Motorcycle fairings are pivotal for enhancing aerodynamics, comfort, and style for riders. Business owners in the motorcycle industry must stay informed about the various options available, specifically the 15 motorcycle fairings that cater to popular models like Harley-Davidson and Yamaha. This article delves into specialized fairings for the Harley-Davidson Tri Glide and Softail Low Rider S, and the Yamaha R15 V3, while also exploring general market trends and procurement strategies for universal fairings. Each chapter will provide detailed insights suitable for discerning business owners looking to better serve their customers with high-quality products.

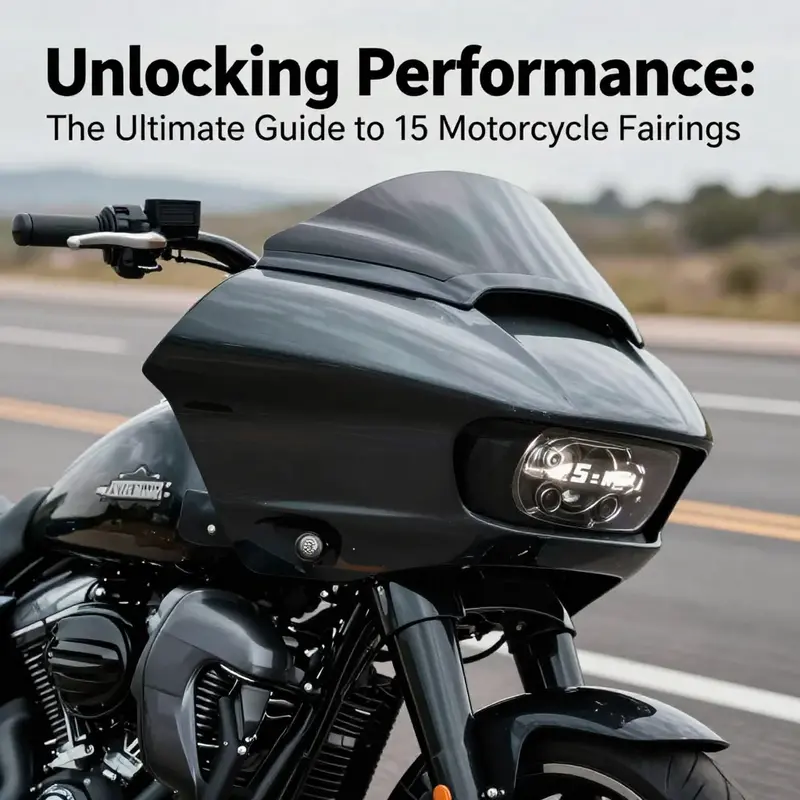

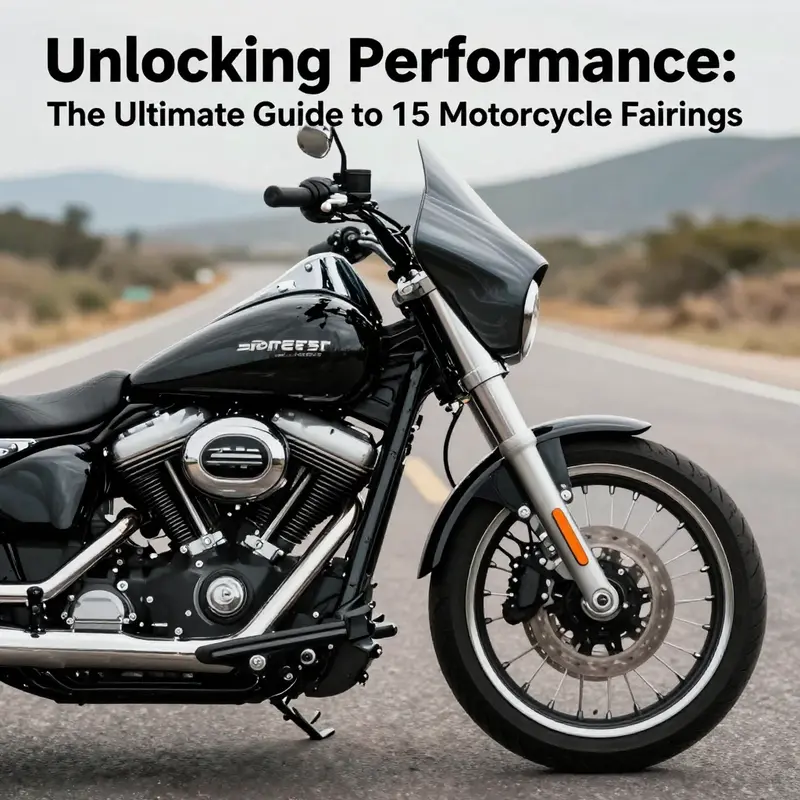

Fifteen-Inch Fairings for Harley-Davidson: Aerodynamics, Aesthetics, and the Art of Fitment

The allure of a motorcycle lies somewhere between sculpted silhouette and engineered purpose. When a rider chooses a front fairing as large as fifteen inches in height, that decision signals a commitment to a particular balance of wind protection, highway poise, and visual statement. On Harley-Davidson machines, a fifteen-inch front fairing is not merely a bolt-on piece; it is a design instrument that reshapes the bike’s air profile, changes how the rider interacts with the wind, and shifts the overall mood of the machine from a seaside cruise to a weather-beaten, open-road expedition. The fifteen-inch dimension has emerged as a sweet spot in many touring and cruiser applications because it offers substantial relief from buffeting at speed without imposing the bulk and weight of larger, more aggressive aeroshells. The fairing becomes a living part of the motorcycle’s character, an aerodynamic cousin to the chrome and leather that already define the brand’s identity. In practical terms, this means choosing a fairing that integrates with the bike’s lines, aligns with the rider’s posture, and accepts the existing mirror, dash, and mounting geometry without forcing compromises elsewhere on the chassis. The complexity of fitment is not a barrier but an invitation to engage with the bike as a system. A thirty-year heritage of touring models has produced a vast ecosystem of mounting kits, color-matching options, and finishing treatments that support a fifteen-inch front fairing in a way that feels natural rather than engineered, even when the bike has spent years on the road chasing curves and long straights alike. The best implementations respect the rider’s need for protection and the machine’s need to breathe; they preserve the line of the tank and shoulder the weight of the fairing without making the bike feel top-heavy when it’s parked or slowed to a stop. The conversation about fitment has to start with a reckoning of intention: is the rider seeking a classic touring silhouette with a windscreen that channels air above the shoulders, or a modern, color-matched statement piece that blends seamlessly with the bodywork while delivering a higher degree of shield and a touch more aggression in the stance? The answer will determine not only the tint of the windscreen and the type of outer shell selected but also the bracket system, the hardware finish, and the degree of integration with the bike’s instrument cluster and storage compartments. The fifteen-inch front fairing, in this sense, is less a singular product and more a philosophy about how much wind is welcome and where the machine’s identity should rest in the windstream. The fitment challenge is real, yet it is a challenge that riders meet with careful market navigation, a willingness to verify part numbers, and an appreciation for that moment when the fairing sits true, its edges aligned with the bike’s bodywork, the gaps uniform, and the mounting points snug enough to feel as reliable as the chassis itself. In this respect, the Harley chassis becomes a canvas. There are touring-oriented frames whose geometry accepts a larger, more contoured fairing with a clean, factory-like integration, and there are cruiser frames where the same fairing must be coaxed onto a slightly different angle, with brackets that respect the bike’s stance and its ride height. The practical path to harmony lies in a methodical approach: confirm the year, verify the frame and engine family, check the exact mounting pattern, and ensure the accessory is designed to coexist with the brackets and mirrors that the rider already relies on. This process is not about chasing the latest trend but about preserving function while achieving a cohesive aesthetic. The two goals can coexist when the selection process is patient and informed. A fifteen-inch front fairing should raise the bike’s visual stance while lowering the rider’s fatigue on long road stretches. It should feel like a natural extension of the bike’s lines rather than a foreign overlay. And when the sun glints off the finish, the rider should notice a uniform glow across all painted surfaces, not a patchwork of mismatched panels. That is the essence of a successful fitment: seamless integration, not a compromise that demands a constant readjustment of mirrors, windshield rake, or seating position. Material science plays a pivotal role in shaping this outcome. The most common choices for these fairings are typically hard-coated polycarbonate, ABS, or carbon fiber composites, each with its own balance of weight, durability, and finish quality. Polycarbonate with a hard coating is favored for its impact resistance and clarity; it resists stone chips and maintains transparency even after years of road exposure. ABS sheets offer lighter weight and cost advantages but can be more prone to flexibility under load; in the right design, however, ABS can deliver excellent scratch resistance and an attractive surface finish. Carbon fiber, while premium and expensive, provides the best strength-to-weight ratio and a distinctive aesthetic that some riders crave for performance-oriented builds. The choice of material has implications beyond weight. It affects vibration damping, weather resistance, heat transfer near the engine bay, and the ease with which a panel can be painted to achieve color matching with the bike’s existing schemes. A color-matched inner fairing section, for example, can create the sense of a single, unified shell, a visual statement that the rider’s bike was designed as a single piece rather than a two-part assembly. The inner fairing often contains instrument housings or storage compartments, and in many builds it serves as the anchor for the wiring harness that feeds the dash, audio, and lighting systems. The rider who envisions a clean, integrated cockpit will appreciate inner fairings that accommodate gauges, infotainment screens, and auxiliary controls in a tidy, recessed manner. An integrated look is more than a surface flourish; it is a statement about the owner’s intent to ride with confidence and clarity, with all the controls accessible without adding visual clutter to the bike’s front end. The process of choosing among available designs thus becomes a balancing act between function and form. There is a lifecycle to these components that begins with fitment and ends with maintenance. Proper installation requires attention to detail: correct torque specifications on fasteners, initiation of bracket alignment with pilot holes or locating tabs, and a careful check of the mirror and headlight alignment after the fairing is fitted. The road test after installation reveals whether the fairing handles airflow in a way that minimizes buffeting and keeps the rider comfortable at typical highway speeds. If the wind flow is too aggressive from the shoulder line or if the air pressure creates an audible drone inside the helmet, the rider may need to revisit the mounting angle, or switch to a different windscreen profile. The design solution is rarely a single component; it often involves adjusting the shield height, the rake angle, or even the protective foam behind the panel to soften vibration