Introduction

Motorcycle fairings, primarily made from plastics like ABS, require specialized primers to ensure paint durability and aesthetic appeal. For business owners in the motorcycle industry, understanding the best primer for motorcycle fairings translates directly to higher customer satisfaction and reduced rework costs. This detailed overview explores the critical role of plastic adhesion primers, the necessity of flexible automotive primers, and the importance of meticulous surface preparation. Additionally, it highlights key brands dominating the market and directs professionals to trusted resources for making informed primer selections. Each chapter builds a foundation to help business owners enhance their product quality and operational efficiency by choosing the optimal primers for motorcycle fairings.

Tables of Contents

Chapter 1: Understanding Plastic Adhesion Primers for Best Primer for Motorcycle Fairings

- The Chemistry Behind Plastic Adhesion Primers: Enhancing Durability and Flexibility for Motorcycle Fairings

- Unlocking Superior Paint Adhesion: The Crucial Surface Preparation for Plastic Adhesion Primers

- Proven Application Techniques to Enhance Plastic Primer Performance on Motorcycle Fairings

- Key Primer Types and Performance Insights for Superior Adhesion on Motorcycle Fairings

- Ensuring Long-Lasting Durability and Flawless Finish with Plastic Adhesion Primers

Chapter 2: Crucial Role of Flexible Automotive Primers in Enhancing Motorcycle Fairings

- How Technological Innovations Elevate Flexible Primers for Durable Motorcycle Fairings

- How Flexible Automotive Primers Deliver Long-Term Cost Savings for Motorcycle Fairings

- How Global Trade Dynamics Shape the Demand for Flexible Automotive Primers in Motorcycle Fairings

- Enhancing Sustainability and Rider Experience Through Flexible Automotive Primers

- Material Science Insights: Why Flexibility and Adhesion Define the Best Primers for Motorcycle Fairings

Chapter 3: Surface Preparation Techniques for Achieving the Best Primer for Motorcycle Fairings

- Mastering Cleaning and Degreasing for Optimal Primer Adhesion on Motorcycle Fairings

- Essential Sanding and Abrasion Control to Optimize Primer Adhesion on Motorcycle Fairings

- Enhancing Primer Adhesion with Etch Primers and Adhesion Promoters in Motorcycle Fairing Preparation

- Mastering High Build Primers: Essential Surface Prep for Flawless Motorcycle Fairings

- Optimizing Drying, Curing, and Primer Layering to Maximize Adhesion on Motorcycle Fairings

Chapter 4: Recommended Brands and Products in the Best Primer for Motorcycle Fairings Market

- Trusted Primer Solutions That Ensure Superior Adhesion and Flexibility for Motorcycle Fairings

- Cutting-Edge Primer Technologies Enhancing Adhesion and Durability for Motorcycle Fairings

- Economic Dynamics Shaping Leading Primer Brands in Motorcycle Fairing Markets

- How Geopolitical Forces Shape Primer Brand Preferences in Motorcycle Fairing Markets

- Balancing Performance with Environmental and Social Responsibility in Motorcycle Fairing Primers

Chapter 5: Professional Guidance and Resources for Selecting the Best Primer for Motorcycle Fairings

- Crucial Material Compatibility Considerations for Primers on Motorcycle Fairings

- Mastering Surface Preparation: Essential Techniques for Optimal Primer Adhesion on Motorcycle Fairings

- Choosing the Right Primer Types for Durable Motorcycle Fairing Finishes

- Trusted Products and Expert Recommendations for Priming Motorcycle Fairings

- Mastering Primer Application: Proven Techniques for Flawless Motorcycle Fairing Finishes

Chapter 1: Understanding Plastic Adhesion Primers for Best Primer for Motorcycle Fairings

1. The Chemistry Behind Plastic Adhesion Primers: Enhancing Durability and Flexibility for Motorcycle Fairings

Plastic adhesion primers play a vital role in preparing motorcycle fairings, often crafted from ABS, polypropylene, or polyethylene, for durable paint application. These primers chemically increase the surface energy of inherently low-energy plastics, improving wettability and promoting mechanical bonding with paint layers. By forming a thin protective layer, they also enhance chemical resistance against oils, solvents, UV rays, and moisture—environmental factors motorcycles frequently encounter. The primer’s compatibility with specific plastic types ensures strong flexibility and adhesion, preventing cracking and peeling amidst vibrations and flexing. Solvent-based primers, which react with moisture to create a robust bond, further support coating longevity. Proper selection rooted in understanding these chemical properties ensures a uniform, weather-resistant finish that withstands the rigors of riding. For deeper insights into primer chemistry and plastic compatibility, visit this comprehensive guide on plastic adhesion primers.

2. Unlocking Superior Paint Adhesion: The Crucial Surface Preparation for Plastic Adhesion Primers

Achieving a durable, flawless finish on motorcycle fairings begins with meticulous surface preparation tailored for plastic adhesion primers. First, the fairing’s surface must be thoroughly cleaned to remove oils, dust, and residues that impede primer bonding. Using lint-free cloths with appropriate solvents ensures a contaminant-free base. Next, lightly sanding the plastic with fine grit sandpapers between P400 and P600 creates a textured profile that enhances mechanical adhesion without harming the substrate. Plastic-specific adhesion primers then seal this surface, improving paint durability by bridging the low surface energy of plastics. Following the adhesion primer, applying a high-build primer smooths imperfections, readying the fairing for multiple thin coats of flexible, heat-resistant paint. This process ensures the primer and paint layers flex harmoniously, resisting cracking under stress. For detailed techniques and visual guidance, refer to expert tutorials like the comprehensive video available here. Explore more on quality motorcycle components at this resource.

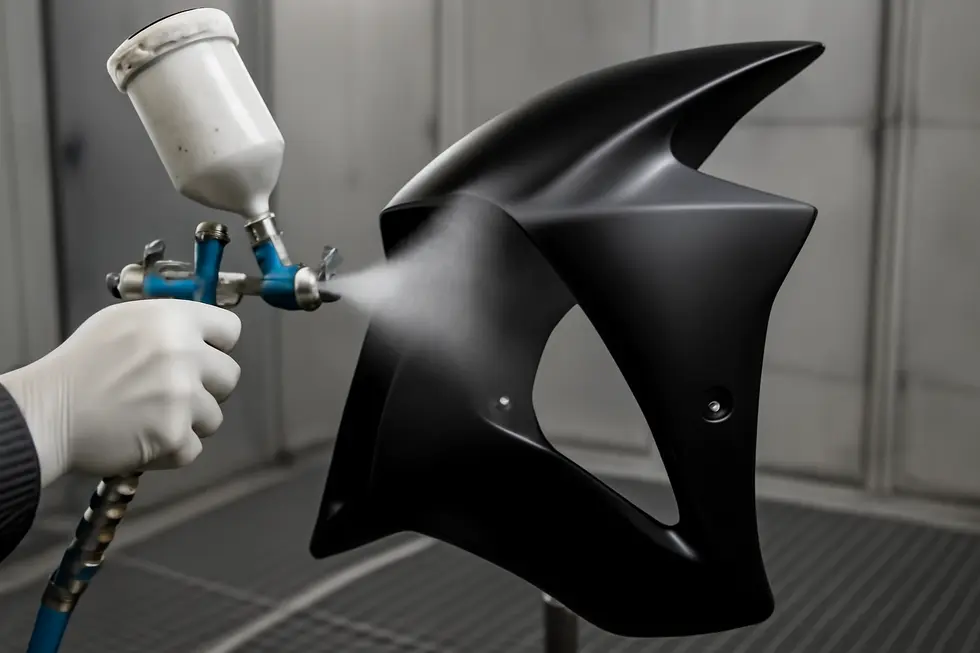

3. Proven Application Techniques to Enhance Plastic Primer Performance on Motorcycle Fairings

Achieving lasting adhesion for motorcycle fairings made from ABS and similar plastics hinges on precise application methods. Begin with thorough cleaning using mild soap followed by isopropyl alcohol to remove contaminants. Lightly sanding the surface with 400-600 grit sandpaper creates essential texture for primer bonding. Select a primer designed specifically for plastic substrates to ensure compatibility and flexibility. Apply a single, thin, and even coat using a soft applicator like foam or felt, maintaining ambient temperatures between 15°C and 25°C. Allow sufficient drying time as specified by the primer manufacturer before proceeding. Subsequent paint layers should be applied thinly and with full curing between coats to prevent peeling and cracking under stress. These carefully coordinated steps enhance paint durability and protect motorcycle fairings against vibration-induced damage. For expanded insights into primer methods tailored to ABS plastics, refer to detailed guides available online, such as this expert resource. For further details on quality fairing options, check out explore the best motorcycle fairings at Summit Fairings.

4. Key Primer Types and Performance Insights for Superior Adhesion on Motorcycle Fairings

Choosing the right primer for motorcycle fairings hinges on selecting products formulated specifically for plastics like ABS. Plastic adhesion primers chemically bond to smooth, non-porous surfaces, ensuring durable paint adherence and preventing peeling under flex and vibration. Urethane-based primers offer exceptional toughness and compatibility with common automotive paints, enhancing longevity and resistance to UV and weathering. Clear adhesion promoters provide an effective, color-neutral base layer, improving paint grip without affecting finish aesthetics. Proper surface preparation including sanding and cleaning remains essential for optimal results. Spray application of thin, even coats with proper drying maximizes primer performance, contributing to a resilient and lasting finish. For deeper insights on fairings and prep methods, explore quality motorcycle fairings options. Detailed techniques can also be viewed in expert tutorials such as this plastic primer spray tutorial.

5. Ensuring Long-Lasting Durability and Flawless Finish with Plastic Adhesion Primers

Plastic adhesion primers for motorcycle fairings are essential to achieving a durable, protective, and aesthetically pleasing finish. These primers bond strongly to smooth plastic surfaces, ensuring paint adheres firmly without flaking or peeling, even under vibration and flexing. They also offer vital protection against UV rays, moisture, and chemical exposure, which preserves both the plastic substrate and the paint over time. Achieving a flawless finish requires careful application of multiple thin coats, allowing each to dry thoroughly, which prevents texture imperfections. Flexible primers enhance this by accommodating fairing movement, maintaining the integrity of the paintjob. Proper surface sanding and cleaning are foundational in maximizing the primer’s effectiveness. For further preparation techniques, see the detailed paint prep video here.

Chapter 2: Crucial Role of Flexible Automotive Primers in Enhancing Motorcycle Fairings

1. How Technological Innovations Elevate Flexible Primers for Durable Motorcycle Fairings

Technological innovations in material science have transformed the requirements for primers on motorcycle fairings. Modern fairings, often crafted from plastics and advanced composites like carbon fiber, demand primers that flex with vibrations and mechanical stresses without cracking. Flexible automotive primers meet these needs by offering superior adhesion and resilience, ensuring the paint layers remain intact despite continual environmental challenges like UV exposure, temperature shifts, and abrasion. Their compatibility with diverse topcoats and durability against chemical and physical wear makes them indispensable for long-lasting finishes. As materials evolve, so do primers, emphasizing the need for flexible formulations that protect and preserve motorcycle fairings effectively. For further insight, explore detailed paint preparation techniques in expert tutorials here.

2. How Flexible Automotive Primers Deliver Long-Term Cost Savings for Motorcycle Fairings

Flexible automotive primers play a crucial role in reducing the overall costs associated with motorcycle fairings. Their ability to adhere strongly and flex with plastic fairings significantly lowers the risk of paint cracking, peeling, or chipping, minimizing the need for frequent repairs and repainting. This durability directly translates into reduced maintenance expenses and preserves the motorcycle’s resale value, as a well-finished exterior appeals more to buyers. Additionally, flexible primers simplify application on complex surfaces, cutting production and customization costs. They also help maintain fairing integrity, which can indirectly improve fuel efficiency by preserving aerodynamic contours. These factors combine to make flexible primers an economically savvy choice. For detailed techniques on preparation and application, expert guidance is available in this paint prep tutorial. For more on motorcycle fairing options, explore resources like Summit Fairings’ comprehensive blog.

3. How Global Trade Dynamics Shape the Demand for Flexible Automotive Primers in Motorcycle Fairings

Global trade tensions and supply chain disruptions significantly influence the need for flexible automotive primers in motorcycle fairings. Tariffs and regional manufacturing shifts compel manufacturers to source primers adaptable to different environments, reducing reliance on single suppliers. Moreover, varying environmental regulations across countries demand primers that comply with diverse standards without frequent reformulations. As electric vehicle markets evolve unevenly worldwide, primers must accommodate changing materials and performance needs tied to composites used in fairings. Thus, geopolitical factors directly drive the development and use of flexible primers, enabling consistent quality and durability despite the complex landscape manufacturers navigate. For deeper insights, see the detailed industry analysis here.

4. Enhancing Sustainability and Rider Experience Through Flexible Automotive Primers

Flexible automotive primers significantly extend the lifespan of motorcycle fairings by adapting to vibrations and flexing without cracking. This durability reduces the need for frequent repainting or repairs, minimizing environmental waste and lowering resource consumption. Beyond sustainability, flexible primers improve rider safety by preserving the fairing’s structural integrity and corrosion resistance. They also support cost-effective maintenance and encourage personalized customization, enhancing the motorcycle culture through reliable, high-quality finishes. By investing in flexible primers, the motorcycle community benefits from lasting aesthetics and environmental responsibility. For deeper insights on primer application and properties, consult expert resources such as the detailed paint prep video here.

5. Material Science Insights: Why Flexibility and Adhesion Define the Best Primers for Motorcycle Fairings

Flexible automotive primers serve a vital role in motorcycle fairings by balancing elasticity with strong adhesion. These fairings endure constant vibrations, flexing, and impact, demanding primers that stretch without cracking or peeling. From a materials science standpoint, formulations often incorporate urethane-modified epoxies or elastomeric additives to achieve mechanical resilience and chemical stability. Such primers bond effectively to plastic substrates while providing corrosion resistance for any metal components. They also smooth imperfections and enable sanding before final coatings. This blend of toughness and flexibility ensures the paint remains intact through stress and environmental exposure, making the primer a cornerstone of durable fairing finishes. For detailed primer application techniques, see this expert paint prep tutorial.

Chapter 3: Surface Preparation Techniques for Achieving the Best Primer for Motorcycle Fairings

1. Mastering Cleaning and Degreasing for Optimal Primer Adhesion on Motorcycle Fairings

Thorough cleaning and degreasing are foundational for ensuring primer properly adheres to motorcycle fairings, which are often made of plastic or fiberglass. Removing oils, waxes, grease, and dirt with a quality degreaser prevents common issues like peeling and bubbling. After degreasing, wiping with a lint-free cloth and using isopropyl alcohol or specialized surface cleaners guarantees a contaminant-free base. Light sanding with fine-grit sandpaper creates a subtle texture that enhances primer grip without damaging the substrate. Finally, a tack cloth or solvent wipe clears sanding dust, promoting a smooth and durable primer layer. Such meticulous preparation maximizes paint job longevity and finish quality, critical for high-performance fairings. For additional insights on motorcycle fairing care, explore trusted motorcycle fairings resources available online. Reference tutorial.

2. Essential Sanding and Abrasion Control to Optimize Primer Adhesion on Motorcycle Fairings

Achieving a durable primer finish on motorcycle fairings begins with precise sanding and controlled abrasion. Starting with medium grit sanding pads, typically 400–600 grit, helps remove old coatings and surface imperfections without damaging the plastic substrate. Progressing to finer grits around 800–1000 ensures a smooth, uniformly roughened surface, creating the ideal “tooth” for primers to adhere. Abrasion control is critical—gentle, even pressure prevents overheating or melting of plastic and avoids deep scratches that harmful affect primer performance. After sanding, thorough cleaning eliminates dust and oils, securing primer adhesion and longevity. For detailed guidance on sanding and prepping your fairings, consider expert surface preparation tutorials such as the one available at Time Warp Custom Paint sanding demo. To explore quality motorcycle fairings for your project, visit Summit Fairings’ blog.

3. Enhancing Primer Adhesion with Etch Primers and Adhesion Promoters in Motorcycle Fairing Preparation

Achieving optimal primer adhesion on motorcycle fairings requires a carefully executed sequence involving etch primers and adhesion promoters. Etch primers chemically roughen metal surfaces at a microscopic level, improving mechanical bonding and corrosion resistance crucial for any metal components embedded in fairings. Conversely, adhesion promoters are essential for plastic substrates like ABS, creating a chemical bridge that prevents peeling and flaking as the fairing flexes. The process begins with thorough cleaning and sanding to prepare the surface texture, followed by applying the adhesion promoter to plastic areas and etch primer to metal parts. This combination ensures a robust, flexible bond that sustains paint integrity despite vibration and movement. Subsequent high-build primers smooth imperfections for a flawless finish. For comprehensive preparation tips and demonstrations, explore detailed guides such as the tutorial found here. Additionally, for a wide selection of high-quality fairings to complement your refinishing efforts, visit Summit Fairings.

4. Mastering High Build Primers: Essential Surface Prep for Flawless Motorcycle Fairings

Achieving a perfect finish on motorcycle fairings requires more than just the right primer—it relies heavily on meticulous surface preparation paired with high build primers. Begin by thoroughly cleaning the fairing to eliminate dirt, grease, or residues that can compromise adhesion. Sanding plays a vital role; start with 180-grit sandpaper to smooth out major imperfections, then progress to 240 and finally 320 grit for a refined surface free from scratches. Applying multiple coats of a quality two-component urethane high build primer with proper equipment ensures minor dents and scratches are filled effectively. Sanding between coats with 320–400 grit wet sandpaper further refines the surface, optimizing adhesion and paint smoothness. For fairings made of plastics, using an epoxy primer first can enhance adhesion before the high build urethane primer. Ensuring full curing and compatibility of primers and hardeners during this process solidifies a durable, paint-ready base. For comprehensive techniques and demonstrations, expert tutorials such as the detailed paint prep video offer valuable visual guidance. This layered approach provides a resilient, smooth foundation essential for lasting, flawless paint on motorcycle fairings. More information on motorcycle fairings and related projects can be found in Summit Fairings’ resource hub.

5. Optimizing Drying, Curing, and Primer Layering to Maximize Adhesion on Motorcycle Fairings

Achieving a flawless primer layer on motorcycle fairings relies heavily on meticulous drying, curing, and layering strategies during surface preparation. After thorough cleaning and precise sanding, applying multiple thin coats of primer ensures even coverage and prevents defects such as runs or uneven adhesion. Each layer must dry adequately, typically 15–30 minutes to the touch, before adding the next, while full curing may take 24 to 48 hours depending on environmental conditions. Controlling temperature and humidity is essential to promote consistent drying and avoid issues like peeling or blistering. Patience in allowing paint and primer to cure fully before reinstallation preserves the finish’s durability and resilience amid the stresses motorcycle fairings endure. For detailed sanding and prep insights, see expert tutorials on effective plastic surface preparation here. This approach complements the broader strategies outlined in mastering surface preparation for premium primer adhesion.

Chapter 4: Recommended Brands and Products in the Best Primer for Motorcycle Fairings Market

1. Trusted Primer Solutions That Ensure Superior Adhesion and Flexibility for Motorcycle Fairings

Leading primer solutions in the motorcycle fairings market prioritize adhesion, flexibility, and compatibility with both plastic and metal surfaces. Effective products include versatile sandable primers ideal for plastic and metal, adhesion promoters specializing in enhancing paint grip on plastics, and self-etch primers suited for aluminum components. Such primers accommodate the fairings’ constant flex and vibration, preserving paint durability. Complementing these are durable clear coats that protect finishes from wear and environmental damage. Choosing from these proven options ensures a smooth, resilient base coat that withstands mechanical stress. For deeper insights into primer options and application tips, explore detailed resources like AutoZone’s primer guide or visit Summit Fairings’ blog for expert advice.

2. Cutting-Edge Primer Technologies Enhancing Adhesion and Durability for Motorcycle Fairings

The best primers for motorcycle fairings leverage advanced technologies to improve adhesion, flexibility, and durability essential for plastic surfaces. These primers feature sandable formulas, allowing smooth surface refinements before painting, which elevates the final finish quality without excessive labor. Their multi-surface compatibility ensures strong bonding over both plastic fairings and metal components common in motorcycle assemblies. Durability is enhanced through corrosion resistance and elasticity, accommodating frequent vibrations and flexing while protecting against environmental wear. Additionally, fast-drying properties optimize workflow efficiency in repair or production settings. These innovations exemplify how primer technology evolves to meet the rigorous demands of modern motorcycle fairings, aligning perfectly with professional painting standards. For a practical overview of surface preparation and primer application techniques, see this expert tutorial on paint prep here. To explore quality motorcycle fairings and compatible finishes, visit the comprehensive resource at Explore the Best Motorcycle Fairings at Summit Fairings.

3. Economic Dynamics Shaping Leading Primer Brands in Motorcycle Fairing Markets

The economic influence of top primer brands in the motorcycle fairing market hinges on quality-driven pricing and strategic value bundling. Premium primers command higher prices thanks to superior adhesion and flexibility, attracting both DIY enthusiasts and professionals. Brands often bundle primers with installation accessories, enhancing customer value while boosting margins. Advanced primer formulations reduce labor time by minimizing coats and easing sanding, cutting overall project costs. Growing customization trends push demand for specialized primers, fueling market expansion. Many manufacturers prioritize sustainable growth and innovation, reflecting a shift from volume-driven sales to long-term customer relationships. For those exploring fairing options, discover affordable motorcycle fairings at Summit Fairings offers valuable insights. Supplementary guidance on paint preparation techniques can be found in expert tutorials such as the detailed video at https://www.youtube.com/watch?v=85lnPyn-ofs.

4. How Geopolitical Forces Shape Primer Brand Preferences in Motorcycle Fairing Markets

Geopolitical factors deeply influence which primer brands dominate motorcycle fairing markets worldwide. Rapid growth in Asia-Pacific, fueled by rising motorcycle ownership, drives demand for affordable, quality primers suited to local consumers. In contrast, stricter environmental regulations in Europe and North America push brands to innovate eco-friendly, durable primers that meet high standards. Cultural riding styles, such as long-distance touring in the West, create a preference for flexible, rugged primers, while emerging markets often prioritize cost-effectiveness. Trade policies and material supply chains also affect product availability and pricing. Consequently, globally recommended primers reflect these regional nuances, balancing compliance, performance, and cost. For further insights into market dynamics, consult the comprehensive Riding Gear Market analysis by Mordor Intelligence.

5. Balancing Performance with Environmental and Social Responsibility in Motorcycle Fairing Primers

Selecting the best primer for motorcycle fairings extends beyond performance to include environmental and societal impact. Many primers act on ABS plastic, a durable yet petroleum-based material with recycling challenges and carbon emission concerns. Prioritizing low-VOC, water-based primers reduces harmful emissions and health risks during application. Ethical manufacturing practices, especially among niche brands, emphasize fair labor and sustainable sourcing, supporting social welfare. Advances in waste-reducing technologies, like additive manufacturing, show promise in minimizing ecological footprints while demanding skilled craftsmanship. Consumers and manufacturers alike should consider these critical factors to promote sustainability and responsibility within the motorcycle fairings aftermarket. For further insight on fairing materials and environmental impact, see the UNDP report. For discovering extensive motorcycle fairing options, visit Summit Fairings blog.

Chapter 5: Professional Guidance and Resources for Selecting the Best Primer for Motorcycle Fairings

1. Crucial Material Compatibility Considerations for Primers on Motorcycle Fairings

Choosing the best primer for motorcycle fairings hinges on understanding material compatibility. Most fairings are crafted from high-impact ABS plastic, requiring primers designed specifically for plastic to ensure durable adhesion and prevent flaking. Fiberglass fairings demand a different approach—applying a quality primer often paired with a gel coat enhances bonding and surface durability. Urethane primers stand out for their versatility, bonding well with both ABS and fiberglass while accommodating various topcoats. Professional advice stresses verifying primer compatibility with the fairing material and paint type to avoid peeling or bubbling. For detailed expert preparation methods and product insights, consult comprehensive tutorials such as this paint prep video. For further fairing selection and primer guidance, explore Summit Fairings’ informative blog resources.

2. Mastering Surface Preparation: Essential Techniques for Optimal Primer Adhesion on Motorcycle Fairings

Mastering Surface Preparation is crucial for achieving lasting paint adhesion on motorcycle fairings, typically made from ABS or fiberglass. Start by thoroughly cleaning all surfaces to remove oils and contaminants, ensuring a pristine base. Then, sanding with 600–800 grit pads creates a subtle texture, enhancing primer bonding without damaging the substrate. Applying plastic-specific or etch primers provides a chemical bond tailored for non-porous plastics. Follow with high-build primer coats for an even, smooth surface ready to accept paint. Proper curing and selecting compatible paint and primer systems preserve durability against environmental stress and flexing. For a visual walkthrough, expert tutorials like those from Time Warp Custom Paint offer valuable insights: https://www.youtube.com/watch?v=85lnPyn-ofs. Explore expert resources such as affordable motorcycle fairings for further understanding.

3. Choosing the Right Primer Types for Durable Motorcycle Fairing Finishes

Selecting the appropriate primer is crucial for achieving a lasting finish on motorcycle fairings, which are mainly composed of plastics like ABS or polycarbonate. Plastic adhesion promoters are essential, as they create a reliable bond between paint and the non-porous surface, preventing peeling and flaking caused by vibrations and flexing. While etching primers excel on metal, they are unsuitable for plastics, where flexible, plastic-specific primers or two-component (2K) primers offer superior durability and chemical resistance. Assessing the fairing’s material and planned paint type ensures the right primer choice. For expert guidance and products tailored to motorcycle fairings, professional resources like specialized motorcycle paint suppliers provide indispensable support. More insights on fairing finishes can be found at Explore the Best Motorcycle Fairings at Summit Fairings. For detailed preparation and application techniques, consult expert tutorials such as this paint prep video.

4. Trusted Products and Expert Recommendations for Priming Motorcycle Fairings

**Selecting the right primer for motorcycle fairings involves relying on products designed specifically for plastic substrates such as ABS. Professionals emphasize primers that provide exceptional adhesion while maintaining flexibility to endure vibrations and flexing during rides. Industry-preferred primers offer smooth application and compatibility with subsequent paint layers, ensuring durability and finish quality. Equally important is surface preparation using fine grit sanding pads to optimize primer bonding. Following expert guidance and using recommended materials builds a reliable foundation for long-lasting paintwork. For detailed surface prep techniques and product demos, consult reputable tutorials available online, such as this painting prep video. For additional insights on quality motorcycle fairings and related finishing tips, explore resources like Summit Fairings blog.

5. Mastering Primer Application: Proven Techniques for Flawless Motorcycle Fairing Finishes

Achieving a durable, smooth finish on motorcycle fairings starts with meticulous surface preparation. Sanding with progressively finer grits removes imperfections and promotes primer adhesion. Applying a high-build, flexible two-component primer formulated for plastics in multiple thin coats creates an even base, essential for preventing cracking and peeling. Each primer layer should be allowed adequate drying time and followed by light sanding with fine grit to maintain smoothness. These careful steps ensure the primer contours the fairing’s shape while withstanding riding vibrations. For those seeking expert-level insight, specialized automotive paint courses and detailed video tutorials demonstrate these techniques effectively. To deepen your understanding, explore the comprehensive surface prep methods shared in this highly recommended guide.

Final thoughts

Selecting the best primer for motorcycle fairings means prioritizing plastic adhesion, flexibility, and thorough surface preparation. Business owners who invest time in understanding these factors will enjoy improved paint durability, reduced maintenance, and enhanced customer satisfaction. The market offers several trusted primers tailored for plastic substrates that can withstand the mechanical stresses motorcycle fairings endure. Coupling product knowledge with expert guidance and proper techniques creates a solid foundation for delivering professional results. By integrating these insights into your workflow, your business can establish a reputation for quality finishes and reliable performance in motorcycle fairing applications.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined