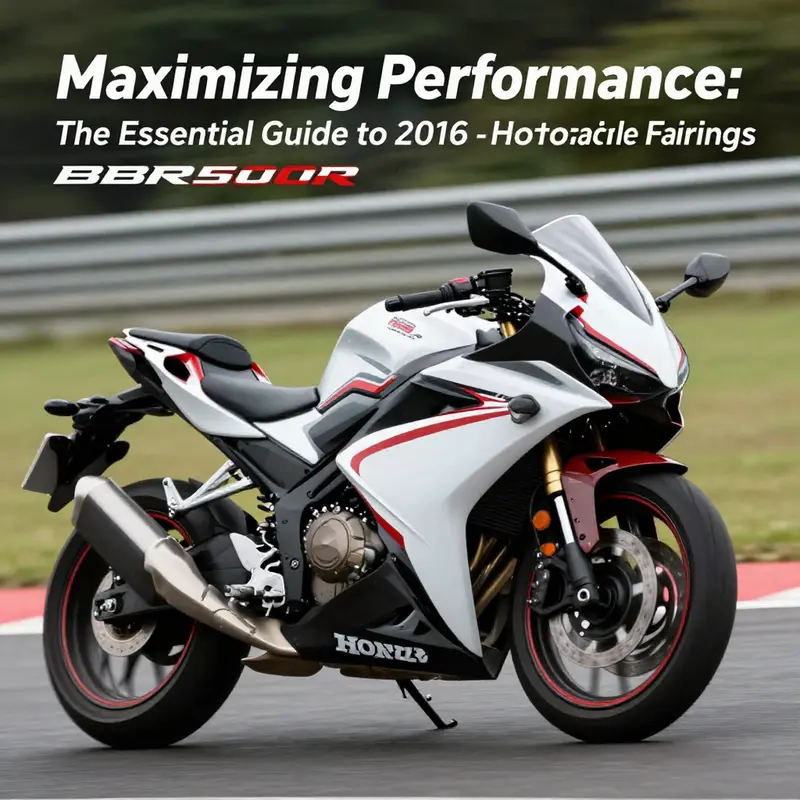

Motorcycle fairings embody the intersection of performance and style, particularly in models like the 2016 Honda CBR500R. These fairings are not just aesthetic accessories; they serve vital aerodynamic functions that can significantly affect a motorcycle’s handling and stability on the road. Derived from rigorous design processes, these fairings create a seamless exterior that efficiently guides airflow, reduces drag, and maintains engine cooling. Business owners in the motorcycle sectors can leverage this information to better understand the value fairings bring not only in terms of performance but also in enhancing customer satisfaction. Each chapter will unfold critical aspects: the aerodynamic design features, material durability, market opportunities for replacement and upgrades, as well as important installation and maintenance considerations. By grasping these factors, business owners can make informed decisions regarding product offerings and customer education.

null

null

A Quiet Armor: Material Composition and Enduring Durability of the 2016 Honda CBR500R Fairings

The 2016 Honda CBR500R’s fairings embody a deliberate engineering choice in the bike’s outer shell. They function as an aerodynamic cocoon and a protective barrier against road life. At the heart of that cocoon is a material system and a manufacturing process designed for reliability across weather, heat, and fatigue. The narrative of these fairings begins with the material itself, moves through how it is formed, and expands into how those choices influence performance, maintenance, and upgrade paths for riders who demand both speed and peace of mind on road or track. The story aligns with the broader design language of middleweight sport bikes of the era, yet it stands on its own when you consider how the 2016 CBR500R fairings balance weight, strength, and practicality.

The dominant material is ABS plastic, a thermoplastic known for a well-rounded property set suited to motorcycle bodywork. ABS provides a practical balance: it resists impact, weathering, and remains workable for mass production. For riders, that translates into fairings that endure typical scrapes and minor drops without inviting catastrophic damage to the chassis. The weather resistance of ABS is valuable for machines that spend time outside, in sun and rain, exposed to humidity and road grime. The material’s UV stability is typically enhanced by factory finishes and by aftermarket coatings if a rider refreshes the look. Thus, the ABS shell remains visually appealing and structurally resilient across seasons, a key factor for a model like the CBR500R that invites year-round use in diverse climates.

