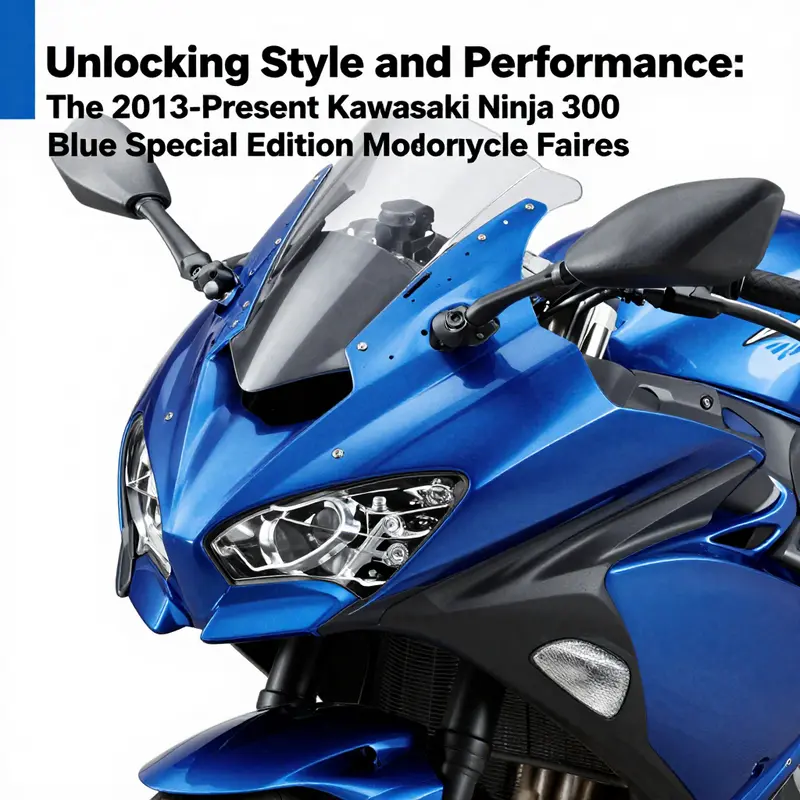

The 2013-Present Kawasaki Ninja 300 Blue Special Edition motorcycle not only captivates riders with its performance but also with its striking aesthetic. For business owners in the motorcycle accessory market, understanding the value and appeal of the aftermarket fairings designed for this model can significantly enhance product offerings. This article delves into various facets of these fairings, from quality materials to design features, aftermarket options, performance benefits, and key purchasing considerations, enabling you to make informed decisions that resonate with your clientele.

Blue Shark, Built to Last: The Quality, Materials, and Craft Behind the 2013–Present Kawasaki Ninja 300 Blue Special Edition Fairings

