Understanding the specific components and diagrams of the 2006 GSXR 600 motorcycle fairing is crucial for business owners in the motorcycle industry. Detailed knowledge of the structural overview and materials, coupled with familiarity with design variants and installation precision, can significantly impact maintenance, customer satisfaction, and customization options. As we delve into the chapters ahead, you will uncover the importance of these aspects and how they collectively influence the service and retail of motorcycle fairings, tapping into a lucrative market.

The Frame Within the Shell: A Structural Narrative of the 2006 Front Fairing System

The front fairing of a 2006-era 600-class sport motorcycle is more than a glossy silhouette riding over the bike’s chassis. It is a carefully engineered, multi-part system that blends protection, aerodynamics, and rider ergonomics into a single, functional surface. To understand its depth, imagine the fairing not as a single shell but as a compact ecosystem where every line, every mounting point, and every material decision serves a precise role. The aim is to minimize drag at high speed, shield sensitive components from airflow and debris, and deliver a predictable ride quality that remains consistent, lane to lane, mile after mile. In this sense the fairing behaves as a form of airframe—an integral part of the bike’s dynamics rather than a cosmetic add-on. And like any airframe, its performance hinges on accuracy of fit, the integrity of joints, and the compatibility of its parts with the bike’s original hardware and subsystems.

At the heart of the 2006 front fairing is a triad of core components that work in concert to achieve this balance. The main front fairing forms the largest, most visible surface, enveloping the headlight cluster, the upper instrument cluster, and the upper portion of the fuel tank. Its shape is a product of wind tunnel intuition and computational refinement, with careful attention paid to how air transitions from the leading edge to the cockpit. On each side, the side fairings extend the shell’s coverage toward the midsection and the mirror mounts, shaping the flow around the rider and the engine bay. Finally, the rear fairing or tail section links rearward to the seat area, contributing to a smoother wake that minimizes turbulent disruption behind the rider and around the rear wheel. Together, these components create a continuous, flowing contour designed to reduce form drag while managing the boundary layer over the bike’s most dynamic region: the front third of the chassis.

The materials chosen for these panels reflect a practical compromise between stiffness, impact resistance, and weight. The standard factory configuration relies on high-strength ABS plastic, a workhorse in the world of motorcycle fairings due to its toughness, heat tolerance, and impact resilience. ABS can maintain a clean, sharp surface under the pressure of highway speeds and frequent road debris while absorbing small impacts without cracking. For riders seeking a performance edge or a distinct aesthetic, there are aftermarket variants that substitute composite materials such as carbon fiber or fiberglass-reinforced polymers. These composites can reduce weight and increase stiffness, which, in turn, can influence how the panels work with the mounting points and how the fairing interacts with the bike’s aerodynamics at elevated speeds. Yet with reduced weight and enhanced rigidity comes a higher cost and a heightened sensitivity to manufacturing tolerances. The choice between standard ABS and advanced composites is more than a cosmetic preference; it affects how the fairing seats on the frame, how the seams align with neighboring panels, and how it responds to flex in aggressive riding scenarios.

From a design perspective, the fairing system is built with two overarching objectives: first, to manage airflow so that the rider experiences stable, predictable behavior at speed; and second, to integrate with the motorcycle’s most vulnerable or functional components without compromising access, serviceability, or safety. The main front fairing must cradle the headlights and instrument cluster with precise cutouts and mounting bosses. The openings for cooling louvered vents, if present, are tuned to channel air toward the radiator and the engine bay while preventing direct intrusion of water or debris into critical areas. The side fairings shield the engine’s sides, contributing to the bike’s silhouette and offering passive protection in a tip-over event. The tail section, despite being visually lightweight, plays a subtle but meaningful role in defining the wake behind the bike and in smoothing the transition from the rider’s body to the rear portion of the chassis. The overall geometry is a careful exercise in reducing parasitic drag and smoothing pressure gradients as the bike moves through the air at speed.

A crucial element of this structure is the production and assembly tolerance. The fairing system is not a loose collection of panels but a precision assembly whose fit is dictated by tight dimensional commonalities across OEM sheets, molds, and mounting hardware. Small deviations in thickness, location of mounting bosses, or the curvature of the panel edges can lead to misalignment, gaps, or rattling that undermines the fairing’s aerodynamic intent or its ability to hold together under wind loads and vibration. The manufacturing process—often mold-based injection for the main shells with additional precision for attachment features—must control these tolerances with care. Any deviation risks misfit that would require shimming, repositioning, or even replacing panels to restore the intended surface continuity and seal. This is why OEM-spec components are frequently emphasized in the installation guidance. They ensure that the panel edges meet the expected curvature, the matching lines align with adjacent skins, and the fasteners locate correctly within their recesses.

The modularity of the fairing system invites a spectrum of customization paths. There are complete, full-body fairings that wrap from the chin to the tail, and there are lighter, half-fairing configurations that cover just the front or midsection. The streetfighter or naked-bike style, which omits the full fairing on the front, represents another end of the spectrum. Each configuration changes the rider’s experience in subtle yet meaningful ways. Full fairings offer the most aerodynamic surface, maximizing shielding and minimizing crosswinds. They also demand the most exacting mounting discipline because every seam must align, the windscreen must create a clean airfoil, and the lower edges require precise clearance around the engine and frame elements. Half-fairing kits reduce some of the complexity but place greater emphasis on protecting the cockpit and the rider’s legs, while still preserving a coherent aerodynamic profile. The streetfighter approach strips away many of the upper panels, exposing more air and creating a different wind signature that can influence rider fatigue and heat management. In each case, the underlying structural concept remains the same: a network of interlocking panels that transfer loads, maintain stiffness, and preserve the machine’s visual language while enhancing function rather than simply covering the frame.

The materials story reinforces this functional narrative. Abs is the default for mass production and serviceability. It tolerates the rigors of daily riding and is forgiving during field repairs. It is also compatible with many factory and aftermarket attachment schemes, which reduces the risk of panel misfit when owners choose to upgrade or replace sections. For riders chasing maximum stiffness or a higher degree of surface hardness, carbon fiber variants provide a more robust boundary layer. However, the thinner layups and the different resin systems used in carbon fiber must be handled with care and require proper bonding credentials to ensure that the attachment points remain secure under vibration and load. In between these extremes lies fiberglass-reinforced composites, a material that blends weight savings with manufacturing practicality, and often serves as a cost-conscious alternative with respectable performance gains.

The fairing’s functionality also depends on how it interfaces with other subsystems. The headlight housings must be accessible, but also sealed against moisture; the instrument cluster must remain legible and shielded from glare; the radiator and cooling channels must not be obstructed by panel geometry. Mounting points are usually arranged in a way that distributes load carried by the fairing across the bike’s frame and subframes, and fasteners are chosen to withstand the cycle of tightening, heat exposure, and vibration without loosening. The installation discipline is a reminder that the fairing is not merely a cosmetic shell but an engineered assembly that requires alignment to OEM specifications to avoid gaps or misfit that can compromise aerodynamics, water sealing, or even the effectiveness of cooling channels.

In terms of documentation and verification, owners and technicians rely on official service manuals and parts diagrams to identify each panel, its proper position, and how it should be assembled. These documents provide the complete breakdown of the bodywork system, with part numbers, service margins, and step-by-step procedures that minimize guesswork. While the diagrams themselves are not visible here, the guidance they offer is invaluable for aligning the panels accurately and for understanding which hardware belongs to which fastener location. As a practical note, viewing visual references—whether from the official manuals or trusted catalogs—helps clarify how the seams line up across adjacent panels, where the vents and openings are located, and how the windscreen integrates with the front fairing’s upper edge. For readers seeking a direct visual reference to a compatible panel set, a curated web collection presents a catalog of panels and assembly diagrams that mirror the OEM fitment logic and provide a tangible sense of how these pieces come together. See this internal collection for a reference that closely mirrors the described system: GSXR 600-750 fairings, 2006-2007.

The chapter would be incomplete without acknowledging the practical realities of sourcing, which is where these diagrams become a bridge between theory and application. The diagrams and part lists guide the technician through disassembly, inspection, and reassembly with confidence that each panel will locate on its corresponding boss, align with its neighboring surfaces, and maintain the bike’s aerodynamic integrity after maintenance. In this context, the fairing is not a static shell but a living interface between rider, machine, and environment. The discipline of aligning multiple parts, calibrating the panel gaps, and ensuring the windscreen’s fit with the front fairing’s curvature demonstrates how deeply engineering thinking informs what many riders perceive as a simple cosmetic asset. The fairing’s surface is where wind tunnels, service manuals, and rider comfort converge, creating a coherent performance narrative that translates the raw capability of the machine into a controlled, confidence-building riding experience.

For readers who want to extend their practical understanding beyond the printed diagrams, a broader landscape of aftermarket listings offers additional visual references. These listings often reveal how different materials, finishes, and thicknesses affect the fit and appearance, while also illustrating how the panels mate with standard mounting hardware. Though not a substitute for OEM documentation, those visuals can illuminate the surface geometry, seams, and alignment cues that a technician uses during installation or replacement. In this sense, the fairing’s beauty is inseparable from its engineering: the aesthetic lines are a visible manifest of a rigorous design and manufacturing process that favors precision over improvisation. If you seek broader context on similar fairing systems and their practical implications, you can explore external resources that discuss a range of panels and their installation considerations across comparable models and eras.

External reference: https://www.alibaba.com

Shaping the 2006 GSXR 600 Fairing Diagram

An integrated view of the 2006 GSXR 600 fairing diagram, this chapter explains how panel geometry, materials, and fastener layout come together to manage airflow, rider protection, and cooling. ABS plastic is discussed as the baseline material for repeatable shape and cost efficiency, with notes on aftermarket alternatives such as fiberglass and carbon fiber and their effects on weight and stiffness. The text also covers OEM assembly discipline, torque targets, and the importance of maintaining OEM geometry to ensure proper fit, gaps, and aerodynamic performance. Finally, it connects the diagram to service manuals, part numbers, and real riding conditions to illustrate how a schematic becomes a reliable guide for maintenance and performance.

Contours of Control: Reading the 2006 Suzuki GSXR 600 Fairing Diagram and Its Design Variants

The fairing of a 2006 Suzuki GSXR 600 is more than a shell of plastic or carbon fiber; it is a precise argument about balance. It speaks to what a rider needs at speed, and it speaks to what the machine can tolerate in terms of heat, airflow, and the alignment of every mounting point with every component hidden behind the panels. The research materials describe a system built around high-strength ABS as the baseline material, with the option to substitute carbon fiber to shave weight and refine rigidity. That material choice is more than a preference; it affects how the panels bend under heat from the radiator, how they resist impact, and how the finish holds up with exposure to wind and sun. When the fairing is examined in diagram form, as a part of the service manual or OEM catalogs, those material decisions become tangible: the lines of the front, the curvature of the side panels, and the subtle transitions where a belly fairing would meet the frame. In this sense, the 2006 GSXR 600 fairing diagram is a map of performance possibilities dressed in protective skin, a schematic that translates engineering constraints into something a rider can actually fit and ride with confidence.

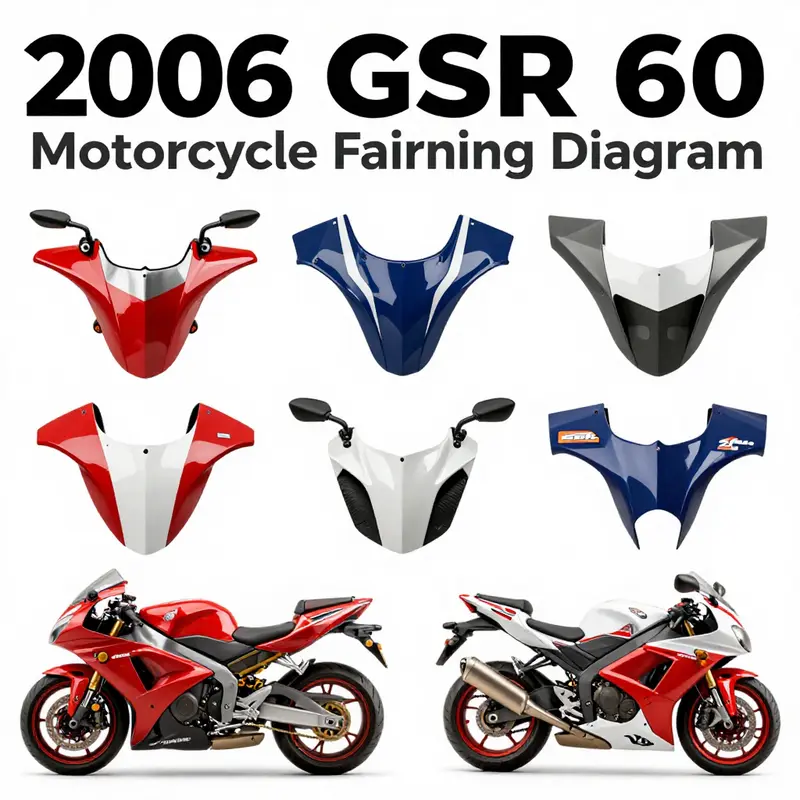

Within the broader story of these diagrams, design variants emerge as the most visible translators of purpose. The full fairing is described as the most comprehensive and aerodynamically efficient option. It wraps the front and the sides, smoothing the path of the air as the machine climbs into higher speeds. Read in a catalog, the full fairing signals a track-oriented mindset, where drag reduction and high-speed stability are not optional refinements but essential requirements. When the exploded view appears in the service manual, every line, every edge, and every seam has a rationale: a place for the headlight assembly, a defined route for the wiring harness, a specific mounting hole that keeps the panel aligned with the radiator shrouds. This is not merely a cosmetic cover; it is a system that interacts with the engine heat, the intake and exhaust geometry, and the rider’s own position on the bike. The diagram makes that complexity legible, turning the glossy outer shell into a clear inventory of parts and a precise sequence for assembly. For riders who want to understand not just what is visible but how it connects to the bike’s core, the diagram is the starting point for evaluating how a full fairing will alter the GSXR 600’s handling at speed and under load.

The half fairing presents a different calculus. Lighter, more accessible, and still aerodynamically meaningful, the upper-front cover offers a more aggressive silhouette without fully closing off the lower portion of the bike. The diagram for this variant reveals the strategic gaps and the curves that still guide air along the engine and radiator, but with greater openness around the lower frame. This openness translates into a riding experience that feels more exposed—a trait that enthusiasts often associate with a more direct connection to the bike’s mechanics. Yet the half fairing preserves enough shielding to reduce buffeting and to direct airflow toward critical components, demonstrating how a single architectural choice—covering the upper portion while leaving the lower section open—can shape both the visual identity and the aerodynamic profile of the machine.

The naked or streetfighter approach is the most radical departure from the traditional GSXR 600 silhouette. In the diagrams and kits that describe this variant, the emphasis shifts from wind management to mechanical showmanship. The panels retreat, exposing the frame, the radiator, and the engine casings, so the rider can observe the machine’s inner rhythm. The effect on aerodynamics is real but different: the lack of full panel coverage changes how air interacts with the bike at even modest speeds, increasing the need for careful tuning in other areas, such as steering geometry or tire choice, to maintain stability. The diagrams for naked setups remind us that a fairing’s purpose can extend beyond protection and speed to visual storytelling—an invitation to see the GSXR 600 as a high-performance machine with its own raw mechanics on display.