The production method reinforces durability as much as the resin itself. A 100 percent injection molding process shapes the components, delivering precise geometries and consistent wall thickness. Injection molding yields tight tolerances that help panels align during installation, reducing gaps that could cause buffet or flutter at highway speeds. The result is a shell that keeps its shape under load, maintains a smooth finish, and resists micro-deformations. For a rider, that means a fairing that preserves its aerodynamic profile after hundreds of hours on the road.

The material features of ABS extend beyond resilience to everyday performance. Impact resistance helps protect the engine, radiator, and internal components that lie beneath the surface when the fairing encounters stones, gravel, or curb contact. Weather resistance preserves integrity across wet spray and sunny heat, with color stability and fewer micro-cracks that could invite moisture infiltration over time.

Real-world performance is also shaped by finishes. Many aftermarket kits include multi-layer clear coats that provide UV protection and scratch resistance. A well-applied finish helps maintain gloss and color depth, supporting the fairing’s look while contributing to long-term resistance to fading. For riders who ride in bright sun or wash and wax regularly, these finishes can be the difference between a fairing that ages gracefully and one that looks dull after a few riding seasons.

OEM vs aftermarket is another practical angle. OEM fairings aim for reliable fit and cohesive appearance with the bike’s engineering. Aftermarket options, while often built from similar ABS, may differ in wall thickness, reinforcement, and finishing. Some aftermarket configurations may use reinforced ABS or carbon fiber to reduce weight or alter stiffness. In practice, these differences can subtly affect panel flex, heat response, and durability, though core ABS properties remain central.

Ventilation and heat management are practical chapters within this story. The 2016 CBR500R’s fairing design balances reduced drag with effective engine cooling. The shell provides a smooth envelope while accommodating vents and channels that guide air to hotspots around the radiator and engine bay. Proper ventilation lowers heat buildup and helps maintain engine performance on long or warm-day rides. The plastic’s thermal stability matters, as repeated cycles of heating and cooling do not lead to rapid fatigue or discoloration in the same way weaker polymers might.

Care and maintenance are practical considerations. ABS surfaces clean easily with standard motorcycle soap and water, followed by careful drying to prevent water spots. Scratches can be touched up with a robust base resin and a durable finish, aided by UV protection to preserve color and gloss. Routine care—cleaning, storage, and protective waxes—extends the fairing’s life, especially for riders who park outdoors or ride in coastal conditions with salt spray.

Fitment and upgrades sit at the intersection of design intent and user experience. Replacement or upgrade options respect the original architecture while allowing for personal expression and performance tweaks. A well-chosen replacement or a treated finish can restore lines and luster, while more aggressive aftermarket assemblies may improve stiffness or reduce weight. Alignment, gasket quality, and careful installation determine the day-to-day reality of riding with a fairing that seals the bike’s silhouette against wind and spray. The 2016 CBR500R benefits from fairings that sustain balance rather than sacrifice it for novelty.

For riders exploring broader options, the market offers choices aimed at different priorities, whether maximum shield, lightest weight, or most pristine finish. The core remains the ABS composition and the idea that a well-made fairing can endure real-world riding while preserving the bike’s aesthetic and aerodynamic intent. The 2016 CBR500R’s fairings stand as a deliberate blend of material science, precision manufacturing, and practical finish work. ABS plastic, molded through injection, yields a shell capable of withstanding riding’s demands while accommodating aftermarket finishes and upgrades. The fairings’ weather and impact resistance, complemented by multi-layer finishes, support daily riding and spirited weekend sessions. Heat management remains practical, with venting and airflow designed to keep engine temperatures in check and rider comfort within reach. For riders who value protection, aerodynamics, and aesthetics, the 2016 CBR500R’s fairings offer a cohesive package that ages gracefully with the bike. They remind us that behind every sleek line lies a careful calculus of materials, processes, and finishes that define a sport bike’s durability.

