The 2013 Suzuki Boulevard C90T stands out as a formidable presence in the motorcycle world, combining power, style, and comfort. As motorcycle enthusiasts seek to personalize and enhance their rides, aftermarket batwing fairings become a focal point for customization. This article delves into the various aftermarket options available for the C90T, providing business owners in the motorcycle accessories market with insights into material quality, design, installation compatibility, and evolving market trends. By understanding these aspects, businesses can better cater to their customers’ needs and stay competitive in the thriving motorcycle industry.

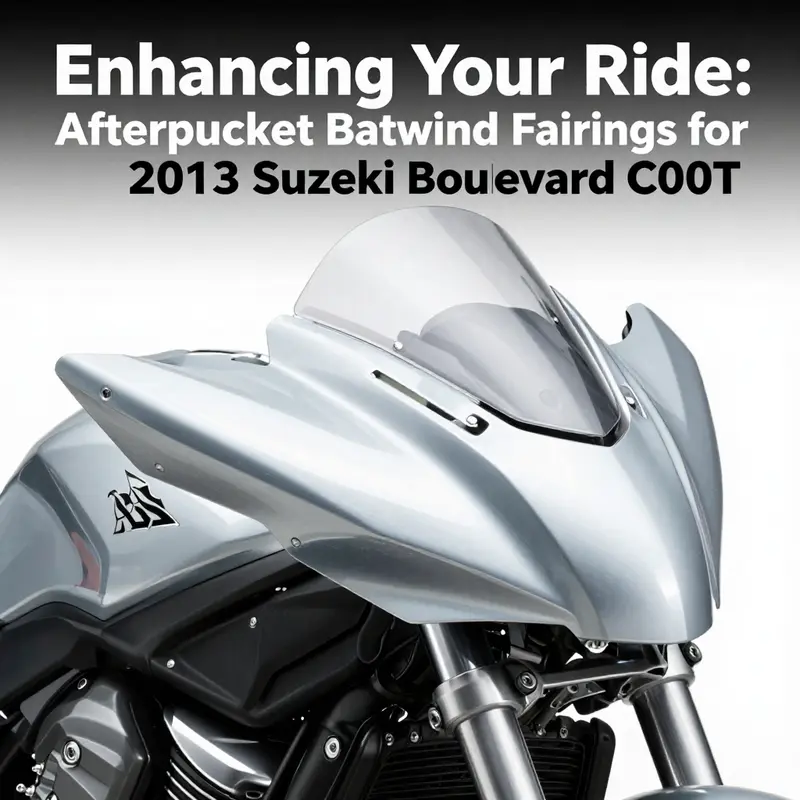

Riding Wind and Style: Aftermarket Batwing Fairings for the 2013 Suzuki Boulevard C90T

The street is a windward plane for the Boulevard C90T, and the rhythm of a long-distance ride is as much about how air behaves around the rider as it is about the engine’s torque. For riders who seek a blend of rugged looks, improved comfort, and a clean, integrated cockpit, aftermarket batwing fairings offer a compelling pathway. On the 2013 Suzuki Boulevard C90T, a model produced through the late 2010s, these fairings are not mere cosmetic add-ons. They redefine the bike’s silhouette, alter wind flow, and provide a canvas to modernize the interior with better technology and refined styling. The charm lies in how a well-designed fairing can harmonize with the bike’s existing lines while delivering tangible benefits to rider fatigue, stability at highway speeds, and even sound quality in daily commutes or weekend tours. The result is a motorcycle that feels simultaneously more weatherproof and more personal, a machine that carries the rider’s intent as visibly as it carries their luggage.