A modular approach completes the portfolio of variants. The module-oriented design principle allows riders to mix and match, selecting individual components from different kits to curate a personal aesthetic and performance balance. The diagram for modular fairings is a reminder that modern sport bikes can be treated as a toolkit rather than a single, fixed configuration. The mounting points, the interface between front spoilers and side panels, and the compatibility notes embedded in the official diagrams show how riders can tailor airflow patterns and protection levels without compromising the underlying structure. The idea of modularity is not merely about changing looks; it is about preserving fit, ensuring that each piece aligns with OEM specifications so that the entire system behaves as a single, cohesive shell rather than a loose patchwork. When the diagrams illustrate modularity, they also reveal how distinct shapes and panel shapes can be swapped with confidence, provided that the right part numbers and mating points are respected. The result is a bike that can be tuned to track demands, street realities, or personal style while keeping the essential integrity of the fairing system intact.

Reading these diagrams requires a careful eye for how materials, geometry, and mounting hardware come together. The ABS base is robust, yet the option of carbon fiber invites a different mechanical relationship with heat and stiffness. The diagrams specify not only where each piece sits, but how it interfaces with the surrounding components—the radiator shrouds, the windscreen, the frame rails, the mounting brackets—and how precise tolerances ensure that panels don’t rub or misalign during vibration. The service manual, in particular, is a source of truth for this alignment. It provides the part numbers, the sequence of installation, and the order in which fasteners are torqued. In other words, the diagram is a guide that protects against the kind of misfit that can undermine performance or cause interference with the steering, the brakes, or the cooling system. For a collector or an owner who intends to restore a 2006 GSXR 600 or to upgrade it with a more modern material, the diagram is a bridge between historical design intent and practical, repeatable assembly.

For those who want to go deeper into the practical dimension of obtaining accurate, official visuals, the Suzuki service documentation remains the most reliable source. It is often complemented by external catalogs and vendor guides that show the same anatomy of parts, numbers, and fittings from different angles. In the world of aftermarket fairings, the choice is not simply which style you prefer, but how faithfully a kit reproduces the OEM geometry and how well it preserves the bike’s cooling, steering, and crash protection. The official diagrams, paired with the right OEM components, help ensure a seamless fit that respects the bike’s original engineering intent. They also support the broader aim of preserving performance characteristics across different riding conditions, from the controlled environment of a racetrack to the variable realities of daily street riding. This is the core of what makes a fairing diagram valuable: it translates design talk into a reliable, repeatable process that keeps the bike coherent as a machine rather than a collection of mismatched shells.

Anyone exploring the 2006 GSXR 600’s fairing choices may encounter a spectrum of aesthetics and responsibilities. A full fairing offers maximal protection and aerodynamic efficiency, best suited to high-speed track work where every fraction of drag matters. A half fairing presents a middle ground with improved aesthetics and wind management that still preserves some open, muscular character around the engine. The naked or streetfighter style, with its stripped-down ethos, foregrounds mechanical transparency and a raw, urban edge, while demanding careful attention to how the exposed components influence heat dissipation and stability. The modular approach pushes the boundaries of customization, enabling a tailored balance between protection, weight, cooling, and appearance while maintaining the reliability of OEM-fitment. Across these variants, the diagrams function as the backbone of a thoughtful selection process. They empower riders to weigh how a particular configuration will affect airflow, engine temperature, steering response, and the bike’s overall demeanor at speed. They also anchor the discussion in a shared, verifiable reference point: the official part numbers and installation steps that ensure any change in appearance does not come at the cost of function.

A useful way to connect this chapter to the broader landscape of fairing culture is to recognize that the GSXR 600’s diagrams sit within a continuum of design thinking that extends beyond a single model year. The same logic—matching material properties to performance goals, aligning every panel with precise mounting points, and offering a spectrum from full to modular to naked—appears in other Suzuki sport bikes as well as in rival brands. The dialogue between protection, aerodynamics, and identity that these diagrams embody invites riders to look beyond the surface and ask how a given fairing choice will influence the bike’s behavior on the street and on the track. It also invites readers to explore the responsibilities that come with modifying a machine so intimately designed around a specific aerodynamic and thermal profile. When reading the diagrams, one can appreciate how a well-executed fairing kit is not just a cosmetic upgrade, but a carefully engineered package that preserves or enhances the GSXR 600’s core attributes.

For readers who want to follow a concrete path to reference materials or to see how these principles translate into a real-world kit, a deeper dive into official and vendor resources can be instructive. The Suzuki community and aftermarket catalogs frequently present the same structural language in slightly different formats, but the essence remains: a well-fitted fairing respects the bike’s geometry, protects critical components, and communicates the rider’s intent through its silhouette. To one observer, the full fairing signals professional discipline; to another, modular assemblies promise personal expression without sacrificing the machine’s integrity. The shared thread across all variants is the disciplined alignment of form and function, captured this year in the 2006 GSXR 600’s fairing diagram. This is the essence of the chapter: that understanding the diagram, and the variants it encodes, reveals a thoughtful, technical conversation about how a sport motorcycle communicates performance through its skin.