The Blue Special Edition fairings that cloak the 2013–present Ninja 300 are more than a color story. They embody a careful marriage of engineering plastics, precision manufacturing, and a design language that prioritizes both performance and personality. Riders seeking this look know that the appeal rests not only in the striking blue hue and the signature shark motif, but in a material and process philosophy that keeps the panels resilient through sunlit commutes, sudden rain, and the inevitable gravel strike of back-road riding. In that sense, the fairings serve as a practical argument for quality as much as they do for style. The material choice—an engineering plastic system that blends impact resistance with lightness—underpins every aspect of the fairing’s life on the bike. So much of what a fairing must endure happens out on the road: heat from the engine, vibration from aggressive corners, and the shifting temperatures of dawn to dusk. The design team’s decision to use a reinforced polycarbonate or ABS composite is a deliberate one, aimed at preserving the panel’s sharp lines while keeping weight on the bike to a minimum. Reinforcement methods and resin systems are chosen to maintain rigidity at key joints, where gaps must stay tight and fasteners do not loosen with time. ABS, with its well-documented resistance to cracking under impact and its resilience against UV exposure, remains a staple in fairing construction. When layered with the right additives and a controlled molding process, it yields panels that resist road rash without turning brittle in cold weather. The Blue Special Edition’s gloss is a function of not just paint but a multi-layer coating technique designed to endure years of exposure. The base color is matched to a standard that ensures consistency across parts produced in separate runs, a consideration that matters for owners who desire a seamless finish after a repaint or repair. The blue shark pattern—the iconic motif associated with this variant—is not merely printed on top. It is integrated through precision molding that defines the line work and edge detailing, so the pattern remains crisp even after exposure to stone chips, rain, and aggressive styling. The paint system itself is built to resist fading and chalking, with a clear coat that preserves depth and wet-look shine. This approach to color is essential for maintaining the visual identity of the edition, which is valued by enthusiasts who chase that factory look on their own bikes. In practical terms, the durability of the finish translates into lower maintenance costs and fewer touch-ups, which is especially important for riders who regularly ride in mixed climates or who rack up miles on weekends. The interplay between material choice and finishing technique also has aerodynamic consequences. While the primary goal of a fairing is to manage airflow and minimize drag, the geometry of the Ninja 300’s bodywork relies on panels that hold their form under wind pressure and heat. When the fairings keep their shape, the rider benefits from consistent handling characteristics and predictable protection for the engine and intake. The results are subtle but meaningful: stable ride feel, improved aero efficiency, and a visual coherence that reinforces the bike’s sporty identity. The official, factory-inspired approach to these parts is supported by sources that emphasize the importance of exact fitment and superior finish. Direct factory sales channels ensure that the parts align with the original specifications, preserving the smooth panel gaps and the precise mating surfaces that matter during assembly or replacement. The master painting process referenced in industry chatter speaks to a level of craftsmanship intended to guarantee a seamless color and sheen across all pieces. When a rider purchases these panels as a kit, the goal is a reliable, torque-ready, one-piece-like integration that doesn’t require fanatical fitment fiddling. The emphasis on OEM compatibility is not merely a buzzword; it’s a promise that the panel set will sit correctly on the frame and align with the mounting points, latching mechanisms, and radiator shrouds that define the fairing’s silhouette. For those who want to verify materials and manufacturing standards, the best course is to consult the official technical documentation or an authorized dealership network, where specifications about plastic grade, thickness, and cure cycles are documented and traceable. In the broader market, reputable distributors echo the same commitments: use of robust, impact-resistant plastics; finishes that resist weathering; and attention to details such as edge radii and fastener locations to ensure a factory-like fit. This approach means the Blue Special Edition’s aesthetic remains coherent through typical wear and tear, a small but meaningful advantage for riders who log long miles or subject their bikes to variable climates. The net effect is a fairing system that performs well as a protective skin and remains visually faithful to its original concept. It also underscores why many riders seek authentic OEM or OEM-quality options when replacing panels after a mishap or during a customization project. The synergy between bodywork materials and the bike’s core performance becomes an argument for reliability as much as for appearance. If a rider chooses a kit with genuine factory lineage and expertly applied color, the result is not a transient upgrade but a durable modification that ages with the bike rather than fading away. For those exploring paths toward authenticity, a targeted search for factory-grade options is worth the extra consideration, as it aligns with the original design philosophy and engineering intent. A reliable starting point for authentic options is a platform known to offer direct factory sales and master painting services, ensuring that fitment and finish meet exacting standards. Within the broader ecosystem of aftermarket fairings, the emphasis on material integrity and precision finish links back to the core purpose of the edition: to deliver a bold, recognizable look without compromising the bike’s integrity or performance. For riders who want to see how this philosophy translates into a finished product, an accessible gateway exists via the Kawasaki fairings hub, which aggregates options that maintain OEM-level quality while offering customization flexibility. Kawasaki fairings gives a sense of the scale of options available, including kits designed for the Ninja 300 family, where attention to fitment and color matching is a recurring theme. In the end, what makes the Blue Special Edition stand out is not only the shade of blue or the aggressive shark motif; it is the careful choice of materials and the discipline of finishing that preserve those attributes through the life of the bike. This combination of engineering plastics, precise molding, layered coatings, and verified fitment forms the backbone of a fairing system that looks like it came off the showroom floor even after years of road-time. The result is a product that respects the original design intent while offering real-world durability, ease of maintenance, and a timeless sense of performance. For enthusiasts who want to explore the materials and process details further, the go-to reference is a dedicated catalog page that documents the manufacturing philosophy behind these panels, reinforcing how quality, weight, and protection come together in a single, cohesive artifact of motorcycling culture. External reference: https://www.gomototrip.com/product/2013-kawasaki-ninja-300-special-edition-fairing/.