and optimize sound insulation. Beyond the immediate mechanical fit, the fairing speaks to the rider’s relationship with the open road. For many riders, a fifteen-inch fairing is a gateway to extended tours that cross long horizons with a calmer, more controlled airflow. It allows burly highway miles to feel less taxing and makes two-up cruising more comfortable when a passenger’s comfort is a priority. Yet a fairing that is too aggressive or too heavy can nip at the bike’s agility, especially in urban traffic or tight twisties where quick steering and easy maneuvering matter just as much as wind protection. In that sense, a rider’s choice becomes a choreography of geography and tempo: a touring rider might lean toward a more substantial, fully integrated solution with generous shielding and integrated storage, while a sportier rider who enjoys occasional highway sprints could prefer a lighter, more aerodynamically tuned shell that preserves nimbleness. The market responds to this spectrum with a variety of options, and the consumer bears the responsibility to verify compatibility through official catalogs or trusted databases. The practice of due diligence begins with confirming the part number against the motorcycle’s year and model family. This step is essential because a fairing built for a particular frame geometry can look visually identical to another, yet its hidden mounting points and instrument housings may not align. The best approach is to consult the manufacturer’s official accessories list, or turn to professional data guides and community knowledge that track compatibility down to the year-by-year changes. When shopping, a prudent buyer will also look for certified brands or manufacturers with proven track records in the aftermarket ecosystem. The most dependable choices come from suppliers who have built a reputation for durability, fit, and a finish that withstands sun exposure and highway grime without deteriorating. It is not simply a matter of choosing a color or a sheet type; it is about selecting a solution that can endure the realities of daily riding, weather exposure, and long-term ownership. For those who are exploring the ecosystem beyond the Harley line, a broader market perspective can be informative. There are universal fifteen-inch fairings designed to fit multiple models, with careful attention paid to mounting patterns, engine clearances, and rider ergonomics. These universal solutions offer attractive price points and a canvas for customization, but they demand careful validation of fitment against the specific bike in question. The reality is that an excellent fit on one bike might require modifications on another, especially when engines, frames, or fairing shapes differ subtly across years and model families. The learning from this is straightforward: thorough due diligence saves time and money and prevents the disappointment of a misfit panel that won’t align with the instrument panel or the mounting points. The practical steps to avoid disappointment are simple and repeatable. Start by verifying the fit using the parts database of the manufacturer or a professional accessory database. Cross-reference the vehicle identification details, including model year, frame type, and engine family, with the listed applications. When possible, consult with a technician who has hands-on experience with similar builds, as they can spot potential clashes before the material is shipped and installed. Prioritize materials that offer durability and ease of maintenance. Polycarbonate is tough and clear, but it can scratch if the riding environment is particularly harsh or if the rider favors aggressive windscreen polishing. Carbon fiber is stunning and lightweight but requires careful handling to avoid surface damage that can undermine the glossy finish. ABS offers cost efficiency and decent rigidity but can be more sensitive to heat exposure in certain installations. In the final analysis, a fifteen-inch front fairing on a Harley-Davidson motorcycle is both a technical and a stylistic choice. It is a choice that foregrounds wind management, rider comfort, and a cohesive look with the bike’s existing lines. It is also a choice that benefits from disciplined research and careful installation. The market offers a spectrum of designs, from color-matched inners that hide the hardware to transparent shells that showcase the frame and gauges beneath, to shells that emphasize a clean silhouette with minimal protrusions. The rider who embraces this spectrum ends up with a machine that does not merely ride but speaks—of long days on the interstates, of weekend escapes into the hills, and of the daily ritual of taking the long way home with confidence in the aerodynamics that carry the road’s stories forward. For riders who wish to dig deeper into the broader ecosystem of fairings yet stay oriented toward Harley-compatible applications, a useful lens is to explore the wider world of fairings across brands and models. A well-curated portfolio of 15-inch options can offer insights into how different frame geometries, mounting philosophies, and surface finishes can influence the final look and feel of the bike. This exploration is not about chasing the trendiest design but about understanding the essential mechanics of fitment, the implications of material choice, and the artistry of color coordination with the bike’s paint and chrome accents. In the end, the fifteen-inch Harley front fairing is a statement of readiness—an instrument of comfort for miles of highway, a vehicle for self-expression, and a testament to the idea that the road’s wind can be shaped by thoughtful design rather than endured uncomfortably. For readers who want a broader contextual view on fairings beyond Harley, an accessible resource lists a variety of model-specific and universal fairings and discusses their fitment considerations and finishing options. See the Harley-Davidson official accessories page for the authoritative catalog and installation guidance that informs every practical choice when selecting a fifteen-inch front fairing. And for readers exploring cross-brand options, additional examples and collections are available through dedicated parts databases and supplier catalogs, where the tradeoffs between weight, rigidity, and aerodynamics are laid out in technical detail. As a final note, the process of selecting and installing a fifteen-inch front fairing invites a patient, methodical approach. Take the time to verify compatibility, understand the mounting system, and consider how the final look will harmonize with the bike’s lines. The result is not merely a better-looking bike; it is a more confident ride with wind management tuned to the rider’s needs and a silhouette that remains true to the machine’s American cruiser heritage. For those who seek a deeper dive into model-specific discussions and broader fairing narratives, a careful reading of manufacturer catalogs, supported by trusted data sources, will yield a more precise map of options, costs, and installation requirements. The journey to the right fifteen-inch front fairing is, at its core, a journey into fit, finish, and function—an approach that makes every mile feel as if the road itself is tailored to the rider’s demands, rather than the rider bending to the road’s whims. For readers who want a concrete touchstone while they explore, one authoritative external resource offers a comprehensive overview of fairings and windshields in the broader category of motorcycle parts and accessories. This resource provides the official context for how fairings interact with windshields, instrument clusters, and mounting brackets, helping riders navigate the practical realities of fitment and performance. External reference: https://www.harley-davidson.com/en-us/accessories/motorcycle-parts-and-accessories/fairings-windshields.html. Internal reference: for a broader catalog of fairings from other brands, see the Yamaha fairings collection. Yamaha fairings collection.

