Maximizing Performance with DZUS Motorcycle Fairing Fasteners: A Business Owner’s Guide

September 17, 2025 | by summitfairings

Introduction

DZUS motorcycle fairing fasteners represent a specialized solution for securing race and high-performance motorcycle bodywork efficiently. For business owners in the motorcycle parts and accessories market, understanding the unique design, installation requirements, and material options of DZUS fasteners is critical to offering products that deliver speed and reliability for customers. These fasteners are valued for their rapid quarter-turn fastening mechanism, enabling quick maintenance and pit stops which are crucial in competitive racing environments. This article dissects the engineering behind DZUS fasteners, installation techniques, material variants and their impact on performance, the primary applications in racing scenarios, commercial availability of comprehensive kits, and emerging innovations that are shaping the market. Each chapter builds a comprehensive understanding that equips businesses to stock, sell, and advise on DZUS fasteners confidently, enhancing customer satisfaction and operational expertise.

Tables of Contents

Chapter 1: Design and Mechanism of DZUS Motorcycle Fairing Fasteners

- Engineering Precision and Innovative Mechanisms Behind DZUS Motorcycle Fairing Fasteners

- Economic Efficiency and Cost Benefits of DZUS Quick-Release Fastener Design

- Global Manufacturing Dynamics Shaping DZUS Fastener Production and Supply

- Embracing Efficiency and Community: User Adoption and Cultural Impact of DZUS Fasteners

Chapter 2: Installation Techniques for DZUS Motorcycle Fairing Fasteners

- Mastering Fairing Preparation and Custom Modifications for Precise DZUS Fastener Installation

- Mastering the Spring-Loaded Assembly and Rapid Unlocking of DZUS Motorcycle Fairing Fasteners

- Balancing Strength, Weight, and Longevity: Material Choices and Durability in DZUS Fastener Installation

- Tailoring Installation for Racing: Custom Solutions and Adaptations of DZUS Fairing Fasteners

Chapter 3: Material Variants and Performance in DZUS Motorcycle Fairing Fasteners

- How Material Choices Influence Strength, Weight, and Durability in DZUS Fasteners

- Balancing Strength and Weight: Material Choices in DZUS Motorcycle Fasteners

- Balancing Corrosion Resistance and Durability in DZUS Fastener Materials

- Balancing Cost, Durability, and Application: Material Choices in DZUS Fairing Fasteners

Chapter 4: Applications and Usage of DZUS Motorcycle Fairing Fasteners in Racing

- Innovations Driving Performance: Technological Enhancements in DZUS Motorcycle Fairing Fasteners for Racing

- Balancing Cost and Performance: The Economics Behind DZUS Fastener Use in Racing

- How Geopolitical Dynamics Shape the Racing Use of DZUS Motorcycle Fairing Fasteners

- Balancing Speed and Safety: Societal Impact of DZUS Fairing Fasteners in Competitive Motorcycling

Chapter 5: Availability and Commercial Kits of DZUS Motorcycle Fairing Fasteners

- Material Innovation and Design Customization in Commercial DZUS Motorcycle Fairing Fastener Kits

- Economic Dynamics Shaping the Market for DZUS Motorcycle Fairing Fasteners: Pricing and Kit Availability

- Navigating Geopolitical and Supply Chain Challenges Shaping DZUS Fairing Fastener Kits

- Embracing Speed and Style: How DZUS Fastener Kits Drive Racing Culture and Custom Motorcycle Innovation

Chapter 6: Innovations and Alternatives to DZUS Motorcycle Fairing Fasteners

- Cutting-Edge Materials and Rapid-Release Designs Transforming Motorcycle Fairing Fasteners

- Economic Dynamics of Modern Motorcycle Fairing Fasteners: Balancing Cost, Value, and Market Evolution