For readers seeking a practical touchstone as they explore or restore a GSXR 600, the internal link to the official and compatible aftermarket options is a helpful starting point: Suzuki GSXR 600-750 2006-2007 fairings. This reference frame connects the design variants to tangible parts and fitting exercises, grounding the discussion in real-world choices while preserving the narrative that diagrams translate engineering intent into maintainable, rideable machines. And to understand the aerodynamic forces at play in any fairing configuration, a broader primer on air resistance and flow around vehicles offers a useful context: https://en.wikipedia.org/wiki/Aerodynamics. This external perspective helps frame the way a fairing’s lines, angles, and gaps shape drag, lift, and stability as speed increases. In the end, the 2006 GSXR 600 fairing diagram is not a closed blueprint but a living document—one that captures the interplay of design, performance, and personal choice that defines motorcycle culture.

Precision in Alignment: Reading the 2006 GSXR 600 Fairing Diagram for Peak Performance and Safety

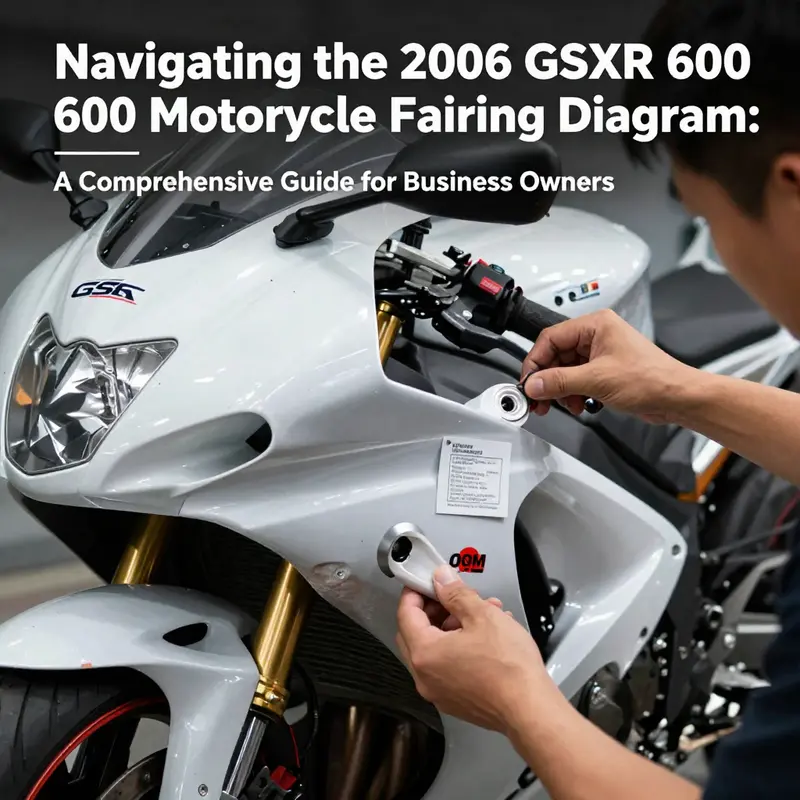

Alignment in the realm of performance motorcycles is more than an aesthetic concern. On a bike like the 2006 GSXR 600, the fairing diagram functions as a compact blueprint for how every panel, every mounting point, and every air channel contributes to balance, stability, and rider confidence. The fairing system is engineered from high-strength ABS as a baseline, with serious riders sometimes opting for carbon fiber components to shave weight and tune stiffness. This material mix matters, but so does how the pieces come together. The diagram is not just a set of shapes on a page; it is a precise map of the frame, the mounting brackets, the hidden fasteners, and the subtle clearances that allow the fairing to sit flush against the silhouette of the machine while leaving room for the steering head, the headlights, and the fuel tank beneath. When you study the diagram, you begin to understand why the installation sequence matters as much as the parts themselves, and why even small deviations can ripple through performance and safety in ways that aren’t immediately obvious to a casual observer.

To a technician or a careful hobbyist, the diagram is a guide to tolerances that are etched into the bike’s design. The 2006 model year, with its integrated full fairing, its half-fairing variants, and the potential for streetfighter-style conversions, presents a spectrum of fitment challenges. The diagram’s precision reflects the need for exact tabs, aligned holes, and perfectly positioned mounting points. Any misalignment—an offset tab that fails to seat into its bracket, or a misdrilled hole that places a fastener off-axis—can create gaps that alter the airflow, invite unwanted vibration, and place uneven stress on the plastics. Over time, that stress can not only mar the finish but also compromise the long-term durability of the panel joints. In short, the diagram is both a specification and a promise: when followed, it yields a predictable, durable, and aerodynamically coherent bodywork package.

Reading the diagram with care begins with acknowledging the role of fitment as the bridge between design intent and real-world performance. The original engineering of the 2006 GSXR 600 fairing system assumes a precise assembly rhythm. The full fairing, with its upper cowls and lower belly panels, orchestrates a smooth front-to-back flow, guiding cooling air around the radiator and into the ram-air intakes while maintaining a controlled pressure gradient along the sides. This harmony rests on exact alignment of the upper and lower pieces, the chin spoiler, the side panels, and the flanks that converge near the headlight assembly. If any one of these pieces is even a few millimeters off, the resulting gaps become channels for turbulent air that disrupts the expected pressure distributions. The effect may be small at a standstill, but at speed the cumulative impact can be measurable, influencing stability, steering feel, and even the rider’s wind buffering. The diagram explicitly encodes these relationships by representing the geometry of each tab, each hole, and each mounting stand with a tolerance band that technicians are trained to respect during assembly.

A practical takeaway from the diagram is how intimately the mounting points relate to the frame and to the rider’s contact zones. When the fairing is installed, the panels must clear the handlebars and the headlight assembly while maintaining a tidy line at the fuel tank seam. The interplay between the mounting hardware and the frame is not merely about keeping panels in place; it is about preserving the integrity of the airflow path across the bike’s front end. The placement of the fairing around the headlight modules, for instance, affects glare control and aerodynamics. If the nose piece or the headlight cavity is misaligned, the airflow can detach earlier than designed, creating a small but real drag increase and a shift in the front-end lift profile. In a sportbike, even modest changes in front-end aerodynamics can alter corner-entry stability, mid-corner feel, and the rider’s tactile feedback through the handlebars. The diagram thus serves as a guardian of both performance and safety, reminding installers that a fairing is an engineered interface, not a cosmetic shell.

The installation sequence, as implied by the diagram, reinforces a discipline: fitment first, then alignment, then finish. This sequence is not arbitrary. Starting with the frame as the anchor point, technicians attach the inner brackets and mounts in a way that allows a progressive, controlled seating of the outer fairings. It is common to begin with the lower belly panels and side pieces, ensuring the attachment points line up with pre-installed brackets. From there, the upper cowl and fairing nose go on, guided by reference lines and the exact pre-drilled holes specified in the OEM schematics. The goal is to achieve a uniform gap around the entire perimeter—no more, no less—so that air can pass smoothly along the body panels rather than creating a labyrinth of micro-eddies at the edges. The texture of that gap matters as much as its width; a consistent, uniform line around the nose, the windscreen, and the sides translates into predictable airflow and better rider protection from wind buffeting at speed.

This is where the practical realities of aftermarket versus OEM components come into play. The diagram presupposes a level of precision that OEM-grade parts and mounts are designed to provide. When aftermarket kits are introduced, their claim of “precision fitment” often rests on the inclusion of pre-aligned tabs and pre-drilled holes that should align with the frame and brackets as the OEM parts do. Yet even with such promises, the user must exercise due diligence. Dimensional drift can occur during production, and packaging variances can introduce minor misalignments that only show up once the panels are brought together. For this reason, technicians frequently verify fitment using CAD-backed digital fitment guides or installation photos supplied by the vendor. In B2B contexts, suppliers who provide these digital aids can help prevent costly returns and unhappy customers by enabling a pre-purchase check of compatibility with the model-year and the sub-model family. The principle is simple but powerful: the diagram’s fidelity is best respected when the purchaser can cross-check a real-world reference against the design intent before a single fastener is torqued.

The cross-referencing discipline extends to the choice of materials. The ABS baseline offers a robust balance of impact resistance and formability, making it a dependable substrate for the aggressive lines of the GSXR 600’s fairing. For riders seeking to optimize stiffness and weight, carbon fiber variants present a different set of challenges and advantages. While carbon can reduce mass and improve torsional performance, its resilience to fastener load distribution and its interaction with the mounting hardware must be considered in light of the diagram’s tolerances. A fairing panel that is slightly off in its alignment may not seat correctly against a carbon backer, or it may stress the composite in places that are not intended to carry high loads. The diagram, therefore, is not merely a two-dimensional depiction of shapes; it is a three-dimensional guide to how the panel surfaces, thickness, and mounting hardware move as a system under torque, vibration, and heat. Respecting these relationships during installation preserves the intended aero profile, reduces noise and vibration, and keeps the rider’s attention on the road rather than on a panel that creaks or gaps at speed.

For riders who rely on a formal maintenance and fitment reference, the official service documentation remains the most reliable anchor. The diagrams, parts lists, and step‑by‑step installation steps provided by reputable sources help ensure that the fairing aligns with the frame and sits at the correct angle to maintain the designed airflow path. In practice, this means paying attention to every little detail—how the fairing aligns with the headlight module, how the side panels kiss the radiator shrouds, and how the upper cowl meets the instrument panel without binding on electrical harnesses. Even the factory-specified torque values for the mounting screws matter, because overtightening can deform panels and introduce micro-gaps that degrade aerodynamic performance or lead to fatigue failures over time. The diagram’s precision is matched by the discipline of installation—an art form that blends accurate measurement, patient assembly, and a respect for the engineering intent embedded in the schematic.

To ground this discussion in practical reference points, technicians often consult model-year specific resources that echo the diagram’s exacting standards. For instance, a reliable catalog entry or service guide for the bike family reinforces the same mounting geometry and hole patterns that the diagram encodes. When a shop or individual purchases aftermarket fairings, confirming these cross-reference points helps ensure that the kit matches the frame geometry and maintains the intended gap tolerances. The result is a consistent, repeatable fit that preserves the bike’s front-end geometry and the rider’s aerodynamic envelope. In the end, the diagram is the compass that keeps the installation faithful to the design’s aerodynamic and structural intent, while a careful hands-on approach ensures the compass is followed with the accuracy that high-performance sportbikes demand.

For readers who want a concrete reference point during the planning phase, see the dedicated model-year collection of the GSXR 600-750 fairings from a reputable supplier, which provides detailed product galleries and fitment notes that echo the diagram’s expectations. suzuki-gsxr-600-750-2006-2007.

Beyond the shop floor, the conversation about fairing diagrams and installation precision touches on how digital resources can support both the rider and the repair ecosystem. Digital fitment guides, CAD files, and installation photos offer a way to validate compatibility before purchase and reduce returns. For B2B buyers and repair shops, this practice translates into a workflow where the diagram’s integrity is verified against a virtual model before any physical parts are touched. Such validation is particularly valuable when dealing with model-year crossovers or subtle differences between generations, where slight geometry shifts can alter mounting point locations or edge alignments. It is a reminder that the diagram’s value multiplies when supported by reliable documentation and a disciplined approach to assembly.

In closing, the 2006 GSXR 600 fairing diagram stands as a reminder that performance is born from precision. The alignment of panels, the respect for tolerances, and the careful coordination of mounting points with the frame are not cosmetic luxuries; they are essential to achieving the designed aerodynamic performance, rider comfort, and long-term durability. The diagram encodes a promise: when the installation follows that map with care, the bike’s front end remains predictable at speed, the airflow remains coherent, and the rider retains a response that feels immediate and confident. The path from diagram to road is a straight line only when every point along the way is interpreted and executed with precision, and the fairing becomes not just a cover, but a carefully tuned component of the machine’s performance profile. For those who want to explore the practical implications further, the Alibaba supplier guide offers a pragmatic view of OEM-aligned fitment documentation and the realities of sourcing fairings that stay faithful to the diagram’s geometry. See the external reference for a deeper dive into supplier documentation and fitment verification: Alibaba OEM Fairings for 2006 Suzuki GSXR 600: Supplier Guide for B2B Buyers.

Shell of the Speed: Reading the 2006 Sportbike Fairing Diagram as a Window into Craft, Fit, and Performance

The fairing system on a late-model, mid-2000s sportbike is more than a shell of plastic and resin. It is a carefully engineered blend of aerodynamics, rider protection, weight management, and serviceability. When you set out to understand the fairing diagram for the 2006 era, you are not just tracing lines on a page; you are tracing a design philosophy that sought to balance high-speed stability with practical maintenance. The story embedded in the diagram begins with material choices and structural intent. The standard fairing for this generation was crafted from high‑strength ABS plastic, a choice that offered impact resistance and ease of manufacturing while keeping a manageable price point for replacement parts. In performance-focused builds, manufacturers and builders explored carbon fiber options to shave weight and increase stiffness in key load-bearing zones. Even though carbon fiber adds cost and complexity, its use highlights a central theme of the era: the desire to optimize aerodynamic efficiency without sacrificing serviceability. In a diagram that looks deceptively simple at first glance, you can see the tension between form and function as the panels line up with mounting points, cutouts for the instrument panel, and passages for wiring looms. The outer silhouette is not merely cosmetic; it is a carefully tuned surface that must harmonize with the frame, radiator, and front wheel travel to shape downforce, reduce drag, and guide airflow to where the engine and brakes need it most.

The diagram itself, in its exploded views and labeled subassemblies, speaks a language of names that become meaningful once you understand the assembly logic. The fairing is divided into outer panels, inner panels, windshields, rubbers, fasteners, and the brackets that connect them to the bike’s frame. In a typical exploded diagram, you will encounter references such as fairing outer panel left, fairing inner panel right, front cowl, lower belly pan, and sub‑assemblies that include mounting brackets and supplementary components. Each label corresponds to a part number listed in the official catalogs. Those numbers are not arbitrary annotations; they are the map by which a technician can source exact replacements and confirm compatibility with the specific model year. This is why the official service manual becomes an indispensable companion for anyone engaged in repairs or restorations. It bundles the fairing with the rest of the bodywork in an integrated set of drawings, photographs, and step‑by‑step procedures that illustrate how the pieces interlock, hinge, and seal against the wind while maintaining the integrity of electrical harnesses and instrumentation.

Accessing the most authoritative diagrams is a matter of following a disciplined path. The official service manual for this generation provides exploded diagrams that label each part by name, show the assembly relationship, and outline how fasteners, spacers, and grommets align with the mounting points on the frame. The clarity comes not only from the photographs or CAD drawings but from the way the pages group components by system. The fairing is presented in relation to the fuel tank, radiator shrouds, and the upper triple clamp area, so a reader can anticipate where a panel should sit in relation to air intake ducts and instrument cluster housings. This relational context matters because misalignment can ripple through the entire aerodynamics package, altering ram air paths and even the perceived helmet wind blast for the rider. The diagrams thus function as both repair guides and design checklists. They reveal whether a panel is meant to be a simple snap-fit, a clip‑and‑gasket joint, or a more involved bolt pattern anchored to a dedicated subframe component.

From the perspective of maintenance and restoration, the precise fit of OEM‑spec pieces is critical. The installation steps in the manual reflect a sequence that preserves gasket compression, ensures cable routing remains unobstructed, and prevents rubbing against the radiator or the tank. When you compare the official diagrams to real‑world replacements, you can appreciate why OEM‑spec parts matter. In that sense, the fairing diagram becomes a reliability document as much as a parts guide. Attempting to substitute non‑OEM panels or non‑standard fasteners can disturb line-of-sight geometry, introduce gaps, and degrade the bike’s aerodynamic profile. The chapter in the manual that covers fairing installation often unfolds in a careful, stepwise fashion: fit the inner panels first to establish anchor points, mount the fore and aft brackets in the correct sequence, attach the outer shells, then verify clearances around the fuel cap, the headlight, and the windscreen. The intent behind this methodical approach is to maintain the smooth surfaces that keep air flowing evenly across the bodywork, thereby preserving the bike’s intended balance of cooling and downforce at speed.

For those who wish to visualize the components beyond the textual descriptions, third‑party diagrams and catalogs can offer helpful complements. These sources typically group parts by system, presenting visual diagrams that show inner panels, windshields, front fairings, and related subassemblies. They are valuable for confirming compatibility when a replacement part is sourced from a catalog or marketplace. Yet, these supplementary diagrams must be used with caution. They often lack the precise assembly notes and the official part numbers that guarantee a true OEM fit. They provide a useful cross‑reference, a way to scan for a particular panel’s position on the schematic, but the final verification still rests on checking the part number against the year‑specific catalog in the official service manual. This is especially vital in a model year where minor facelift adjustments may alter the exact mounting holes or the contour of a panel, thereby influencing fitment with the surrounding components.

Beyond the manual and catalog diagrams, the broader ecosystem for fairing parts and diagrams emphasizes two complementary practices: verifying visual accuracy through official catalogs and validating mechanical compatibility through material and manufacturing quality indicators. A practical route for buyers seeking factory‑spec fairings in bulk is to consult supplier guides that discuss material authenticity and production tolerances. These guides highlight the importance of processes—whether dry or wet carbon fiber builds or traditional ABS molding—in how a panel will perform under race‑inspired stresses and over time. They also underscore quality assurance systems that track dimensions, resin content, and cure cycles. While these guides do not replace the exact exploded views found in the official manual, they provide a framework for assessing the reliability of aftermarket or bulk replacement sets. The overarching message is clear: to preserve the bike’s intended aerodynamics and the integrity of its cooling and electrical routing, you need not only the correct shape but the correct tolerances and finish.

For readers who are building or restoring a 2006‑era sportbike, the practical workflow emerges from combining these threads. Begin with the official service manual to internalize the exploded views, the part naming, and the exact assembly order. Use the parts diagrams found in official catalogs to confirm the precise panel identification and to verify part numbers before ordering. When you explore third‑party catalogs, use them as a cross‑check for visual confirmation, but always revert to the OEM references to avoid mismatches in fit and aerodynamics. If you are purchasing in bulk for a shop or a restoration project, the supplier guide section on material authenticity and production tolerances becomes essential, offering a set of criteria you can apply to multiple vendors. In the end, the fairing diagram is not a single image but a conversation among sources—the manual, the parts catalog, and the supplier documentation—that together ensures you maintain the bike’s designed balance of stability, cooling, and rider protection. The result is a frame of reference that supports precise, repeatable maintenance and thoughtful customization, whether one is aiming for a pristine showroom restoration or a performance‑oriented streetfighter that remains faithful to the original engineering intent.

To connect these ideas with practical steps you can take today, consider locating the official installation guidance and diagrams in the manufacturer’s documented service materials as your first priority. Then, supplement your understanding with the best available visual diagrams from reputable catalogs that categorize components by system. Finally, if you are purchasing replacement fairings in bulk, review supplier documentation that discusses materials, manufacturing tolerances, and quality controls to ensure the parts you choose will align with the OEM mounting geometry and aerodynamic targets. The diagram is a map; the panels are the terrain; and the rider’s experience is the destination. By reading the diagram with this mindset, you can approach restoration, customization, or routine maintenance with confidence.

Internal reference for an OEM‑aligned catalog visual—one widely used resource in this space is a dedicated parts collection that mirrors the original organization of fairing components. This collection provides a coherent index that helps pinpoint the front fairing, inner panels, and windscreen within a single, navigable view. For convenience, you can consult this catalog collection here: suzuki-gsxr-600-750-2006-2007. This link offers a practical visual cue to the component groupings you will encounter when cross‑referencing the official diagrams and part numbers. While it is not a substitute for the authoritative manual, it provides a useful visual crosswalk when planning parts replacements or evaluating non‑OEM alternatives. The combined approach—manual guidance, catalog illustrations, and careful supplier evaluation—creates a robust framework for understanding and working with the fairing system of this era.

External reference: for a broader, technical context on materials used in bodywork and the implications for performance and durability, see the general overview of composite materials and their applications in automotive and motorcycle components. https://en.wikipedia.org/wiki/Composite_material

Final thoughts

A comprehensive understanding of the 2006 GSXR 600 motorcycle fairing diagram is invaluable for business owners aiming to enhance their services. From grasping the structural intricacies to recognizing the significance of materials and design variants, these elements play a pivotal role in the maintenance and customization landscape. Moreover, ensuring precise installations can elevate customer satisfaction and improve repeat business. As we have explored the resources available for in-depth information, leveraging these insights can position your business advantageously in the competitive motorcycle market.