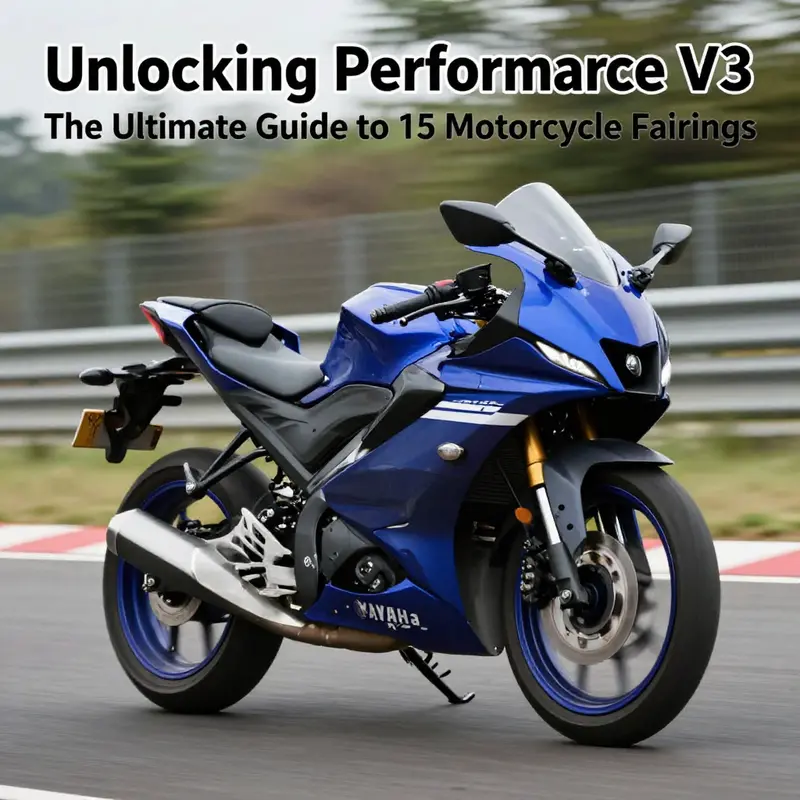

The 15-Inch Fairing Frontier: Aerodynamics, Aesthetics, and the Yamaha R15 V3 Experience

The 15-inch motorcycle fairing has become more than a simple shield against wind; it is a carefully engineered interface between rider, machine, and the air that surrounds them. On a widely tuned machine like the Yamaha R15 V3, the 15-inch fairing acts as a kinetic sculpture—an integral part of the bike’s silhouette, its cooling paths, its protective envelope, and its aerodynamic profile. This chapter follows that thread, weaving together material science, manufacturing geography, fitment realities, and the practicalities of purchase and integration so riders can appreciate not just what the fairing looks like, but what it does for performance, comfort, and identity on the road. The R15 V3 serves as a compelling anchor because it sits at a crossroads: a compact chassis with a high-revving temperament that rewards precision in aerodynamics and aesthetics alike. When the fairing is scaled to 15 inches, the geometry of the upper panels, cowling, and side shrouds begins to interact with the rider’s posture, the bike’s frame stiffness, and the air’s boundary layer in ways that smaller or larger fairings simply cannot replicate. Every line, curve, and panel edge becomes part of a conversation that riders start whenever they pull away from a curb. The result is not merely a look; it is a tuned performance envelope that can influence everything from top speed to fuel efficiency, from engine overheating margins to the tactile feel of wind on the chest and shoulders at mid-range speeds. In essence, the 15-inch fairing is a compact wind tunnel you carry with you, a shape that negotiates the throttle, the road, and the rider’s sense of speed in a single, coherent movement. The choice to deploy this dimension is not accidental. It reflects a balancing act between the desire for aggressive, race-inspired aesthetics and the realities of street use. A 15-inch fairing tends to offer a sweet spot where the rider’s line of sight remains unobstructed, while the cockpit is sheltered enough to reduce under-tank turbulence that can buffet the rider at urban speeds. The craft of the fairing therefore becomes a study in proportion: how much coverage is enough to smooth airflow without imposing excessive weight or visual bulk. On a model like the R15 V3, which blends lightweight chassis dynamics with a high-revving engine character, the fairing helps unlock a broader envelope of performance. It begins with a full-body approach that wraps around the cycle’s radiators and intake, guiding air toward cooling paths while avoiding stalls at mid-cspeed regimes. The fairing’s shape also matters for rider ergonomics. The alignment of the upper cowl with the rider’s line of sight and the way the fairing reconnects with the seat’s geometry can influence posture, reducing fatigue during longer stints and improving control feel when maneuvering through twisty roads. In this sense, the 15-inch fairing is not a cosmetic add-on but a deliberate asset that supports the bike’s intended character: a precise, responsive machine that encourages confident riding. The fairing’s materials speak to the same truth. ABS engineering plastics provide a robust baseline that tolerates color finishes and spray coatings with predictable performance. For riders who demand lower weight and higher stiffness, carbon fiber-reinforced composites offer an attractive, albeit pricier, option that can enhance the bike’s inertia characteristics and acceleration feel. Fiberglass remains a cost-conscious middle ground, delivering decent stiffness and impact resistance while keeping production costs accessible for hobbyists and small shops. Each material choice carries consequences for heat management, UV