- Geopolitical and Supply Chain Forces Shaping DZUS Fastener Alternatives

- Enhancing Rider Experience and Community Impact Through Fastener Innovation

Chapter 1: Design and Mechanism of DZUS Motorcycle Fairing Fasteners

1. Engineering Precision and Innovative Mechanisms Behind DZUS Motorcycle Fairing Fasteners

DZUS motorcycle fairing fasteners are engineered around a quarter-turn cam locking mechanism that balances rapid operation with reliable clamping strength. This rivet-style fastener uses a rotating cam or latch, which, when turned a mere 90 degrees, engages securely with a catch or slot mounted on the fairing or frame. The cam’s design generates a firm clamping force, holding the panel tightly during high vibrations encountered in racing scenarios while enabling swift removal without tools. Precision machining of components ensures dependable engagement and consistency of operation, critical for frequent pit stops and maintenance. Materials such as corrosion-resistant aluminum or titanium enhance durability and reduce weight, optimized for performance demands. Ergonomic knobs or levers further empower users to manually release or fasten bodywork efficiently, minimizing downtime. This integration of mechanical simplicity, strong retention, and material innovation makes DZUS fasteners an indispensable technology for competitive motorcycling. For more insights on race bodywork integration, visit Discover unmatched choices in motorcycle fairings at Summit Fairings. Additional technical details are available at Otter Springs’ resource on quick latch fasteners: https://ottersprings.com/10x-Motorcycle-Quick-Latch-Turn-Lock-1-4-quot-Race-Fairing-e-561698

2. Economic Efficiency and Cost Benefits of DZUS Quick-Release Fastener Design

DZUS motorcycle fairing fasteners utilize a quarter-turn cam locking mechanism enabling fast panel removal and secure reattachment. This design significantly reduces the labor time required during maintenance or repairs since fairings can be handled swiftly without tools. The robust construction from materials like steel, aluminum, or titanium ensures long-term durability and repeated reuse, minimizing replacement frequency and thus lowering material expenses. Moreover, the standardization of DZUS fasteners across many racing and performance motorcycles creates manufacturing economies of scale, driving down unit costs. This combination of reliability and operational speed enhances efficiency in pit stops and routine servicing, allowing teams and shops to optimize workflows and reduce downtime. Overall, the DZUS system delivers measurable cost savings while maintaining mechanical integrity—making it a smart investment for manufacturers and riders focused on performance and budget alike. For those interested in detailed product options and systems, various suppliers provide specialized kits catering to different motorcycle models and racing needs. Learn more about fairing options and compatible hardware at Summit Fairings. For technical details and procurement, suppliers like Otter Springs offer an array of quarter-turn fasteners tailored to motorcycle applications.

3. Global Manufacturing Dynamics Shaping DZUS Fastener Production and Supply

DZUS motorcycle fairing fasteners rely on a precise quarter-turn cam mechanism that locks with secure, vibration-resistant force. While their design remains consistent, manufacturing and supply are deeply influenced by global geopolitical forces. Production centers in Asia and Europe dominate due to advanced metalworking industries, but trade policies and tariffs between these regions and key markets impact pricing and availability. Political tensions or export restrictions may cause delays, affecting motorcycle manufacturers and aftermarket suppliers alike. Additionally, sourcing materials such as steel, aluminum, or titanium is vulnerable to mining regulations and sanctions, which can influence material quality and costs. Variations in manufacturing standards across countries also affect fastener reliability, making quality control crucial. These global factors intertwine with the mechanical design, determining how quickly and dependably these fasteners reach riders and racers. For enthusiasts seeking performance components, understanding this supply landscape highlights challenges behind quick-release fairing solutions. More insights on motorcycle components and sourcing can be explored at Summit Fairings blog.

4. Embracing Efficiency and Community: User Adoption and Cultural Impact of DZUS Fasteners

DZUS motorcycle fairing fasteners have become a hallmark of efficiency and performance within motorcycle communities. Their quarter-turn mechanism allows riders and mechanics to quickly secure or remove fairings without tools, making fast repairs and adjustments seamless. This design not only reflects technical ingenuity but also promotes a culture that values precision and practical speed.

The widespread adoption of DZUS fasteners highlights a collective appreciation for reliability and streamlined maintenance, bridging the gap between amateur enthusiasts and professional racers. Users embrace these fasteners not only for functionality but also because they represent shared knowledge and a standard of quality in motorcycle customization and maintenance.

Beyond racing, DZUS fasteners have influenced the aftermarket industry, encouraging faster customization and upgrades. Their presence supports a community-driven approach to motorcycle care, where performance and accessibility intersect. For further insights on motorcycle upgrades and accessories, explore expert motorcycle fairings guidance.

