Introduction

Motorcycle fairings are essential components that balance style, aerodynamics, and protection. For business owners in the motorcycle aftermarket and customization sectors, understanding emerging manufacturing methods like 3D printing can unlock new growth opportunities. The question “Can you 3D print motorcycle fairings?” invites a detailed exploration of how advanced printing technologies are reshaping production paradigms. This examination covers three pivotal dimensions: first, the technological possibilities enabling 3D-printed fairings; second, the critical materials that impact performance and durability; and third, the practical applications alongside limitations businesses must consider. By integrating these aspects, motorcycle enterprises can make informed decisions about incorporating 3D printing into their design and manufacturing processes to enhance customization, prototyping speed, and market responsiveness.

Tables of Contents

Chapter 1: Technological Perspectives on Can You 3d Print Motorcycle Fairings

- Precision and Innovation: Reverse Engineering and 3D Scanning Shaping Motorcycle Fairings

- Emerging Materials and Advanced Additive Techniques Transforming 3D Printed Motorcycle Fairings

- Mastering Post-Processing Techniques to Elevate 3D Printed Motorcycle Fairings

- Unlocking Design Freedom: Customization and Rapid Prototyping in 3D Printed Motorcycle Fairings

- Industrial Breakthroughs and Emerging Trends Shaping the Future of 3D Printed Motorcycle Fairings

Chapter 2: Material Considerations in Can You 3d Print Motorcycle Fairings

- Navigating Material Choices: Strength, Weight, and Durability in 3D Printed Motorcycle Fairings

- Balancing Strength and Durability: ABS, PLA, PETG, and ASA for 3D Printed Motorcycle Fairings

- Advancing Fairing Strength and Design: Metal 3D Printing for High-Performance Motorcycle Components

- Enhancing Durability and Aesthetics: The Crucial Role of Post-Processing in 3D Printed Motorcycle Fairings

- Balancing Durability and Environmental Resistance in 3D Printed Motorcycle Fairings

Chapter 3: Practical Applications and Limitations in Can You 3d Print Motorcycle Fairings

- Tailored Design and Speed: Unlocking Customization and Rapid Prototyping in 3D Printed Motorcycle Fairings

- Unlocking Design Complexity and Creative Freedom in 3D Printed Motorcycle Fairings

- Navigating Material Strength and Durability Challenges in 3D Printed Motorcycle Fairings

- Navigating Size Limits and Assembly Challenges in 3D Printed Motorcycle Fairings

- Mastering Surface Finish and Aesthetics: Post-Processing Essentials for 3D Printed Motorcycle Fairings

Chapter 1: Technological Perspectives on Can You 3d Print Motorcycle Fairings

1. Precision and Innovation: Reverse Engineering and 3D Scanning Shaping Motorcycle Fairings

Reverse engineering combined with 3D scanning has revolutionized the production and customization of motorcycle fairings. This approach begins by capturing the exact geometry of existing fairings, often employing devices capable of scanning large components in multiple sections. The high-fidelity scans generate digital models that serve as the foundation for modifications tailored to additive manufacturing constraints.

Once the complex surfaces are digitized, CAD software refinement becomes essential. Designers use these tools to optimize mounting points, adjust wall thicknesses, and transform hollow injection-molded structures into solid parts better suited for Fused Deposition Modeling (FDM) 3D printing. These modifications enhance mechanical strength and reduce the risk of fragile prints, delivering practical improvements over the original components.

The printing process then realizes these refined digital designs using filaments chosen for durability and finish quality. Post-processing steps—such as sanding, trimming supports, and painting—further elevate the aesthetics and functionality, aligning the 3D printed fairings with traditional production standards. This seamless workflow allows not only exact replicas but also bespoke customizations, accommodating unique rider preferences and design innovations.

Industries leveraging reverse engineering and 3D scanning benefit from rapid iteration cycles, going from physical part capture to digital enhancement and final production with greater efficiency. This method supports smaller-scale manufacturing and prototyping phases where flexibility and precision are paramount, distinguishing it as an invaluable tool alongside conventional injection molding.

For enthusiasts and professionals exploring modern solutions, this synergy between scanning and 3D printing demonstrates how cutting-edge technology reshapes fairing design and manufacturing. More about the possibilities of motorcycle fairings customization can be found at Summit Fairings.

