Introduction

Motorcycle fairings serve essential roles, from improving aerodynamics to protecting riders and enhancing aesthetics. For business owners in the motorcycle aftermarket sector, sourcing affordable yet quality fairings is a strategic challenge that directly affects customer satisfaction and profitability. Understanding the materials and quality considerations, exploring the key market options, and analyzing the economic and practical trade-offs involved are crucial to making informed purchasing decisions. This comprehensive overview provides actionable insights to navigate the diverse landscape of cheap motorcycle fairings, empowering businesses to select products that align with budget constraints without compromising value. Each chapter builds on one another: beginning with the core material and quality aspects, moving to a review of leading suppliers and product offerings, and concluding with the economic realities impacting procurement decisions and customer expectations.

Tables of Contents

Chapter 1: Material and Quality Considerations in Cheap Fairings for Motorcycles

- Balancing Durability and Affordability: The Role of ABS Plastic and Lightweight Metals in Economical Motorcycle Fairings

- How Manufacturing Techniques Shape the Material Quality and Durability of Affordable Motorcycle Fairings

- Overcoming Fit and Finish Obstacles in Affordable Motorcycle Fairings

- Balancing Durability and Structural Integrity in Affordable Motorcycle Fairings

- The Crucial Role of Additional Components and Hardware in Affordable Motorcycle Fairings

Chapter 2: Market Options and Suppliers of Cheap Fairings for Motorcycles

- Exploring Leading Suppliers and Material Choices in Affordable Motorcycle Fairings

- Advanced Materials and Manufacturing Techniques Driving Affordable Motorcycle Fairings

- Economic Drivers Shaping Pricing and Competition Among Suppliers of Cheap Motorcycle Fairings

- Navigating Global Dynamics: How Geopolitics and Supply Chains Shape Accessibility and Cost of Affordable Motorcycle Fairings

- Embracing Style and Individuality: Trends and Consumer Preferences in Budget Motorcycle Fairings

Chapter 3: Economic and Practical Trade-offs When Purchasing Cheap Fairings for Motorcycles

- Balancing Material Quality and Longevity: The Core Trade-offs in Affordable Motorcycle Fairings

- Balancing Fitment Accuracy and Installation Effort in Affordable Motorcycle Fairings

- Weighing the Long-Term Financial Impact of Choosing Budget Motorcycle Fairings

- Balancing Visual Appeal and Practicality: Aesthetic and Finish Trade-offs in Budget Motorcycle Fairings

- Balancing Rider Comfort and Aerodynamics in Affordable Motorcycle Fairings

Chapter 1: Material and Quality Considerations in Cheap Fairings for Motorcycles

1. Balancing Durability and Affordability: The Role of ABS Plastic and Lightweight Metals in Economical Motorcycle Fairings

Cheap motorcycle fairings increasingly rely on ABS plastic as the core material, providing an effective balance of durability, weight, and cost. ABS is roughly 20% lighter than traditional metal alternatives, which contributes to improved motorcycle handling and fuel efficiency by reducing overall drag. Its inherent weather resistance, including protection against UV rays and corrosion, makes ABS suitable for all riding conditions without degrading rapidly. Additionally, ABS’s pliability allows manufacturers to mold complex aerodynamic shapes more easily than metals, enhancing wind resistance reduction by up to 25%.

Complementing ABS fairings, mounting hardware typically uses lightweight metals such as aluminum and steel. These materials offer robust strength to safely secure fairings against vibrations and wind pressure encountered at high speeds, ensuring reliable attachment without adding excessive weight. Adjustable brackets made from these metals grant compatibility across various motorcycle models, reducing the need for specialized mounts and lowering costs.

Fairing kits commonly include stainless steel fasteners, which resist rust and maintain structural integrity over time. By combining ABS plastic with metal mounting components, manufacturers strike a practical balance between performance, longevity, and affordability—fitting the needs of budget-conscious riders seeking functional yet reliable upgrades.