External context can be found in broader motorcycle parts literature discussing materials and finishes in depth: https://www.motorcyclespareparts.com

Air, Armor, and Aesthetics: Navigating Upgrades and Replacements for the 2016 Honda CBR500R Fairings

The 2016 Honda CBR500R sits at an intersection where performance sensibilities and street‑friendly styling meet in a single, cohesive package. The fairings that wrap its engine and frame do more than merely shield mechanical parts from the wind; they craft an aerodynamic profile that shapes how the bike cuts through air, how it behaves at speed, and how boldly it presents itself to onlookers as it tucks into a lean, confident stance on the road. When riders begin to consider upgrades or replacements, the conversation shifts from a purely cosmetic inquiry to a nuanced assessment of airflow, heat management, fitment, and the long-term durability of the shell that encases the heart of the machine. The market that has grown up around the 2016 CBR500R’s fairings mirrors this complexity, offering a spectrum from streamlined, full‑cover kits to more modular options that replace individual panels. Behind each option lies a set of trade‑offs that reflect the rider’s goals, whether those goals tilt toward ultimate aerodynamic efficiency, personal color accents, or a balance of both without sacrificing reliability on longer rides in warmer weather.

At the core of any fairing upgrade is the recognition that the fairing is more than a cosmetic shell. It is a carefully engineered enclosure that channels air around the rider and the engine with minimal disturbance to stability. A full fairing kit, for instance, is designed to replace the entire outer shell—front cowling, side panels, and rear sections—so that airflow is managed in a seamless, uninterrupted fashion. When a rider opts for a complete kit, the objective is clear: to maximize aerodynamic efficiency, reduce drag, and improve high‑speed stability. The appeal of this route is not solely about speed; it is about confidence. When the lines of the bike are clean and the air flows smoothly around the chassis, throttle response can feel more immediate, and the rider’s body position appears more in harmony with the machine’s intent. The outcome is a silhouette that communicates purpose at a glance, a visual signature that says the CBR500R is ready for sport‑bike miles and spirited backroad forays alike.

From a materials perspective, these fairings are typically fashioned from a durable ABS plastic that balances rigidity with impact resistance. The material choice matters because it underpins warranty considerations, heat resistance, and the ability to hold a paint job over time. ABS is favored for its resilience against the kind of scuffs and minor knocks that often accompany riding in urban environments and parking lot sessions. It also lends itself well to injection molding, a process that yields panels with consistent thickness and predictable fitment, a critical factor when you are assembling an entire fairing kit. In addition to the structural and aerodynamic benefits, ABS fairings can be finished in a variety of colors and textures, from gloss black to gloss red, allowing riders to customize their machine’s appearance while maintaining the practical advantages of a factory‑style shell. (A note on finishes: high‑gloss surfaces can emphasize the bike’s lines and accentuate its speed‑oriented stance, while deeper, darker finishes can deliver a more aggressive look. The choice of finish is a personal expression as much as a design decision.)

Among the most compelling options in the market today are full fairing kits designed specifically for the 2016 model year, with compatibility extended to subsequent years that share the same frame geometry and bodywork philosophy. These kits encapsulate the bike more completely, creating a continuous air channel from the front of the motorcycle to the tail. The aerodynamic payoff is not only about reducing drag; it also relates to storage lines and cooling paths. Proper ventilation remains crucial, especially on longer rides or in hot climates. Today’s full kits often include ventilation considerations that align with the CBR500R’s engine bay geometry, ensuring that heat accumulates in a controlled manner rather than becoming a source of rider discomfort or thermal stress for the engine bay. The design philosophy behind these options is to preserve, if not enhance, the bike’s cooling efficiency while delivering an integrated, street‑ready aesthetic.

