In the world of motorcycle customization, the term $12,000 motorcycle fairings often stirs curiosity and skepticism. This article explores the niche market of high-end motorcycle fairings, focusing on their distinct positioning, the rarity of such pricing, and the common misconceptions surrounding it. Understanding these facets provides valuable insights for business owners in the motorcycle industry looking to navigate or enter this high-stakes sector. Each chapter rigorously dissects a particular aspect of high-end fairings, from market positioning to pricing narratives, culminating in a nuanced view of what these fairings entail.

The 12k Mirage: Decoding the Market Reality and Subtle Value of Ultra-High-End Motorcycle Fairings

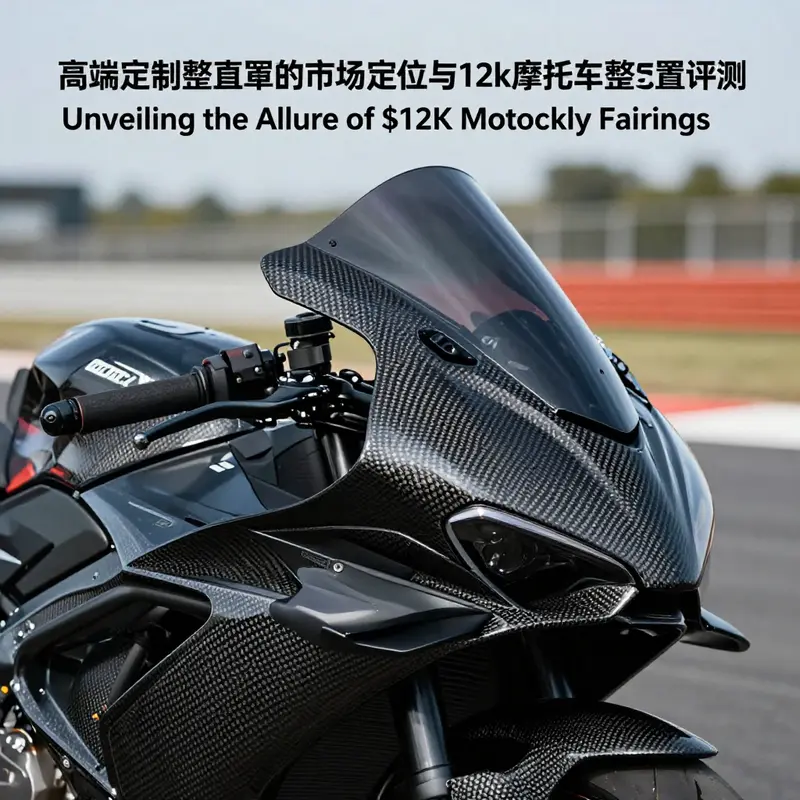

In the world of motorcycle aesthetics and aerodynamics, a whisper often circulates about a singular figure—twelve thousand dollars for a single fairing set. The notion feels audacious, almost mythical, and it invites a roadside debate about value, necessity, and identity. Yet the chapter we are about to unfold does not merely chase a price tag. It dives into what such a number would entail in the real market, how the language of performance and prestige travels between the racetrack, the gallery wall, and the showroom floor, and why most riders will instinctively pause before ever considering a $12,000 fairing for a street or track bike. What follows is a cohesive examination of the market for high-end, bespoke fairings, a landscape that stretches far beyond pure function and into material science, craft, brand storytelling, and the economics of limited runs. It is an inquiry that frames the broader article on 12k motorcycle fairings not as a catalog of products, but as a narrative about value, risk, and the limits of wishful budgeting in a field where marginal gains can come at extraordinary cost.

To understand why a $12k figure is more a premium signal than a common market offering, one must first map the terrain of the aftermarket fairing ecosystem. Standard aftermarket fairings exist in a wide, practical price corridor. In the mainstream, a complete set for many modern sport bikes typically sits between a few hundred and a few thousand dollars. Even high-performance variants, crafted with carbon fiber or advanced composites, rarely stray far beyond the $3,000 to $6,000 range for a full body set, depending on the bike model, the complexity of the design, and the finish. The price ceiling climbs when the project distinctly crosses from a mass-market replacement into a bespoke, Chinese-drawn art piece or a certified, limited-run collaboration. In those cases, the fairing becomes a design object as much as it is a functional component, and the final ticket on a customer invoice can surprise even seasoned riders who have watched their credit cards bend under the weight of top-tier hoods, secret hardware, and meticulous surface finishing.

The economic logic behind a 12k price tag is not solely about the raw material cost. It begins with material selection. Carbon fiber has become the lingua franca of performance fairings because of its favorable strength-to-weight ratio, corrosion resistance, and the high-end connotations it carries. But it is not simply about picking carbon. The most exclusive projects layer additional technologies: non-Newtonian epoxies that stabilize under heat, layers of Kevlar for impact resistance, and sometimes even ceramic or metallic topcoats for UV resilience and a museum-like luster that shrugs off micro-scratches. Then there are molds. A high-end, one-off or limited-run fairing requires precision tooling—molds that must capture every contour of a bike model with a tolerance window measured in hair-thin fractions. The upfront cost of creating those molds can be thousands, even tens of thousands, depending on the complexity and the need to accommodate electronics, mounting hardware, and air-intake geometry that interacts with the bike’s body rather than simply sitting on top of it.

But even with the materials and molds in place, the price is not automatically justified. The cost curve also includes design labor, hand-finishing, paintwork, and clear coatings that must look perfect from every angle under various lighting conditions. The finishing stage in particular can be a hidden sink of dollars, because it is not merely about applying color. It encompasses flatting, sanding, polishing, and a color-match process that is as much art as science. For certain collaborations, the finish must withstand trackday punishments—grit, heat, and the occasional high-speed rain shower—without yellowing or cracking. The aesthetic premium, therefore, is earned not only by the use of premium materials but by the guarantee of enduring beauty that can survive years of exposure to sun, weather, and enthusiastic riding.

Another essential factor in the calculus is brand and craft prestige. In high-end markets, a name can carry enough value to tilt a consumer’s willingness to pay. Limited editions, artist collaborations, and designer influence can convert a functional part into a collectible object. The social currency of ownership matters, particularly for a subset of riders who view the bike as an extension of personality or status as much as a tool for speed. This is where the market begins to blur with art and with lifestyle branding. A fairing may be built to optimize airflow and weight, yet the buyer’s perception of exclusivity, heritage, and storytelling can be the decisive element that rationalizes a six-figure risk of investment over decades of use.

In this context, a price point like $12,000 can be deciphered as a hybrid signal: it speaks to materials excellence, expansive craftsmanship, and a limited distribution strategy. It signals that the project is meant to be more than a practical upgrade; it is a statement about what the rider is willing to invest for a unique relationship between bike, body, and experience. Yet the practical reality remains: for most riders, extraordinary performance gains from a single fairing upgrade are marginal beyond a certain threshold once a baseline has already been achieved by affordable carbon or composite sets. The physics of aerodynamics is a continuum rather than a cliff. The incremental gains from a highly tuned fairing can be meaningful, but in the real-world street or even track environment, these gains are often contingent on hundreds of additional variables—bike power, rider position, tire choice, suspension tuning, and even weather. The cost-to-performance ratio begins to tilt steeply as the price climbs toward the 12k mark, particularly when one considers the total scope of a build, which might include a full engine tune, upgraded exhaust, prestige wheels, advanced electronics, and bespoke ergonomic adjustments. In short, the 12k fairing, if it exists as a standalone product, is not merely a piece of hardware; it is a capsule of design, material science, and risk, sitting inside a broader ecosystem where performance and aesthetics are interwoven with the identity of the rider.

Beyond the weighty cost, there is a fundamental question of market availability. The post-2000s market has seen an ever-widening spectrum of aftermarket bodywork: from inexpensive, mass-produced panels to meticulously engineered carbon fiber sets that require precise alignment and subframe integration. Still, the segment at or near six digits—if it exists as a motorcycle fairing in the true sense—tends to be characterized by two rules of thumb. First, you are almost certainly looking at a bespoke or highly limited production, which translates into long lead times and a high degree of customization. Second, you are looking at a product that carries dramatic brand value, possibly tied to a signature designer or a collaboration with a celebrated shop, which complicates the supply chain and the after-sales landscape. The economics of limited runs are not purely about scarcity—they are also about the costs of quality control, certification compliance for certain markets, and the premium service commitments that accompany a high-ticket purchase. A buyer entering this space is not only paying for a shell; they are paying for a service ecosystem—the guarantee that the product will fit precisely, perform as intended on dangerous or high-speed environments, and be supported by a level of customer care that ranges from installation guidance to ongoing refinements.

In light of these realities, many observers would describe a $12k fairing as a rarefied, niche proposition rather than a standard offering. The research landscape for motorcycle fairings across major market channels shows broad price dispersion, with most credible, performance-driven parts occupying a spectrum below that figure. The typical high-end, off-the-shelf carbon or fortified composite fairing often sits somewhere between $1,000 and $4,000 for a complete kit, with professional installation and finish potentially adding another several hundred to a couple thousand dollars depending on the shop and the bike. Only when the project steps into the realm of bespoke design, artisanal fabrication, and strategic branding does the price risk tipping toward or beyond five figures. Those cases, while captivating as stories, rarely represent the mainstream market segment for sport bike owners who want a balance of cost, performance, and reliability. The 12k figure then emerges not as a widely adopted benchmark but as a cautionary symbol: it invites buyers to scrutinize the full value proposition, to assess whether the gains in weight reduction, rigidity, and airflow performance justify not only the price but the long-term ownership considerations, including repairability, resale, and compatibility with other performance upgrades in the rider’s ecosystem.

A helpful way to ground this discussion is by distinguishing the buyers and their objectives. A track-day enthusiast may prioritize precise aerodynamic tuning and weight reduction to shave seconds off lap times. The rider who wants a bike that looks like a museum piece yet remains perfectly streetable may pursue the highest finish quality and color-matching precision, even if the performance gains are less dramatic. A collector might seek a collaboration that references a storied era or brand ethos, where the fairing’s value is not only in how it performs at speed but how it conveys a narrative when parked in a showroom or presented at an event. Each of these archetypes weighs the same numbers differently, and their decisions ripple through the market in subtle ways: the readiness to pay a premium, the willingness to wait for a limited run, and the desire for a service layer that ensures longevity. When you connect these decision threads back to the idea of a $12k fairing, you begin to see that the price tag is not simply about material costs or speed margins. It is a complex social and economic artifact that sits at the crossroads of engineering excellence, artisanal craft, and aspirational branding.

What, then, should a reviewer or buyer look for when considering a project that might be described in the same breath as a $12k fairing? The guiding framework remains anchored in three domains: function, form, and feasibility. Function concerns the actual aerodynamic impact, the weight savings, and the integration with the bike’s electrical system and chassis geometry. In this area, it is essential to evaluate whether the fairing has been designed with precise CFD-backed or wind-tunnel-validated curves, and whether mounting interfaces align with factory hardware without forcing changes to subframes, mounts, or body panels that could undermine safety or durability. Form addresses the aesthetic and tactile excellence—the uniformity of resin surfaces, the absence of depth variations, the fidelity of color and gloss, and the invisible craftsmanship that becomes apparent only on close inspection. This is where a high-end project earns its charisma, but also where it risks appearing hollow if the finish is inconsistent or the edges reveal a rushed hand. Feasibility examines supply chain realities: lead times, service support, compatibility with aftermarket brakes and electronics, and the ability of the vendor to provide ongoing parts, replacements, and warranty coverage. For a fairing that could command $12k, all three domains must be resolutely convincing and articulately documented. Absent such evidence, the price remains an alluring but risky proposition that demands a rigorous due diligence process.

In the broader arc of this chapter within the article’s sequence, the conversation about value inevitably loops back to the reality that the market for motorcycle fairings is deeply regional and micro-segmented. What resonates with a rider in one market—performance metrics that satisfy a sport-rider’s appetite, or a look that signals exclusivity in a local scene—may not translate into universal acceptance elsewhere. The global market is filtered through supplier capabilities, export controls for advanced materials, and the patchwork of authorized service centers that can handle a product of such complexity. This heterogeneity is why a universal, mass-market rule about pricing never fully captures the truth. Instead, the narrative revolves around alignment: alignment of a rider’s ambition with a product’s promises, alignment of the fairing’s technical profile with the bike’s architecture, and alignment of the purchase with the dedicated aftercare that keeps a high-end investment functional under adverse riding conditions.

The caveat of misinterpretation also surfaces in discussions about “12k” as a symbol rather than a specific price. If a brand or workshop markets a kit as the pinnacle of heroic materials and craftsmanship, the buyer must remain vigilant about what else is included in that number. Are the subcomponents—the windscreen, the fasteners, the mounting hardware, the hardware’s corrosion resistance—also premium, or are they commoditized elements that get upgraded as the customer aligns more with the brand’s narrative? In practice, many of the most striking high-end projects are couched within a broader ecosystem: the bike itself may be a platform for a years-long collaboration that includes service, updates, and a future path to re-finishing. The buyer’s decision to invest in such a package is then less about the single shell and more about the entire, ongoing relationship with the designer, the shop, and the community that surrounds the project. In this sense, the 12k number may function as a pledge of seriousness—an entry barrier that signals both the consumer’s readiness to commit and the market’s readiness to deliver a level of care and exclusivity that ordinary parts cannot.

So where does this leave the claim of a fairing priced at 12k in the context of a practical review? The honest truth is that, based on current market observations and credible industry commentary, there is no widely documented, standard motorcycle fairing sold outright for $12,000. The data suggests a rare, bespoke, or collaboration-driven item that sits at the intersection of engineering excellence and artistic design. If such a product exists, it is a case study in how premium pricing is built: not merely on materials or aerodynamics, but on the narrative around the product, the rarity of the run, and the certainty of aftercare that would justify such a level of investment for a rider who views the fairing as a long-term companion. For the broader rider population, though, the fairing spectrum remains heavily skewed toward functional value, reliability, and affordability. The middle ground—where most enthusiasts operate—offers compelling performance and aesthetic options without venturing into the realm of the 12k gatekeeper prize.

In closing, the market for ultra-high-end fairings is less about chasing a single price point and more about understanding how value is constructed in a market that blends engineering fidelity, artistic expression, and aspirational branding. When a discussion surfaces about a “12k motorcycle fairing,” it is essential to parse whether the claim refers to a standalone shell, a complete bespoke project, or a broader, multi-component upgrade that just happens to carry a premium label in its marketing language. The prudent approach for a reviewer or buyer is to evaluate not only the shell’s weight, stiffness, and finish but also the total cost of ownership—the installation, maintenance, and potential future updates required to keep the system aligned with evolving bike platforms. Ultimately, the chapter in this article that explores the 12k benchmark should be read as a lens into how a niche market negotiates value, risk, and identity, rather than a simple catalog entry of price and part numbers. If the reader seeks practical guidance on high-end, cost-conscious options, the core message remains. Seek credible evidence of performance, verify fit with your bike, demand a transparent material and process breakdown, and make sure the story behind the product matches your riding philosophy and long-term plans. For readers who crave the allure of exclusivity, the market offers plenty of pathways to personal expression—paths that do not always require the vault-breaking sum of twelve thousand dollars, but still reward careful discernment and a willingness to engage with a community that treats a fairing as more than a plastic shell. For those who insist on exploring beyond the ordinary, a thoughtful dive into the broader ecosystem of fairings—where design, materials, and service converge—can illuminate why some projects command premium prices while others deliver outstanding value at a fraction of the cost. And for those who want a concrete starting point to explore fairing options without committing to a headline investment, the following path can be especially helpful: explore established catalogs that emphasize fit, finish, and compatibility with your specific model, then weigh those options against your performance goals; and when you encounter a claim that hints at a 12k price, proceed with meticulous evaluation rather than instant awe.