Material choice matters as much as the visual outcome. Most aftermarket batwing fairings for the Boulevard C90T are built from ABS plastic, a material known for its balance of rigidity and impact resistance. ABS lends itself to smooth, paintable surfaces, which is important because the fairing must meet the rest of the bike’s finish and the rider’s color preference. A robust ABS shell can withstand road debris and seasonal weather tests while remaining relatively light. The weight is a practical consideration; a well-designed fairing adds bulk but keeps the rider’s center of gravity consistent with the stock arrangement. This is not about adding unnecessary heft, but about introducing a panel system that can be anchored securely to the bike’s foundational mounting points and, when necessary, disassembled with minimal fuss for maintenance. When you consider long trips, this kind of design matters because it influences how the bike behaves at speed and how easy it is to service after a season on rough roads.

Aesthetics and customization sit side by side with fit and function. Batwing fairings come in a spectrum of finishes, from glossy black to matte and even custom color matches. The gloss finish often emphasizes the fairing’s contours and reflects light in a way that accents the bike’s chrome or aluminum accents. Matte finishes tend to hide minor imperfections, offering a different mood—more understated, more aggressive, depending on the surrounding paintwork. For riders who want a highly personal look, the option to prepaint or to work with a painter to achieve a matching color code is appealing. The goal is a seamless integration where the new fairing looks like an extended part of the Boulevard rather than an aftermarket addition. The result should be a balanced proportion where the fairing’s width, height, and curvature complement the C90T’s proportion, rather than appearing as a separate add-on that fights with the bike’s lines.

Functionality is the other half of the equation. The batwing fairing is designed to redirect air away from the rider’s torso and shoulders, reducing buffeting and fatigue on long rides. The geometry of the fairing—its height, sweep, and the shape of the chin or lower edge—plays a crucial role in wind management. A well-tuned fairing lowers drag and can stabilize the ride by smoothing the airstream around the rider and, to some extent, the passenger. Riders frequently report that a fairing with carefully tuned air channels communicates a calmer sense of velocity, even when the speedometer climbs. And because the C90T is an upright, comfortable tourer by design, the fairing should preserve the bike’s approachable seating position while subtly improving highway manners. Beyond wind management, the fairing can also serve as a host for added conveniences. The interior becomes a space where gauges and controls can be more accessible, and the cockpit can be anchored with additional mounting options for devices or accessories. The key is that the fairing system integrates without forcing a reimagining of the rider’s natural posture.

Compatibility is a practical concern that deserves careful attention. These batwing assemblies are marketed as fitting the Boulevard C90T from 2013 through 2019, a broad window that encompasses minor changes and several mid-cycle updates. A proper fit means precise alignment with the bike’s mounting rails, nose brackets, and the fairing’s fastener locations. It also means that the installation should not interfere with the headlight, instrument cluster, or turn signal assemblies. The right kit will include a bracketry set, gaskets, and hardware that allows the fairing to sit flush against the fairing mount points without gaps that could collect moisture or vibrate loose over time. Regardless of the kit, the rider should expect to perform a careful check of alignment after a first ride to ensure there are no rubbing points at full steering lock or in the area of the forks and nacelle. That process often takes a little time, but it pays dividends in ride quality and long-term durability.

What about the electronics and interior cockpit? A notable feature in many aftermarket batwings is the accommodation they offer for audio or navigation integration. Some kits provide mounting provisions for a multimedia or audio head unit with a screen of a certain size. In the context of the Boulevard C90T, the designed space is often intended for a seven-inch double-DIN radio setup. It’s important to emphasize that while the mounting space is provided, the radio itself is not included. This means riders can select a head unit that fits their desired feature set—be it Bluetooth connectivity, touchscreen navigation, or enhanced audio processing—and pair it with the fairing’s internal space in a way that feels integrated rather than tacked on. The inclusion of 6×9 inch speaker cutouts inside the fairing is another common attribute, offering a straightforward route to updated audio without modifying the bike’s fairing structure or the engine’s acoustic ambiance. The result is a cockpit that feels like a modern touring arrangement rather than a retro profile with an awkward, aftermarket audio solution.