On the marketplace front, the journey from concept to installation begins with the alignment of expectations. If maximum aerodynamic performance is the priority, the full fairing kit represents a direct path. It delivers a singular, cohesive surface that minimizes seams and potential drag points where air could become turbulent. That cohesion also contributes to a stable ride at higher speeds, where even small drag reductions compound into measurable improvements in straight‑line stability and wind buffering around the rider. Yet there is beauty and value in modularity as well. Some riders prefer swapping individual panels to refresh styling or to repair a damaged piece without buying a complete kit. In this scenario, the decision becomes a balancing act between preserving a consistent look and allowing for faster, piecewise replacements after a minor mishap or curb encounter.

The market landscape reflects these desires with a mix of direct‑to‑consumer and marketplace options. For many riders, platforms that promise a guaranteed fit bring a much‑needed layer of certainty to an otherwise variable supply chain. The complexity of fairing fitment should never be underestimated. Even when a kit proclaims compatibility with the 2016 model, minor differences in mounting points, bracket alignments, or the headlight nacelle shape can require careful inspection and perhaps some reasonable mechanical modification. The best buyer experience hinges on clear guidance about fit and a straightforward installation path. In the end, the decision often comes down to how much a rider values the assurance of a guaranteed fit and the return options that accompany a purchase, versus the desire to push the envelope with a slightly bespoke, non‑OEM look that reflects personal taste.

From an aesthetic standpoint, the aftermarket fairing market is a canvas. The versatility of ABS panels makes color changes and finish transitions feasible without sacrificing the structural integrity of the bodywork. A gloss black finish can lend the bike a stealthy, track‑ready persona, while a gloss red or other high‑contrast color can highlight the bike’s sporting stance and sharpen its silhouette against the road. The visual impact is more than skin deep; it interacts with how light plays across the curves of the fairings, how the intake shapes guide airflow, and how the rider’s gear color plays off the surrounding panels. In practice, riders often pair a full kit with complementary components—updating the tank trim, the tail section, and even the mirrors—to craft a unified aesthetic that reads as a deliberate design statement rather than a simple cover upgrade.

As with any significant aftermarket purchase, the path to acquiring a fairing upgrade for the 2016 CBR500R benefits from a critical appraisal of available pathways. The full fairing kit, by providing the most complete aerodynamic envelope, is rated highly by riders who chase high‑speed confidence and consistent air handling during track days or fast mountain passes. For those who ride more pragmatically or who value rapid replacement after a mishap, panel‑level updates offer a practical compromise, enabling targeted repairs without sacrificing too much of the bike’s original geometry. In either case, the market’s breadth—encompassing various finish options, materials, and mounting configurations—affords a degree of customization that mirrors the rider’s evolving needs as skill, terrain, and riding goals shift over time. The ability to dial in both speed and style is a core advantage of choosing a kit designed for the 2016 model year and its successors, a compatibility window that reflects the continuity of the CBR500R’s design language.

For riders who want to explore options with confidence, it can be helpful to consult a curated source that aggregates fitment data, panel configurations, and finish choices. A reliable starting point is the Honda fairings collection at Summit Fairings, which offers a focused selection of components designed to align with a broad spectrum of Honda sport bikes. This resource provides a straightforward path to evaluating compatibility, colorways, and pricing across a family of fairing options that share design philosophy with the 2016 CBR500R. Honda fairings collection at Summit Fairings can serve as a pragmatic anchor for riders who want to visualize how a given kit will impact the bike’s stance and aerodynamics before committing to a purchase. The aim is not simply to acquire a new shell, but to harmonize the bike’s geometry, airflow characteristics, and visual identity into a coherent, ride‑ready package. It is this integration—the alignment of mechanical fit, aerodynamics, heat management, and aesthetics—that defines a successful upgrade path for the 2016 CBR500R’s fairings.

