieces like 5 x 25 millimeters for deeper mounting points. Truss screws, speed clips, and a collection of washers with different thicknesses accommodate a range of fairing materials and mounting tolerances. Well nuts, which provide a reliable gasketed seal in panel interfaces that pass through composite or cast surfaces, help keep moisture out while maintaining clamping force even when panels experience minor misalignment due to heat, vibration, or impact. Some sets also include hex wrenches to ensure that technicians can perform a quick maintenance sweep without hunting for tools, reinforcing the portability and practicality of the system. These configurations are designed with the reality of motorcycling in mind: parts should be lightweight, durable, and straightforward to handle in constrained workshop spaces or on the side of a track.

From a compatibility standpoint, the 1/4-turn paradigm is intentionally universal in its philosophy. The concept operates well across a spectrum of brands and fairing families, which is part of its appeal for riders who swap between different model years or aftermarket bodies. This universality explains why you will frequently encounter similar fastener systems across many brands, including models that emphasize performance and a racing pedigree. It’s not just about keeping a panel attached; it’s about preserving the fidelity of the bike’s aerodynamic envelope while allowing the rider to tailor the setup in response to changing track conditions, weather, and riding goals. When a rider stands in a workshop with a fairing deck laid out for refitting, the familiar quarter-turn motion becomes a quiet anchor, a reminder that the system is designed to be reliable under stress and straightforward when a panel needs to be removed for a quick check of air ducts, intake plenums, or wiring routes.

The idea of universal compatibility is often reflected in the way parts are sourced and referenced in collections that categorize fairings by model families. For those looking to align a quick-release strategy with a specific aesthetic or mounting layout, it can be helpful to explore a broader range of fairing options within a given brand’s family. For instance, a rider curious about integrating these fasteners with a particular line of Honda fairings might find value in exploring the Honda fairings collection, which showcases panels, mounting geometry, and the general fitment philosophy that informs fastener placement and panel thickness. This approach ensures that the fastener selection remains consistent with the bike’s original design language while still delivering the performance benefits of rapid access and secure clamping. Honda fairings collection demonstrates how a well-curated fairing family aligns with the hardware philosophy described here, providing a reference point for mounting depth, panel thickness, and the typical stud-to-surface interface that supports a clean quarter-turn engagement.

The broader takeaway is that 1/4-turn screw fasteners offer a practical synthesis of speed, reliability, and durability. They empower riders to manage the often complex skin of the motorcycle—the fairings—without sacrificing performance or access. The panels glide on and off with a deliberate, almost surgical ease, and the ride remains smooth because the fasteners resist loosening from vibration and wind pressure. The system’s effectiveness, however, rests on disciplined installation, thoughtful material choice, and regular maintenance. It rests on paying attention to thread integrity, surface cleanliness, and the mounting geometry that defines how the fairing sits in relation to the bike’s frame and axes of movement. When these conditions are met, the fairing assembly behaves as a coherent, aerodynamic shell rather than a loosely connected exterior; it becomes a unified surface that channels air, stabilizes the ride, and accommodates the ongoing demands of maintenance and customization that define modern motorcycle performance.

As you plan a setup or upgrade, consider how the fastener system aligns with your riding priorities. If you value speed above all else, the 1/4-turn approach offers a safety margin in the paddock and on the track. If you prize durability in challenging environments, the choice of alloy and finishes becomes a decision about long-term resilience. If your aim is to preserve ease of maintenance for frequent track sessions or weekend wrenching, the kits that include a selection of lengths, washers, and well nuts become an essential toolkit that fits inside a small bag or a tool box. In short, these fasteners are a small detail with a disproportionate impact on how a bike feels when you ride it and how quickly you can service it between laps or after a fall. They illustrate how a seemingly minor design choice can ripple outward, shaping the cadence of a rider’s day, the efficiency of a race weekend, and the continued harmony between form, function, and the relentless pursuit of speed.

External resource for further reading: https://www.motorcyclefairings.com/fairing-fasteners-1-4-turn-guide

Fast Access, Broad Reach: 1/4-Turn Fasteners for Motorcycle Fairings

The market for 1/4-turn fasteners—the quick-release quarter-turn mechanisms that lock fairing panels with a simple 90-degree twist—illustrates how small, precise fasteners affect maintenance workflows and performance customization on modern motorcycles. Tool-free installation, reduced maintenance time, and gentler surfaces on fairings drive demand in both racing and street riding. The design typically features a stud embedded into the fairing or frame and a female clip or nut that locks on with a 90-degree rotation, balancing aerodynamics and reliability. Common sizes include M5 and M6 with lengths like 16, 20, and 25 millimeters, often paired with washers, well nuts, and sometimes a small hex key. Many kits are multi-panel solutions that let teams rapidly reconfigure panels for testing aero setups or weight distribution, reflecting a trend toward standardization that simplifies procurement and maintenance planning.

Current market signals show a preference for corrosion-resistant materials, with stainless steel common for durability under humidity, rain, or road spray. The goal is not only rust resistance but reliable sealing when well nuts and washers are used. Robust clip designs and integrated D-ring connectors are becoming more common, including a 17-millimeter quick-release D-ring variant designed for repeated removals without losing clamping force. Such features help prevent stripped threads or loose panels after track sessions, and are valuable for aerodynamic testing. Fitment emphasizes broad compatibility; universal or near-universal kits are designed to align with common thread pitches and panel thicknesses across major brands, reducing the need for on-the-spot adaptation during events.

Availability has expanded with online marketplaces and specialist platforms, offering standard stainless options and lighter titanium-grade components for weight savings. Pricing tends to be competitive, with discounts that reflect market saturation. Typical kits include a mix of M6 bolts in several lengths and M5 options, with 5–20 pieces per size and assorted clip types to cover popular configurations. Replacement parts and a robust supplier network further reinforce a one-stop maintenance approach, helping riders and teams swap panels quickly without compromising fit or aerodynamics.

Bottom line: faster, easier, more durable. 1/4-turn fasteners support modular, serviceable fairings and quick reconfiguration for testing or race weekends, while corrosion resistance, robust clip design, and cross-brand compatibility underpin reliability and uptime. For buyers, catalogs from brands like Honda fairings illustrate how fitment lines accommodate quick-release hardware within a consistent mounting geometry. External resource references can provide real-time product offerings: https://www.amazon.com/s?k=1%2F4+turn+quick+release+fasteners+motorcycle+fairing

Final thoughts

1/4 turn screw fasteners represent a critical innovation in motorcycle design and maintenance, enabling users to perform rapid adjustments that can enhance both performance and convenience. As the market trends lean towards efficiency and performance optimization, understanding the design and applications of these fasteners becomes essential for motorcycle businesses aiming to cater to modern rider needs. By incorporating these components into product offerings, businesses can not only improve their customer support but also elevate the riding experience, ensuring their products meet the demands of speed and functionality.