resistance, and crack propagation in the face of vibration and road debris. The 15-inch measurement also frames a practical procurement conversation. In many markets, especially those with dynamic import and distribution networks, the fairing is available as a full body kit rather than a loose assembly of panels. A body kit approach aligns with the R15 V3’s tight packaging and modular philosophy, because it ensures that all components—front cowl, side panels, canards or vented ducts, and mounting subframes—work in concert. The market has evolved to offer options that range from OEM-style replicas to fully integrated kits that require minimal tailoring. The supply chain for these parts has become particularly nuanced in several manufacturing hubs where scale and precision tooling converge. In recent years, Guangdong and its adjacent industrial zones have emerged as central nodes for the production of ABS and reinforced composites used in sport bikes. Guangzhou and Foshan, in particular, host mature facilities equipped with precision injection molding, multi-cavity tooling, and rigorous mold validation processes. The result is a sequence of components that ship with tight tolerances and clear, paint-ready finishes. That level of precision helps mitigate a common pitfall: misalignment. A fairing kit that claims a precise fit must be verified against the bike’s frame geometry, mounting points, and the exact year of manufacture, because minor changes in subframes, exhaust routing, or instrument cluster profiles can ripple through the mounting surfaces. For riders who want to pursue a more aggressive aesthetic, the 15-inch fairing provides a canvas for a Shark-fin-like silhouette or other sculpted details that convey motion even when the bike is stationary. The visual language of the fairing—measured vents, sharp creases, and a disciplined balance between negative space and panel mass—speaks to a philosophy of speed before speed is felt. The perceptible density of the form communicates the rider’s intent and the bike’s capability at a glance. It is at this intersection of style and function that careful selection matters most. A fairing that is too heavy or too aggressive for a given chassis can amplify steering inertia or provoke steering lag at low speeds, while one that lacks enough coverage may fail to reduce wind buffeting at the rider’s chest and head. The ideal 15-inch fairing, then, behaves as an integrated system: it complements the bike’s geometry, coordinates with the windscreen or its replacement, aligns with the rider’s posture, and sits within a manufacturable tolerance window that makes installation feasible for both professional shops and skilled enthusiasts. In practical terms, buyers should verify a few key fitment aspects before purchase. First, confirm the exact model year and variant for the R15 V3, because even within a single generation, there can be small but consequential differences in mounting points and fairing thickness. Second, consult official parts databases or professional distributors to cross-check part numbers and compatibility, using references such as Cyclepedia or Partzilla when possible. Third, evaluate the material composition in light of intended use. ABS provides impact resilience and color versatility, but carbon fiber fairings offer superior stiffness-to-weight ratios, which matters for riders who chase precision handling or track-day performance. Fourth, consider the paint and finish options. A kit that supports complete painting or the ability to hold a factory-like finish will simplify the restoration or customization process, preserving resale value and rider satisfaction. When it comes to the practical step of selecting a 15-inch fairing for the R15 V3, the marketplace often presents a spectrum of options. Some vendors