Blue Shark Lines: The Design and Engineering of the 2013–Present Ninja 300 Blue Special Edition Fairings

The color story and the geometry of a sport bike are inseparable, and nowhere is that fusion more evident than in the 2013–present blue edition that marks a distinctive chapter for the model. The vibrant blue, punctuated by a bold shark motif that slashes across the fairing panels, announces intent before the rider even twists the throttle. This edition didn’t rely on color alone; it built a cohesive visual language that complements the bike’s performance characteristics. The fairing kit, arranged as a cohesive 17-piece assembly, wraps the machine from nose to tail, shaping not only its silhouette but also the way air moves around it. In this sense, the blue edition serves as a case study in how color, contour, and engineering meet to produce a visually striking yet aerodynamically honed sport appliance. The result is a motorcycle that looks as fast standing still as it feels at speed, a harmony of paint and form that speaks to a rider’s instinct for precision and control.

The design language of the kit leans on sharp lines and abrupt angles that follow the bike’s natural creases, creating a continuous flow from the front of the nose to the tail. The blue shark motif is more than a decorative flourish; it traces the body in a way that enhances perceived speed and guides the eye along the machine’s profile. As a full-body coverage set, the fairings are shaped to minimize unnecessary gaps while preserving access to critical points for maintenance and inspection. The result is a composite surface that feels part of the vehicle’s original architecture, not merely an external wrapper. When a rider sits aboard, the panels align with the rider’s line of sight and the bike’s stance, reinforcing a sense of cohesion between human and machine. This approach reflects Kawasaki’s broader commitment to craftsmanship—where visual drama, aerodynamics, and rider ergonomics are interwoven rather than treated as separate concerns.

From a materials and manufacturing perspective, the fairings are crafted in high-quality ABS plastic. This choice offers a practical balance between elasticity, impact resistance, and heat tolerance—an essential combination for high-speed riding and variable weather exposure. ABS provides enough flexibility to absorb minor shocks without cracking, yet remains stiff enough to hold the crisp lines that define the bike’s aggressive look. The panels are engineered for precise OEM fitment, ensuring that each piece aligns with mounting points, brackets, and ducting so well that the installation feels like an original equipment swap rather than a retrofit. This precision is not incidental; it is built into the design process to maintain the bike’s intended cooling paths, air channels, and vent geometry which, in turn, support rider comfort by managing heat in the cockpit at speed.

Finish quality is a core part of what makes the blue edition feel special. The factory-direct approach, often facilitated by authorized retailers who provide master painting services, aims for a flawless, factory-like finish that matches the original color and gloss across every panel. The painting process is not just about color replication; it also involves careful masking, consistent pigment consistency, and layered clear coats that resist UV fading and micro-scratches. The aesthetic payoff is immediate: a seamless, showroom-like surface that speaks to authenticity when viewed up close and a durable barrier against the elements when the bike is ridden and parked in a range of climates. The combination of material resilience and meticulous finish work ensures that the blue shark pattern remains sharp and legible, even after miles of highway and exposure to sun, rain, and wind.

The practical benefits of the 17-piece design extend beyond appearance. A full-body fairing kit influences aerodynamics by smoothing entry and exit planes, reducing turbulent wake behind the rider, and guiding airflow toward cooling ducts and the engine bay without creating intrusive drag. The result is a package that supports stable airflow at speed while preserving rider comfort, particularly on longer sessions where heat management and wind buffeting can affect focus and stamina. In this sense, the blue edition is not cosmetic theater; it embodies an integrated approach where aesthetic decisions are aligned with performance needs. The fairings’ geometry also plays with the perception of mass and speed, giving the impression of a leaner, more aggressively sculpted motorcycle even when it sits at rest.

For buyers and builders who seek authenticity, the market offers both OEM-quality and aftermarket variants, with the latter often positioned as faithful reproductions or with bespoke finishes. The emphasis remains on verified compatibility and material standards so that the upgrade respects the bike’s original engineering philosophy. In practice, this means choosing parts that align with the model year and variant, ensuring proper seam alignment, clearance between panels, and uninterrupted access to serviceable components. When authenticity is prioritized, the fitment feels deliberate, and the result is a coherent, clockwork-like assembly that does not scream “aftermarket” but rather reads as a sanctioned enhancement. A robust distributor network and factory-direct sales models further support this goal by offering panels that have already passed fit checks and color-matching audits before they reach the customer.