Further insight into rapid prototyping and scanning applications can be explored through resources on additive manufacturing advancements.

2. Emerging Materials and Advanced Additive Techniques Transforming 3D Printed Motorcycle Fairings

3D printing motorcycle fairings has evolved significantly through the integration of advanced materials and additive manufacturing techniques, enabling the production of parts that blend performance, customization, and intricate design. Central to this innovation are materials like carbon fiber composites and high-performance polymers, which deliver the lightweight strength essential for motorcycle aerodynamics and durability. Carbon fiber composites, known for their exceptional stiffness-to-weight ratio—up to three times that of steel—and superior UV resistance, are increasingly utilized for premium fairings. These composites enhance not only mechanical properties but also thermal management, with designs incorporating integrated air vents to optimize heat dissipation during high-speed riding.

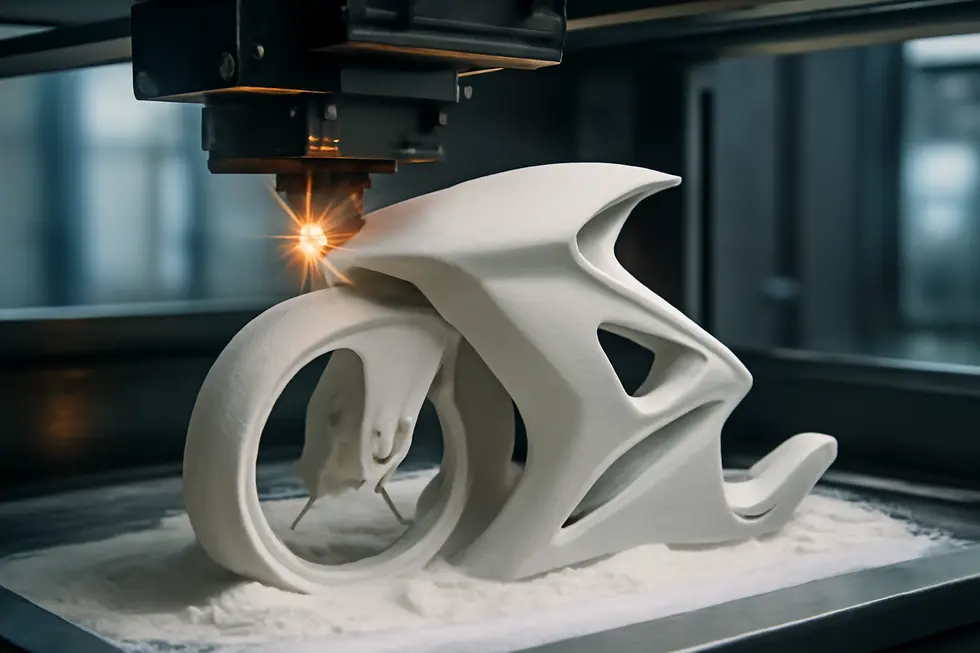

Parallel to composites, polymers such as nylon have become a mainstay in 3D printing fairings, especially for prototyping and cosmetic applications. Techniques like Selective Laser Sintering (SLS) harness nylon powders to create robust, lightweight parts without the need for support structures, supporting complex geometries which are difficult to achieve through traditional manufacturing. Alongside, Digital Light Processing (DLP) offers exceptional surface resolution and finish, making it ideal for detailed prototypes and cosmetic enhancements.

In some cases, metal 3D printing—using methods like Electron Beam Melting (EBM) and Selective Laser Melting (SLM)—produces structurally critical components. While less common for exterior fairings, these metals contribute to the broader ecosystem of motorcycle additive manufacturing.

The technological landscape is also witnessing the rise of digital twin models, virtual replicas that streamline quality control and minimize defects by closely monitoring production parameters and material behavior. Furthermore, the ability to design fairings tailored to rider ergonomics and chassis specifics exemplifies the customization advantage 3D printing holds over conventional methods. Sustainable practices are emerging as well, focusing on recyclable composites and eco-friendly fabrication processes, echoing trends in related motorcycle accessories.

For those interested in a deeper technical understanding of additive manufacturing technologies, an informative overview can be found from expert sources here. Additionally, exploring the variety of motorcycle fairings available at trusted suppliers can provide insight into current market options and custom solutions (Summit Fairings blog).

3. Mastering Post-Processing Techniques to Elevate 3D Printed Motorcycle Fairings

Post-processing is a pivotal stage in the fabrication of 3D printed motorcycle fairings, bridging the gap between raw prints and high-quality, functional components. The process begins with the careful removal of support structures, which are often necessary during printing but can leave rough edges or marks. For polymer-based fairings commonly printed with ABS or composite materials, sanding is a fundamental step. It physically eliminates surface imperfections, providing a smoother foundation for more advanced finishing techniques.

To achieve the glossy, professional look essential for motorcycle fairings, chemical vapor smoothing is frequently employed. This technique uses controlled chemical vapors, such as acetone for ABS, to gently melt the surface, erasing layer lines and imparting a uniform, glossy finish without mechanical abrasion. Though costlier, this method significantly enhances aesthetics and surface durability, which is vital considering the fairing’s exposure to environmental elements and aerodynamic forces.

Painting and priming follow smoothing procedures to enhance both appearance and protection. Primers fill micro-gaps, ensuring paint adheres evenly and creates a weather-resistant barrier, critical for longevity. Heat treatments might be applied occasionally, particularly for metal parts, to alleviate residual stresses and improve structural integrity. In smaller-scale or batch post-processing, media tumbling can also refine surfaces mechanically, although it is less common for large fairing components.

Together, these finishing methods yield motorcycle fairings that combine visual appeal with strength and durability. The integration of mechanical, chemical, and coating steps forms a comprehensive workflow catering to the unique demands of 3D printed parts in motorcycle applications. For riders seeking bespoke or rapid prototyping solutions with premium finishes, understanding these post-processing strategies is essential.

For more insights on high-quality motorcycle fairing options and innovations, explore Summit Fairings’ collection.

Reference: post-processing protocols outlined at 3D Hubs (https://www.3dhubs.com/knowledge-base/3d-printing-post-processing-techniques/).

4. Unlocking Design Freedom: Customization and Rapid Prototyping in 3D Printed Motorcycle Fairings

3D printing revolutionizes motorcycle fairing design by enabling unmatched customization and rapid prototyping capabilities. Unlike traditional manufacturing, where molds and tooling restrict flexibility, 3D printing allows designers to tailor every detail—from precise dimensions and textures to color choices and functional elements—directly from digital models. This flexibility empowers riders and manufacturers to produce fairings that perfectly fit their unique style preferences and performance requirements without incurring prohibitive costs.

Rapid prototyping accelerates the entire development cycle. What once took weeks or months now happens within hours, enabling quick creation and testing of physical prototypes. This swift iteration process reduces development expenses and enhances innovation by allowing designers to refine aerodynamic shapes, integrated cooling vents, or structural reinforcements efficiently. Moreover, 3D printing supports the fabrication of complex geometries impossible to achieve with casting or machining, such as internal lattice structures that reduce weight while maintaining strength.

Beyond prototyping, 3D printing facilitates low-volume and on-demand production of replacement fairings for rare or discontinued motorcycle models. This capability minimizes inventory needs and supply chain delays, delivering bespoke parts precisely when needed. The continued advancement of materials—featuring heat resistance, durability, and wear performance—ensures printed fairings withstand real-world riding conditions.

Together, these technological advantages make 3D printing a powerful tool for personalized, cost-effective motorcycle fairings that blend aesthetic appeal with functional excellence. For further insights on how rapid prototyping and customization transform motorcycle parts production, see the video “Can You 3D Print Motorcycle Parts? – How It Comes Together”.

Explore more on achieving unique fairing designs and customization possibilities in the detailed coverage at Summit Fairings blog.

5. Industrial Breakthroughs and Emerging Trends Shaping the Future of 3D Printed Motorcycle Fairings

Industrial Breakthroughs and Emerging Trends Shaping the Future of 3D Printed Motorcycle Fairings

The integration of 3D printing into motorcycle fairing production is evolving from experimental to industrial significance. Advanced additive manufacturing techniques, particularly metal 3D printing with titanium alloys, are enabling the creation of components that combine exceptional strength with intricate design freedom. Companies specializing in large-scale titanium printing have demonstrated the feasibility of producing thousands of durable motorcycle parts with consistent quality, signaling a shift toward serial production. These components fulfill both structural and aesthetic roles, benefiting from shapes and internal geometries impossible to achieve through conventional fabrication.

Alongside metal parts, plastic components produced through 3D printing cater to rapidly evolving electric motorcycle designs. Dashboards, protective covers, and headlight housings can be customized and iterated swiftly, offering manufacturers and riders the flexibility to refine or personalize features with ease. This fluid development process accelerates time-to-market and encourages design innovation.

Looking ahead, the scaling of industrial 3D printers to meter-sized build volumes significantly broadens production capacity, enabling larger fairing sections and higher throughput. Concurrent advancements in material science introduce specialized composites and metals that enhance mechanical performance while reducing weight, echoing the demands of high-performance motorcycling. Automation is also penetrating the additive workflow, with robotic integration streamlining production and finishing operations to achieve consistent, cost-effective output.

The combined impact of these developments fosters a manufacturing environment that supports bespoke creations and sustainability goals by minimizing waste compared to subtractive methods. Although traditional manufacturing still dominates mass production, 3D printing secures a crucial niche for luxury, electric, and performance-oriented bikes—where customization, complexity, and lightweight strengths are prized.

A prominent example of this industrial momentum is the collaboration showcasing titanium 3D printed parts designed for serial use in electric motorcycles. This validates the readiness of 3D printing to meet stringent quality and performance benchmarks, hinting at its growing role in next-generation motorcycle manufacturing.

For riders and industry watchers seeking comprehensive options in motorcycle fairings, exploring specialized sources like Summit Fairings’ wide offerings reveals how customization and innovation continue to transform this space.

Further details on large-scale metal additive manufacturing can be found in studies highlighting recent industrial applications by Farsoon and Stark Future, demonstrating a clear path from prototyping to sustainable serial production.

Chapter 2: Material Considerations in Can You 3d Print Motorcycle Fairings

1. Navigating Material Choices: Strength, Weight, and Durability in 3D Printed Motorcycle Fairings

Selecting the right material is a critical factor when 3D printing motorcycle fairings, as it directly influences performance, durability, and cost. Among the most accessible options, ABS plastic stands out for being lightweight, impact-resistant, and budget-friendly, making it a popular choice for everyday street fairings. Its ease of printing and post-processing allows for practical, durable parts, though it may fall short in extreme or track-specific conditions where stress resistance is paramount.

For riders and manufacturers targeting racing or premium applications, fiberglass and carbon fiber composites dominate. These materials offer remarkable strength-to-weight ratios and superior aerodynamic qualities. While carbon fiber, in particular, provides exceptional durability and weight reduction, the trade-off is higher cost and processing complexity. Such composites excel in customizing fairings that require stiffness and fine aerodynamic shaping without adding unnecessary bulk.

Advanced 3D printing has also introduced metal alloys such as titanium and aluminum to the landscape of motorcycle components. These metals, fabricated through processes like powder bed fusion, offer unmatched mechanical strength and precision. Titanium’s exceptional corrosion resistance and strength make it ideal for structural elements in premium motorcycles, although its expense and complexity limit its use primarily to functional parts rather than full fairings.

Printing techniques vary with these materials, often demanding support structures and extensive post-processing to ensure a smooth finish and optimal fit. The ability to rapidly prototype and iterate designs digitally maximizes customization potential. Ultimately, the selection hinges on balancing mechanical requirements, weight considerations, and budget constraints, making it essential to align material choice with intended use—whether casual riding or competitive racing. For further insights on fairing options and customization, explore this resource on affordable motorcycle fairings.

More detailed industry trends and aftermarket developments can be found at Accio’s 2024 ZX10R body kit overview, offering a glimpse into how materials impact fairing design today.

2. Balancing Strength and Durability: ABS, PLA, PETG, and ASA for 3D Printed Motorcycle Fairings

Selecting the right material is vital when 3D printing motorcycle fairings, as these components must withstand mechanical stress, heat, and outdoor exposure. Among common filaments, ABS offers robust impact resistance and heat tolerance, making it suitable for functional parts. However, it suffers from UV degradation and warping during printing, reducing its longevity and stability outdoors without protective coatings. PLA is user-friendly with minimal warping and excellent surface finish but falls short for fairings due to brittleness, poor heat resistance, and vulnerability to abrasion. It suits decorative or prototyping purposes rather than functional, load-bearing parts.