The installation experience itself is a defining part of the aftermarket journey. For many riders, the process is a weekend project rather than a rushed afternoon task. The sequence begins with a careful assessment of the bike’s current hardware, followed by the gathering of the right tools and a methodical approach to loosening and re-tightening fasteners. It’s common to work with a light hand, using thread-sealant or wax on metal-to-metal joints, and to verify the seal between the fairing and the gas tank or the dash area. A well-prepared kit often includes detailed instructions and mounting templates that make it easier to locate each hole and bracket. The rider benefits from a logical plan: start with the primary mounting rails, verify headlight clearance, then align the fairing with respect to the instrument cluster and the handlebars. A final step involves test-fitting, running the bike at low speeds to feel for any plate or edge contact, and then performing a careful road test. The overall experience should feel smooth and deliberate, with minimal roughness or vibration transmitted through the fairing panels. If anything feels off, revisiting the alignment and tightening sequence is a prudent move.

Alongside practicality, the social and aesthetic appeal of a well-executed batwing bat wing project should not be underestimated. The Boulevard C90T gains a distinct personality when the fairing’s lines echo other chrome and painted surfaces on the bike. A faithful color match, combined with careful attention to seams and gaps, makes the transformation feel intentional rather than opportunistic. Riders who chase a “factory-inspired” look often find that a high-quality aftermarket fairing can achieve this without resorting to drastic modification. The result is a motorcycle that looks like it grew into a more complete touring stance rather than a factory customization that arrived late to the party. For those who value a curated, cohesive effect, the batwing becomes a design language—an expression of a rider’s taste that still honors the Boulevard’s original virtues of balance, comfort, and momentum.

Availability is another practical piece of the puzzle. These aftermarket fairing systems are widely offered by various retailers and marketplaces. The common thread across vendors is an emphasis on fitment accuracy, installation support, and a guarantee of compatibility with the 2013–2019 Boulevard C90T lineup. When shopping, riders should carefully verify that the kit is specified for the exact model and year range, as even small differences in mounting points or gauge clearance can lead to misalignment and frustration. Reading customer reviews becomes an invaluable step in this process, helping to surface real-world fit and finish experiences that go beyond product descriptions. A thoughtful buyer will also assess whether the kit includes all the required hardware and whether it provides adequate weather sealing to keep moisture from creeping into the cockpit or the radio bay. The goal is a finish that integrates both visually and functionally, with reliable long-term performance.

From a maintenance perspective, the batwing fairing is not a one-off install. It becomes part of the bike’s daily routine. The user should plan for periodic checks of mounting hardware, especially following vibrations from rough roads or temperature-driven contractions and expansions that can loosen fasteners over time. It’s wise to inspect seals around the edges to ensure that the windjammer remains weatherproof, particularly if the bike is ridden through rain or winter conditions. This mindful approach to upkeep helps preserve the fairness of the bike’s lines and ensures that the integrated multimedia system, when installed, remains stable and accessible. The rider’s experience, ultimately, hinges on the fairing’s ability to combine form with function in a way that serves the ride rather than complicates it. When this balance is achieved, the Boulevard C90T feels not just upgraded, but reimagined for modern touring—an enduring companion for highways and backroads alike.

For readers exploring options, one practical route is to browse curated listings that emphasize fitment for this exact model. A targeted search can yield a range of batwing fairing setups, each with its own nuances in accessory compatibility and finish choices. A confident buyer will cross-check dimensions, mounting hardware, and the availability of any required brackets. In the end, the choice should feel like a continuation of the Boulevard’s original spirit, now enabled by a streamlined, integrated enclosure that respects the rider’s comfort, the passenger’s experience, and the machine’s enduring silhouette. If you want to explore a broader range of Suzuki-specific options, you can visit the Suzuki fairings collection for a sense of how this family of components is treated across models and years, which helps to ground expectations for fit and style while preserving the bike’s discerning identity. This approach keeps the focus on a coherent customization path rather than a series of one-off experiments.

As a final note, the practical path toward a satisfying batwing upgrade rests on thoughtful evaluation, precise fitment, and careful installation. The Boulevard C90T rewards riders who approach the project with a clear plan, a respect for the bike’s original geometry, and a willingness to invest time in achieving a clean, integrated result. The payoff is not merely aesthetic; it is a more comfortable, confident ride that stands up to the demands of long days on the road and the unpredictability of weather. For many riders, that balance of wind protection, cockpit modernization, and personal expression makes the batwing upgrade a defining moment in the lifecycle of their Boulevard.

Internal resource for further exploration: for a curated selection of Suzuki fairings and related components, see the Suzuki fairings collection. This link offers a sense of how different designs harmonize with the Boulevard’s proportions and with riders’ preferences for color and finish. Suzuki fairings collection.

External resource:

- eBay listing overview for batwing-style fairings and related bodywork for the 2013 Suzuki Boulevard, useful for understanding current usage patterns, general fitment notes, and real-world installation considerations: https://www.ebay.com/b/Fairings-Bodywork-for-2013-Suzuki-Boulevard/186495/bn_1438526

Engineered for Cruising: Material Quality and Design of 2013 Suzuki Boulevard C90T Batwing Fairings

The batwing style fairing that wraps the front end of a modern cruiser is more than a stylistic flourish. It is a carefully engineered shield that balances aerodynamics, rider comfort, and the stubborn realities of road exposure. For the 2013 era of a midweight boulevard cruiser, the aftermarket batwing fairings that enthusiasts install are a study in how material choice and architectural design intersect to deliver a better ride without sacrificing the bike’s iconic silhouette. This chapter follows the thread from raw material selection through finished form, showing how makers translate a rider’s needs into a component that feels almost native to the machine when properly installed. The result is a tangible blend of durability, weather resilience, and visual cohesion with the line’s classic look, rather than a jarring afterthought tacked onto the front end.

Material quality begins with the outer shell. The most prevalent choice is a high grade ABS plastic, a material valued for its impact resistance and its ability to shrug off weathering without cracking or crazing. ABS provides a sturdy base that resists the kind of subtle scuffs and impact exposures that bikes routinely encounter, from gravel kicked up by trucks to incidental bumps in a garage. The weather resistance of ABS is not just about remaining intact; it also means colors stay truer longer under sun and rain, reducing the chance that the fairing looks aged after a season on the road. The reliability of the ABS curve is enhanced when the design integrates reinforcement layers. In many options, fiberglass is used in combination with the plastic to create a composite that increases rigidity. That extra stiffness matters when the fairing is exposed to wind pressures at highway speeds and when the headset and instrument panel are subjected to vibrations. The fiberglass layer is not so much about bulk as it is about damping and structural integrity. The result is a shell that resists deformation, holds its profile, and dampens some of the vibration that otherwise travels through the fork crown and the handlebars.

This layering also has practical implications for ride quality. A stiffer shell can support better alignment with the bike’s contour, which reduces creaking or flexing noises that riders typically notice after miles of rough pavement. The dampening effect, even if modest, contributes to a calmer cockpit. It translates into an impression of solidity while you’re in the saddle, especially on long, straight stretches where wind is a steady companion. The pursuit of this balance—lightweight enough to avoid adding unnecessary unsprung mass, yet rigid enough to maintain its shape at speed—drives the choice of materials and the way they are fused together during fabrication. In the realm of aftermarket parts, that blend is often described as a composite approach: ABS as the primary body, fiberglass as a secondary structure that boosts rigidity and insulates against low-frequency resonance. It is a practical compromise, one that respects both the rider’s wallet and the road’s demands.