For those exploring the aftermarket ecosystem, references to reliable retailers and compatibility guides are essential. Some buyers use platforms that offer compatibility filters to verify fitment for the 2013–2017 EX300B and related variants, reducing the risk of misfit and miscolor. In the search for authenticity, it helps to look for suppliers that provide detailed specifications, mounting diagrams, and documented color-match processes. When the goal is a faithful restoration or a visually identical upgrade, these checks matter as much as the beauty of the finish. Within the broader community of fairing enthusiasts, it is common to contrast the OEM-like finishes with aftermarket options that may offer alternative gloss levels or different injection-mold finishes, reminding us that the journey to a personal aesthetic is as much about the process of selection as the end result. To broaden the scope beyond a single aesthetic choice, it can be informative to browse the Kawasaki fairings collection, which aggregates compatible options and related components in a structured way: Kawasaki fairings.

Those who want to examine exact replacements or upgrades often discover that a balance between fidelity and customization exists. The core aim remains a seamless pairing with the bike’s frame and mechanical interfaces, preserving the intended airflow patterns and the rider’s sense of control. The Blue Special Edition’s fairings, with their 17-piece composition and a bold blue shark graphic, illustrate how a color case study can become an integration test for form, function, and finish. When one considers the broader discourse on fairing design, the Ninja 300 blue edition stands as a reminder that performance and aesthetics are not separate disciplines but a shared language spoken by engineers and painters alike. It is this language—the careful alignment of lines, the disciplined choice of material, the fidelity of color, and the confidence of fit—that underpins a fairing kit’s enduring value on the road and in the garage.

External resource: Understanding Fairing Kawasaki Ninja Blue: Composition, Standards, and Applications (https://www.oscarbennett.com/kawasaki-ninja-blue-fairing-composition-standards-applications)

Shaping Speed: Aftermarket Fairings for the 2013–Present Blue Edition of the Ninja 300

The allure of the blue edition quickest to catch the eye is not just its color; it is the way a rider can transform stance, wind management, and personal expression with a carefully chosen set of aftermarket fairings. For a mid-displacement sport bike that arrived in the early 2010s, the blue edition carved out a distinct visual identity and a practical edge. The aftermarket world responds in kind, offering full fairings, partial fairings, and paint-ready shells that let riders tailor the bike’s silhouette to their riding goals. Whether a rider seeks maximum wind protection for highway runs, a tighter, more aggressive profile for canyon routes, or a bold aesthetic that echoes the bike’s iconic hue, the fairing market presents a spectrum of choices designed to bolt onto the bike’s existing mounting points with minimal fuss—and, ideally, with finish and durability that approach factory standards.

Material choice sits at the heart of this equation. The most common offering is a high-quality ABS plastic, valued for its balance of toughness, elasticity, and heat resistance. ABS panels resist cracking under the punishing conditions a sport machine endures on warm days, after rides through sun and rain, and during the occasional tip-in to a windy highway. The plastic’s ability to hold sharp lines matters, too; the blue edition’s distinctive angles and creases get their definition from panels that keep their shape even after countless heat cycles from the engine bay and exhaust proximity. A well-made ABS kit will also exhibit edge finishing that reduces snag points on entry and exit from corners, helping both wind management and rider confidence at speed.

Design language matters as much as material. Full fairings, which enclose the majority of the bike’s profile, deliver the most noticeable aerodynamic gains. They smooth the air over the engine and rider, disciplinely guiding flow around the sides and underbody, which can translate to more stable handling at higher speeds and improved wind protection for the rider. Half fairings, by contrast, offer a compromise: they emphasize the bike’s lines and color while leaving some mechanical surfaces visible for maintenance access and a lighter feel. A custom paint job can elevate either option, harmonizing the blue palette with the rider’s preferred hue or adding subtle metallic flecks and gloss levels that imitate or surpass factory finishes. The eye is drawn to the way color meets contour—how the blue shade accents the sharp creases and the bike’s overall stance, almost as if the color and geometry are locked in a single, high-velocity pose.