PETG bridges some gaps by combining ease of printing with greater flexibility and chemical resistance compared to PLA. It endures moderate heat and impact stresses, which makes it a practical choice for fairings exposed to some mechanical load and weather conditions—though it may lack the stiffness required for aggressive riding.

ASA stands out as the top candidate for outdoor motorcycle fairings due to its strong UV resistance, color stability, and superior mechanical toughness. Engineered to withstand sunlight and harsh environments, ASA also resists chemicals better than ABS while maintaining comparable durability. It does demand higher printing temperatures and a heated bed for optimal results, but the payoff is parts that remain resilient and visually consistent over time.

To achieve reliable performance, adjusting printing parameters such as bed temperature (90–110°C for ABS and ASA, 80–100°C for PETG) and infill density is essential. Post-processing methods including smoothing and painting further enhance aesthetic appeal and environmental resistance. Overall, ASA and PETG balance the rigors of fairing applications best, while ABS and PLA play more limited roles. For deeper practical insights into ASA printing and its applications, see Wevolver’s detailed guide. For additional perspectives on custom motorcycle components, visit this discussion on custom motorcycle cockpit instruments.

3. Advancing Fairing Strength and Design: Metal 3D Printing for High-Performance Motorcycle Components

Metal 3D printing has emerged as a transformative approach for producing high-performance and structural motorcycle components, expanding possibilities well beyond traditional plastic fairings. Utilizing powder bed fusion methods, this technology melts fine metal powders like titanium or aluminum layer by layer in an oxygen-free environment. The result is a robust, lightweight, and intricately shaped part, capable of withstanding rigorous mechanical stresses commonly encountered on motorcycles.

Although fairings have historically relied on plastics such as ABS or PLA to keep weight and costs low, metal 3D printing opens new frontiers where durability and precision are critical. For premium motorcycles or electric models emphasizing strength and design complexity, metal fairings offer exceptional resistance to impacts and environmental factors. These parts often require post-processing—trimming, smoothing, and coating—to achieve optimal surface finish and protection, ensuring both functional reliability and aesthetic quality.

Beyond individual customization, metal 3D printing supports rapid, repeatable manufacturing. Examples from industry innovators producing thousands of titanium parts for electric motorcycles prove its scalability and cost-effectiveness for structural components. This capability enables riders and manufacturers to explore designs with complex geometries unattainable through traditional means, granting greater aerodynamic and stylistic freedom without compromising strength.

While metal fairings remain a niche compared to plastic alternatives due to material cost and weight considerations, the growing accessibility of this technology signals strong potential for advanced motorcycle applications. For enthusiasts prioritizing top-tier durability and bespoke engineering, metal 3D printing stands as a compelling solution enhancing both form and function.

For more insights on motorcycle fairings and their evolving materials, explore the best motorcycle fairings available today.

Learn more about the capabilities and applications of metal 3D printing in motorcycle manufacturing here.

4. Enhancing Durability and Aesthetics: The Crucial Role of Post-Processing in 3D Printed Motorcycle Fairings

When 3D printing motorcycle fairings, the material selection alone does not guarantee a part’s final performance or appearance. Post-processing techniques play a pivotal role in refining the raw printed components, bridging the gap between functional prototypes and race-ready or street-worthy fairings. Since additive manufacturing often leaves parts with distinct surface textures and visible layer lines, surface smoothing methods such as sanding, polishing, and chemical vapor smoothing are essential. These steps enhance aerodynamic efficiency and provide an attractive finish, matching or exceeding the standards expected from traditionally manufactured fairings.

Beyond visual refinement, post-processing directly impacts the structural integrity of printed fairings. Heat treatments and curing protocols can mitigate internal stresses and improve impact resistance, particularly in plastic or composite materials commonly employed for fairing fabrication. Coatings and primers not only protect against environmental factors like UV exposure and moisture but also contribute to the mechanical robustness necessary for demanding riding conditions.

Moreover, the responsiveness of different materials to finishing protocols dictates their suitability for fairing production. Materials like ABS benefit from acetone vapor smoothing, enabling faster and more uniform surface finishes. Carbon fiber composites, on the other hand, may require specialized treatments to preserve their high strength-to-weight ratios during post-processing.

Finally, post-processing ensures that fairings fit precisely, allowing for trimming and modifications to meet exact frame tolerances and functional needs. Adding paint or decals not only enhances aesthetic appeal but also provides protective layers essential for durability. By tailoring these finishing methods to the chosen material, creators can produce customized, durable, and visually striking motorcycle fairings that elevate both style and performance.

For practical demonstrations and deeper insights into the effects of post-processing on 3D printed motorcycle materials, the video “Can You 3D Print Motorcycle Parts? – How It Comes Together” offers valuable guidance.

Explore more on material innovations and customization possibilities in motorcycle fairings with insights from the Summit Fairings blog.

5. Balancing Durability and Environmental Resistance in 3D Printed Motorcycle Fairings

Balancing Durability and Environmental Resistance in 3D Printed Motorcycle Fairings

When selecting materials for 3D printed motorcycle fairings, durability and environmental resistance are paramount. Carbon fiber reinforced nylon (CF PA6) stands out for its impressive tensile strength, often two to three times greater than standard 3D printing polymers, delivering robust performance under dry conditions. However, exposure to moisture reduces its strength to nearly half, presenting a challenge for parts constantly subjected to rain and humidity. While post-print heat treatments offer modest improvements, protecting these parts from water remains critical.

Thermoplastic Polyurethane (TPU) delivers a complementary set of properties. Its elasticity and abrasion resistance make it ideal for impact-absorbing components, especially where flexibility is valuable. TPU’s chemical stability and skin safety reinforce its practical use in outdoor and frequent-contact scenarios, though it cannot match the rigidity of carbon fiber composites.

ABS plastic, often used in 3D printing of full motorcycle assemblies, offers balanced strength and impact resistance. Yet without surface treatments like vapor smoothing or UV-resistant coatings, it tends to degrade under direct sunlight and weather, limiting its long-term outdoor durability.

Metal alternatives such as titanium and steel offer superior longevity and environmental resistance. Titanium’s natural oxide layer provides exceptional corrosion protection, making it suitable for harsh conditions, although its cost and weight limit it primarily to structural parts rather than fairings. Steel is durable and stiff but requires protective coatings to fight corrosion in outdoor settings.

Overall, for fairings, materials must offer strength, moisture resilience, and UV stability. Carbon fiber nylon combined with protective coatings can meet these needs, while TPU provides necessary flexibility. ABS requires finishing for outdoor use. Understanding these traits helps optimize 3D printed fairings for real-world riding conditions.

For further insights into high-performance fairings, explore a wide range of motorcycle fairings designed for durability and style.

Chapter 3: Practical Applications and Limitations in Can You 3d Print Motorcycle Fairings

1. Tailored Design and Speed: Unlocking Customization and Rapid Prototyping in 3D Printed Motorcycle Fairings

3D printing has revolutionized the customization and rapid prototyping of motorcycle fairings, enabling riders and designers to create unique, highly personalized parts with remarkable speed. Unlike traditional manufacturing, which relies heavily on tooling and molds, 3D printing offers a flexible, layer-by-layer approach that dramatically shortens the time between concept and physical prototype. This allows for swift design adjustments to perfect the fit, aerodynamics, and aesthetic elements before committing to final production.

Customization thrives in this space, as printers can produce fairings with tailored shapes, textures, and even integrated functional features like cooling vents to meet specific rider needs. This is particularly valuable for limited runs or bespoke parts, where producing tooling for mass manufacturing would be cost-prohibitive. Moreover, digital design files offer endless possibilities to experiment with styles and functionalities without incurring major overhead, supporting creative expression and targeted performance improvements.

However, practical limitations surface in material durability and production efficiency. Typical 3D printed plastics may lack the heat resistance and impact strength necessary for long-term road use, and while metal printing offers stronger alternatives, it introduces higher costs and complexity. Additionally, post-processing steps—such as smoothing, coating, or painting—are essential to achieve the finish quality expected on motorcycle fairings, adding time and expense. For large-scale manufacturing, conventional methods like injection molding remain faster and more cost-effective.

Ultimately, 3D printing excels as a tool for rapid prototyping and bespoke customization, empowering enthusiasts to bring innovative designs to life quickly. Its strength lies in creating precise, tailor-made components that would otherwise take significantly longer and cost more to develop. For those interested in exploring the possibilities of custom motorcycle fairings, this technology offers a unique blend of artistic freedom and practical functionality, bridging the gap between concept and reality. For further insights into available custom components, see unmatched choices in motorcycle fairings.

Learn more about advanced metal 3D printing applications in electric motorcycle manufacturing here: https://www.youtube.com/watch?v=xsXe71dquSE

2. Unlocking Design Complexity and Creative Freedom in 3D Printed Motorcycle Fairings

3D printing revolutionizes the design possibilities for motorcycle fairings by enabling intricate geometries and unprecedented creative freedom. Unlike traditional manufacturing, where tooling and molds restrict form, additive manufacturing allows for seamless production of custom-fitted parts that conform precisely to a bike’s frame. This flexibility facilitates the integration of advanced features such as lightweight lattice structures that enhance impact absorption without adding bulk, and built-in channels or vents tailored for optimal cooling—elements nearly impossible to realize through conventional methods.

Large-format 3D printers can fabricate entire fairings with fine detail, capturing complex curves and aerodynamic shapes in one piece. This capacity not only accelerates prototyping but offers riders bespoke customization options, from aesthetic flourishes to functional enhancements, delivering performance-tailored components quickly and affordably.

However, significant practical constraints remain. Material selection limits the fairing’s ultimate strength and longevity; while engineering-grade plastics like high-strength nylon offer durability and lightness, they cannot wholly match the stiffness or UV resistance of carbon fiber or aerospace composites preferred for high-performance production. Metal 3D printing brings superior mechanical properties but introduces high costs, longer timelines, and increased post-processing complexity, making it less feasible for everyday fairings.

Additionally, build volume restrictions often require fairings to be printed in sections and assembled, adding complexity and potential weak points. Surface finishing processes become necessary to meet aesthetic and functional standards, increasing production time and cost.

Despite these limitations, 3D printing excels in delivering complex, lightweight, and custom motorcycle fairings that push design boundaries. For further insights on printing large-format parts and relevant materials, consult industrial 3D printing technologies like those detailed by BigRep.

3. Navigating Material Strength and Durability Challenges in 3D Printed Motorcycle Fairings

3D printing motorcycle fairings presents notable challenges in achieving the necessary material strength and durability for real-world use. While plastics like PLA, ABS, PETG, and ASA are common for 3D printing due to ease and cost, they often fall short when exposed to the rigors of motorcycle riding. These materials tend to suffer from brittleness and weak layer adhesion, resulting in reduced impact resistance and limited fatigue life. The constant exposure to UV light, temperature swings, and weather means that these plastics may discolor, degrade, or become brittle over time, restricting their suitability for durable, long-term fairings.

Metal 3D printing, using titanium or steel alloys, offers exceptional mechanical properties and weather resistance, showing promise in structural parts such as frames. However, the process is costly, complex, and inefficient for large, thin-walled surfaces like fairings. This makes metal 3D printing impractical for widespread fairing production, despite its strength advantages.

Traditional fairing materials—including injection-molded ABS, fiberglass, and carbon fiber composites—strike a balance between strength, weight, and outdoor durability with well-established manufacturing workflows. These materials perform reliably under impact, vibration, and UV exposure, making them the industry standard for production motorcycle fairings.

Although 3D printed plastics allow for rapid prototyping and cosmetic customization, their mechanical limitations and the need for extensive post-processing restrict them mostly to experimental or limited-use parts. The trade-offs in strength and environmental resistance underscore why, for now, 3D printing is primarily a complementary approach rather than a replacement for traditional fairing manufacturing.

For more insight into balancing customization and material demands, explore this article on motorcycle fairing choices. Additionally, to understand metal printing challenges in detail, the Farsoon and Stark Future projects provide valuable perspectives on the cutting-edge capabilities and cost barriers of metal additive manufacturing.

4. Navigating Size Limits and Assembly Challenges in 3D Printed Motorcycle Fairings

3D printing motorcycle fairings offers impressive design freedom but faces notable size and assembly constraints that impact practical application. Even the most advanced large-format 3D printers have finite build volumes, often necessitating the division of fairings into multiple sections. This segmentation is not trivial, as each part must be carefully designed to ensure precise alignment, smooth fitment, and structural integrity when assembled. Motorcycle fairings, with their sweeping curves, mounting holes, and aerodynamic contours, demand meticulous attention to how components join. Without this, joints may introduce weak points or misalignments that compromise both appearance and function.