For readers seeking a tangible entry point into credible, model-specific options, one useful resource is the Honda fairings catalog from a reputable aftermarket supplier. It provides a clear sense of how a standard, compatible set is organized and priced, and it helps set expectations about what constitutes a high-end upgrade versus a premium appearance package. If you want to explore such options, you can visit the Honda fairings collection of a respected retailer to get a sense of fitment, finish, and price ranges in a real-world context: Honda fairings collection.

External resource for broader context: for readers who want to see how premium customization narratives are discussed in wider automotive and aerospace communities, a reliable reference is Motorcycle.com, which regularly features in-depth analyses of high-end parts, customization projects, and market dynamics. You can access a broad spectrum of perspectives at https://www.motorcycle.com.

In sum, the 12k figure should be treated as a provocative price signaling device rather than a normative market entry point. The fairing market remains diverse, with credible high-end options offering material excellence and meticulous craftsmanship at a premium—but not necessarily at a fixed, universal price. The core of the conversation is not simply what the number is, but what it represents: a commitment to performance, a pledge of exclusivity, and a belief that the rider’s relationship with the machine is worth a substantial investment. As the chapter closes, the reader is invited to carry forward a discerning approach to future reviews. Seek clarity about materials, manufacturing processes, installation logistics, and aftercare. Let the price tag be the last thing you decide on, not the first, and let the story—the blend of science, craft, and culture—be the guiding frame for any fairing that claims to be worth a chapter of your riding life.

价格的边界与空气动力的边缘:为何12k级别的整流罩在摩托市场难以成为常态

当人们从字面理解“12k”的时候,往往会联想到一个相对简单的购买决策:花更高的钱就能获得更好的外壳、更强的空气动力学性能,甚至是一件艺术品级别的改装件。然而市场的真实情形要复杂得多。这里的核心在于价格并非单纯等同于材料成本的直接折算,更涉及到设计深度、制造难度、产量规模、品牌附加值以及对整车使用场景的契合度。所谓的12k级整流罩,常常折射出两层现实:第一层是极少数情况下的高度定制与限量发行,第二层则是对材料、工艺和品牌系统性溢价的综合体现。这种组合在一般的改装需求中并不具备广泛的性价比优势,因此在日常市场中往往并不常见。市场的实际情况可以从几个层面来理解:成本结构、应用场景、以及消费者对性价比的敏感度。\n\n首先,进入专业改装与高端定制领域的整流罩,其价格往往超过普通消费者的预算线,甚至对改装车友而言也只能算作“奢侈件”。这类产品通常来自限量版的跑车工程、赛道专用车辆的演示套件,或是与知名设计师、艺术品牌的跨界合作产物。材料方面,碳纤维、凯夫拉以及某些3D打印复合材料成为主流选择,这些材料的成本远超常规玻璃钢或普通树脂。更重要的是,价格的上涨不仅体现在原材料上,还包括复杂的模具开发、表面处理、手工打磨、以及制造过程中的高端工艺附加值。正因为要在极短的量级中实现极致的精度与装配的无缝性,生产端往往要承担更高的研发成本和小批量生产带来的单位成本,从而被放大为市场售价的核心部分。\n\n其次,关于市场定位,所谓“12k级整流罩”更像是一种标牌式的价格标签,用以区分普通改件与专属定制之间的鸿沟。普通的高性能后市场整流罩,常见的价格区间在数百美元到一千多美元之间,甚至有些高端材质的整流罩也不过在五千美元左右。即便采用碳纤维材料,完整的生产与供应链管理也通常将成本控制在五千美元以下,资本回报率的考量使得厂商在没有强烈品牌或艺术附加值支撑的情况下,难以将价格推高到12,000美元甚至更高。品牌溢价在此处发挥着重要作用,但它并非仅靠材料本身的高价就能实现。还包括设计师的名号、限量发行的稀缺性、售后定制服务(如安装、调校、贴合层处理、质保条款等)以及对整车全局风格的协调性。\n\n在此背景下,理解价格的边界就要看清市场对“整流罩”这一件件物件的实际需求。对多数车主而言,整流罩的核心价值在于三件事:提升外观的运动感、优化空气动力学性能以及对前部部件的保护。由此带来的好处并非只体现在速度的直接提升上,更体现在高速巡航时的稳定性、风噪的减轻以及在雨天或碎石环境中的遮挡保护。这些效应在不同排量、不同功率水平的车型上呈现出不同的显著性。对于高性能、竞技取向的改装车来说,整流罩的价值也往往不仅仅是“挡风挡雨”,它还在于把空气流线进一步优化,提升散热与动力响应的协同效果。\n\n在谈及市场对“12k”这个价格门槛的反应时,另一个重要维度是误解的来源。第一种误解来自于将整车改装的总成本误读为单一部件的价格。实际情况往往是,整流罩只是整车改造中的一个环节,若要把整车改造推向高端,往往还需要悬挂、制动、ECU调校、轮毂甚至轮胎等多项升级叠加,其总成本可能远超单件整流罩的价格。这类情形下,12k更像是一种总投资的概念标签,而非某一件件件的单独定价。第二类误解来自于时间与限量的错配。最具艺术性与收藏价值的定制件,往往在市场中具有很高的价格稳定性,但其数量极少,且对维护、保值与再销售价格的影响极为复杂。这些产品用极高的材料成本、复杂的制造工艺和品牌故事来承载价值,因此对普通改装者来说,选择这类件时往往是对“个性化与独特性”的一种投资,而非单纯的使用成本。第三类误解来自于将“12k”视为某一固定车型或统一标准的标签。事实上,市场上没有一个普遍的、通用的“12k整流罩”标准。不同厂商、不同定制工坊对同一材料在不同工艺下的成本构成存在显著差异。对普通消费者而言,真正需要关注的,是整流罩在自己的车型、驾驶场景和预算范围内能提供的综合收益,而不是简单地以价格数字进行对比。\n\n在这样的背景下,我们可以将视野转向另一个更细的市场分支,即小排量车型中的整流罩应用。传统观念认为125cc及以下的入门级摩托更像“裸车”或半裸车,整流罩的需求并不强烈。然而,市场正在发生微妙的变化,越来越多的入门级运动型或街跑型车型开始采用轻量化、模块化的整流罩设计,以提升视觉运动感,同时兼顾日常通勤的风阻与风噪。这类设计往往不是全包覆的高端定制,而是以成本效益为导向的改进方案。你会发现,整流罩的工程实现正在向更低成本、更易维护的方向发展,同时保持对空气动力性能的正向作用。对于这一趋势,消费者需要理解的是,整流罩的作用并非以“越贵越好”为唯一准则,而是要看它是否契合该车型的定位、目标市场的消费能力以及日常使用情境的实际需求。\n\n在前述讨论中,提到的小排量市场正逐渐展现出不同的策略:一些车型在保持低成本的同时,采用透明或半透明的导流罩设计,既提供了视觉上的运动感,也通过合理的气流设计提升日常巡航的舒适性与稳定性。这样的设计趋势,符合广义的“性价比优先、性能与美学并重”的消费偏好。具体到实现层面,整流罩的材料选型、粘接与表面处理,以及与底盘几何的配合,成为决定其性价比的关键因素。对消费者来说,关注点应从单一价格跳转到对综合性能的评估:风阻降低、风噪减轻、散热与前部件防护、视觉美感与品牌辨识度的提升。即使在较低排量的车型上,若整流罩实现了对日常使用的实际增益,它仍然具备值得考量的价值。\n\n为进一步理解行业实践,可以参考一些行业案例数据库与行业媒体对高端定制件的深度评测。相关权威参考来源指出,高端定制整流罩在市场上确实存在,并且常以限量版和艺术化设计作为核心卖点。这类内容强调的是“价值得以体现的不是单一件件成本,而是材料科学、制造工艺、品牌故事和稀缺性共同作用的综合体”。在对比时,我们应避免以价格作为唯一衡量标准,而应更多关注整体的价值创造与使用场景的契合度。对于那些希望理解市场全景的读者,除了关注价格、材料与工艺之外,还应关注售后服务、可持续性和二手市场的流通性等维度。\n\n在本文的讨论框架中,一个值得注意的细节是行业对“定制化与标准化”的并行推进。高端定制并非完全抹去标准件;许多工作室通过模块化设计,将定制元素嵌入到可重复生产的框架中。这种策略帮助降低单位成本、缩短交付周期、提升外观一致性,同时保留了个性化的表达空间。这也解释了为什么12k级别的整流罩在总体市场中难以成为常态:即便在高端定制中,真正实现规模化生产的能力仍然有限。对于普通车主而言,理解这一点有助于在购买时作出更清晰的判断:是否需要极致的定制,或是更注重日常使用与性价比的综合平衡。\n\n在市场趋势的视角下,整流罩对小排量车型的渗透正在逐步加深。与此同时,厂商也在探索更先进的材料与制造方法,以降低成本、提升性能并简化维护。例如,轻量化材料与更高效的涂覆工艺,让整流罩在不显著增加整车重量的前提下,提升了空气动力学效应的实际可感知性。这些技术演变的核心,是以“可持续性、可维护性与美学表达”为导向的综合考量。对消费者而言,这意味着未来的整流罩设计将更强调跨场景的适应性:在城市通勤中提供舒适性,在周末的赛道日或周边自驾活动中提供挥洒自如的性能感,同时保持相对友好的价格区间与良好的耐用性。\n\n从这个角度来看,12k级别的整流罩并非毫无市场,只是它的市场定位、目标群体与使用场景与大众需求之间存在明显的错配。更合理的叙述,是将整流罩的价格、材料与工艺、设计语言、以及对车型整体改装策略的协同效应放在一个框架中进行评估。对于追求高端定制的爱好者,12k可能只是一个起点,背后是对手感、观感、以及收藏价值的综合诉求;对于大多数日常驾驶者和通勤者,最有价值的,往往是性价比和长期维护成本的平衡。\n\n在讨论完上述市场与定价逻辑之后,我们要把视线拉回到具体的应用场景上,尤其是125cc市场中的整流罩应用。这一细分市场的变化,映射出更广泛的行业趋势:整流罩逐渐从高价定制领域向更广泛的入门级市场扩散。尽管在价格区间上,仍有很大差异,但通过模块化设计、轻量化材料和成本可控的工艺路线,整流罩在小排量车型上的价值正被逐步放大。这种演化有助于提升车型的视觉识别度、增强高速巡航的舒适性,并对日常使用中的噪音、震动和风挡效果产生切实影响。对于厂家而言,这也是一个以较低风险实现品牌升级与市场扩张的机会点。\n\n在实际采购与评估时,消费者应关注几个关键要素:材料的耐用性与环境适应性、贴合精度与安装便利性、表面处理的耐久性、以及对整车散热与前部件的影响。尽管段落中的数据会因车型与风洞测试条件而异,但在多数研究中,优质整流罩确实能够在一定速度区间内减少风阻、降低风噪,并提升仪表区的可读性和风格一致性。与此同时,设计语言也在持续演化,力求在保持经济性的同时,将赛车感与日常实用性融为一体。\n\n在总结这一章时,重要的是要认识到价格并非衡量整流罩价值的唯一标准。12k级别的标价更多体现了材料与工艺的极致、限量的稀缺性、以及与设计师品牌的深度合作,而在大众市场中,性价比、可维护性与实际使用体验才是决定性因素。对于那些希望在预算内实现“看起来像改装、却不愿承受高额维护成本”的用户,整流罩的选择空间正在扩大,尤其是在入门级运动型车型和小排量市场。你会发现,越来越多的设计语言开始以模块化、轻量化和可替换的策略呈现,以满足不同用户的需求。若你想进一步了解在这一领域具有代表性的设计与制造思路,可以参考 Honda fairings 的相关系列,了解行业在材料、工艺和风格上的多样化表达。\n\n此外,关于高端定制整流罩的案例与行业背景,可以参考权威行业媒体的深入报道。相关外部资源显示,高端定制的价值核心不只是件件件的材料成本,而是对整车整体美学、技术极致和收藏属性的综合体现。读者若愿意深入了解,可以访问行业报道,以获取对比性更强的案例分析与市场趋势判断。更多关于高端定制整流罩的案例可以参考 Motorcycle.com 的报道,了解行业在不同市场与时间维度上的演变与挑战。https://www.motorcycle.com

12K Realities: Material Science, Market Myths, and the Craft of High-Performance Motorcycle Fairings

On the surface, a 12K motorcycle fairing sounds like a price tag. In the market literature and consumer chatter, the phrase often migrates from price to material terms, then back again, until the line blurs. The reality behind the 12K label is more nuanced: it is a specification for a type of carbon fiber weave, a key piece of a wider materials and manufacturing stack that shapes how modern fairings perform, look, and endure.

In this chapter, we pull apart those threads. We trace the origin of the 12K term, explain what it means for a rider choosing a replacement or upgrade, and examine how the market interprets the concept. There is a strong undercurrent in the industry that 12K equals premium, which while sometimes true, is not a universal rule. The differentiation rests not merely in the fiber count per bundle, but in how the fabric is laid, cured, finished, and integrated with resin systems, core materials, and surface treatment. The 12K carbon fabric is a step in a chain that begins long before a fairing is bonded to a bike and ends long after a bike has rolled off the track or street into the garage and the setting sun hits a polished surface, revealing the weave pattern like a signature.

To understand why the 12K label matters, it is necessary to differentiate the material science from the marketing. 12K carbon fiber cloth refers to the structure of the fabric itself: each bundle, or tow, contains roughly 12,000 carbon filaments. When laid into a composite, these tows form a pattern whose geometry can influence stiffness, impact resistance, and how the skin behaves under aerodynamic loads. The cloth is then impregnated with resin, either through prepregs in a manufacturing line or through hand layup followed by vacuum-assisted resin transfer molding on a smaller scale. The choice of resin, curing temperature, and the presence of any core materials or fillers all contribute to whether the final piece remains light and strong or becomes heavier and more brittle under stress. The point is not simply that 12K is a fancy way to say “good stuff,” but that the weave structure interacts with the rest of the laminate to define behavior across speed, wind pressure, and heat from sun and braking.

In the marketplace, the idea that a 12K weave automatically commands a high sticker price is partly true, but it is not the sole driver. A true high-end fairing is the culmination of many decisions: the engineering intent, the surface finish, and the production ecosystem around it. A 12K fabric can be used in a fairing that is layered on a bike for track-day duty or for a sports bike aimed at street performance. But the cost landscape involves more than material; it includes the complexity of molds or patterns, the integration with mounting hardware, and the labor that goes into trimming, sanding, sealing, painting, and clear coating. The surface must be flawless to reveal the true beauty of the weave, and that requires skilled hands and time. In some cases, producers combine 12K carbon skins with a lighter core material, such as foam or honeycomb, to tune stiffness and energy absorption. The result is not simply a skin but a structured assembly designed to be as aerodynamic as possible while also protecting vital components.

The concept of value also extends to the aesthetic and brand dimension. A 12K weave is visually unmistakable; when light passes over the surface, the parallel dark lines create a micro-rhythm that accentuates the bike’s silhouette. For some riders, this is an essential feature because the fairing is part of the brand story of the machine, a physical sculpture as much as a protective shell. The blend of form and function becomes a selling point that can justify premium pricing in a market that rewards craftsmanship as much as performance. Yet the narrative around 12K can also mislead. It is quite common to encounter claims that “12K denotes the highest grade” or “12K is the factory standard,” which in many cases is an overstatement. In reality, many composite suppliers offer a range of weave counts—such as 3K, 6K, 12K—each with different mechanical properties and cost implications. A vendor may choose 3K for a lighter, more flexible skin while using 12K for thicker, stiffer panels. Therefore the consumer who hears 12K and assumes universal superiority risks overlooking other critical design decisions.

For most riders, the practical story is more pragmatic than myth. The performance gains from upgrading to carbon fiber fairings will hinge on the overall weight savings, the aerodynamic shape, and how those improvements interact with the motorcycle’s handling dynamics. It is not solely about the fabric count. A well-executed 3D-printed insert or a precisely composed laminate can deliver exquisite aerodynamics with lower cost, while a 12K skin applied on a rough mold with insufficient finishing can underperform, or worse, fail to meet durability expectations. The tradeoffs between stiffness, impact resistance, and impact energy absorption become especially visible in areas prone to stone strikes and speed bumps. In track settings, a fully engineered laminate system that distributes impact energy without cracking is more important than the mere presence of a premium weave.

This is where the broader market context matters. The supply chain for carbon fiber has matured significantly in the last decade. A growing number of manufacturers across Asia and Europe offer 12K fabrics and prepregs at scale, making it possible to source material for a broad spectrum of fairings—from mass-market replacements to niche, track-focused shells. The presence of 12K fabrics in mainstream supply mirrors a convergence between performance and accessibility. It is no longer a niche topic reserved for elite custom shops; rather, it is increasingly included in mid-tier offerings that claim improved rigidity and a crisper finish. The result is a more layered, nuanced price ladder. The perceived premium attached to the 12K label is often a function of not just the material itself but also the implied engineering sophistication, the degree of hand-finishing, and the availability of a full surface decoration and protective topcoat that preserves the weave’s appearance over time.

A crucial nuance emerges when considering the difference between a brand’s marketing presentation and the actual product attributes. On the surface, two fairings may appear similar, but their performance profiles can diverge based on how the panels are bonded to the bike, how evenly the resin cures, and how well the laminate resists microcracking under cyclic loading. The 12K reference alone cannot capture this complexity. The consumer, therefore, should look beyond a blanket claim and assess the engineering dossier of a given fairing system: the exact resin system, the layup schedule, the laminate stiffness, the venting and cooling strategy that prevents heat buildup in the engine bay, and the way the fairing integrates with other aerodynamic devices on the motorcycle. In track-focused configurations these factors influence slipstreams, turbulence, and the likelihood of delamination under high-speed gusts. In street-oriented setups, they influence wind noise, buffeting, and the perceived quality of the finish as the bike ages.

From a materials science perspective, 12K carbon fiber weaves represent a balance point between performance and practicality. The highest-grade fabrics might use finer tow counts or multi-directional weave patterns that optimize torsional stiffness and damage tolerance. But these advantages come with more intensive manufacturing pipelines and higher raw material costs. A well-engineered 12K laminate, with a consistent cure and careful handling, can deliver robust performance that suits many riders without pushing the price into the stratosphere. Conversely, a 12K label attached to a cosmetic skin with minimal structural support often signals a marketing veneer rather than a measurable performance gain. The distinction rests in how the rest of the system is designed to take advantage of the material, not in the fiber count alone.

The broader takeaway for readers of the 12k motorcycle fairings review is that you should approach the material choice as part of a larger system—one that includes the rider’s goals, the bike’s architecture, and the intended environment. If your priority is weight reduction for a track day, you may be better served by a complete fairing built around a carbon fiber skeleton with a tuned core and integrated venting, rather than a simple skin applied over a once-layup mold. If aesthetics are paramount, a manufacturer’s finishing process—clear coats, UV protection, resin-rich surfaces, edge-handling, and weave alignment—will determine how the weave looks after years of exposure to sun, rain, and heat. The interplay between function and form illuminates why some 12K-based products command a premium while others occupy the mainstream space.

A surprising yet important aspect of the 12K conversation is the role of standardization and transparency in the market. Consumers should demand clarity about material thickness, weave orientation, resin system, and any fillers or cores. Where possible, seek independent tests and third-party certifications or at least documentation that demonstrates how a fairing will behave under real-world loads. The difference between a sculpture and a structural component is precise engineering and rigorous testing. When a retailer or a maker presents a fairing as a “carbon” product, it should be backed by data that fights the ambiguity that sometimes accompanies marketing claims. This is not to say that all products are misrepresented; rather, it is a reminder that material labels can be misinterpreted when not backed by specific technical details.

In terms of consumer guidance, it helps to develop a set of practical evaluation questions. What is the exact weave count and tow size of the carbon fabric used? How many layers are used in critical areas, and where are they oriented? What resin system is used, and what is the curing profile? Is there a core material, and if so, what is its density and orientation? How is the fairing bonded to the frame, and what fasteners or adhesives are specified? How is the finish protected against UV exposure, and what is the expected service life under exposure to rain, road salt, and gravel? Are there any performance claims derived from wind tunnel or computational fluid dynamics analyses, and can the vendor share data or simulated results? These questions, while technical, translate into practical outcomes for the rider: safer, stiffer, and more predictable handling; or more attention to surface care and longevity.

In terms of practical buying decisions, the 12K narrative invites a balanced view: weight savings versus price, aesthetics versus durability, and the alignment of a product’s performance promise with the rider’s actual use-case. A rider who uses a race bike on a dry track may value extremes of stiffness and aerodynamic efficiency that a multi-layer 12K laminate can deliver, while a street rider might prioritize comfort, weather resistance, and ease of maintenance. The choice between different weave counts becomes a conversation about compromises rather than a single best option. To keep expectations grounded, consider the total package: combination of materials, finish, mounting hardware, painting, and after-sales support. The “12K” tag, in this sense, is a compass rather than a crate label. It points toward premium composites while acknowledging that the true measure of value lies in how the system performs across the lifecycle of riding.

The chapter also recognizes the broader cultural and economic threads that attach to carbon fiber fairings. The fascination with ultralight components is part of a longer arc in motorsport culture, where weight and aerodynamics teach discipline to engineers and riders alike. The same logic that pushes a team to shave grams from a tail section or to optimize a canopy for maximum laminar flow also informs aftermarket offerings that claim to cheat wind with elegant shells. This is not mere status signaling; it is a practical response to the reality that small changes in weight and shape can yield meaningful differences in acceleration, braking, cornering, and stability. The 12K label is a symbol of this discipline, not its final proof. It invites scrutiny, testing, and honest comparisons across a field of competing claims.

For those who want to explore manufacturer and vendor options within a broader ecosystem, it is useful to look at the channel landscape that supports high-end fairings. Distribution networks, avatar-like product pages, and showroom narratives often combine technical details with artistic presentation. The reality is that many riders encounter fairings as an opportunity to reframe their bikes visually while reducing drag and improving reliability. A well-executed fairing project—whether it uses 12K carbon fabric or another composite approach—requires careful coordination across engineering, manufacturing, and service. The result can be a bike that not only performs at the edge of physics but also carries the rider’s personality in the surface, the subtle shading of a clear coat, and the geometry of a line that catches the eye in a way that makes the machine feel new again.

Finally, the electrification of the riding world and the wave of new materials science will continue to influence how 12K carbon fiber is used in fairings. While the electrified and hybrid motorcycles bring their own design challenges, the core physics does not vanish. Airflow management remains essential for efficiency, engine cooling, and rider comfort. The way a fairing handles heat, softens vortex shedding, and channels air around a rider will still hinge on the careful combination of materials and architecture. 12K carbon fiber will keep serving as a tool in the toolbox, not a magic solution. The fairing becomes a balancing act among weight, stiffness, durability, thermal behavior, aesthetics, and price. The consumer who understands this balance is better prepared to navigate the market without falling into the trap of equating a weave count with universal superiority.

For readers who want to connect this deeper with practical shopping and real-world examples, there is a helpful path to explore an established collection that demonstrates how brands interpret fairings in this language. The Honda fairings collection, for instance, illustrates how a balanced approach blends high-quality finish with precise fitment and credible durability. By examining such collections, readers can glean what goes into panel design, how a craftsman handles edges and transitions, and how the weave interacts with the overall surface. This is not simply about a single model year or a single manufacturer; it is about the ongoing process of translating material science into a usable, reliable, and aesthetically compelling product that a rider can rely on, day in and day out. You can browse this collection to gain a clearer sense of how the fairing landscape is organized and how a modern fairing integrates into a broader riding experience. Honda fairings collection

In the end, the narrative around 12K carbon fiber in motorcycle fairings is not a one-note chorus about price but a chorus about how material excellence, engineering rigor, and thoughtful presentation come together to deliver performance and persona. The 12K label remains, at its best, a reliable shorthand for a certain class of composite laminate and for a particular aesthetic experience. It does not guarantee perfection, nor does it seal away the potential for trade-offs. Instead, it invites a voyage through the subtleties of materials science, manufacturing discipline, and rider-first design. As this chapter shows, the 12K conversation is really a conversation about how we value lightness, strength, and beauty in the machines we ride, and why that valuation matters for the future of aftermarket fairings in a market that continues to evolve with new materials, new processes, and new riders who crave both performance and expression.

External resource: https://www.motorcycle.com

Final thoughts

The high-stakes realm of $12,000 motorcycle fairings offers a fascinating look at the intersection of performance engineering, aesthetic value, and consumer psychology. While these high-end fairings are rare and often misunderstood, they reflect the pinnacle of what is possible in motorcycle customization. Understanding their true nature helps business owners better cater to discerning customers who appreciate both the artistry and engineering involved. A thorough examination of why these fairings command such prices reinforces the need for clear communication with potential buyers about their unique value proposition.