Choosing the right kit also involves a practical understanding of fitment. For the model in question, aftermarket kits are typically designed to bolt onto the existing mounting points with OEM-style fitment guarantees. This is a relief to riders who want to avoid excessive modification or the risk of misalignment that can come with unverified parts. The reality, however, is that even well-engineered kits may require some basic preparation before installation: a careful inventory of mounting hardware, a quick check of fastener lengths, and perhaps a touch of alignment during the first tighten. A properly designed kit will use the original frame points, radiator shrouds, fender attachments, and instrument cluster proximity to maintain the bike’s original geometry while delivering a refreshed front and side profile. For a rider chasing that classic blue Special Edition look, color-matched finishes with precise gaps around the windscreen and fairing edges ensure the overall effect reads as a cohesive whole rather than a patchwork overlay.

From a value perspective, the aftermarket spectrum offers its own hierarchy. Genuine-feel finishes that approximate OEM color depth, matched seams, and engineered edge radii tend to be priced higher than basic, no-frills shells. Yet even budget-conscious panels can deliver meaningful gains in appearance and protection. The critical lens here is not just color or gloss, but surface integrity: a panel surface that remains smooth after repeated wipe-downs with a mild cleaner, that resists chalking under sun exposure, and that maintains color stability against UV light. A well-done paint process, whether factory-like or factory-direct, supports long-term aesthetics and minimizes the need for frequent touch-ups. In practice, riders often find the most satisfying outcomes come from combinations that pair a sturdy shell with a high-quality finish, where the color depth echoes the blue’s intensity and the clear coat provides a robust, glassy surface that resists micro-scratches.

The purchasing landscape for these parts is layered. Some buyers lean toward factory-direct or OEM-feel options that emphasize compatibility and seamless color matching. Others explore aftermarket suppliers that promise a balance between affordability and performance, with finishes that can rival the look of the original paintwork. Regardless of price tier, discerning buyers prioritize verified compatibility, high-grade materials, and a finish that remains faithful to the bike’s color and lines after installation. A trusted path for many riders is to compare kits against the bike’s original geometry, verify mounting points, and assess whether the kit includes all necessary gaskets, fasteners, and instructions. The result is a clean aesthetic upgrade that respects the bike’s engineering while letting the rider push the look a step further.

Riders who are eyeing customization should also consider how the fairings integrate with other upgrades. A windscreen with a slightly taller profile, for example, can complement the new panels by altering the wind arc that meets the rider’s helmet. A lower or higher line on the fairing’s edge can also influence the perceived speed and aggression of the bike’s silhouette. It is not unusual for a like-new paint job to reveal small differences in panel gaps once installed, underscoring the value of thoughtful mounting and, if needed, air-damming or weather-stripping additions that improve sealing against rain and dust. The goal is a cohesive, streamlined presentation where the blue tone reads consistently from every angle, and the fairings’ transitions with the rest of the bike are visually continuous rather than abrupt.

For riders who want to dip their toes into the aftermarket world without committing to a full repaint or a complete shell, the option of starting with a single panel or a limited set of pieces can be appealing. This approach keeps the budget contained while allowing the rider to assess fit, paint quality, and color fidelity before expanding to a broader kit. It also lets enthusiasts preserve the bike’s original ergonomics and weight distribution while enjoying a refreshed appearance. If the objective is to honor the bike’s iconic color while still pursuing a modern, aggressive aesthetic, a staged upgrade can provide the best of both worlds: striking visual drama and confidence-inspiring ride quality.

To help readers navigate toward practical choices, consider the starting point of a centralized reference point for compatibility and color matching. The Kawasaki fairings collection on a reputable distributor’s site serves as a baseline for OEM-style options and ensures that the mounting points align with the bike’s original design. For those inclined to explore beyond the basic shell, a direct comparison of finish quality, thickness, and edge precision can reveal how close a kit comes to factory standards. An important detail is the existence of variants that offer both OEM-quality finishes and more affordable aftermarket options, with the trade-off typically affecting fit tolerance and long-term surface resilience. In this sense, the decision becomes not just about price, but about long-term appearance and the bike’s ability to hold up under regular riding conditions.