Chapter 2: Installation Techniques for DZUS Motorcycle Fairing Fasteners

1. Mastering Fairing Preparation and Custom Modifications for Precise DZUS Fastener Installation

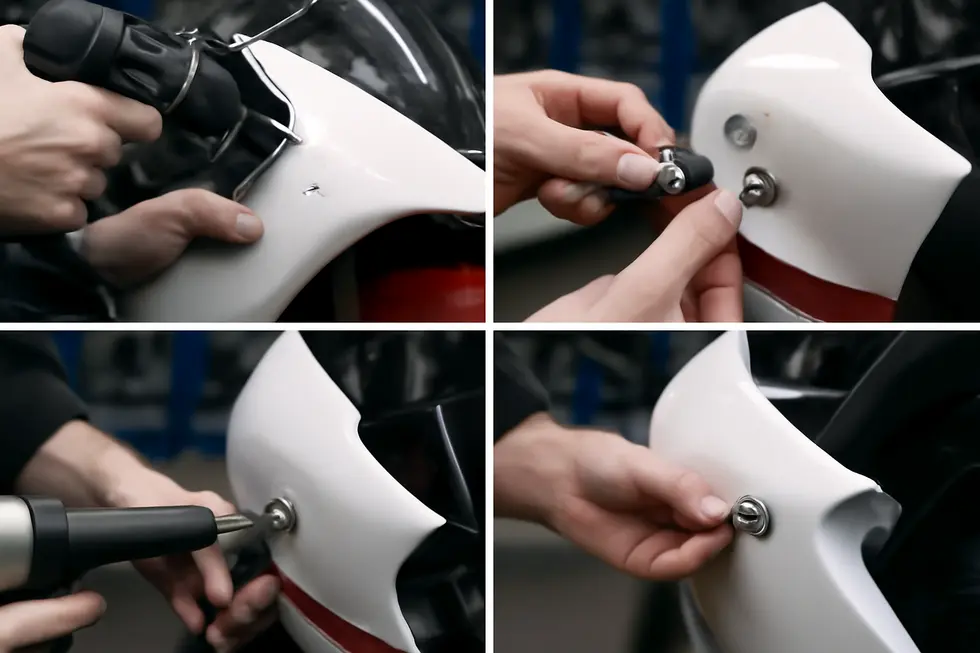

Preparation and custom modification are essential steps when installing DZUS motorcycle fairing fasteners. Since these fasteners rely on a quarter-turn rivet-style mechanism, the fairing must be carefully altered to accommodate mounting points for the fasteners, retainer washers, and springs. Most standard street fairings lack these provisions, so drilling or trimming is often necessary to ensure proper alignment and secure engagement. This process demands precision; even slight misalignments can hinder the quick-release function or damage the bodywork over time. Typically, a comprehensive fastener kit includes the rivets, springs, and retainers needed to retrofit race-style quick mounts. However, customizing fairing mounts or reinforcing mounting points ensures durability under repeated use and racing conditions. Skillful use of tools for drilling, riveting, and measuring is crucial to preserve the fairing’s structural integrity. Given the specialized nature of this modification, consulting detailed installation guides or experienced professionals is advisable to achieve a reliable, fast-access setup. For enthusiasts seeking premium fairing options that facilitate DZUS integration, exploring Summit Fairings’ extensive selection can provide valuable solutions.

(Source: Graves Motorsports DZUS Fastener Kit product details on RevZilla)

2. Mastering the Spring-Loaded Assembly and Rapid Unlocking of DZUS Motorcycle Fairing Fasteners

DZUS motorcycle fairing fasteners feature a cleverly engineered spring-loaded rivet system that revolutionizes how fairings attach and detach. This quarter-turn pin fastener allows riders and mechanics to secure panels quickly and remove them effortlessly by simply turning the pin, eliminating the need for conventional tools during maintenance or race pit stops. The assembly consists of precision components such as the rivet-style fastener, retainer washers, and bodywork springs that maintain consistent tension, ensuring the fastener stays locked even under intense vibrations and high-speed conditions. While the design prioritizes speed and convenience, installation typically requires custom mounts or modifications to the fairing to ensure a flush, aerodynamic fit. This tailored fitting guarantees that the fasteners integrate seamlessly with the motorcycle’s bodywork, preserving structural integrity and style. By replacing traditional bolts with these quick-release fasteners, users gain enhanced efficiency and reliability, making frequent access to internal components swift and hassle-free. For enthusiasts seeking fast, secure, and durable attachment solutions, understanding this mechanism is key to optimizing fairness installation and removal. More details on fairing options and compatible accessories can be found at Explore the Best Motorcycle Fairings at Summit Fairings.

For further insights on the fastener design, see the Graves Motorsports DZUS Fastener Kit specifications.

3. Balancing Strength, Weight, and Longevity: Material Choices and Durability in DZUS Fastener Installation

Selecting the appropriate material for DZUS motorcycle fairing fasteners is crucial in achieving durable, lightweight, and corrosion-resistant installations. Common materials include steel, aluminum, and titanium, each offering distinct advantages tailored to racing and high-performance needs. Aluminum fasteners provide a significant weight reduction—up to 60% lighter than steel—while anodized finishes enhance corrosion resistance and visual appeal. Titanium fasteners stand out with an exceptional strength-to-weight ratio, prized in racing, as they weigh roughly 42% less than steel but maintain superior durability. Steel, although heavier and prone to corrosion, remains a strong and cost-effective option for less demanding applications. Installation compatibility depends on the precise fit of mounts and fastener thickness; for instance, aluminum suits fairing panels around 5-7 mm thick, whereas titanium accommodates more intense structural demands. Understanding these material properties ensures that quick-release DZUS fasteners not only enable rapid removal and installation but also withstand the rigors of racing environments, maintaining secure fastening without compromising performance. For riders interested in exploring tailored fairing solutions, detailed insights can be found at Discover Affordable Motorcycle Fairings at Summit Fairings. More information on racing-oriented kits exemplifying these materials and installations is available through specialized vendors.

4. Tailoring Installation for Racing: Custom Solutions and Adaptations of DZUS Fairing Fasteners

Installing DZUS motorcycle fairing fasteners in racing contexts demands precise customization to accommodate unique race bodyworks. Unlike standard setups, race panels often feature varied shapes, thicknesses, and mounting points that require modifying drill patterns, rivet placements, and spring tensions for optimal securement and rapid release. Kits designed for competitive use include specialized hardware—fasteners, retainer washers, and springs—engineered to endure intense racing conditions. The quarter-turn quick-release mechanism significantly speeds pit stops, allowing swift panel removal and replacement without compromising attachment strength. Since many race fairing kits differ by model or class, adaptations frequently involve hands-on fitting or fabrication of mounts to replace stock rivets, improving durability and access. This customization ensures fairing fasteners integrate perfectly with race motorcycles, balancing performance and maintenance efficiency. For riders and mechanics, following detailed guides on hardware and modification strategies is essential to maximize the benefits of DZUS fasteners in racing environments. To explore curated fairing options that often pair well with such fasteners, visit Explore the Best Motorcycle Fairings at Summit Fairings. For additional technical details on installation and hardware, refer to the comprehensive Graves Motorsports DZUS Fastener Kit guide.

Chapter 3: Material Variants and Performance in DZUS Motorcycle Fairing Fasteners

1. How Material Choices Influence Strength, Weight, and Durability in DZUS Fasteners

The selection of materials for DZUS motorcycle fairing fasteners plays a pivotal role in balancing performance, durability, and weight. Stainless steel fasteners offer exceptional strength and corrosion resistance, making them highly durable but heavier, which can slightly impact overall motorcycle agility. Aircraft-grade aluminum stands out for its lightweight nature and corrosion resistance, enhancing handling by reducing added mass; however, it is less resistant to wear and mechanical stress compared to steel or titanium. Brass, while visually appealing and corrosion resistant, falls short in strength and durability, making it uncommon in high-performance racing applications. Titanium fasteners, especially those made from Grade 5 (6AL-4V), provide an optimal combination of high strength, outstanding corrosion resistance, and significant weight savings—approximately 42% lighter than steel—delivering superior performance benefits. This strength-to-weight balance reduces unsprung weight and enhances durability, making titanium the top choice for competitive racing setups. Ultimately, determining the appropriate material involves carefully weighing these trade-offs to meet specific performance, cost, and longevity requirements inherent to motorcycle racing and maintenance. For riders wanting to explore high-quality fairing options compatible with these fasteners, consider visiting Explore the Best Motorcycle Fairings at Summit Fairings.

[1]

2. Balancing Strength and Weight: Material Choices in DZUS Motorcycle Fasteners

DZUS motorcycle fairing fasteners must strike a careful balance between weight and strength, crucial for racing and high-performance setups. Stainless steel fasteners offer excellent durability and corrosion resistance but are the heaviest option, often chosen where toughness outweighs the need for weight savings. Aluminum alloys, such as 7075 or 6082, present a compelling compromise—they significantly reduce weight while maintaining good strength, ideal for riders seeking track performance without sacrificing longevity. At the pinnacle, titanium fasteners deliver outstanding strength-to-weight ratios, being approximately 42% lighter than steel while sustaining impressive mechanical robustness. This makes titanium the preferred choice in racing contexts focused on minimizing unsprung mass to enhance handling and acceleration. However, this superior performance comes at increased cost. Selecting the right material depends not only on weight and strength priorities but also on factors like corrosion resistance, fatigue life, and budget. For riders interested in exploring fairing options that complement these advanced fastening solutions, discover affordable motorcycle fairings at Summit Fairings provides a great resource. Understanding these trade-offs ensures that DZUS fasteners meet the specific demands of both street and race applications effectively.

3. Balancing Corrosion Resistance and Durability in DZUS Fastener Materials

Balancing Corrosion Resistance and Durability in DZUS Fastener Materials

DZUS motorcycle fairing fasteners must withstand diverse environmental stresses while enabling quick-release functionality. Their material composition fundamentally impacts corrosion resistance and long-term durability. Stainless steel fasteners excel in resisting rust and corrosion, enduring exposure to moisture and road salts, making them ideal for harsh conditions. In contrast, anodized aluminum fasteners offer significant weight reduction—up to 60% lighter than steel—while maintaining enhanced corrosion resistance through anodizing, which also increases surface hardness and preserves an attractive finish. Titanium fasteners represent a premium choice, merging exceptional strength, superior corrosion resistance, and minimal weight, favored in high-performance racing contexts where every gram counts. Manufacturing quality, surface treatments, and proper installation practices—such as thread lubrication—further enhance durability by mitigating wear and preventing corrosion at critical contact points. Selecting the appropriate DZUS fastener material involves weighing performance priorities, environmental exposure, and maintenance demands to ensure secure and resilient fastening of motorcycle fairings. For riders exploring lightweight fairing solutions without sacrificing protection, understanding these material trade-offs is essential. Learn more about reliable motorcycle fairing options at your ultimate source for affordable motorcycle fairings.

Comprehensive material insights and product options help tailor fastener choices to specific racing or street needs.

4. Balancing Cost, Durability, and Application: Material Choices in DZUS Fairing Fasteners

DZUS motorcycle fairing fasteners present varied material options, each with unique economic and performance implications. Steel fasteners are the most cost-effective, offering robust strength but greater weight and susceptibility to corrosion unless treated. Stainless steel provides a middle ground, delivering enhanced corrosion resistance and longevity, making it suited for street motorcycles exposed to weather elements. For top-tier racing applications, titanium fasteners stand out due to their exceptional strength-to-weight ratio and corrosion resistance, despite their significantly higher cost. Choosing the right fastener material involves weighing initial costs against maintenance needs and performance gains. Installation complexity can add to expenses since custom mounts or modifications are often necessary, especially with lightweight or premium fasteners. Racing demands prioritize rapid removal and minimal weight, favoring titanium and specialized steel variants, while street use balances durability and economy with stainless steel. Understanding these trade-offs helps riders select fasteners tailored to their bike’s intended use and budget. For deeper insights on selecting compatible race bodywork, explore this detailed guide on motorcycle fairings and customization. A comprehensive discussion on these factors can also be found in technical reviews covering titanium fasteners and their applications.

Chapter 4: Applications and Usage of DZUS Motorcycle Fairing Fasteners in Racing

1. Innovations Driving Performance: Technological Enhancements in DZUS Motorcycle Fairing Fasteners for Racing

Technological advancements have significantly refined DZUS motorcycle fairing fasteners, aligning their design with the rigorous demands of racing. Central to these improvements is the adoption of lightweight, high-strength materials like titanium and aluminum alloys. These materials not only reduce overall bike weight but also enhance corrosion resistance and durability under intense racing conditions. The hallmark quarter-turn quick-release mechanism enables racers and pit crews to remove and replace fairings swiftly, trimming valuable seconds during maintenance. Additionally, modern finishes such as black oxide and zinc plating bolster longevity and maintain the fasteners’ reliability even after repeated exposure to harsh environments. Customization is also pivotal; fasteners now accommodate bespoke mounts that enhance aerodynamic efficiency and ensure a secure fit. Moreover, innovations in fastener threading and internal wrench designs preserve integrity across numerous assembly cycles, critical for frequent pit stops. Collectively, these technological strides optimize balance between speed, durability, and ease of use—key factors that elevate race performance and teams’ operational efficiency. For an in-depth understanding of fastener options and technical details, consult specialized fastening kit providers.

2. Balancing Cost and Performance: The Economics Behind DZUS Fastener Use in Racing

The economic practicality of DZUS motorcycle fairing fasteners hinges on balancing initial investment with long-term benefits in racing environments. While kits involving twenty fasteners and mounting hardware represent a moderate upfront expense, their durability and quarter-turn quick-release design enable repeated removal and reinstallation without thread wear. This repeatability translates into significant savings by minimizing pit stop durations and servicing labor costs. Material choice profoundly influences cost: steel fasteners remain cost-effective, whereas aluminum variants provide reduced weight and corrosion resistance at a higher price, and titanium fasteners offer premium strength and lightweight advantages, critical in competitive contexts, though with elevated costs. Installation demands often require bodywork customization, increasing upfront labor but ensuring seamless performance during rapid maintenance. The widespread availability of compatible parts alleviates concerns over replacement delays and costs. Overall, the investment in quality fasteners and materials can reduce operational downtime and maintenance frequency, optimizing lifecycle expenses and justifying their role in racing setups. For richer insights into fairing options complementing fastener applications, explore comprehensive motorcycle fairings available at Summit Fairings. For an expert economic perspective on fastener durability and service, refer to detailed analyses by industry professionals.

3. How Geopolitical Dynamics Shape the Racing Use of DZUS Motorcycle Fairing Fasteners

The global landscape significantly influences the availability and adoption of DZUS motorcycle fairing fasteners in racing. Geopolitical factors impact supply chains, with disruptions from trade restrictions or political conflicts affecting production hubs known for advanced metallurgy. Such issues can lead to increased costs or shortages, especially for critical materials like titanium, prized for its strength and lightness in racing applications. Moreover, regional racing standards aligned with economic or political blocs dictate the types and materials of fasteners permitted, indirectly steering which DZUS fasteners become standard in various markets. Economic sanctions and trade agreements further alter accessibility, sometimes limiting elite-grade fasteners in certain regions and prompting substitutions or modifications among racers. Additionally, geopolitical ties influence technological transfers, enhancing production capability and innovation in partnered countries while constraining others. Thus, while DZUS fasteners remain universally prized for quick-release functionality and durability, their practical use in racing circuits worldwide reflects a complex interplay of geopolitical forces that shape manufacturing stability, regulatory compliance, market access, and technology sharing. For those interested in competitive motorcycle components, exploring reliable sources can ensure access to quality parts despite these challenges. More details on racing fastener kits can be found here.

4. Balancing Speed and Safety: Societal Impact of DZUS Fairing Fasteners in Competitive Motorcycling

DZUS motorcycle fairing fasteners epitomize the racing culture’s demand for swift efficiency, enabling quick removal and reattachment of bodywork during intense competitions. Their design uniquely supports rapid maintenance, crucial for minimizing downtime in high-pressure race environments. This functionality has transcended professional circuits, inspiring enthusiasts to adopt these fasteners and cultivate a DIY modification culture. However, implementing DZUS fasteners often requires custom mounting, posing challenges for those without technical expertise. Improper installation risks loosening under vibration, potentially causing fairing detachment that endangers riders and others on track. Economically, the investment in these fasteners is primarily aligned with professional use where performance gains justify costs, while hobbyists may find the expense prohibitive. Consequently, this dynamic shapes how widely DZUS systems permeate the broader motorcycling community. Ultimately, their societal influence is intertwined with a commitment to safety and precision installation practices that uphold the integrity and security essential in racing. For enthusiasts seeking reliable bodywork solutions, exploring affordable motorcycle fairings at Summit Fairings offers complementary options. [1]

[1] Industry sources and manufacturer specifications on DZUS fastener kits and their application in motorcycle racing.

Chapter 5: Availability and Commercial Kits of DZUS Motorcycle Fairing Fasteners

1. Material Innovation and Design Customization in Commercial DZUS Motorcycle Fairing Fastener Kits

DZUS motorcycle fairing fasteners are engineered for swift, reliable fastening, making their commercial kits highly sought after in racing and custom motorcycle communities. These kits predominantly feature a rivet-style, quarter-turn pin mechanism that secures fairings while enabling rapid removal and installation. Materials play a crucial role; standard steel fasteners offer durability, but premium kits often utilize lightweight titanium alloys, notably Grade 5 (6AL-4V), enhancing strength-to-weight ratios by reducing mass significantly without sacrificing resilience. Aluminum variants provide a corrosion-resistant, lighter option ideal for competitive settings. Design-wise, complete kits include not just the fasteners but also retainer washers, springs, and rivets, typically available in multiples suited for full fairing setups. Some kits target specific motorcycle models with pre-configured mounts, while universal options accommodate custom mounting needs. The variety extends to clip-type fasteners offered in smaller packs, providing versatile fitting solutions. This spectrum of materials and designs allows racers and enthusiasts to tailor their fastener choice for optimal performance, durability, and ease of maintenance. For more insights on accompanying fairing options, explore affordable motorcycle fairings at Summit Fairings. Detailed hardware sets can be found through specialty suppliers offering comprehensive DZUS fastener kits that emphasize quick-release efficiency and customization.

2. Economic Dynamics Shaping the Market for DZUS Motorcycle Fairing Fasteners: Pricing and Kit Availability

The market availability and pricing of DZUS motorcycle fairing fasteners are heavily influenced by economic dynamics tied to their specialized manufacturing and niche demand. These fasteners require precise production methods and use robust materials like steel, aluminum, or titanium, which inherently raise costs compared to generic fasteners. Their primary use in racing and custom motorcycle bodywork limits mass production, restricting suppliers and reinforcing premium pricing. Commercial kits typically package multiple fasteners with washers, springs, and rivets, reflecting their technical complexity and the need for custom installations. Retailers price these kits to cover specialized components and services, with costs fluctuating based on material quality and bundled hardware. This specialized focus results in a moderate market supply, often concentrated in specialty vendors, maintaining DZUS fasteners as a premium option for performance-focused riders. For more on quality components that complement DZUS fasteners, explore the explore the best motorcycle fairings at Summit Fairings store. External sources confirm that such commercial kits typically retail around $127, reflecting advanced engineering and materials used in their manufacture.

3. Navigating Geopolitical and Supply Chain Challenges Shaping DZUS Fairing Fastener Kits

The availability and commercial offerings of DZUS motorcycle fairing fasteners are deeply intertwined with geopolitical and supply chain realities. Trade policies and tariffs on raw materials like steel and aluminum directly impact production costs and retail pricing, influencing accessibility for racers and custom builders. Political instability or export restrictions in key manufacturing regions can delay shipments or limit component supply, exacerbating scarcity. Additionally, disruptions such as those caused by the COVID-19 pandemic have revealed vulnerabilities in global logistics, causing delays in shipment and shortage of fastener components. Because DZUS fasteners cater primarily to niche markets, production volumes remain modest, making supply fluctuations more pronounced compared to mass-market fasteners. Manufacturers respond to these challenges by diversifying kit configurations, including complete hardware sets with fasteners, springs, washers, and rivets tailored for various motorcycle models or racing requirements. This adaptability aids in maintaining a steady supply despite geopolitical and logistical pressures. For enthusiasts seeking a reliable source of comprehensive fastener kits, exploring options through specialty vendors provides valuable solutions amid these constraints. More on choosing fairings and accessories can be found at Discover affordable motorcycle fairings at Summit Fairings.

4. Embracing Speed and Style: How DZUS Fastener Kits Drive Racing Culture and Custom Motorcycle Innovation

DZUS motorcycle fairing fastener kits have become indispensable within racing and customization communities, significantly shaping user adoption and societal trends. Their hallmark quarter-turn design enables swift fairing changes vital for competitive racing, enhancing pit stop efficiency and mechanical reliability under pressure. Beyond the track, these fasteners have sparked a cultural shift in motorcycle customization, where enthusiasts prize both practicality and aesthetic appeal. The ready availability of commercial kits, often featuring premium materials like titanium or aluminum, empowers riders to upgrade their motorcycles with race-grade hardware that blends durability with lightweight performance. This accessibility nurtures a vibrant aftermarket scene, encouraging manufacturers to integrate DZUS-compatible mounts in their designs, thus broadening market reach while advancing hardware innovation. As a result, DZUS fasteners transcend mere functionality, symbolizing a commitment to modular design and streamlined maintenance favored by today’s performance-focused riders. For those seeking comprehensive options in motorcycle fairings paired with efficient hardware solutions, Summit Fairings offers an excellent resource to explore. Additional insights on competitive use and specialized parts are available at RoadracingWorld.com.

Chapter 6: Innovations and Alternatives to DZUS Motorcycle Fairing Fasteners

1. Cutting-Edge Materials and Rapid-Release Designs Transforming Motorcycle Fairing Fasteners

Modern advancements in motorcycle fairing fasteners focus heavily on integrating advanced materials and refined quick-release mechanisms to surpass traditional DZUS fasteners. Fasteners crafted from stainless steel deliver superior corrosion resistance and enhanced strength, ideal for enduring rigorous riding conditions. Titanium alternatives offer racers a premium edge by combining exceptional lightweight properties with high durability, significantly reducing overall motorcycle weight while maintaining secure attachment. Beyond material innovation, evolving quick-release designs improve on the classic quarter-turn mechanism by incorporating undercut locking features that allow faster, tool-free fairing removal. These refined mechanisms not only reduce maintenance and pit-stop times but also enhance rider convenience without compromising panel security. Finishing touches such as anodized coatings and precision machining elevate the aesthetic appeal, matching the high-performance nature of modern motorcycles. Additionally, model-specific kits ensure flawless compatibility and fitment, further streamlining installation and upkeep. Together, these technological strides create fasteners that are more durable, user-friendly, and visually striking compared to traditional options, advancing the standards for race and street motorcycle fairing solutions. For a detailed perspective on cutting-edge fairing options, explore premium motorcycle fairings and accessories.

2. Economic Dynamics of Modern Motorcycle Fairing Fasteners: Balancing Cost, Value, and Market Evolution

The evolving landscape of motorcycle fairing fasteners is shaped by economic factors that weigh cost, material innovation, and shifting market demand. Traditional DZUS fasteners, typically stainless steel, offer an affordable balance of durability and corrosion resistance, appealing to the mainstream market segment. On the other hand, premium alternatives crafted from titanium or aircraft-grade aluminum command higher prices but deliver superior strength, lightweight benefits, and enhanced aesthetics, targeting performance-focused enthusiasts willing to invest more. Budget options using aluminum or brass provide accessible solutions, though sometimes at the expense of longevity. Market trends show a clear preference for fasteners that combine quick-release convenience with customizable features, fueling competition across OEM and aftermarket suppliers. This diversity supports a segmented economy where cost-sensitive riders coexist with premium buyers, encouraging manufacturers to diversify product lines and innovate designs. Such developments stimulate aftermarket sales and reinforce the economic significance of fairing fasteners in motorcycle maintenance and customization industries. For riders seeking both affordability and quality, exploring affordable motorcycle fairings can complement choices in fasteners effectively. Source on titanium fasteners

3. Geopolitical and Supply Chain Forces Shaping DZUS Fastener Alternatives

DZUS motorcycle fairing fastener innovations are deeply influenced by geopolitical realities and supply chain dynamics. The sourcing of metals like stainless steel, aluminum, and titanium—integral to fastener production—is often subject to export controls, tariffs, and regional political stability. For example, titanium, favored for its strength and lightness, relies on supply chains centered in specific countries vulnerable to trade restrictions. Manufacturing hubs spread across Asia and Europe further add complexity; disruptions such as trade disputes or shipping delays can delay both original DZUS fasteners and alternative products. This uncertainty encourages development of designs using more readily sourced materials or locally manufactured kits to assure supply resilience. Online marketplaces reflect these dynamics, displaying diverse fastener kits in materials and designs that balance performance with availability and cost. Riders and manufacturers navigate these layered challenges, weighing geopolitical factors alongside technical requirements to select fastener solutions. For deeper insight into motorcycle fairing options complementing these fastener considerations, explore the range of affordable motorcycle fairings available at Summit Fairings.

4. Enhancing Rider Experience and Community Impact Through Fastener Innovation

Innovations in motorcycle fairing fasteners go beyond mere mechanics, deeply enriching the rider’s experience and resonating within enthusiast communities. Upgrading to quick-release or corrosion-resistant fasteners made from stainless steel, titanium, or aircraft-grade aluminum elevates convenience by enabling faster, tool-free fairing removal. These improvements not only reduce maintenance time but also contribute to prolonged durability and a refined aesthetic appeal. Riders appreciate customizable options that match their bike’s style while ensuring dependable performance under racing conditions.

At a societal level, such advancements echo broader sustainability goals by utilizing durable materials that lower the need for frequent replacements, thereby decreasing environmental impact. The growth of aftermarket offerings fosters a vibrant network of suppliers and enthusiasts, invigorating local economies and empowering riders to personalize their machines. Additionally, quick and reliable fastening systems promote safer, more efficient servicing, potentially minimizing roadside issues and enhancing overall rider safety.

These combined user-centric and societal benefits spotlight how modern alternatives to traditional DZUS fasteners are pivotal to both motorcycle culture and responsible innovation. For those interested in exploring a wide selection of fairing options that complement fastener upgrades, consider reviewing offerings at Explore the Best Motorcycle Fairings at Summit Fairings.

Learn more about material advantages and product variety here: https://www.alibaba.com/showroom/1-4-turn-fasteners.html

Final thoughts

DZUS motorcycle fairing fasteners remain a fundamental component for businesses serving the racing and high-performance motorcycle market. Their distinctive quarter-turn design delivers unmatched speed and convenience for pit stops and maintenance, making them indispensable for race teams and enthusiasts alike. Selecting the appropriate installation techniques and material variants directly influences durability, corrosion resistance, and weight savings—key factors driving customer satisfaction and performance outcomes. With numerous commercial kits available, businesses can provide tailored solutions that cater to universal or model-specific requirements. Additionally, emerging fastener innovations present fresh opportunities to diversify product offerings and meet evolving customer demands. By mastering the technical, practical, and market aspects of DZUS fasteners, business owners position themselves to enhance their competitive edge and supply high-value products that blend efficiency, reliability, and cutting-edge performance.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined

RELATED POSTS

View all