Ultimately, the decision to upgrade or replace the fairings on a 2016 CBR500R rests on how a rider balances efficiency, protection, and appearance. A full kit promises the most complete aerodynamic envelope, a clean silhouette, and the potential for improved high‑speed stability. Panel replacements offer flexibility and cost control, enabling refreshes without wholesale rework. The materials—durable ABS, designed for injection molding and shaped to minimize drag while standing up to road use—provide a dependable platform for either path. Finishes such as gloss black or gloss red offer personality customization without compromising the shell’s structural role. And the market’s available pathways—whether through guaranteed‑fit marketplace listings or targeted manufacturers—provide the practical means to translate ambition into a tangible update on the bike’s exterior. In the end, upgrading or replacing the fairings is less about chasing a single best option and more about crafting a cohesive aerodynamic and aesthetic package that reflects how the rider intends to deploy the CBR500R on real roads and real days of riding. For many, that means embracing a balanced approach: select a full kit when performance is the priority, or choose strategic panel replacements to refresh style while preserving familiar handling characteristics.

External resource for broader context: https://www.ebay.com/sch/i.html?_nkw=Fairings+%26+Bodywork+for+2016+Honda+CBR500R

Fit, Flow, and Longevity: Mastering Installation and Maintenance of the 2016 Honda CBR500R Fairings

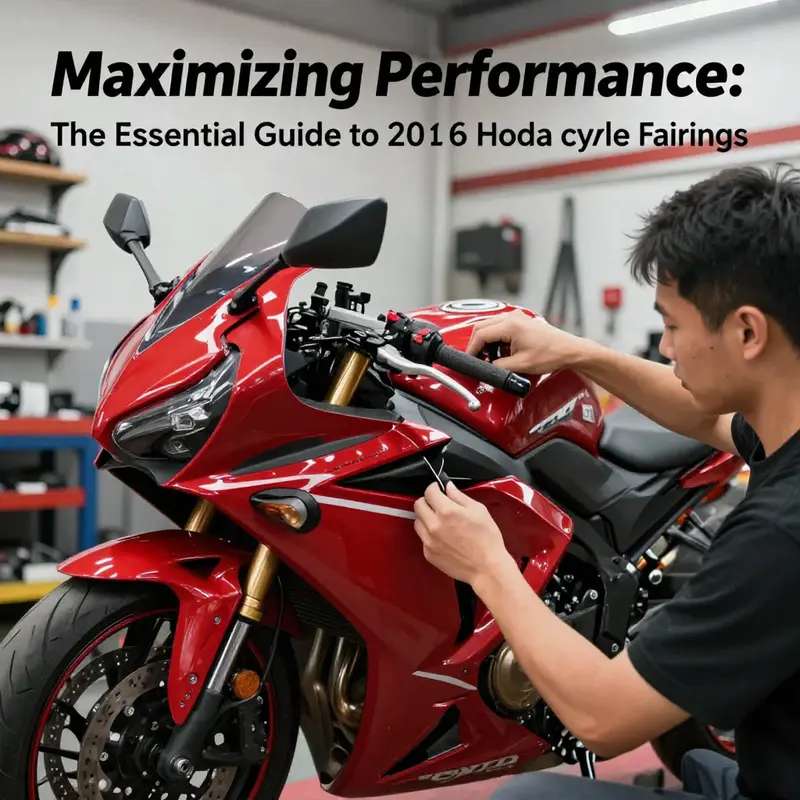

The 2016 Honda CBR500R arrives with a fairing package that is as much about aerodynamics as it is about attitude. The full fairing acts like a streamlined shell, guiding air smoothly around the engine and chassis to reduce drag and bolster high‑speed stability. It also gives the motorcycle a compact, aggressive silhouette that signals intent as clearly as its performance curve. But the fairings are more than a cosmetic layer; they are a functional system that interacts with the bike’s breathing, wiring, and mechanical linkages. Installing and maintaining this system requires a careful eye for fitment, a respect for the flow of air, and a systematic approach to how the panels sit, twist, and flex under the stresses of riding. The end result, when done well, is not only a cohesive look but a measurable improvement in ride quality at speed, a quieter wind environment for the rider, and a level of protection for the vulnerable components that lie beneath the plastic shell.