Riders who tip into the details often discover that a well-chosen set of fairings does more than alter color and shape. It refines wind handling, helps manage heat in the upper body region, and creates the impression of a more aggressive stance even when the bike is at rest. The blue edition’s identity is preserved through careful color matching, edge treatment, and gloss levels, while the rider enjoys the practical benefits of improved aerodynamics and a tightened silhouette. In the end, the right choice depends on how the rider rides, where they ride, and how deeply they want to customize the appearance without compromising core performance.

For readers seeking a direct route to compatible options from a trusted source, you can explore the Kawasaki fairings collection. This entry point provides a baseline for OEM-like fitment and color fidelity while offering pathways to more elaborate styling packages if desired. In all cases, the objective remains consistent: a cohesive, durable, and visually striking upgrade that respects the bike’s original engineering while enabling personal expression on the road.

External reference: For official parts and accessories, visit the Kawasaki Parts & Accessories page: https://www.kawasaki.com/PartsAndAccessories

Blue Armor, Balanced Pulse: Understanding the Subtle Performance and Aesthetic Benefits of Upgrading Fairings on the 2013–Present Ninja 300

The allure of upgrading fairings on a lightweight sport bike—especially a blue-toned edition that marks a distinctive lineage—runs deeper than a fresh coat of color. For riders who cherish the Ninja 300’s nimble handling and approachable power, the fairings serve a dual role: they shape the machine’s silhouette and shield its innards, while subtly shaping the rider’s perception of performance itself. In the world of the 2013–present Ninja 300, the fairing shell is more than a cosmetic shell; it is an integrated system that influences how heat, airflow, and rider comfort interact with the bike’s chassis. When the blue-toned bodywork is replaced or refreshed with a design that preserves fit and finish, the bike retains its factory balance while gaining a refreshed demeanor that can lift confidence on winding roads and during weekend sessions at the track or on backroads byways. This is where aesthetics and function perform a careful dance, and where the true value of a fairing upgrade begins to reveal itself—not as a horsepower delta, but as a measured enhancement to the rider experience.

From the outset, the most tangible benefit of upgrading is visual: a refreshed colorway or sharper lines that hark back to the bike’s sportbike heritage while signaling a personal touch. The blue colorway, in particular, has a vitality that can change how a rider perceives the bike’s stance in the mirror and how teammates or passing riders perceive the rider’s commitment to sport riding. But the eye is only part of the story. A well-made set of fairings typically uses high-quality ABS plastic with heat-tolerant and impact-resistant properties. This material choice matters when the sun climbs or when the radiator breathes hard on a hot day; the improved heat shielding and robust outer shell reduce the likelihood of cracking or warping under sun exposure and road debris. While the rigid panel doesn’t magically shave seconds from a lap time, it contributes to a more consistent ride by preserving the bike’s geometry and reducing flex, which can translate into steadier feedback through the handlebars and better control on imperfect pavement.

Aerodynamics is another facet worth considering, though it’s important to keep expectations aligned with the bike’s class. For a light sport model like the Ninja 300, aftermarket fairings can offer minor improvements to airflow around the radiator and to the rider’s chest and thighs, but these gains tend to be incremental rather than transformational. The core of the machine’s performance—torque across the midrange, throttle response, gearing, and suspension setup—remains the dominant driver of how the bike actually accelerates and navigates corners. The fairings’ role, then, is more about streamlining the overall package and smoothing the ride than about delivering a race-ready aerodynamic advantage. In practice, a well-fitted fairing set can minimize vibration-induced looseness at certain speeds and reduce the air pressure pushing against the rider’s chest, which, in turn, can influence rider fatigue over longer sessions. These are subtle benefits, but for riders spending hours in the saddle, they matter more than would be obvious at a casual glance.

Within the frame of material quality, the choice of ABS with heat-shielding properties is a cornerstone. ABS holds up better to road debris and temperature swings than some cheaper polymers, preserving color and gloss longer and resisting micro-cracking that can trap moisture and mud under the paint layer. Durable shells also resist the onslaught of road spray and gravel—a practical advantage for riders who commute through mixed weather or who ride in climates where temperature and grit collide at the end of a long highway roadhouse run. The knock-on effect is that the bike’s exterior stays looking sharp, and a rider who values a clean aesthetic gains confidence that the machine’s appearance reflects the care given to its mechanical health. In practical terms, this means fewer unsightly chips that could lead to deeper fatigue cracks and, eventually, more involved repairs.

Fitment is the other side of the coin. The 2013–2017 EX300B variants, and their blue-tinted siblings, were designed with an emphasis on precise alignment and clean stacking of the panels. A direct-fit, OEM-like interface means fast installation and predictable gaps along the seams. Reliability in fit translates to fewer rattles along long rides and less air intrusion into the cockpit around the steering head at high speeds. For riders, this translates into a more composed feel; the bike does not exhibit the kind of flutter or flex that can be unsettling on fast corners or rough pavement. An added benefit of proper fitment is that the fairings do not introduce scrapes or rubbing that could prematurely degrade the paint or the mounting points during a lean. When a kit offers a master-painted finish and a seamless color match to the factory blue, the result is a cleaner, more integrated package that preserves the bike’s original lines while letting the rider wear a personal interpretation of its look.

Beyond bodywork equals confidence, the decision to pursue a blue-themed upgrade often intersects with the rider’s broader goals. Those who value the aesthetic payoff of color and line work will notice how the updated panels communicate a sense of readiness and care. The psychological aspect—seeing a bike that looks tuned and cared for—can influence riding style in a positive, non-structural way. The rider may ride with a bit more purpose, a touch more precision, and a greater awareness of every line of the machine’s silhouette. The net effect is a bike that feels prepared for the road ahead, not because the engine is suddenly stronger, but because the rider perceives a refined, coherent package that reflects attention to detail.

For riders who crave a clearer path to performance gains, it is essential to understand that fairing upgrades alone do not unlock dramatic horsepower or acceleration. If a rider’s aim is to enhance overall performance, the path typically leads beyond the shell. Engine mapping devices and ECU tuning tools can extract more from the existing powerplant by optimizing fuel delivery and ignition timing for a given exhaust configuration and riding altitude. Such adjustments interact with the engine’s software rather than the bodywork, and they depend on a holistic approach to the bike’s tuning. In this sense, the fairing upgrade acts as a catalyst for a broader upgrade plan: it lets the rider realize the full day-to-day usability of performance-centric changes without compromising the bike’s ride on public roads. The conclusion of this line of thinking is practical: embrace aesthetic upgrades for confidence and longevity, and pursue engine and electronics enhancements as a separate, targeted pathway if the goal is measurable performance on a track or a competitive venue.

For riders in search of credible, compatible options that respect the bike’s original intent, the emphasis should be on components that guarantee a proper fit and durable construction. A modern fairing kit that aligns with the bike’s geometry, uses heat-resistant materials, and finishes with a uniform color and gloss will deliver the most satisfying return on investment. When the goal is to mirror a distinctive blue edition while preserving the bike’s original soul, the critical factors are fit, finish, and material quality. Access to a range of OEM-like variants and aftermarket equivalents offers the flexibility to tailor the level of color saturation and gloss, while maintaining a coherent overall appearance with the rest of the bike’s components. The decision should be guided by a balance of aesthetic desire and the practical realities of fitment, protection, and long-term durability. As the ride continues, the fairing set serves as a steadying influence on the bike’s personality, harmonizing the machine’s lines with the rider’s ambitions.

To connect this discussion with hands-on possibilities, riders can explore the broader catalog of Kawasaki fairings to find a collection that emphasizes compatibility and finish. For those who want a direct path to a cohesive styling, a visit to the Kawasaki fairings collection can be a good starting point. Kawasaki fairings collection.

External reference: https://www.gomototrip.com/products/2013-ninja-300-special-edition-fairing

null

null

Final thoughts

The 2013-present Kawasaki Ninja 300 Blue Special Edition motorcycle fairings represent a blend of style, quality, and enhanced performance. As a business owner, understanding the distinct characteristics of these fairings can empower you to cater effectively to the needs of motorcycle enthusiasts. By emphasizing quality materials, unique design features, and the advantages they bring, you position your offerings as not only accessories but essential upgrades for riders seeking to enhance their motorcycles. Embracing these insights allows you to attract a dedicated customer base eager to invest in high-quality aftermarket solutions.