Finish options are not mere cosmetics. They are a statement of how seamlessly the accessory integrates with the bike’s existing color language and chrome accents. Higher end fairings frequently arrive pre-finished in a color that matches the cruiser’s original palette, sometimes described as painted versions, sometimes as painted black or another deep tone that harmonizes with the frame and fenders. Pre-painting reduces the time and effort required to deliver a visual match, but it also means the finish has to be durable enough to withstand road grit and UV exposure without fading in a season or two. The premium finish is often more than a gloss; it can include a factory-like sheen that mirrors the motorcycle’s own paint depth, which matters for a product that’s meant to sit close to the rider’s line of sight and to be observed from the curb. In a broader sense, the finish is a visual extension of the fairing’s functional traits: color stability, resistance to chipping, and a surface that cleans easily after a ride through bug splatter and rain-dusted spray.

Design philosophy travels beyond the shell and into the geometry of fitment. These batwing fairings are tailored to the silhouette of the cruiser in the model year window spanning roughly 2013 to 2019, which means curves flow into the tank, the forks, and the headlight assembly with a sense of continuity rather than a separate add-on. A well-designed fairing follows the machine’s lines rather than fighting them. The curve around the headlamp, the sweep of the lower edge, and the way the fairing meets the handlebars all contribute to an integrated stance. Aerodynamics are part of the equation, but the objective is not to turn the bike into a wind tunnel subject; instead, the aim is to smoothen the rider’s transition of air around the torso and arms, reducing drag just enough to ease fatigue on longer rides. Smoothing the wind stream also reduces windshield buffeting, a common distraction on long cruises. The fraternity of aftermarket design that converges on these fairings often emphasizes a clean seam line and a precise fit. The last thing a rider wants is an airy creak as the fairing shifts minutely at speed or a nut working loose after a few road miles.

The question of compatibility is not just about chassis mating points. It also concerns how the fairing interacts with the bike’s radio and audio layout. A number of designs are intended to accommodate a single DIN or a larger 7-inch double DIN radio, with mounting points that align with the factory-referenced dimensions. The beauty of that design strategy is its predictability: once you have the correct enclosure, the installation can be more straightforward, with fewer aftermarket adjustments to the bike’s internal wiring or to the fairing’s internal bracing. At the same time, the inclusion of integrated cutouts for radios and speakers demands careful attention to the mounting hardware and the internal routing of wires. The goal is a clean, factory-like installation that looks as if the unit came with the bike from the start, not something stapled on after the fact. For riders who desire a minimalist look, some kits offer single DIN covers sold separately to preserve a seamless exterior when the larger radio option isn’t used. This flexibility—more than one radio path, more than one cover option—speaks to a broader design ethic: the fairing must be adaptable without demanding a wholesale rework of the front end.

Beyond the aesthetic and practical considerations, the material choice has a direct bearing on longevity and maintenance. ABS plastic, while inherently resilient to minor abrasion, benefits from a protective coating during the finishing stage. A good finish resists UV degradation, keeping color from washing out and preventing the material from becoming brittle in sunlight. The same logic applies to the clear coat and any gloss that sits on top of the paint or pigment. A well-applied finish reduces the likelihood of micro-scratches that could turn into more visible scars after a few road trips. In addition to the outer surface, the interior surfaces and mounting brackets are often treated with finishes that resist corrosion from road salts, moisture, and humidity. When these coatings fail, you may encounter more rapid wear, misalignment, or a drifting of the fairing away from its intended position. Keeping a watchful eye on the finishing integrity is part of the ongoing care that extends the life of the fairing and preserves the bike’s visual coherence with its engine and chrome highlights.

One of the advantages of the batwing approach is the scope for personalization without breaking the overall visual grammar of the machine. The fairing can accommodate audio upgrades, weather protection enhancements, and even small lighting accents that improve nighttime visibility. The modular nature of the mounting system means that owners can assemble or reconfigure as their needs evolve, whether that means a heavier radio setup for long highway runs or a lighter arrangement to preserve a lean aesthetic for weekend rides. The interplay of material choice, finish quality, and mount design creates a composite product that feels purpose-built rather than assembled. When done well, the fairing becomes an extension of the motorcycle’s character, maintaining the lineage of classic cruiser styling while granting the rider modern conveniences and comfortable wind management.

From a practical standpoint, installation considerations matter as much as the raw materials. The panels themselves are relatively lightweight, a contrast to older, more robust fiberglass-only fairings that could add noticeable mass to the front of the bike. The modern ABS-plus-fiberglass approach is designed to strike a balance: a shell light enough to be handled by a single installer, yet stiff enough to resist warping and rattling over time. Most kits include the essential mounting hardware, with variations to accommodate different fork configurations and radio placements. The instruction sheets, while concise, rarely replace the need for a careful, step-by-step approach that respects the bike’s electrical harness and the fairing’s own bracing. A methodical installation preserves alignment and ensures that the fairing’s edges sit flush against the bike’s lines, preventing gaps that collect water or accumulate grime.

In describing material quality and design, it is impossible to ignore the broader ecosystem that surrounds aftermarket fairings. Enthusiasts share feedback about how the fairings age, how well the paint holds, and how stable the radios feel under a variety of weather conditions. The discourse extends to fitment, with some notes about variations in model years that influence how well a given shell pairs with a specific bike’s geometry. The long view is that a well-chosen batwing fairing, crafted from a thoughtful blend of ABS and fiberglass, can deliver not only improved wind management but also a refreshed aesthetic that respects the machine’s classic proportions. The result is a component that feels like a natural upgrade rather than a retrofit, something that a rider can be proud to show off and comfortable spending hours behind the wheel of.

For readers seeking a broader sense of how these pieces live within the larger catalog of compatible assemblies, a widely used reference point is the Suzuki fairings collection, which offers a spectrum of options that respect the same design principles described here. This internal resource provides a sense of how different lines balance function, fit, and finish while keeping the core cruiser silhouette intact. It’s not a shopping list so much as a map of design language—how the wind deflection, the sensor and radio cutouts, and the edge radii align with each generation of the bike’s front-end geometry. By comparing the patterns of fit and finish in the collection, a rider can gain a clearer expectation of what a well-matched fairing can look and feel like once installed. For readers who want to dive deeper, consult the Suzuki fairings collection as part of your design brief and planning process.

External resource: https://www.ebay.com/itm/405066724338

Batwing Boundaries: Installation and Compatibility of 2013 Suzuki Boulevard C90T Fairings

On long, wind-lashed highway days, the 2013 Suzuki Boulevard C90T is more than a touring machine; it becomes a canvas for personal style and rider comfort. The aftermarket batwing fairings that people install on this chassis are valued not just for looks but for the way they reconfigure rider wind exposure, cabin noise, and overall cruising ergonomics. These fairings, typically molded from high-quality ABS plastic, are designed to fit a range of model years around the 2013–2019 window for the C90 and C90T variants. The goal is a unified silhouette that keeps the bike’s natural stance while adding a broader shelter from gusts and rain. When a rider approaches this kind of upgrade, the first questions are not only about aesthetics but about how well a particular fairing will align with the bike’s geometry, mounting points, and electrical system. The best-informed choice often comes from understanding three core elements: what the fairing is designed to accommodate, what hardware is included, and what extra parts may be needed for a clean, safe installation.

The design philosophy behind batwing fairings is straightforward but crucial for the long-haul rider. A properly shaped fairing can channel air smoothly around the rider, reducing fatigue on extended trips and preserving stability in crosswinds. A common feature set includes a windshield or windscreen and space for audio or electronics, offering a degree of customization that can turn a good touring bike into a personal touring ecosystem. For models in the C90/C90T family, a fairing of this type is typically prepared to accept a radio area or a display mount, with the understanding that the head unit itself is not included. In practical terms, this means you’re paying for the shell, the mounting interface, and the cutouts that allow for optional electronics to be integrated later. A fairing configured with a 7-inch double-DIN radio opening and 6×9 speaker cutouts, for example, provides a clear path to adding a modern audio experience without sacrificing the bike’s original proportions. The value of this approach is not merely cosmetic; it is a tangible upgrade to rider enjoyment and cabin acoustics, particularly on longer journeys where cabin noise can become fatiguing.

Yet fitment is never guaranteed by appearance alone. The 2013–2019 window for C90 and C90T models is broad enough to attract a variety of aftermarket designs, but not every option will align perfectly with every bike. Compatibility hinges on several practical realities. First, the fork arrangement must be able to accept a fairing’s mounting system. In many cases, the installation requires fork clamps that are compatible with exposed forks, and this can necessitate additional components or modifications to ensure a solid, vibration-free mount. When the fork geometry is altered or when the clamps don’t align with the bike’s original fork tubes, the fairing can sit too high, too low, or out of true, which immediately affects wind protection and ride feel. Second, the mounting hardware included with a kit matters a great deal. Some kits come with stainless steel mounting brackets and a complete hardware set that promises a straightforward bolt-on process. Others require separate purchases or the reuse of existing hardware. The presence or absence of these brackets can determine whether the fairing can be installed with only basic tools or whether a more elaborate approach is needed. Third, there are sometimes ancillary pieces that must be sourced to complete the fit. A CD cover, for example, is mentioned in several kits as a component that ensures the fairing aligns visually with the instrument cluster and dash area. When such items aren’t included, the installer faces a choice between improvising or seeking a package that includes all necessary pieces for a seamless install.

To avoid guesswork, one practical approach is to treat fitment as a systems problem rather than a single alignment task. Begin by confirming the model year range the chosen fairing kit claims to support and compare it with the bike in your garage. If the kit is advertised as compatible with 2013–2019 C90/C90T models, that’s a strong starting point, but you should also verify the routing of any wiring harnesses, the clearance around the steering stem area, and whether the fairing’s mounting points can share or replace the bike’s stock points. The fork clamps are a good example of a potential friction point. In several installations, the need for adapters or modifications to expose forks becomes a deciding factor. This is not just about the physical reach of a bolt; it’s about ensuring there’s enough material thickness and correct geometry to resist torque and road vibrations over thousands of miles. It is here that professional installation reveals its value. The process often involves careful alignment checks, torque specification adherence, and sometimes an evaluation of whether the fairing’s weight distribution interacts with the bike’s steering dynamics in certain weather conditions. A rushed or imprecise install can translate into flutter at cruising speeds, unexpected deflection under gusts, or interference with the rider’s instruments.

Another critical dimension is the integration of electronics. If the kit is designed to accommodate a modern infotainment display or audio components, the installer must consider how the fairing’s inner pockets accommodate such devices. The 7-inch double-DIN opening is a generous feature that allows a broad spectrum of head-unit options, though the radio itself is not supplied with the kit. The 6×9 speaker cutouts also provide a ready-made enclosure for a pair of larger speakers, which can significantly improve the listening experience on the highway. That said, the presence of cutouts and the intended electronics do not guarantee plug-and-play success. A clean installation requires careful routing of power lines, grounding points, and, if applicable, antenna placement. Weather sealing around the edges must be checked to prevent moisture ingress into any electronics housed behind the fairing. These considerations underscore why many riders choose professional installation when they are not 100 percent confident in their mechanical and electrical skill sets.

For riders who prefer more autonomy, the process can still be deeply rewarding when approached with a methodical plan. Start with a clear inventory: confirm the fairing’s weight, mounting point locations, and whether any bracketing is designed to interface with the bike’s existing windshield or instrument cluster. Then map out the sequence of installation steps, from removing any stock wind protection or dash components to torquing the final mounting bolts. It is wise to perform a dry-fit before any drilling or permanent fastening, to ensure all bolts align with their holes and that no component interferes with the steering or front brake system. During the test fit, check for clearance around the fuel tank, the fuel cap, and the radiator or cooling shrouds if your bike employs exposed cooling elements. In many cases, a careful test fit reveals subtle conflicts that a quick eyeballing would miss. If you encounter rubbing or misalignment, you may need to source precision spacers or adjust the angle of the fairing’s mounting brackets. If the installation involves modifying the fork clamps, it is particularly important to verify that the clamps do not compromise the fork’s travel or introduce any binding in the steering action.

The riding experience after installation is where all the planning pays off. With the batwing fairing correctly mounted, riders often report a noticeable improvement in stability at highway speeds and a quieter cockpit that makes long trips less taxing. The wind impact around the chest and shoulders can be softened without sacrificing the bike’s sporty handling. The surrounding wind buffer also contributes to a more consistent airflow over the head and helmet, which can translate into reduced fatigue on extended voyages. The audio and electronics integration, when executed cleanly, can turn a cross-country ride into a more personalized journey, with tunes and navigation that are easy to access from a cockpit that looks and feels integrated rather than tacked on. It’s important to reiterate that achieving this outcome relies on accurate fitment and proper electrical routing, which is why many experienced riders prefer skilled hands for the job.

When contemplating where to source a compatible kit, a careful buyer notes not only the advertised compatibility window but also the specifics of what is included in a package. Some listings explicitly note that mounting brackets, stainless steel hardware, and even the necessary hinges or alignment shims are included, while others require separate purchases. The presence of a robust hardware package can eliminate a lot of guesswork and premature improvisation, enabling a cleaner, more secure installation. It is also prudent to review the seller’s return policy and any fitment guarantees. The right seller can make a substantial difference, offering guidance on whether a particular kit has historically fit well on C90/T models and what additional steps other riders have taken to finalize the install.

For riders seeking a broader sense of direction beyond product listings, there is value in consulting the bike’s service manual or connecting with an authorized dealer when in doubt. The official documentation provides specifications for fasteners, torque ranges, and recommended mounting practices that are compatible with the bike’s frame geometry and electrical system. Even with a strong aftermarket ecosystem, these authoritative sources can help prevent installation mistakes that could compromise safety or performance. If you want to explore related accessories and fairing options from reputable sources, you can browse the Suzuki fairings collection, which compiles a range of compatible shapes and mounting schemes from a single source. This resource can be a helpful starting point for a rider weighing aesthetics against engineering fitment. Suzuki fairings collection

As you consider the installation path for a 2013 Boulevard C90T, keep in mind the trade-offs between a quick cosmetic change and a longer-term, functional upgrade. A fairing that fits and seals well will pay dividends in comfort and ride quality, but it also requires careful alignment and a thoughtful hardware strategy. If you decide to pursue a more involved setup, the project becomes as much about the rider’s skill and patience as it is about parts. The payoff is a motorcycle that not only preserves its cruising character but also adapts to modern electronics and audio expectations without sacrificing the bike’s clean profile and original lines. Throughout this process, maintain a practical perspective: confirm fitment, prepare for necessary hardware, plan for possible modifications, and seek professional assistance when the task exceeds your comfort level. The right balance of preparation, precision, and persistence will yield a result that feels like a natural extension of the bike rather than a bolt-on add-on. For riders who want to extend their knowledge and cross-check fitment details, a broader external resource can provide additional installation guidance and context for fairing integration across different cruiser models. External resource: https://www.cycleworld.com/

null

null

Final thoughts

One can see that aftermarket batwing fairings for the 2013 Suzuki Boulevard C90T represent not merely aesthetic enhancements but also improvements in rider comfort and functionality. By tapping into the varied options available, understanding the importance of material composition, ensuring compatibility, and staying updated on market trends, business owners can position themselves effectively within this lucrative sector. Investing in high-quality aftermarket parts is crucial for maintaining customer satisfaction and loyalty. As riders continue to personalize their motorcycles, the demand for innovative, durable accessories will only grow, making it essential for businesses to adapt their offerings accordingly.