Material choice further influences these challenges. While high-strength polymers like nylon offer durability, the seams between printed parts often require additional reinforcement or bonding strategies. Post-processing becomes essential—not just for aesthetics but also to enhance joint strength and weather resistance. Sanding, painting, and sealing improve surface finish and protect against UV and environmental damage, but add time and complexity to the workflow.

Despite these hurdles, 3D printing’s capacity for rapid prototyping shines in iterative design cycles. Adjustments based on physical test fits and rider feedback can be rapidly incorporated, bypassing costly tooling changes common in traditional manufacturing. However, for large-scale production or applications demanding the highest mechanical performance, conventional composite materials still dominate due to inherent stiffness and seamless construction.

Understanding and addressing these size and assembly constraints is crucial to successfully leveraging 3D printing in motorcycle fairing fabrication. For a deeper exploration of the potential and limitations of large-format 3D printing, see insights from the Farsoon titanium 3D printing project and industrial contract manufacturing examples. To explore options in aftermarket fairings that balance customization with quality, visit this comprehensive motorcycle fairings resource.

5. Mastering Surface Finish and Aesthetics: Post-Processing Essentials for 3D Printed Motorcycle Fairings

Achieving an exceptional surface finish and visual appeal is crucial when 3D printing motorcycle fairings, as these elements significantly influence both the form and function of the part. Unlike traditional manufacturing, 3D printed fairings often emerge with visible layer lines and textures inherent to common processes like FDM. To elevate these prints into professional-quality components, thorough post-processing becomes indispensable. Techniques such as sanding, filling, and polishing help smooth out rough surfaces and erase the telltale stepping from layered printing. This groundwork allows for superior paint adhesion, crucial for creating visually striking, durable coatings that enhance both the aesthetic and aerodynamic performance of fairings.

Different printing technologies offer varying initial surface qualities. Resin-based methods (SLA/DLP) produce finely detailed, almost flawless surfaces with minimal post-processing, ideal for decorative sections and detailed inserts. Conversely, nylon parts created via SLS or Multi Jet Fusion often have a slightly gritty texture that must be carefully refined to approach a smooth finish while maintaining strength. Meanwhile, polycarbonate prints can achieve a glossy surface, but require precise tuning and additional finishing to hide layer marks.

Post-print treatments extend beyond sanding and painting. Protective clear coats improve UV resistance and durability, essential for outdoor exposure. Advanced finishes might include heat treatment or CNC machining to ensure tight tolerances and seamless assembly—particularly when large fairings are printed in sections, posing a challenge for consistent joint appearance.

While 3D printing accelerates prototyping and bespoke designs, the extra effort and costs associated with achieving OEM-caliber aesthetics confine its practicality mainly to customization and low-volume production. For those pursuing tailored motorcycle fairings, investing in meticulous post-processing unlocks the full potential of 3D printed parts, marrying unique design freedom with competitive function. For detailed techniques on smoothing and finishing, see Prusa’s post-processing guide.

Additional insights on finishing methods can be found in DEK’s comprehensive overview [1].

Final thoughts

3D printing motorcycle fairings represents a compelling convergence of design freedom, rapid prototyping, and tailored customization for businesses in the motorcycle aftermarket sector. By leveraging technologies like Selective Laser Sintering and Digital Light Processing, manufacturers can fabricate strong, intricately shaped fairings that challenge traditional design constraints. Material choices such as high-strength nylon composites further empower lightweight, durable fairings suitable for both aesthetic and functional demands. However, despite these strengths, 3D printing faces hurdles in scalability, cost-efficiency, and matching the performance of carbon fiber composites for large-scale production. For businesses seeking innovation through bespoke orders or accelerated development cycles, 3D printing offers tangible benefits. Understanding these technological, material, and practical dimensions equips business owners with the insight needed to integrate 3D printing effectively alongside conventional manufacturing. Ultimately, embracing 3D printing can position companies to meet evolving rider preferences and niche market demands with agility and precision.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined