The Kawasaki ZX-9R, a standout in the sport motorcycle category, embodies a unique relationship between design and performance, particularly through its fairings. The number ‘9’ represents more than just a model; it intertwines with aesthetic value, aerodynamic efficiency, and market demand for motorcycle fairings. Understanding how this model impacts fairing components, economic insights, and manufacturing standards offers invaluable knowledge for business owners in the motorcycle industry. This article delves into these crucial elements that sculpt the identity of the ZX-9R fairings and set trends in the aftermarket realm.

null

null

The Ninefold Shield: Economics, Craft, and the Aftermarket Lifecycle of ZX-9R Fairings

The fairing is more than a protective shell. It is a carefully engineered envelope that shapes a machine’s character, its handling, and the rider’s experience at speed. In the classic nine-portion silhouette of a sport bike’s upper body, the shell acts as both barrier and aeronautical surface, translating the rider’s intent into a streamlined flow of air that bleeds energy from the wind, channels oxygen more efficiently around the rider, and reduces fatigue over long laps. This is not merely cosmetic. The economics of these panels—how they are produced, distributed, and purchased—reveal a microcosm of the broader market for aging performance machines and the dedicated culture that preserves them. The ZX-9R era, with its particular design language and a robust aftermarket, offers a compelling case study in how fairing components migrate through authenticity, price, and availability as they cycle through a rider community that values both performance and provenance. The resulting market is not a single pathway but a web of choices that riders navigate with experience and sensitivity to their own priorities: fit, finish, and the feel of speed translated from metal and resin to the road beneath the tires.

In this milieu, the fairing is a focal point where engineering meet aesthetics and where supply chains reveal the layered costs of maintaining a beloved model. The distinction between OEM and aftermarket kits is not simply about price. It maps onto a broader story about fidelity to factory specifications, the reliability of fit, and the emotional reassurance of color matching and finish. Genuine OEM kits are precise in fitment, alignment, and gloss, designed to reproduce the bike’s original appearance down to the subtle curves and radii that ensure the panels mate cleanly with the frame and other bodywork. The materials commonly used—high-impact ABS plastic—offer a blend of stiffness, resilience, and weight that is central to performance. ABS holds its shape under thermal stress, resists impact from small debris on fast roads, and, crucially, absorbs energy without cracking in ways that would complicate alignment after a teardown. This is a practical characteristic for a machine whose rider routinely pushes into the wind at highway and track speeds. When OEM kits are installed, a rider often experiences a seamlessness that mirrors factory craft: there is no visible seam that betrays the replacement, no offset that interrupts airflow, and no mismatch in color that requires touch-up after installation.