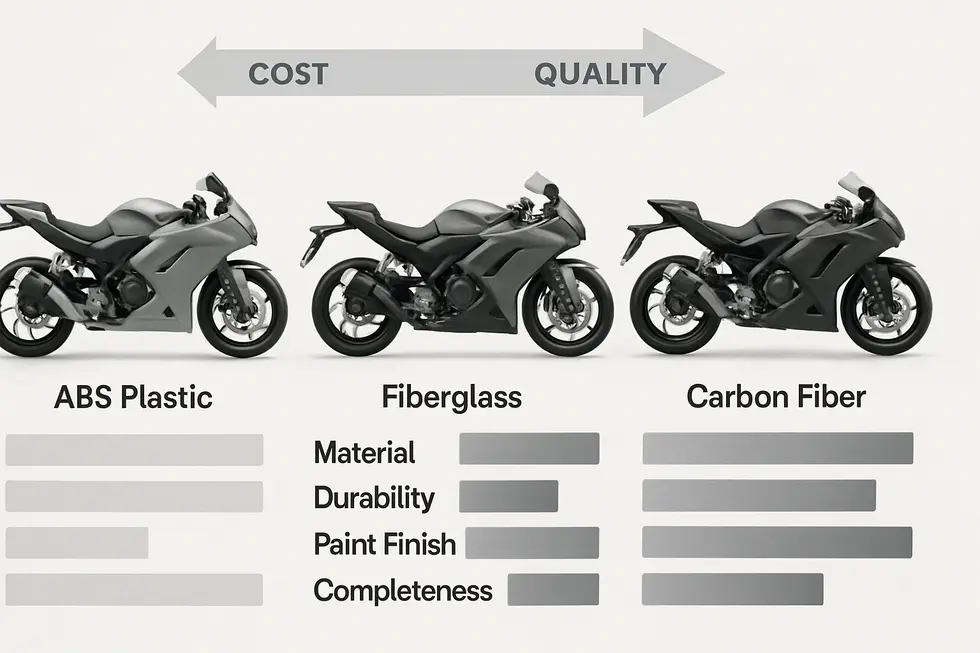

Though advanced composites like carbon fiber or filament-wound fiberglass can surpass ABS in strength-to-weight ratio, their higher prices and complex finishing requirements often place them beyond the scope of cost-effective options. Instead, ABS remains the predominant choice for economically priced fairings due to its mass-production suitability and favorable mechanical properties.

For riders interested in exploring affordable and durable options tailored for cost and quality, the market offers a variety of ABS-based kits with professional paint finishes and functional hardware designed for multiple major motorcycle brands. These products underscore the industry’s commitment to accessible customization and performance enhancement.

Explore more about the diverse range of affordable motorcycle fairings here.

Source: Alibaba Motorcycle Batwing Fairing Kit product details

2. How Manufacturing Techniques Shape the Material Quality and Durability of Affordable Motorcycle Fairings

Affordable motorcycle fairings commonly rely on the injection molding of ABS plastic, a process that balances cost, durability, and fitment accuracy. During injection molding, molten ABS plastic is pressed into precise OEM-grade molds, producing fairings that closely match original equipment in shape and size. This precision ensures that installation is often straightforward, with pre-drilled holes allowing bolt-on assembly without extensive modifications. ABS plastic’s inherent toughness and impact resistance make it a practical choice for budget fairings, though it is less resistant to severe impacts compared to fiberglass or carbon fiber composites.

The quality of these fairings largely depends on the molding precision and the finishing stages. Professional multi-layer painting procedures—from primers to multiple paint coats and clear finishes—enhance visual appeal and extend resistance to environmental factors like UV rays, moisture, and minor abrasions. The thoroughness of surface preparation and finishing can significantly elevate the perception of value and longevity in cheap fairings.

Beyond the molded parts themselves, many kits include hardware such as brackets, windscreens, and headlights, simplifying installation and improving customer satisfaction. While other manufacturing finishing methods, like mass finishing techniques used for metal components, do not apply directly to plastic fairings, the commitment to thorough finishing remains crucial to product quality.

Though injection molded ABS plastic fairings may not offer the lightweight strength of higher-end materials, their consistent fit and durability present a practical compromise for riders seeking affordable upgrades. For riders interested in exploring more about manufacturing and quality aspects of ABS fairings, detailed insights can be found through specialized suppliers dedicated to high-precision molding and professional finishes, offering a reliable source for cost-effective yet quality-focused parts.

For more on affordable, quality motorcycle fairings and their manufacturing, see Discover Affordable Motorcycle Fairings at Summit Fairings.

3. Overcoming Fit and Finish Obstacles in Affordable Motorcycle Fairings

Choosing cheap motorcycle fairings often involves navigating significant fit and finish challenges rooted in material quality and manufacturing precision. Lower-cost fairings frequently rely on less durable plastics or fiberglass, which are more susceptible to warping, cracking, or fading due to prolonged exposure to sunlight and weather. These material shortcomings commonly result in panels that fail to align correctly, creating visible gaps or rubbing points that not only detract from the bike’s appearance but can also hinder aerodynamic performance.

Installation is further complicated by inconsistencies such as uneven thicknesses and inaccurately placed pre-drilled holes. Such imprecision demands patience and occasional modifications to achieve a functional fit, contrasting sharply with the seamless mounting experience offered by higher-grade options. The surface finish on budget fairings is often uneven or thin, which diminishes visual appeal and leaves the components vulnerable to early wear and discoloration.

Structurally, these fairings lack post-impact resilience; even minor impacts may deform panels, worsening fitment over time and increasing the frequency of repairs or replacements. In contrast, fairings crafted with meticulous attention to mold precision and material selection strike a balanced harmony between weight, strength, and UV resistance, enabling smoother assembly and enduring aesthetics.

Understanding these limitations is crucial for riders seeking affordable upgrades without compromising functionality. While unpainted or fiberglass kits may offer the lowest upfront price, the noticeable drawbacks in fit and finish often translate to added effort during installation and a less polished end result. Navigating this balance is easier when informed by resources that highlight these challenges and recommend options that maximize value within a constrained budget. For a deeper dive into common fitment pitfalls and tips for installation success, the blog on affordable motorcycle fairings provides practical insights.

4. Balancing Durability and Structural Integrity in Affordable Motorcycle Fairings

Affordable motorcycle fairings commonly rely on lightweight ABS plastic, a material valued for its weather resistance and UV protection. This plastic balances a light weight—about 20% less than metal—with durability under normal riding conditions. However, absent the advanced composites found in premium fairings, ABS can become brittle when subjected to repeated strong impacts or extreme stress, occasionally leading to cracks or warping over time.

The structural integrity of these fairings also hinges on their mounting systems. Many budget fairings feature adjustable aluminum brackets and reinforced clamps designed for versatile fitment across various models. While this modularity aids installation, the stability depends heavily on the quality of mounting points and proper securing of hardware. Loose brackets or broken mounting tabs can cause vibrations or shifting during rides, which not only degrades durability but also risks rider safety.

Beyond the material and mounting hardware, the aerodynamic design incorporated in many inexpensive fairings is noteworthy. Even at entry-level price points, fairings often aim to reduce drag and improve stability at speeds up to 120 mph. Yet, these aerodynamic benefits are contingent on a precise fit and secure attachment; any compromise affects both functionality and longevity.

Signs such as cracks, faded finishes, or loose mounting serve as indicators of compromised structural integrity, signaling the need for timely maintenance or replacement. Ultimately, cheap fairings strike a careful compromise—offering reasonable weather resistance and aerodynamic advantages through ABS and adjustable mounts, yet inherently sacrificing some impact toughness and long-term resilience compared to premium alternatives. Ensuring correct installation and ongoing maintenance is vital to maximizing their durability and safety.

For further insights into typical materials and mounting strategies used in economical fairing kits, examine the detailed specifications available in the Motorcycle Batwing Fairing Kit example on Alibaba.

Additionally, riders interested in exploring a wide range of affordable fairing options with balanced quality may find value in exploring this collection of affordable motorcycle fairings.

5. The Crucial Role of Additional Components and Hardware in Affordable Motorcycle Fairings

When evaluating cheap motorcycle fairings, the quality of additional components and hardware plays a pivotal role in the overall durability and fit of the assembly. While the outer shell often garners most attention, it is the fasteners, mounting brackets, and internal reinforcements that determine how well a fairing performs under vibration, stress, and impact. Affordable fairings tend to compromise here, using plastic or nylon mounting points without the metal inserts found in higher-quality versions. These metal inserts, commonly aluminum, strengthen critical attachment areas, reducing the risk of cracking or stripping during installation or road use.

Fasteners included in low-cost kits often prioritize savings over longevity. Bolts, screws, and clips may be constructed from lower-grade metals prone to corrosion, weakening their ability to firmly secure the fairing. This can result in an insecure fit that may lead to rattling, misalignment, or even detachment over time. In contrast, better aftermarket options include hardware designed to resist corrosion and endure the stresses of daily riding.

Another dimension is the presence or absence of additional protective components such as frame sliders, impact-absorbing brackets, or abrasion-resistant reinforcements. These features are invaluable for safeguarding both the fairing and motorcycle frame during minor collisions or drops. Budget fairings frequently omit these altogether or substitute them with inferior materials that offer minimal protection, further affecting overall value.

The workmanship and finishing applied to these extra parts also influences longevity. Poorly finished hardware can wear prematurely or rust, compromising both the aesthetic appeal and structural security of the fairings. In sum, while cheap fairings may appeal through initial pricing, their compromise on the quality of supplemental components often results in reduced durability and poorer fitment.

For riders seeking affordable yet dependable solutions, understanding these hardware disparities is essential. More detailed insights into related hardware quality, particularly frame sliders, can be found in this guide on frame sliders and motorcycle accessories.

Chapter 2: Market Options and Suppliers of Cheap Fairings for Motorcycles

1. Exploring Leading Suppliers and Material Choices in Affordable Motorcycle Fairings

The market for affordable motorcycle fairings features diverse suppliers who balance cost with quality, fit, and customization. Among these, manufacturers specializing in ABS plastic fairings dominate due to the material’s durable yet economical nature. One key supplier produces OEM-grade ABS plastic fairings using precision injection molding, ensuring excellent fit and durability. They offer complete kits with options for custom paint, tank covers, and windscreens that suit popular motorcycle brands such as Honda, Yamaha, Kawasaki, Ducati, BMW, and Triumph. This approach appeals to riders seeking value without compromising factory-like finishes.

Parallel to this, multiple overseas producers accessible through global trade platforms offer a variety of aftermarket fairings, leveraging ABS plastic and carbon fiber materials. These firms frequently hold certifications, catering to broad markets including Europe, North America, and Southeast Asia, and provide customization options tailored to high-demand models like Kawasaki Ninja and Yamaha sportbikes. This export experience brings economies of scale that reduce costs while maintaining acceptable quality.

Specialized custom parts vendors complement this landscape by focusing on specific niches such as Harley-Davidson and vintage motorcycles. These suppliers emphasize fitment guarantees and innovative designs that appeal to enthusiasts customizing their rides on tighter budgets. Similarly, providers focusing on DIY enthusiasts offer affordable aftermarket parts with streamlined shipping and customer support, targeting garage builders and hobbyists.

While carbon fiber parts are generally more expensive, fiberglass fairings provide a lighter yet cost-effective alternative suited for both street and track use. This variety means riders can choose based on performance needs and budget constraints. Ultimately, for those seeking the best balance of affordability, quality, and completeness, suppliers offering professionally molded ABS kits with customization and accessories stand out.

For a deeper look at affordable motorcycle fairings choices, visit Discover Affordable Motorcycle Fairings at Summit Fairings.

External resource: Kings Motorcycle Fairings – About Us

2. Advanced Materials and Manufacturing Techniques Driving Affordable Motorcycle Fairings

The landscape of affordable motorcycle fairings is shaped by strategic choices in materials and manufacturing technologies designed to balance cost, durability, and aesthetic appeal. Affordable fairings predominantly utilize ABS plastic, prized for its toughness, lightweight nature, and flexibility during impacts. This material’s compatibility with injection molding allows manufacturers to produce parts with precise OEM-level fitment and consistent structural integrity. Injection molding also accelerates production, making it economically viable to offer pre-drilled, bolt-on kits that simplify installation without sacrificing quality.

These manufacturing advances enable suppliers to include multi-layer professional paint finishes, often featuring expertly applied primers and clear coats. This approach elevates the visual quality and extends the lifespan of fairings, achieving a premium look without excessive expense. Moreover, customization options—such as alternative color schemes and decals—add value, broadening appeal without complicating production.

While ABS plastic dominates the budget-friendly segment, carbon fiber fairings represent a higher-cost alternative favored by riders prioritizing performance due to carbon’s superior strength-to-weight ratio. Nevertheless, carbon fiber’s expense limits its presence mainly to specialized aftermarket options rather than broad low-cost availability.

In the realm of vintage or custom chopper fairings, fiberglass remains relevant as a hand-crafted choice, although it generally involves a different production scale and price point, reflecting more artisanal manufacturing methods.

Ultimately, the integration of durable composite materials like ABS with precision injection molding and professional finishing techniques empowers suppliers to deliver cost-effective fairings that do not compromise on fit or durability. These advancements underpin the availability of high-quality, affordable motorcycle fairings suitable for both practical replacements and style-conscious customization. For a deeper exploration of affordable options, interested riders can visit this ultimate source for affordable motorcycle fairings.

Reference: Kings Motorcycle Fairings manufacturing and materials overview [1]

3. Economic Drivers Shaping Pricing and Competition Among Suppliers of Cheap Motorcycle Fairings

The market for affordable motorcycle fairings is shaped by economic factors that influence pricing and supplier competitiveness. Key players range from online retailers offering direct-to-consumer sales to regional wholesalers who leverage bulk purchasing power. Online platforms typically present a wide selection of fairings designed for specific models, balancing exact-fit precision with accessible price points—often between $70 and $250. These suppliers enhance their appeal by providing discounts, free shipping, and customer-friendly return policies, which can justify slightly higher base prices and foster buyer confidence.

Wholesalers, particularly in large manufacturing hubs, drive down costs through economies of scale, enabling them to offer aggressive pricing when selling in bulk. This cost advantage trickles down to end consumers, especially those willing to purchase large volumes or work with local distributors. Meanwhile, aftermarket specialists blend competitive pricing with versatile product ranges that include both custom and universal fit fairings. Their strategies include comprehensive customer service policies, such as no restocking fees and free shipping over certain thresholds, which increase market appeal.

Supplier competitiveness hinges not only on pricing but also on how well they manage product quality and service to meet diverse rider needs. Exact-fit parts command premiums due to design intricacies and the demand for seamless replacements or upgrades. Conversely, more generic offerings may sacrifice fit precision for cost savings, appealing to a different segment of price-sensitive riders. Market demand trends further influence inventory and pricing strategies, with styles like cafe racer fairings fluctuating in popularity and impacting supplier focus.

These economic dynamics create a diverse landscape where consumers can select from a spectrum of price-quality trade-offs. Suppliers who successfully combine cost efficiency with value-added services maintain strong positions in this competitive market. For those exploring detailed product listings and competitive pricing strategies, a thorough overview can be found through specialized online retailer sections tailored for various motorcycle styles and budgets. More insights on affordable options and market trends are available at discover affordable motorcycle fairings.

For direct reference to the role of online retail platforms in shaping pricing and offerings, see the range featured by RevZilla that balances exact fitment and customer incentives.

4. Navigating Global Dynamics: How Geopolitics and Supply Chains Shape Accessibility and Cost of Affordable Motorcycle Fairings

The market for affordable motorcycle fairings relies heavily on a global network shaped by geopolitical forces and complex supply chains. Most budget-friendly fairings are manufactured in Asia, where lower labor costs and advanced injection molding technologies allow suppliers to produce durable ABS plastic kits with reasonable quality and fit. Yet, this reliance adds vulnerability. Trade tensions and tariffs imposed on raw materials like ABS plastic or finished goods create ripple effects that push prices higher and delay shipments. Export restrictions and shipping bottlenecks further complicate timely availability of these products, especially when materials or components face shortages stemming from volatile petrochemical markets.

Transparency into the supply chain reveals how critical factors like the sourcing of premium plastics and multi-stage painting processes influence affordability and product quality. Injection molding precision defines fit, while layered paint finishes add desirable appearance but also increase cost. Freight disruptions and fluctuating currency exchange rates amplify price variability for Western buyers importing from Asia or other manufacturing hubs.

Meanwhile, niche suppliers working closer to their customer bases often offer hand-assembled kits tailored to specific models, blending localized expertise with supply chain agility. However, such offerings may carry moderate price premiums reflecting craftsmanship and shipping logistics.

This intricate interplay underscores why the cheapest fairings often come as unpainted or fiberglass kits sourced from broad aftermarket channels but may sacrifice perfect fit or finish. Riders balancing cost with quality find that leveraging advanced manufacturing from specialized suppliers achieves an optimal middle ground.

By understanding these global geopolitical and supply chain influences, buyers can better navigate the market’s diversity and dynamic pricing structures to secure affordable, reliable fairings fitting their motorcycles and budgets.

Explore more insights on sourcing affordable motorcycle fairings in this comprehensive guide from Summit Fairings’ blog: discover affordable motorcycle fairings at Summit Fairings.

For deeper reference on manufacturing origins and supplier backgrounds, visit this external resource: Kings Motorcycle Fairings About Us.

5. Embracing Style and Individuality: Trends and Consumer Preferences in Budget Motorcycle Fairings

The market for affordable motorcycle fairings is shaped profoundly by riders’ desire for personalization alongside budget-conscious choices. Consumers increasingly seek fairings that not only protect and improve aerodynamics but also reflect their unique style preferences. This shift has encouraged suppliers to offer diverse options, ranging from ready-to-install exact-fit kits to handcrafted custom styles geared toward various motorcycle models and cultural trends.

Riders, particularly those aged 25 to 50, often balance form and function by choosing fairings that enhance their bike’s aesthetic appeal while maintaining affordability. For many, this means selecting offerings that allow for customization, such as unpainted kits promising a canvas for personal artwork or vintage-inspired designs that invoke nostalgia without a hefty price tag. The rise of e-commerce has broadened access to these options, offering competitive pricing and convenience that fuel market growth.

Moreover, the demand extends beyond just the visual; it includes integrated features like headlights, brackets, and windscreens tailored for specific styles and uses. This holistic approach to styling encourages suppliers to innovate, catering to enthusiasts who want both unique looks and practical enhancements at a reasonable cost.

Such consumer trends illustrate how the cheap fairings market thrives on the interplay of affordability, variety, and customization. Riders no longer settle for mass-produced options alone but seek products that affirm their identity on the road. This dynamic drives continual expansion and diversification across both mainstream and niche suppliers.

For riders exploring cost-effective fairing styles that combine value with customization potential, comprehensive collections are conveniently accessible through various online platforms, as detailed in this exploration of affordable motorcycle fairings.

Further market insights into accessory growth and rider preferences can be found in this Motorcycle Accessories Market Growth Overview.

Chapter 3: Economic and Practical Trade-offs When Purchasing Cheap Fairings for Motorcycles

1. Balancing Material Quality and Longevity: The Core Trade-offs in Affordable Motorcycle Fairings

When selecting cheap motorcycle fairings, the balance between material quality and durability is central to economic and practical trade-offs. Affordable fairings often rely on lower-grade plastics or composites, which can compromise strength and flexibility. These materials are prone to cracking or brittleness, contrasting with premium options made from 100% high-grade ABS plastic known for its superior impact resistance and resilience. The manufacturing precision behind the materials profoundly affects longevity as well. High-quality fairings benefit from precision injection molding, guaranteeing an exact fit and robust structural integrity. Conversely, lower-cost fairings usually involve less precise molding or rudimentary fabrication, resulting in poor fit and weaker components prone to damage and wear.

Beyond the base material, the paint and finish quality play a critical role in the fairing’s lifespan. Premium kits feature multi-layer paint processes topped with clear coats, which shield against UV rays and harsh weather, preserving both color and surface condition over time. Cheaper fairings, by contrast, often have thin or uneven paint application that chips or fades rapidly, diminishing visual appeal and protection. Durability also extends to how these fairings withstand the vibrations and impacts inherent to motorcycle use. Economical fairings frequently succumb faster to these stresses, necessitating more frequent replacement and potentially exposing the motorcycle to damage.

Fit and installation are additional factors affected by material and manufacturing quality. Premium fairings come ready with pre-drilled holes and professional-grade bolt kits, simplifying installation and ensuring a secure fit that reduces vibrations or rattling. More budget options tend to require adjustments or suffer from loose attachment, impacting both safety and aesthetics.

Though cheap fairings offer immediate savings, their lower material quality and lesser durability can lead to increased long-term costs due to replacements and repairs. Riders seeking to maximize value often find that opting for fairings made from high-grade ABS with precision crafting and enhanced finishing provide a superior balance of cost, durability, and appearance over time. Readers can explore more on selecting affordable quality motorcycle fairings through this comprehensive resource on affordable motorcycle fairings and learn about durability advantages from trusted manufacturers here.

2. Balancing Fitment Accuracy and Installation Effort in Affordable Motorcycle Fairings

When opting for cheap motorcycle fairings, riders frequently encounter challenges related to fitment precision and installation ease. Lower manufacturing standards and less rigorous quality control often lead to misaligned panels, warping near mounting points, or stress-induced fractures. These imperfections commonly produce gaps and rubbing that can compromise both the motorcycle’s aesthetics and aerodynamic efficiency, affecting ride quality and performance.

Affordable fairings typically rely on less accurate molding methods and lower-grade materials, resulting in inconsistent sizing that almost always requires on-site modifications or adjustments. This contrasts markedly with premium-grade options, which employ precision injection molding processes using high-quality ABS plastics and include pre-drilled bolt kits. Such features ensure factory-level fitment, significantly reducing installation difficulties and the risk of damage.

Though initially appealing for their lower price tags, budget fairings can exact hidden costs: extra time spent trimming or sanding parts, additional tools, potential reinforcement of cracked mounting points, and sometimes professional help. These factors can cumulatively offset the initial savings and add frustration during the installation process.

Conversely, investing in higher-quality fairings generally yields a smoother assembly experience, greater structural durability, and better long-term performance, despite the higher upfront expense. Buyers must carefully weigh these trade-offs, assessing whether their budget aligns with the anticipated effort and potential need for maintenance post-installation.

For motorcyclists seeking guidance on installation challenges and fitment troubleshooting, detailed manuals from reputable suppliers provide essential advice on verifying model compatibility and meticulous panel alignment to minimize issues. Balancing cost savings with installation practicality remains a key consideration in the search for affordable yet reliable fairings.

For additional insights into purchasing options and fairing materials, explore a comprehensive resource on affordable motorcycle fairings.

Source for common fitment and damage issues: Kings Motorcycle Fairings blog[3].

3. Weighing the Long-Term Financial Impact of Choosing Budget Motorcycle Fairings

Opting for cheap motorcycle fairings may provide immediate savings, but it often comes with notable long-term cost implications that riders must consider closely. Budget fairings typically rely on lower-grade materials, such as thinner ABS plastics or fiberglass of varying quality, which tend to degrade faster under stress, impact, or exposure to elements. This reduced durability means riders may face more frequent repairs or replacements, ultimately charging more over time than initially apparent.

Beyond material wear, the precision of manufacturing plays a crucial role. Cheaper fairings often lack injection molding accuracy, resulting in imperfect fitment to the motorcycle frame. These misalignments can cause mounting strain, vibration, or rattling noise, which not only diminish the riding experience but may also incur extra labor costs for adjustments or retrofitting hardware. Poorly fitted fairings can accelerate structural fatigue both in the fairings and in mounting points, further driving maintenance expenses.

Aesthetic longevity is another hidden cost. Many inexpensive kits arrive unpainted or with inferior paint quality that quickly fades, chips, or peels. This degrades the bike’s appearance and can compel riders to invest in repainting or touch-ups, adding to out-of-pocket expenses and reducing potential resale value.

From a safety standpoint, improperly crafted fairings can compromise aerodynamics and rider protection. Poorly fitting or fragile components might impair handling or fail to protect critical areas during minor impacts, introducing risk factors that could translate into costly repairs or medical bills.

While more expensive aftermarket fairings often include warranties and robust customer service support, cheap fairings usually do not. This absence leaves riders exposed to risks of additional, unforeseen costs without recourse. Bridging initial cost savings with these long-term economic realities is essential. Investing in higher-quality fairings that offer durable materials, precise molding, and reliable finishes often proves more cost-effective and satisfying in the life cycle of motorcycle maintenance.

For riders seeking affordable yet value-driven options, exploring detailed resources on durable motorcycle fairings can provide guidance on balancing upfront savings against future expenditures. More insights are available at your ultimate source for affordable motorcycle fairings.

External reference: https://www.kingsmotorcyclefairings.com/pages/aboutus

4. Balancing Visual Appeal and Practicality: Aesthetic and Finish Trade-offs in Budget Motorcycle Fairings

Purchasing cheap motorcycle fairings inevitably involves weighing aesthetic quality against cost savings. Lower-priced fairings often rely on economical materials like ABS plastic or fiberglass and streamlined manufacturing methods. While these choices keep prices accessible, they usually lead to compromises in surface finish, color accuracy, and overall durability. Many budget fairings arrive unpainted or use factory-applied paint that can lack depth and consistency, making additional finishing work—such as sanding, primer application, and repainting—necessary to match the bike’s original look.

Beyond appearance, practical concerns intertwine with these aesthetic trade-offs. Less precise moldings and simplified mounting systems in inexpensive fairings may cause fitment issues. Misaligned panels can result in gaps or rattling, diminishing the motorcycle’s visual coherence and possibly increasing wind resistance. Furthermore, the absence of reinforced brackets or strategically designed mounting points—often skipped to reduce costs—can reduce structural integrity. This raises the risk of cracking or breaking during minor impacts or normal riding stresses, ultimately leading to extra expenditures for repairs or replacements.

Riders opting for cheap fairings must consider that initial savings might come with a need for time-consuming modifications or supplementary investments in hardware and finishing supplies. Researching reviews to gauge fit accuracy and finish quality can help inform better choices. For those seeking guidance on related installation and protection compromises, resources such as Motovation Accessories provide useful perspectives on mounting solutions and frame protection strategies.

Striking a balance between affordable styling and dependable durability remains key. While cheap fairings may not match OEM finishes perfectly, careful selection and some post-purchase enhancements can preserve both the bike’s appearance and functional protection without overshooting budget constraints. For more detailed insights on fairing options, explore affordable motorcycle fairings options.

5. Balancing Rider Comfort and Aerodynamics in Affordable Motorcycle Fairings

Affordable motorcycle fairings often rely on lightweight, durable plastics like ABS to provide noticeable aerodynamic benefits. These economical fairings can reduce wind resistance by up to 25%, enhancing stability and fuel efficiency at highway speeds. Even basic batwing-style fairings with curved designs and airflow channels effectively cut drag by 15-25%, contributing to smoother rides and improved performance above 120 mph. Some budget kits include adjustable mounting brackets, enabling riders to fine-tune fairing angles to optimize wind deflection according to personal comfort preferences.

However, these cost-saving benefits come with trade-offs. Fitment and finish tend to be less refined compared to premium fairings, which may result in increased wind buffeting and vibration that can diminish overall rider comfort during long rides. The universal rather than model-specific designs found in many budget options can add complexity to installation and limit precise aerodynamic tuning. Moreover, cheaper plastics rarely feature advanced aerodynamic enhancements like integrated spoilers or winglets that increase downforce and improve handling at speed.

Regarding comfort, economical fairings do provide essential wind coverage for the torso and head, reducing fatigue from wind blast. Nonetheless, they generally lack the tailored ergonomics and factory-grade finishes of high-end cruiser fairings that better manage airflow and vibration. This balance reveals a practical compromise between cost and performance where meaningful aerodynamic gains and comfort improvements are achievable, but at the expense of polish and specialized features.

Riders seeking value in aftermarket fairings can thus expect notable enhancements in stability and fuel efficiency with budget-friendly options. Yet, achieving ideal comfort and refined rider experience may require accepting simpler materials and minimal customization compared to pricier alternatives. This dynamic highlights the careful consideration shoppers must give to material quality, aerodynamic design, and installation practicality when choosing fairings on a budget. For more insights on affordable motorcycle options, explore affordable motorcycle fairings at Summit Fairings.

External Reference: Aerodynamic impacts of motorcycle fairing designs

Final thoughts

Choosing cheap fairings for motorcycles demands a nuanced understanding of materials, supplier reliability, and economic trade-offs. Business owners must assess which balance of quality, cost, and completeness best serves their target market segments to maximize satisfaction and profitability. ABS plastic fairings offer a compelling value proposition through durable, precise products that often come ready to install and paint, while fiberglass fairings cater more to budget riders willing to invest in finishing. Supplier selection is integral; partnering with reputable leaders like Kings Motorcycle Fairings or BMC Next Level ensures consistent product quality and dependable support. Finally, economic considerations around fit, finish, and post-sale support influence long-term business success more than just initial purchase price. With these insights, businesses can confidently navigate the cheap motorcycle fairings market, anticipating customer needs and delivering cost-effective, quality solutions that drive loyalty and growth.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.