offer full-body kits that include the front fairing, side panels, and a rear fender extension that integrates with existing tail sections. Others provide more modular assemblies, allowing riders to replace only the most visibly worn panels while maintaining the original structural components. The choice between a full-body kit and a modular approach depends on the rider’s goals: aesthetic refresh, weight optimization, or a targeted upgrade for airflow and cooling. The R15 V3, with its compact frame and high-revving engine, benefits from a careful blend of airflow management modules. The fairing’s interaction with the radiator intakes, the engine’s airbox routing, and the rider’s protective wind layer all contribute to a stable operating envelope across a broad RPM range. It is not uncommon for riders to pursue a combination of a clear windscreen with a 15-inch fairing that emphasizes downforce at higher speeds while maintaining visibility and comfort in urban riding. In regions where weather patterns and road conditions vary, this combination can produce a noticeable difference in ride quality. The fairing’s perforations, vents, and ducting are often engineered to direct air toward cooling fins or toward ram-air inlets, thereby enhancing engine thermal management without introducing excessive noise or turbulence. For many enthusiasts, the visual identity of the R15 V3 is inseparable from the fairing’s shape. The 15-inch dimension, in particular, lends itself to a disciplined aesthetic language—an arching line along the top edge that silhouettes the rider’s shoulders, and a lower contour that hugs the engine case and swingarm with a protective hug. This is where the collaboration between designer and engineer becomes most evident: form must follow function, yet function is guided by the rider’s desire to feel both connected to the road and protected from a shifting wind. As with any performance upgrade, the installation process deserves attention. Mounting points must align with existing mounting brackets and subframes, while gaps must be addressed to prevent wind from greedily lifting panels at speed. Some kits are designed to use the stock windscreen mounting hardware, which reduces installation complexity and helps preserve the bike’s original geometry. Others require dedicated brackets or a revised mounting ring to ensure rigidity under load. Regardless of approach, a careful pre-fit check is recommended. A common practice is to perform dry-fit assembly on the bench, then clamp the panels in their intended positions on the bike to confirm clearance with the tank, fuel cap, and fairing edge near the headstock. After confirming alignment, riders can proceed with gasket sealing, adhesive checks, and, if needed, a brief mock run to listen for rattles or contact points. This careful, deliberate process is especially important for 15-inch fairings, where the vertical and horizontal alignment tolerances are tight and small deviations can be felt in steering response and rider comfort. The opportunity to customize beyond stock finishes also excites many riders. With paint and clear coats, a well-applied finish can resist UV exposure and maintain color cohesion across panels. Clear finishes can enhance depth, while matte or satin textures offer a contemporary look that complements aggressive body lines. For riders who value exclusivity, lightweight composites can be finished in carbon-like textures or dyed to match a particular color scheme, while still preserving structural performance. The broader market context for the R15 V3’s 15-inch fairing is one of increasing sophistication in design and distribution. Guangdong’s manufacturing milieu, coupled with the presence of established local suppliers, has helped bring affordable, high-quality options into the hands of independent riders and shop professionals alike. The result is a buyer’s landscape in which fitment verification, material selection, and proper assembly are more accessible than in the past, yet still demand careful attention to detail. Among the practical takeaways for readers is the value of engaging in due diligence. Before committing to a kit, consult multiple sources, compare weights and thicknesses, review return policies, and request dimensional drawings or 3D mockups when available. This approach reduces the risk of a mismatch that can lead to installation difficulties or compromised performance. The journey toward choosing and installing a 15-inch fairing for a capable sport street bike is thus as much about discipline as it is about design. It is about recognizing that every millimeter of curvature contributes to the bike’s behavior on the road, and that the rider’s experience is shaped not only by speed, but by how the air guides, cushions, and communicates intent back to the cockpit. The end result should feel seamless: a fairing that seems to disappear into the bike’s lines when at rest, yet reveals its aerodynamic intelligence when the throttle is opened. For those who want to explore this further, the Yamaha fairings collection provides a useful starting point for understanding the range of shapes and configurations that align with a modern R-series philosophy. This chapter has traced the contours of the 15-inch fairing as a practical and expressive upgrade, showing how it sits at the intersection of engineering rigor, manufacturing capability, and rider imagination. It invites readers to consider not just the visual outcome, but how the fairing acts as a catalyst for improved airflow, refined handling, and a more personalized riding experience. As you plan your next upgrade, keep in mind that the best outcome emerges from a thoughtful, data-informed approach that respects the bike’s chassis, the rider’s ergonomics, and the realities of the supply chain. The next chapters will extend this conversation by examining how different materials alter the balance of stiffness, weight, and impact resistance, and how regional production ecosystems shape availability and lead times. For those curious to see concrete examples and to explore further product lines, a curated collection of Yamaha fairings is available here: Yamaha fairings collection, which offers a spectrum of designs and compatibility notes that align with the themes discussed. As with any aftermarket upgrade, these decisions are ultimately about aligning the bike’s performance envelope with the rider’s goals and the road’s realities. For colleagues seeking additional perspectives on sourcing and specifications, the following external resource provides broader context on R15 V3 fairing body kit suppliers and manufacturers: https://www.sourcingguide2026.com/yamaha-r15-v3-fairing-body-kit-suppliers/.

null

null

通用型15英寸前整流罩的市场洞察与采购实践

在全球改装市场持续升温的背景下,通用型15英寸前整流罩成为跨车型兼容的重要组成。选型时应重点关注三大维度:材料与重量、安装接口的标准化,以及供应链的稳定性。材料方面,ABS、聚碳酸酯(PC)与碳纤维三类材质各有优劣:ABS成本低、加工便利,但耐热性与长期耐久性有限;PC具备更好的抗刮擦性与透明度,重量与强度比也更优;碳纤维在重量与强度方面表现最佳,但成本显著较高且加工难度高。安装接口方面,越高的标准化程度越利于批量采购和跨车型落地,需要关注固定孔距、螺栓规格以及风挡连接方式。采购策略方面,建议优先选择正规品牌与有售后保障的供应商,同时通过多源采购和可追溯的质检记录降低风险。最后,时效与成本并重,整套件或提供喷涂、贴膜等增值服务的供应商通常能提升门店周转率与客户满意度。

Final thoughts

Understanding the diverse options available for 15 motorcycle fairings is crucial for business owners aiming to stay competitive. By focusing on tailored solutions for specific motorcycle models and remaining aware of market trends for universal fairings, businesses can enhance their offerings and satisfy customer demands. Investing in high-quality, compatible fairings not only improves rider experience but also builds brand loyalty, as satisfied customers are likely to return for future upgrades and recommendations.