From the moment a new ABS plastic fairing kit is unpacked, the work centers on alignment. The pre‑drilled holes and the small alignment tabs are the map of the bike’s original geometry. When the holes do not line up with the mounting points on the frame, the entire assembly begins to resist the air it is meant to caress. The consequence, if misaligned, ranges from conspicuously poor airflow and elevated wind noise to chance contact with the engine or subframes during operation. This is not just a matter of cosmetics; a misaligned panel can alter the intended aerodynamics, creating eddies that reduce stability at speed and, over time, add unnecessary stress to mounting fasteners and the interfaces that secure the fairing to the bike’s backbone. The installation process thus becomes a test of geometry as much as a test of fit.

Beyond the obvious alignment concerns, there is a broader systems perspective that riders often discover only after the fairing is in place. Wiring harnesses that traverse under or behind the panels must be routed with care to prevent pinch points and to preserve serviceability. Brake lines and hydraulic hoses need room to articulate with every steering input without rubbing or binding. These considerations transition the task from a simple bolt‑on job into a careful choreography where each piece of the fairing kit must breathe with the bike’s existing systems. The principle is straightforward: if a panel can be gently moved without disturbing a connector or a hose, it should be, and if a panel sits tight and still without misalignment, it is a sign the installation is on the right track. The rider’s eye, trained to notice the fine interplay of line and light, becomes a tool for diagnosing the subtle cues that tell you the fairing is aligned correctly.

Once the physical fit is achieved, the question turns to the long‑term interaction between air, heat, and accessibility. The full fairing, by design, increases the surface area through which air must travel and, in doing so, alters the path of heat escaping from the engine and frame. In hot conditions or during extended highway runs, the enclosure can trap heat to a degree, potentially impacting performance, especially if cooling vents are obstructed or misdirected. This is not a signal to abandon the concept of full fairings; it is a reminder to pay attention to ventilation and to verify that the kit’s vents or channels remain unobstructed after installation. The goal is to preserve that balance between streamlined aerodynamics and adequate cooling, ensuring that the bike maintains its performance envelope even as the rider’s speed and temperature rise.

A second layer of maintenance emerges once the fairings are fitted and the bike is back on the road. Accessibility, which is often touted as a benefit of a more open chassis, becomes a practical constraint with a fully enclosed shell. Routine engine checks, oil changes, and spark plug inspections require deliberate disassembly and reassembly of the panels to reach the hard‑to‑touch corners of the engine bay. The more comprehensive the fairing system, the more time a technician or an attentive owner should budget for service intervals. For this reason, many riders who opt for full fairings appreciate the trade‑off—improved aerodynamics and a bolder appearance—in exchange for planned maintenance time. The careful observer notes that the fairing’s presence should not thwart routine checks but should encourage a disciplined schedule so that performance remains consistent over thousands of miles.

In practice, heat management within the enclosed environment is a matter of practical upkeep as well as design. The fairings’ ventilation must be kept clear of debris and dirt that could impede airflow. Regular inspection of vent channels, air scoops, and gill‑style openings helps ensure that cooling air reaches the critical regions around the cylinders and the radiators or oil coolers where applicable. If a panel or vent becomes clogged, heat can accumulate in places that the original design intended to stay cool. Addressing this early—before heat stress becomes a service issue—extends both the engine’s life and the fairing’s own longevity. A small routine such as brushing out air intakes with a soft brush and rinsing away grime with mild soap and water can make a meaningful difference over time.