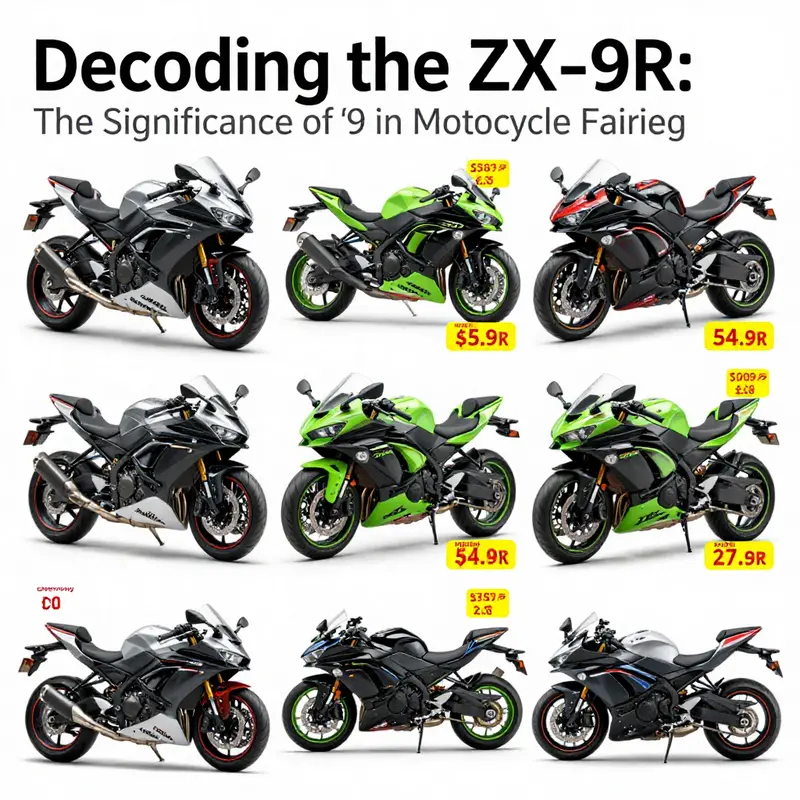

The economic story of these components unfolds through three main channels: the availability and pricing of OEM fairing kits, the breadth and price points of aftermarket alternatives, and the invisible but powerful pressure of market demand that sustains a robust secondary market. Each channel serves different rider needs. For some, the priority is exact color matching and a factory-like finish. For others, the priority is affordability or the chance to customize a bike’s look with color combinations that were not offered at the factory. The spectrum of options is broad enough to accommodate a long-term ownership philosophy—one that treats a motorcycle as a living project rather than a finished product. The data that anchor this narrative come from a mix of marketplace listings and industry observations. Some OEM fairing kits, listed by authorized dealers or respected marketplaces, reflect the premium placed on factory-original parts that guarantee consistent fit and color. One illustrative example shows a new gloss black fairing kit for a particular model year landing at a price that embodies the value of authenticity: a brand-new OEM kit listed with a price just under four hundred dollars, signaling a market where originality carries a specific premium and the assurance of color uniformity is treated as a distinct benefit. The figure is not merely about the sticker price; it speaks to a rider’s willingness to pay for predictability of fit and the confidence that the kit will align with the bike’s geometry, mounting points, and existing fasteners without the need for guesswork or iterative modifications.

On the other end of the spectrum lies the aftermarket ecosystem, a dynamic force that expands the practical reach of the fairing through material choices, design variations, and economical packaging. The core material remains ABS in most cases, but the value proposition shifts toward affordability, customization, and availability. Aftermarket kits can be considerably cheaper to acquire, with wholesale pricing often dipping into a fraction of the OEM cost range. In some marketplaces, wholesale prices for aftermarket fairings can be found in the single-digit or low-tens range per set, particularly when purchased in bulk or non-branded configurations. These kits are usually designed to fit specific model years and may emphasize color schemes that were not offered by the factory, enabling riders to craft a distinctive visual identity for their bikes. The trade-off, however, lies in fitment and finish. While many aftermarket kits strive to match every contour with precision, the tolerances can vary between manufacturers and production batches. Some kits may require additional detailing, alternative fasteners, or minor warm-up and test fits to achieve a near-perfect alignment. In practical terms, the rider becomes not just a consumer but a partner in the craft of completing the bike’s silhouette. The freedom to mix and match panels, to replace a side panel in a color that one’s garage walls inspired, can transform ownership into a creative enterprise. Yet the democratic nature of aftermarket pricing also means that a rider should weigh the benefits of cost savings against the potential need for more hands-on adjustment and the possibility of color or finish mismatches that would otherwise be imperceptible with OEM parts.

This interplay of OEM and aftermarket access creates a market that is both wide and nuanced. Market trends over the past decades show that the availability of ZX-9R fairings spans a broad spectrum—from premium, exact-fit replacements to diverse, cost-effective aftermarket solutions. This breadth is not a sign of market chaos but a reflection of a vibrant ecosystem in which a faithful replica can mate with a rider’s budget and a painter’s palette. The continued presence of listings across major online channels signals a robust secondary market that thrives on the dual goals of restoration and customization. For riders seeking to preserve the look and performance of a much-loved model, OEM parts provide a route to a trustworthy restoration, while the aftermarket routes offer practical routes for staying on the road when budgets or urgency demand flexibility. The result is a market in which a well-maintained classic sport bike can continue to compete, feel, and look like its younger self, even as the clock ages metal and plastic at different rates.

A closer reading of the pricing landscape reveals the core economic decision riders make, often subconsciously, when choosing between original equipment and aftermarket components. The price gap between OEM and aftermarket kits is not simply a line on a receipt; it is a signal of whether the rider values the predictable color consistency and assured fit that comes with factory-origin parts, or whether they prefer a broader range of aesthetic options and lower upfront costs offered by aftermarket makers. OEM pricing remains a premium that is justified for those who obsess over perfect color matching, precise contouring, and the sense that every panel aligns as the factory intended. But the aftermarket space has evolved to deliver not just lower prices, but an expanded palette of finishes, textures, and even unconventional colorways that reflect a culture of personalization as well as practical maintenance. When a rider contemplates replacement, the decision process naturally trades off the certainty of OEM fit with the flexibility of aftermarket design, and that trade-off is at the heart of the aftermarket economy surrounding this classic sport machine.

As a rider moves through this decision landscape, the platform used to acquire fairings matters as well. The rise of online marketplaces and direct-from-manufacturer portals has transformed the speed with which a replacement panel can arrive, the diversity of options available, and the friction involved in the purchase. The eBay listing cited in the research results, for instance, is a compact illustration of how the secondary market functions today. It represents a cross-section of a community of enthusiasts who value the bike’s heritage and seek to maintain it in usable condition, often with a willingness to navigate the tradeoffs between price, authenticity, and condition. The listing itself is not merely a price point; it is a snapshot of collective memory, a small evidence that the model’s identity persists, and a signal of the ongoing demand for reliable, cost-effective repairs. Such listings are not anomalies but a constant feature of the market, illustrating the cycle through which a once-new component becomes a candidate for replacement and then a stick for the next stage of the bike’s life, be it a tidy restore or a transformation of its character.

The market’s strength also rests on the predictable demand that accompanies enthusiasts who own older bikes and want them to remain roadworthy or track-ready. The ZX-9R legacy—if we can use that term in a way that respects the broader history—has inspired a community that values supply chain resilience as much as it values the aesthetic of speed. When a rider wants to recapture the look or refresh the panels after years of exposure to sun and weather, the availability of both OEM and aftermarket options reduces the risk of extended downtime and keeps the machine in service. This is not purely a matter of price or prestige; it is about getting back on the road, or back on the track, with the confidence that the fairing will not warp or peel in the same way that a less carefully chosen replacement might. In that sense, the market is as much about confidence as it is about cost. The rider’s relationship with the bike—built on maintenance cycles, garage habits, and a willingness to invest time in fitment—determines which path will feel most natural at the point of purchase.

A note on the practicalities of choosing between options: OEM kits, because they are built to exact factory standards, often require less adjustment during installation. The mounting points line up, the fasteners align, and the hinge lines and edge radii tend to look and feel like the bike’s original build. This consistency has tangible benefits for those who race or ride aggressively, where even small misalignments can affect aerodynamics and rider comfort. In contrast, aftermarket kits, while highly variable in their finish and fit, can offer an immediate advantage to the cost-conscious rider who wants to achieve a dynamic new look without an outsized investment. The ABS material itself offers a versatile platform for both paths: it can be finished to a like-new gloss with minimal effort, and it can be repainted or re-finished without compromising the structural integrity of the panels. The trade-offs, then, revolve around reliability and ease of installation versus customization and price flexibility. The decision is rarely one of absolutes; most riders end up adopting a hybrid approach—replacing only the most battered panels with OEM parts while using aftermarket components to refresh or personalize the rest of the bodywork—and they navigate this hybrid path with the same pragmatic instincts that drive any long-term project.

The chapter would be incomplete without recognizing the role that color, finish, and texture play in the buyer’s perception of value. For a factory-matched look, OEM panels offer certainty: a known shade that aligns with the original colorway and the rest of the bike’s palette. For those who care about a striking or limited-edition finish, aftermarket offerings provide access to colorways and finishes that are either scarce or never offered originally. The marketplace rewards this creativity with a vibrant array of options, and the consumer benefits through the increased likelihood of finding something that reflects personal taste while still delivering the physical protection and aerodynamic function that the fairing provides. The result is a rider community that treats the fairing not as a single, static piece but as a mutable system—one panel at a time—that can be upgraded, repaired, or transformed as the bike ages or as the rider’s ambitions shift.

For readers exploring the material reality behind the myth of the ninefold shield, a practical cue is to look at how fairing options are described in listings and catalogs. The distinction between OEM and aftermarket is rarely opaque; it often comes down to fitment notes, the stated model-year coverage, and the presence or absence of color-matching guarantees. The market’s ability to address these questions with concrete data—such as the exact years covered by a particular OEM kit or the year ranges supported by an aftermarket set—helps riders calibrate their expectations before committing to a purchase. In the end, the fairing is a bridge between speed and style; it is where engineering language meets the tactile reality of riding. A well-chosen set of panels can reduce wind fatigue, preserve cornering stability by maintaining consistent aerodynamics, and deliver the right image for a rider who wants the bike to look as purposeful as it feels when accelerating out of a turn.

Within the broader catalog of fairings, one can navigate a curated path that respects both history and innovation. A noteworthy resource for those who want to see a focused collection dedicated to this family of machines is the Kawasaki Ninja ZX-9R fairings collection, which concentrates on the lineage and the lineage’s ongoing relevance in the aftermarket world. This link is a useful waypoint for riders who want to examine how the design language of the ninefold shell has evolved and remained resonant through years of development and collector interest. It also acts as a reminder that the aftermarket economy is not an inert market but a living archive of the bike’s ongoing life, a shared space where builders and riders co-create the machine’s future along with its past.

In closing, the economics of fairing components—OEM versus aftermarket, the spectrum of pricing, the role of materials, and the distribution channels—offer a window into how a beloved sport bike continues to be cared for and enjoyed. The ninefold shell serves as a metaphor for the market itself: a layered, resilient, and adaptable system that can shelter speed, shelter memory, and shelter future plans. The consumer’s choice is not simply a price calculation; it is a decision about the kind of relationship the rider wants to have with the bike. Will the shell be a precise reproduction of factory form, a robust and economical shield, or a canvas for personal expression? The answer lies in a straightforward calculus—fit and finish for certainty, or price and personalization for flexibility—and the ongoing availability that keeps the bike alive on road and track. This is the essence of the ZX-9R fairing story: a practical, storied, and ongoing conversation between rider, machine, and marketplace.

External reference: https://www.ebay.com/itm/165879934983

Internal reference: For a focused look at a dedicated catalog of Kawasaki fairings that includes a ZX-9R related collection, see the Kawasaki ZX-9R fairings page in the site’s catalog.

Between Form and Function: How the Nine in Fairings Encodes Standards, Style, and Speed

The fairing is more than a shell that shields a rider from wind. It is a carefully engineered interface where aesthetics, aerodynamics, and safety converge. When one looks at the long arc of motorcycle design, the fairing appears as a living record of how standards shape shape. It records fractions of seconds shaved from top speeds, kilograms saved in weight, and the quiet, cumulative discipline of maintenance and manufacturing. The chapter that follows threads these ideas together, using the notion of the so-called nine in fairing lineage—a nod to a storied series of sport bikes whose bodies became a standard for performance aesthetics—without reducing the subject to a single model or era. Instead, the discussion grows outward, tracing how classifications, materials, and regulatory expectations crystallize into forms that riders recognize and manufacturers defend on the factory floor. In doing so, it reveals how the nine-point relationship between design intention and production reality shapes every fairing that meets a rider at high speed, whether in a showroom, in a workshop, or on the track.

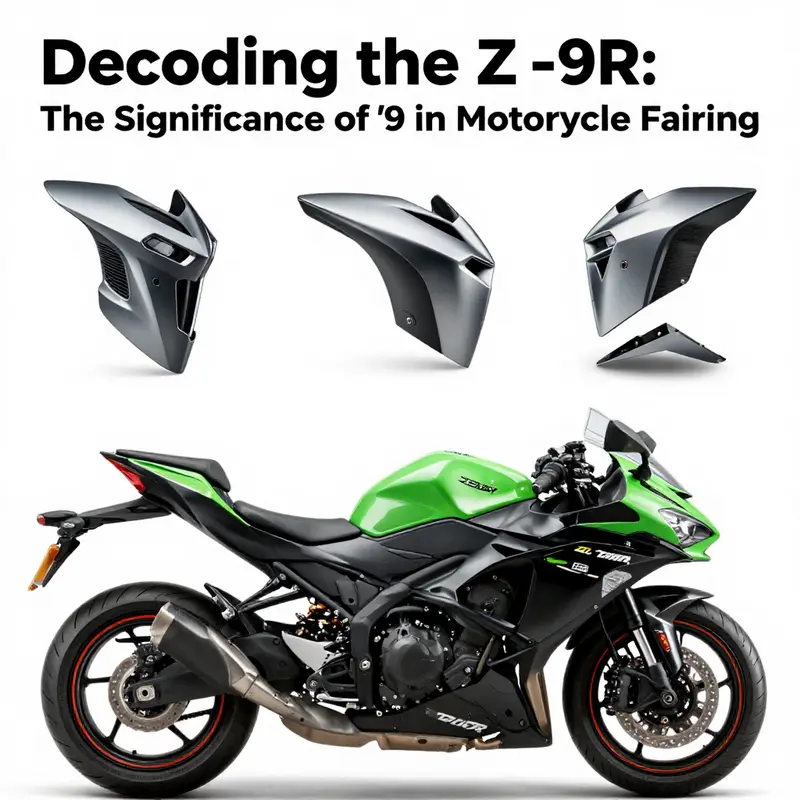

To begin, consider the fairing as a system rather than a mere external shell. It is a fabric of components that must work in concert: the upper panels, side panels, belly cowl, windscreen, vents, and fijaciones that anchor them to the chassis. The classifications—full, half, and quarter fairings—are not mere labels but reflect how a rider experiences wind, noise, and weight at speed. A full fairing wraps the bike in one continuous surface, shaping the flow around the rider and the engine. A half fairing offers a compromise: more access to the rider’s legs, improved cooling, lighter weight, and a different relationship to turbulence created by the engine and wheels. A quarter fairing, with its minimal coverage, foregrounds maneuverability, serviceability, and a more tactile connection between rider and machine. Each type implies a distinct set of manufacturing and design challenges, from the locus of stiffness to the distribution of loads when the bike meets a sudden gust or a slip angle at lean.

The way these classifications are realized in practice depends on standards that govern dimensions, tolerances, and fit between components. Standards are not only about safety; they define repeatability. They enable a frame of reference for suppliers, assemblers, and aftermarket fabricators who want to reproduce a look or improve a performance outcome without reengineering from first principles every time. In the modern supply chain, standardization enables interchangeable panels, consistent mounting points, and predictable integration with lighting, instrumentation, and the rider’s visibility. The windscreen, for instance, is not merely a transparent shield. It is an aerodynamic element whose curvature, height, and edge treatment impact drag, lift, and the rider’s line of sight. The headlight mask and the fairing’s scalloped edges interact in ways that influence ventilation for the radiator as well as the rider’s perception of speed. Packaging these elements within a uniform set of specifications reduces risk for the manufacturer and expands the range of options available to the consumer, from naked aesthetics to performance-oriented configurations.

Material choice sits at the core of this engineering logic. The most common fairing materials—ABS plastic, fiberglass, and carbon fiber—each bring a different weight-to-stiffness ratio, cost, and processing path. ABS plastic, widely used for mass production, has the dual virtues of resilience and moldability. Its ease of shaping makes it a favored choice for mass market lines and for aftermarket replacements, where a precise, glossy finish matters as much as structural integrity. Fiberglass offers a middle ground between strength and weight, with the advantage of flexibility in tuning resin contents and layup schedules to suit different performance goals or budget constraints. Carbon fiber represents the pinnacle of stiffness-to-weight performance, but its cost and manufacturing complexity demand tight quality control and a mature supply chain. The standards that govern material specification, such as minimum thickness, resin content, and environmental resistance, are not decorative constraints; they are the rules of engagement for the cross-disciplinary teams that include mold makers, structural analysts, paint technologists, and assembly technicians. When a panel is designed to meet a crashworthiness criterion, every fiber orientation, resin system, and core material signature must be tested and validated under conditions that mimic high-speed impact and debris impact in real riding scenarios.

The interplay between manufacturing standards and safety resonates most clearly in the crashworthiness discourse. Crash simulations, crumple zones, and energy absorption characteristics have become indispensable tools in modern fairing development. Designers must anticipate how a fairing will behave when a rider is ejected or when a collision occurs, and how the piece will transfer or distribute impact loads to the rider or the bike’s frame. The objective is not to design a shield that survives a crash unscathed but to channel impact forces away from vital rider contact zones and to prevent catastrophic failure that would compromise control or breathing. The integration with the bike’s electrical harness, lighting, and windscreen means that every internal channel for wires and fasteners is part of a broader protection strategy. Standards steer these interfaces so that once a rider chooses a given fairing type, the installation remains replicable across production lots and aftermarket kits, maintaining consistent performance across the fleet of bikes sold in a given market.

The manufacturing narrative is incomplete without recognizing the global nature of the supply chain. In regions where tooling, resin systems, and plastics fabrication have matured, fairing manufacturing has become an industrial backbone that supports a wide ecosystem of suppliers, mold makers, and finishing trades. Guangdong’s manufacturing clusters, for example, have become notable for their capacity to scale production while maintaining quality control and process discipline. Here, the standards that govern product safety, environmental compliance, and process reliability translate into a durable chain of custody from raw materials to finished parts. It is in this ecosystem that the concept of the “nine” of fairings—whether it is a nod to a family of sport bikes or a mnemonic for the nine critical attributes that must be balanced in design—finds a practical translation: a set of criteria that designers and manufacturers adhere to, even as they push the envelope of aerodynamics and aesthetic nuance. The standardization makes it possible for riders to experience a familiar silhouette across different generations, while the underlying materials and techniques evolve to meet new demands for efficiency, regulatory compliance, and consumer expectations.

The aesthetic dimension, often overlooked in discussions of standards, deserves careful attention. A fairing’s lines, curvature, and surface finish are not merely about attractiveness; they encode wind behavior and the rider’s channel of perception. The runway of curves on the outer surface is a deliberate negotiation with boundary layer effects and vortex shedding. Subtle radii, edge transitions, and panel gaps can alter the pressure distribution along the bike’s surface, impacting not only drag but also hand fatigue and steering feel. When a designer envisions a fairing that looks as if it grew from the bike rather than being bolted on, they are balancing a spectrum of constraints dictated by the standards: structural integrity, manufacturing feasibility, surface quality, and functional performance. Aesthetic decisions that prioritize clean, uninterrupted lines must be reconciled with the realities of multi-piece assemblies, access panels, and the conventions of paint and coatings required to survive the road and the showroom.

For riders and collectors who cherish the historical lineage echoed in the nine’s naming, aftermarket fairings have been a bridge between old and new. They carry with them the memory of a design language that emphasized compact silhouettes and aggressive aerodynamics, while offering the practicality of contemporary materials, improved fit, and modern finishing. The aftermarket ecosystem thrives by setting its own internal standards for fitment, finish, and durability, yet it must still align with the general regulatory landscape that governs product safety, consumer information, and environmental impact. Buyers evaluate these offerings by considering how a new panel assembly will integrate with the bike’s existing front end: the alignment of the fuel tank, the line of the radiator, the seating position, and the rider’s line of sight toward the instrument cluster. The decision becomes a careful calculus: more protection and a new look can come at the cost of slightly increased weight and complexity, while leaner, lighter panels might deliver a razor-sharp silhouette but demand more precise fitment and greater attention to mounting hardware. Standards help negotiate these tradeoffs by ensuring that even disparate parts can be assembled into a coherent whole without introducing unexpected gaps, vibrations, or misalignments that compromise performance or comfort.

Crucially, the practical implications of these standards extend to the maintenance and customization culture that surrounds sport bikes. The patient, methodical work of replacing a fairing section, repainting a panel, or installing a new windscreen becomes a lesson in respect for the established interfaces. The standardization of mounting points and electrical connectors simplifies the process of upgrading or restoring a machine, while also inviting a broader set of suppliers to compete on quality and service. Enthusiasts who pursue the nine-inspired design language understand that the beauty of a fairing lies not only in its outward form but in how reliably it can be restored to factory alignment when it sustains wear or impact. In this sense, standards serve as guardians of both performance and heritage, ensuring that a modern frame can house a classic silhouette without sacrificing the predictability that riders rely on when they push their machines toward the limits.

The discussion would be incomplete without acknowledging the role of lighting and instrumentation as integrated into the fairing system. Modern fairings coordinate the lighting package and the instrument display with the contour lines, then weave these elements into a seamless surface. The challenges here are not purely cosmetic but functional: ensuring that lights illuminate the rider’s path without causing glare, that sensors and indicators remain accessible, and that switches and harnesses do not disrupt the aerodynamic envelope. This integration depends on standards that govern electrical load, connector compatibility, and environmental sealing. The result is a cohesive whole where the fairing, lighting, and instrumentation speak a common design language. Each piece must harmonize with the others, even as it serves different teams and suppliers within the global supply chain. The ultimate measure of success is a surface that looks integral—more sculpture than accessory—while delivering predictable performance across a spectrum of riding conditions.

As the industry continues to evolve, the conversation about fairing standards remains dynamic. Regulators, manufacturers, and designers respond to new safety data, new manufacturing technologies, and changing consumer expectations. Computational tools and wind tunnel testing now inform decisions that once relied solely on hand-fitted prototypes. The concept of a standard is not a constraint that shackles creativity; it is a framework that protects riders, promotes interoperability, and accelerates innovation. When a designer contemplates a new fairing line, the baseline assumptions—how it will affect center of gravity, how it will interface with the cooling system, and how it will endure road debris—are anchored in a shared understanding of the rules. From there, the process of evolution begins: a series of iterations, each informed by performance data, user feedback, and the realities of manufacturing throughput.

In closing, the nine in fairings—whether invoked as a historical reference, a design ideal, or a practical cue in production planning—signals a broader truth: standardized forms, when well conceived, can carry both the weight of legacy and the promise of future performance. The fairing is a narrative object that tells how a bike breathes, how it carries its rider, and how it travels through a world of climates, roads, and regulations. It is a testament to the discipline of engineering that respects both the art and the science of motion. The result is not a single solution but a family of solutions—the full, half, and quarter configurations—each tuned to a particular rider, purpose, and environment. The story of the nine, in this sense, becomes less about a single model and more about a continuous conversation between design intent and production reality. And as long as standards guide the conversation, fairings will continue to evolve in ways that honor the past while chasing the wind toward new horizons.

For readers who want to explore a concrete example of how these ideas translate into ongoing practice, a dedicated collection of fairings can serve as a useful reference point. The ZX-9R-era lineage, in particular, offers a historical lens through which to view the evolution of shape, method, and market expectations. A collection focused on that line helps illustrate how a single family’s silhouette can endure while its components—materials, panel geometry, mounting systems, and finishing processes—advance to meet contemporary demands. The linking of this concept to the broader discussion of classifications and design impact illustrates how a seemingly simple question—what does a fairing do?—unfolds into a complex narrative about manufacturing standards, technical regulations, and the shared culture of performance riding. For those who want to dive deeper into the specific curation of fairings for a given line, the following resource offers a gateway to a wide spectrum of options and compatible assemblies: ZX-9R fairings collection. ZX-9R fairings collection.

As we stretch the horizon further, it is worth noting that the lessons of fairing standards transcend individual models and brands. They inform how engineers think about the rider-machine interface, how painters plan the finish to survive years of exposure, and how technicians approach repairs in the field or in a workshop. The standards provide a shared vocabulary for discussing fit, finish, and function, a vocabulary that helps riders and builders alike separate quality from guesswork. The result is not merely a better looking bike, but a more predictable, safer, and more enjoyable riding experience—one that respects the heritage that makes the sport meaningful while embracing the innovations that drive it forward. In this sense, the fairing’s form is the visible expression of a broader engineering discipline, and the nine in fairings—whether read as a nod to a lineage or as a reminder of the nine essential elements of design and production—remains a reliable compass for everyone who cares about speed, safety, and style.

External resource for broader context: Understanding Chinese Motorcycle Fairings: Composition, Standards, and Industrial Benefits. This external piece situates many of the manufacturing and materials considerations in a global context, highlighting how standards intersect with industrial practice in large production ecosystems. It offers a complementary perspective to the chapter’s focus on classifications and design impact, grounding the discussion in a wider discussion of global manufacturing pressures and opportunities. External research on fairing standards.

Final thoughts

The Kawasaki ZX-9R is not just a motorcycle; it is a testament to the importance of well-designed fairings. Through its rich heritage, economic insight into aftermarket fairings, and established manufacturing standards, understanding the role of ‘9 in motorcycle fairing’ becomes not only essential but also lucrative for business owners. By leveraging this knowledge, businesses can better cater to the needs of motorcycle enthusiasts while elevating the aesthetic and performance of their machines.