The care routine extends to the finish as well. ABS plastic, though resilient, is not immune to UV degradation, especially when the bike spends long hours under direct sunlight. A regular cleaning regimen that uses mild soap and water removes grime and helps prevent the build‑up that can stain or haze the surface. Avoid harsh solvents and heavy abrasive tools that can mar paint or the attachment points. Over time, scratches and cracks in the fairing’s surface are more than cosmetic concerns; they can alter the structural integrity of the panel and may allow moisture to penetrate seams that should remain sealed against the elements. When such damage occurs, prompt repair is prudent, and it should be performed using repair methods appropriate for ABS plastic. A small crack, if addressed early, can often be stabilized with the correct adhesive and a precise curing process that maintains both strength and appearance.

The practical wisdom of maintenance also includes a thoughtful approach to tools and technique. Use manufacturer‑approved fasteners and the recommended torque specifications to avoid over‑tightening, which can crack the panels or strip mounting points. The temptation to substitute hardware to save time is strong, but it is precisely the kind of shortcut that leads to misalignment and rattling at speed. The right tools reduce the risk of damaging paint, trim, or interior fasteners and help preserve the fairing’s tight, uniform fit. A well‑maintained fairing should feel as if it’s an integrated part of the bike rather than a clumsily attached shell. When a fairing is properly cared for, its seamless lines contribute to an impression of precision that matches the bike’s ride characteristics.

For those contemplating replacements or upgrades, the installation philosophy remains consistent: ensure that any new kit respects the bike’s geometry and does not introduce misalignment or clearance problems with the wiring and brake lines. A full fairing kit should come with clear fitment guides and, ideally, support for the model year. When selecting a replacement or upgrade, the aim is to preserve the airfoil‑like efficiency while maintaining access to essential service points. It is worth noting that many riders appreciate the availability of certified fitment information and the promise of a precise, repeatable installation. In this context, a curated selection of fairings that are designed for the 2016 CBR500R range from a number of reputable suppliers, with a focus on consistent fitment and reliable finish. To explore a curated collection of fairings and bodywork, consider reviewing the Honda fairings collection that aggregates compatible options for riders seeking a cohesive aesthetic and reliable performance upgrade.

As the installation completes and the bike takes its first full lap around the block, the test is not finished. A careful rider will assess all the senses—the feel of the fairing against the leg, the absence of rattles, the smoothness of airflow at highway speeds, and the soundscape of reduced wind noise. The stability at speed, the ease of handling through gusts, and the subtle cues of a well‑seated panel all contribute to a final judgment about the installation’s success. The goal is to achieve a harmonious balance where the fairings ride as one with the motorcycle’s frame, rather than acting as a separate weighty shell. This synergy is what elevates the 2016 CBR500R from a mere machine to a crafted instrument whose aerodynamics, access, and aesthetic all reinforce one another.

In the end, the installation and maintenance of the fairings are about respect for the machine’s original design intent and an honest appraisal of how a full fairing system alters the rider’s relationship with the bike. The rider becomes more aware of air, heat, and line of sight, while the machine rewards careful attention with better high‑speed behavior, a cleaner silhouette, and a sense of precision that extends beyond mere torque and horsepower. When done with care, the installation not only preserves the motorcycle’s identity but enhances its character, inviting riders to explore the open road with confidence and a touch of aerodynamic confidence. For those pursuing a curated, balanced approach to fairing selection and fitment, a visit to the Honda fairings collection provides a pathway to reliable coverage that respects the bike’s geometry and the rider’s expectations.

External reading can deepen this understanding of how fairings influence performance. For a broader look at the science of air flow and aerodynamic considerations, see https://en.wikipedia.org/wiki/Aerodynamics

Final thoughts

Understanding the integral role of fairings in the 2016 Honda CBR500R allows business owners to enhance both performance and customer satisfaction within the motorcycle industry. By emphasizing the aerodynamic designs, durable materials, upgrade options, and maintenance practices, businesses can effectively cater to the needs of motorcycle enthusiasts. Focusing on these elements drives customer interest and loyalty, making it imperative for retailers to remain knowledgeable and proactive about fairing offerings and their associated benefits.