Mastering Fiberglass Repair for Motorcycle Fairings: A Business Owner’s Guide

September 18, 2025 | by summitfairings

Introduction

Fiberglass motorcycle fairings are both aesthetic and structural components critical to a bike’s performance and appeal. For business owners in the motorcycle repair or customization industry, understanding the nuances of fiberglass fairing repair not only improves service quality but also optimizes customer trust and retention. Mastery over this process involves precise cleaning and surface preparation, accurate damage assessment and removal, selection of appropriate resins, expert layering with fiberglass cloth, and meticulous curing and finishing. Additionally, knowing when replacement is the better option ensures cost-effectiveness and long-term satisfaction. This guide breaks down each essential stage so business owners can elevate their repair offerings, ensuring every motorcycle fairing repaired matches the original strength and appearance that customers expect.

Tables of Contents

Chapter 1: Cleaning and Surface Preparation for Fiberglass Repair Motorcycle Fairing

- Essential Steps to Remove Contaminants and Ensure Optimal Surface Readiness for Fiberglass Fairing Repair

- Mastering Surface Abrasion: The Key to Durable Fiberglass Fairing Repairs

- Effective Removal of Damaged Fiberglass and Practical Dust Management for Safe, Durable Repairs

- Mastering Resin Application and Ideal Conditions for Optimal Fiberglass Fairing Repair

Chapter 2: Assessing and Removing Damaged Fiberglass in Fiberglass Repair Motorcycle Fairing

- Mastering Damage Evaluation and Preparation for Durable Fiberglass Fairing Repairs

- Essential Surface Cleaning and Preparation for Optimal Fiberglass Fairing Repairs

- Mechanical Techniques for Precise Removal of Damaged Fiberglass in Motorcycle Fairing Repairs

- Integrating Reinforcement and Finishing Techniques for Durable Fiberglass Motorcycle Fairing Repairs

Chapter 3: Resin Selection and Application in Fiberglass Repair Motorcycle Fairing

- Choosing the Right Resin and Preparing the Surface for Durable Motorcycle Fairing Repairs

- Balancing Cost, Durability, and Availability: Practical Resin Choices for Motorcycle Fairing Repairs

- Navigating Global Supply Dynamics: How Geopolitical Factors Shape Resin Choices in Fiberglass Fairing Repair

- Balancing Safety, Durability, and Sustainability: The Societal Role of Resin Choices in Fiberglass Fairing Repairs

Chapter 4: Fiberglass Cloth Layering Techniques in Fiberglass Repair Motorcycle Fairing

- Mastering Materials and Methods: Essential Tools and Fiberglass Cloth Layering for Motorcycle Fairing Repair

- Maximizing Cost Efficiency and Resource Use Through Strategic Fiberglass Layering

- How Global Supply and Trade Shape Fiberglass Cloth Choices in Motorcycle Fairing Repairs

- Cultivating Expertise and Sustainability: The Broader Impact of Fiberglass Cloth Layering in Motorcycle Fairing Repairs

Chapter 5: Curing, Sanding, and Finishing Processes in Fiberglass Repair Motorcycle Fairing

- Mastering Resin Curing, Precision Sanding, and Flawless Finishing in Fiberglass Fairing Repairs

- Balancing Cost and Quality: Economic Factors in Fiberglass Fairing Curing, Sanding, and Finishing

- Global Geopolitical Impacts Shaping Materials and Techniques in Fiberglass Motorcycle Fairing Repairs

- Balancing Safety, Skill, and Sustainability in Fiberglass Fairing Repairs

Chapter 6: Navigating Replacement Choices and Material Essentials in Fiberglass Motorcycle Fairing Repair

- Choosing the Right Materials and Resins for Durable Fiberglass Motorcycle Fairing Repairs

- Mastering Surface Preparation and Application for Durable Fiberglass Fairing Repairs

- Choosing Aftermarket Motorcycle Fairings: Material Insights and Installation Tips

- Tailored Techniques for Carbon Fiber Repairs: Ensuring Strength and Durability in Motorcycle Fairings

Chapter 1: Cleaning and Surface Preparation for Fiberglass Repair Motorcycle Fairing

1. Essential Steps to Remove Contaminants and Ensure Optimal Surface Readiness for Fiberglass Fairing Repair

Preparing a fiberglass motorcycle fairing for repair begins with meticulously removing contaminants that can weaken resin adhesion. Start by thoroughly cleaning the damaged area using mild soap and water or a gentle degreaser to eliminate dirt, oils, and loose debris without harming the existing finish. Next, carefully sand the repair zone with fine to medium grit paper (typically 80–120 grit) to roughen the surface and expose solid fiberglass, removing any fragile or loose fragments. This light abrasion encourages stronger mechanical bonding when the resin and fiberglass cloth are applied. Following sanding, wipe the area with isopropyl alcohol or acetone to remove fine dust, skin oils, and residues that might compromise the repair’s durability. Avoid harsh chemicals throughout, as they can deteriorate the fairing’s underlying material. This combined approach—progressive cleaning, abrasion, and solvent wipe—provides an ideal foundation ensuring that the fiberglass repair will bond securely and last. For more insights on fairing care and repair, explore detailed guides at Summit Fairings Blog.

2. Mastering Surface Abrasion: The Key to Durable Fiberglass Fairing Repairs

Achieving a durable fiberglass repair on motorcycle fairings hinges on meticulous surface abrasion techniques. Using fine-to-medium grit sandpaper (220–320 grit), lightly scuff the area surrounding the damage to remove oxidation, old paint, and contaminants without compromising the integrity of the fiberglass substrate. This creates an ideal texture that enhances adhesion of epoxy or polyester resin. Thorough cleaning follows abrasion, employing mild soap and water then wiping with solvents like acetone to eliminate dust and oils that weaken bonding agents. Controlled manual sanding or low-speed abrasion tools ensure the fiberglass fibers remain intact; aggressive grinding can cause structural weakening and should be avoided. For enhanced wear resistance, adding colloidal silica to epoxy coatings applied over the abraded surface improves hardness and durability. This approach, adapted from marine fiberglass repair practices, prepares the fairing for resilient, long-lasting restoration. For more insights on motorcycle fairings, explore the full range of options and repair tips.

3. Effective Removal of Damaged Fiberglass and Practical Dust Management for Safe, Durable Repairs

Removing all compromised fiberglass is crucial to restoring your motorcycle fairing’s strength and longevity. Begin by carefully inspecting the damaged area, then use sandpaper to eliminate loose or weakened fibers, creating a solid foundation for the repair. Since sanding fiberglass generates fine, hazardous dust, always wear a respirator mask rated for particulate filtration to protect your respiratory system. After sanding, thoroughly clean the workspace and use vacuum equipment to remove lingering dust, preventing contamination and health risks. Once dust is cleared, wipe the surface with a solvent or cleaner to remove grease and residues that could interfere with resin adhesion. Ensure the surface is completely dry before proceeding. This meticulous approach to damaged material removal and dust control not only safeguards your health but also enhances the effectiveness and durability of your fiberglass repair. For those seeking detailed visual guidance on these critical steps, this tutorial offers a clear walkthrough. Additionally, best practices on dust control during composite material sanding are outlined in professional resources such as longEZpush.com. To explore a wide range of high-quality motorcycle fairing options that complement your repairs, visit Summit Fairings’ blog.

4. Mastering Resin Application and Ideal Conditions for Optimal Fiberglass Fairing Repair

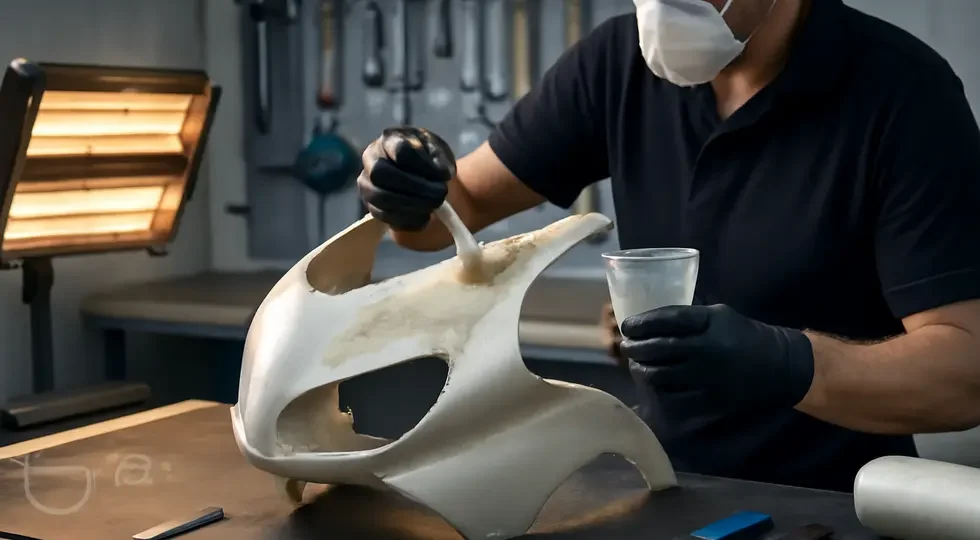

Effective fiberglass repair begins with thoroughly cleaning the damaged fairing area, removing all dirt, grease, and contaminants. Light sanding roughens smooth surfaces to enhance resin adhesion. Selecting the correct resin, polyester or epoxy, is vital; epoxy is often favored for stronger, durable bonds. When applying resin, saturate the fiberglass cloth fully using a brush without trapping air bubbles that weaken the patch. Layering starts with smaller patches over holes, gradually feathering edges with larger pieces to replicate original thickness. Curing demands careful attention to temperature and humidity—ideally around 70°F (21°C) with low humidity—to ensure proper hardening over several hours. Work in a well-ventilated space to prevent inhaling resin fumes. After curing, sanding with progressively finer grit helps achieve a smooth finish, ready for filler or paint. Proper disposal of resin waste prevents environmental harm, making each step crucial to restoring both strength and appearance. For further guidance on sourcing fiberglass fairings and repair tips, explore Summit Fairings’ comprehensive resources.

Chapter 2: Assessing and Removing Damaged Fiberglass in Fiberglass Repair Motorcycle Fairing

1. Mastering Damage Evaluation and Preparation for Durable Fiberglass Fairing Repairs

Effectively repairing a fiberglass motorcycle fairing begins with a precise evaluation of damage. Start with a detailed visual inspection to identify cracks, holes, delamination, or weakened fiberglass fragments that could jeopardize repair strength. Thoroughly cleaning the area removes contaminants like dirt and grease, while light sanding with 80 to 120 grit paper roughens the surface, enhancing resin adhesion. Removing all compromised or loose fiberglass layers is crucial; leaving fragile material beneath can cause future failure. For structural flaws, cutting fiberglass cloth patches slightly larger than damage ensures solid reinforcement from inside the fairing. Applying epoxy resin, preferred for its superior bonding and strength, combined with structural fillers like flox, rebuilds missing sections and restores toughness. Clamping the area during curing preserves shape and bonding integrity. After curing, sanding and finishing prepare the repair for final painting, balancing both durability and aesthetics. This meticulous process ensures your motorcycle fairing regains strength and looks seamless. For expanded visual guidance, see practical tutorials like the motorcycle fiberglass fairing repair video.

2. Essential Surface Cleaning and Preparation for Optimal Fiberglass Fairing Repairs

Successful fiberglass repair begins with meticulous surface cleaning and preparation to ensure durable adhesion and a smooth finish. After initial cleaning with acetone or a degreaser removes oils and contaminants, the damaged area must be lightly sanded until the surface appears dull and roughened. This sanding step eliminates loose fibers and creates the ideal texture for resin bonding. Complete removal of dust, typically by vacuuming or wiping, follows to prevent weak spots in the repair. Careful inspection of the surface identifies any underlying cracks or delamination requiring material removal before reinforcement. Clamping or stabilizing the fairing section may be necessary to preserve its shape during resin application and curing. Using marine-grade polyester or epoxy resin compatible with the original fiberglass enhances strength and longevity. This thorough preparation not only promotes a stronger bond but also guards against future moisture intrusion and UV damage. For comprehensive guidance on fairing materials and repair techniques, explore expert insights at Explore the Best Motorcycle Fairings at Summit Fairings.

3. Mechanical Techniques for Precise Removal of Damaged Fiberglass in Motorcycle Fairing Repairs

Effective repair of a motorcycle’s fiberglass fairing begins with skillful removal of compromised material. This involves sanding damaged areas with grit between 80 and 120 to expose a clean, rough surface free from dirt, grease, and loose fibers. For thicker or more extensive damage, mechanical cutting tools like saber saws or rotary devices are employed to remove excess cured fiberglass swiftly and with precision. When the fiberglass layup is partially cured but still pliable, careful trimming with a sharp knife prevents harm to the underlying structure while eliminating unwanted material. Vacuuming after sanding clears harmful dust and debris, ensuring an optimal bonding surface for new fiberglass layers. Employing these mechanical removal methods with protective gear safeguards both repair quality and user safety. This precise preparation underpins the structural integrity and seamless finish essential to a successful fiberglass fairing restoration. For detailed guidance, refer to specialized aircraft gear fiberglass trimming techniques that translate well to motorcycle fairing repair here.

4. Integrating Reinforcement and Finishing Techniques for Durable Fiberglass Motorcycle Fairing Repairs

Successfully restoring a damaged motorcycle fairing requires thoughtful reinforcement and meticulous finishing. After carefully removing weakened fiberglass and cleaning the area, reinforcement begins by cutting fiberglass cloth or mat slightly larger than the damaged patch. Applying a resin layer—preferably epoxy due to its superior strength—on the clean surface is essential before laying the cloth to ensure thorough saturation and strong bonding. Multiple resin and cloth layers might be necessary for extensive holes, applied primarily from the fairing’s interior when accessible to maximize structural integrity. Once fully cured, sanding smooth blends the repair into the surrounding surface seamlessly. Minor imperfections are filled with body putty, then sanded for an even finish. Finally, priming and painting restore the fairing’s original look and provide protection, revitalizing both appearance and durability. This holistic process ensures the repaired fiberglass fairing performs reliably while matching the motorcycle’s aesthetic needs. For in-depth visual guidance, see the detailed repair demonstration. For affordable replacement options and additional repair insights, explore this comprehensive source for motorcycle fairings.

Chapter 3: Resin Selection and Application in Fiberglass Repair Motorcycle Fairing

1. Choosing the Right Resin and Preparing the Surface for Durable Motorcycle Fairing Repairs

Selecting the appropriate resin is crucial for successful fiberglass motorcycle fairing repair, relying on resin properties such as adhesion, curing time, flexibility, and chemical resistance. Polyester resin remains popular due to its affordability and ease of use, making it ideal for non-structural fixes and rapid curing projects. Epoxy resin, however, offers superior strength, enhanced water and chemical resistance, and greater flexibility, which suits structural repairs and composite materials like carbon fiber. Ensuring a clean, dry, and well-sanded surface maximizes resin bonding, with all loose or weak fiberglass removed to establish a stable base. The application involves saturating fiberglass cloth or mat with resin, applied slightly beyond the damage edges, then allowing full curing under controlled conditions before sanding. This method balances durability, structural integrity, and finish quality for reliable repairs. For further expert insights, explore comprehensive guidance on motorcycle fairings and repairs.

2. Balancing Cost, Durability, and Availability: Practical Resin Choices for Motorcycle Fairing Repairs

Economic factors guide the choice of resin in fiberglass motorcycle fairing repairs, particularly balancing cost, efficiency, and accessibility. Polyester resin stands out as the most budget-friendly option, prized for its quick curing time and broad availability at automotive suppliers. This makes it ideal for typical DIY repairs where cost and ease of use are priorities. Epoxy resin, while more expensive and requiring precise mixing, offers enhanced strength and chemical resistance—attributes critical for longer-lasting or structural repairs and for composites like carbon fiber. Vinyl ester resins provide a middle ground in cost and performance but may be harder to source. The decision hinges on the repair’s demands: polyester suits standard fixes, while epoxy benefits premium or high-stress applications. Considering resin availability can affect both price and project timing, especially when specialized suppliers are needed for epoxy systems. Understanding these trade-offs ensures a cost-effective, durable repair tailored to the motorcycle’s specific fairing needs.

For more insights on selecting materials for fairing repairs, visit the Discover Affordable Motorcycle Fairings at Summit Fairings blog.

Reference: Turn1 – Carbon Fiber Parts & Maintenance Considerations

3. Navigating Global Supply Dynamics: How Geopolitical Factors Shape Resin Choices in Fiberglass Fairing Repair

The selection and application of resin in fiberglass motorcycle fairing repair extend beyond technical merits, deeply influenced by geopolitical and economic factors shaping raw material availability. Most common resins like polyester and epoxy originate from petrochemical feedstocks, subject to volatility in oil-producing regions where geopolitical instability can cause price surges and supply interruptions. Trade policies including tariffs and sanctions imposed by key producers such as the US, China, and EU impact resin costs and accessibility, prompting repair professionals to weigh not only resin performance but supply security. Disruptions in global shipping—such as port congestion or maritime delays—can further complicate procurement timelines, encouraging local sourcing or alternative resin formulations to maintain repair consistency. Navigating these geopolitical pressures requires balancing material durability with supply reliability, underscoring the importance of flexible sourcing strategies to ensure effective, durable fairing repairs. For broader insight on motorcycle fairing materials, explore the comprehensive resources at Summit Fairings.

4. Balancing Safety, Durability, and Sustainability: The Societal Role of Resin Choices in Fiberglass Fairing Repairs

The selection and application of resin in fiberglass motorcycle fairing repairs profoundly affect safety, durability, and environmental responsibility. Choosing the correct resin type—often epoxy, polyester, or vinyl ester—influences the repair’s structural integrity and impact resistance, critical for rider protection and preserving the fairing’s original aerodynamic properties. Epoxy resins notably provide superior adhesion and mechanical strength, essential for lasting repairs that withstand high-speed stresses. Concurrently, the curing process must minimize defects like air bubbles to maintain resilience and prevent premature failure. Beyond performance, traditional petrochemical-based resins release volatile organic compounds (VOCs) that pose health risks and environmental concerns during curing. Progressive resin technologies now emphasize reusability, recyclability, and safer formulations, aligning repair practices with ecological stewardship. Adopting careful application methods, including waste minimization and protective equipment use, reduces chemical exposure and environmental impact. This integrated approach ensures that fiberglass fairing repairs not only restore functionality and aesthetics but also reflect broader societal commitments to safety and sustainability. For further insights on fiberglass fairing care, refer to this comprehensive motorcycle fairings guide and the external resource on repair methodology “How Do You Repair Fiberglass On A Motorcycle?” on YouTube.

Chapter 4: Fiberglass Cloth Layering Techniques in Fiberglass Repair Motorcycle Fairing

1. Mastering Materials and Methods: Essential Tools and Fiberglass Cloth Layering for Motorcycle Fairing Repair

The effectiveness of fiberglass cloth layering in motorcycle fairing repair hinges on selecting the right materials and applying precise methods. Fiberglass cloth or mat serves as the core reinforcement—cloth provides a smoother finish while mat adds bulk and strength. Polyester resin offers cost efficiency, but epoxy resin is often preferred for its superior bonding and durability, especially on structural repairs. Critical tools include sandpaper to create a rough, adhesive-friendly surface and sharp cutters for trimming cloth slightly larger than the damage. Applying resin evenly with brushes or rollers ensures thorough saturation without air bubbles. Repair begins by cleaning and sanding the damaged area, followed by layering resin and fiberglass cloth from the inside out to reinforce cracks or holes effectively. Each layer must cure fully to develop strength before smoothing and optionally finishing with gel coat or primer for added protection and aesthetic appeal. This meticulous integration of materials, tools, and methods ensures restored fairings regain their original resilience and sleek appearance essential for motorcycle performance. For additional advice on sourcing quality fairings, explore affordable motorcycle fairings.

2. Maximizing Cost Efficiency and Resource Use Through Strategic Fiberglass Layering

Fiberglass cloth layering techniques in motorcycle fairing repair offer substantial economic benefits by enabling precise material usage and enhancing repair durability. By strategically applying layers only where reinforcement is critical, material waste is minimized, lowering costs for both cloth and resin. This targeted approach avoids excess application, reducing labor time during resin spreading, sanding, and curing phases. Consequently, repairs are completed more efficiently, saving both time and money.

Moreover, layering creates stronger, longer-lasting repairs that diminish the need for frequent rework or full part replacement, resulting in significant long-term cost savings. Compared to premium carbon fiber alternatives, fiberglass repair kits present a practical, budget-friendly solution without sacrificing structural integrity or appearance. Optimized layering produces financial and environmental value by balancing material expenses, labor efficiency, and repair longevity. This sustainable method supports motorcycle owners in maintaining their fairings affordably and effectively.

For further insights on affordable repair options and fairing materials, explore this comprehensive resource on affordable motorcycle fairings.

3. How Global Supply and Trade Shape Fiberglass Cloth Choices in Motorcycle Fairing Repairs

The techniques of fiberglass cloth layering in motorcycle fairing repairs are indirectly shaped by global geopolitical dynamics. Fiberglass cloth, essential for restoring strength and aesthetics, depends heavily on materials sourced from countries like China, the U.S., Germany, and Japan. Trade policies, tariffs, and political tensions influence availability and pricing, often forcing repair specialists to adjust layering strategies based on accessible materials. Supply chain disruptions arising from conflicts or sudden regulations cause delays, altering resin and cloth quality at hand. Moreover, nations investing in composite technologies create advanced fiberglass fabrics that affect fabric weight, weave, and layering methods, with innovation sharing restricted by intellectual property laws rooted in geopolitical climates. Environmental and safety regulations also dictate resin compatibility and layering parameters, ensuring compliant repairs. Thus, while geopolitical factors do not command specific layering steps, they determine the quality and type of materials technicians employ, shaping repair outcomes. For further insights, explore comprehensive motorcycle fairing options and guides.

4. Cultivating Expertise and Sustainability: The Broader Impact of Fiberglass Cloth Layering in Motorcycle Fairing Repairs

Fiberglass cloth layering in motorcycle fairing repair goes beyond technical application; it nurtures valuable skills and prompts environmental mindfulness. Those who engage in these repairs develop expertise in damage assessment, surface preparation, and resin application. This hands-on experience enhances mechanical literacy and craftsmanship within the motorcycle community, empowering enthusiasts and professionals alike. Small repair businesses often thrive by specializing in these niche skills that help preserve motorcycle heritage. Simultaneously, repairing rather than replacing fairings reduces waste and conserves resources. However, working with polyester or epoxy resins introduces challenges, as these composites are non-biodegradable and may emit volatile organic compounds during curing if not managed properly. Efforts to improve resin formulations and recycling techniques are emerging yet still limited in adoption. Balancing skilled craftsmanship with careful environmental practices fosters a responsible repair culture that supports both community growth and sustainability. For those interested, a comprehensive tutorial on this subject offers practical guidance and further skill development insights. For additional insights on sourcing parts to complement your repairs, explore this affordable motorcycle fairings resource.

Chapter 5: Curing, Sanding, and Finishing Processes in Fiberglass Repair Motorcycle Fairing

1. Mastering Resin Curing, Precision Sanding, and Flawless Finishing in Fiberglass Fairing Repairs

The curing, sanding, and finishing stages are critical to restoring both the structural integrity and appearance of a fiberglass motorcycle fairing. Effective curing ensures the resin fully polymerizes, creating a strong bond with the fiberglass cloth. This typically occurs at room temperature with catalysts, although controlled heat can speed the process and improve mechanical strength, especially in advanced composites. Once cured, the fairing’s surface undergoes progressive sanding, starting with coarse grits to remove excess resin and shape the repair, followed by finer grits to achieve a smooth, aerodynamic finish. This meticulous sanding also promotes reliable adhesion of primers and paints. The finishing stage applies primers, fillers, base coats, and clear coats to restore the fairing’s original color and gloss while protecting against UV exposure and wear. Polishing finalizes the process, providing a seamless, showroom-quality look. Mastery of these interconnected steps guarantees a durable and visually pristine repair. For more insights on quality motorcycle fairings, exploring premium sourcing options can be invaluable. External resources such as comprehensive aftermarket body kits detail advanced finishing techniques for high-performance repairs.

2. Balancing Cost and Quality: Economic Factors in Fiberglass Fairing Curing, Sanding, and Finishing

Economic considerations play a crucial role in the curing, sanding, and finishing stages of fiberglass motorcycle fairing repair. The costs of materials like resin, sandpaper, and finishing compounds directly impact repair budgets, while labor intensity during sanding and finishing often dominates expenses due to the skill and time required. Choosing quality materials can reduce labor and rework but increase upfront costs, creating a delicate balance between price and durability. Investing in efficient curing equipment and quality sanding tools boosts process speed and consistency, lowering long-term costs and enhancing repair strength. Properly cured and finished fairings retain shape and fit, minimizing future damage and replacements, which translates into extended service life and preserved motorcycle value. These economic dynamics make optimizing the repair process essential for delivering durable results while managing total costs effectively. For practical insights into quality and cost trade-offs in bodywork repairs, explore unmatched motorcycle fairing options at Summit Fairings. Additional technical details on curing stresses in fibreglass moulds provide depth at Fiberglass moulds and curing stresses.

3. Global Geopolitical Impacts Shaping Materials and Techniques in Fiberglass Motorcycle Fairing Repairs

Geopolitical dynamics play a crucial role in shaping the materials and methods used during curing, sanding, and finishing of fiberglass motorcycle fairings. The availability and cost of essential raw materials like resins, hardeners, fillers, and abrasives largely depend on regional political stability and trade relations, especially since many originate from geopolitically sensitive zones such as parts of Asia-Pacific. Supply chain disruptions caused by tariffs, sanctions, or political unrest can compel repair professionals to adapt their techniques or source alternative materials. This volatility affects resin quality and abrasive effectiveness, directly impacting repair durability and finish smoothness. To mitigate these challenges, innovations in curing agents and substitute sanding materials have emerged, prioritizing consistent performance despite constrained supply. Regional manufacturing trends and shifting production hubs further influence how repair technicians select materials, ensuring both structural integrity and cosmetic appeal. Understanding these global influences is essential to maintaining effective repair standards, as explored further through resources detailing diverse motorcycle fairings and repair approaches at Summit Fairings.

4. Balancing Safety, Skill, and Sustainability in Fiberglass Fairing Repairs

The processes of curing, sanding, and finishing fiberglass motorcycle fairings demand not only technical precision but also mindful user practices that influence health, environment, and culture. Proper curing requires controlled temperatures to solidify resin strength, while careful sanding minimizes dust that contains harmful fiberglass particles. Users must equip themselves with protective gear such as respirators to guard against inhalation hazards. Skillful execution is vital; uneven resin layering or aggressive sanding can weaken repairs, whereas precise application of primers and paints ensures lasting aesthetics. On a wider scale, these repair activities contribute to environmental challenges through VOC emissions and particulate pollution. Although technological advances reduce these effects, many DIY enthusiasts remain unaware of best practices for eco-friendly repairs. Beyond technicalities, repairing fairings supports sustainability by extending product lifespans and reflects a cultural passion among riders who value customization and identity. Choosing between DIY and professional service often hinges on balancing cost, skill level, and desired quality. Embracing safe, informed methods fosters durable repairs that respect both user well-being and environmental stewardship. For additional insights on advanced composite processes reducing environmental impact, explore innovations in composite manufacturing.

Chapter 6: Navigating Replacement Choices and Material Essentials in Fiberglass Motorcycle Fairing Repair

1. Choosing the Right Materials and Resins for Durable Fiberglass Motorcycle Fairing Repairs

Selecting the appropriate materials and resin types is pivotal in repairing or replacing motorcycle fairings. Fiberglass cloth remains the most common reinforcement, prized for its lightweight properties and ease of handling. Alternatives such as ABS plastic offer enhanced flexibility and impact resistance, making them favorable for replacement parts, while carbon fiber delivers unmatched strength and reduced weight but at a higher cost. The resin choice profoundly influences repair quality; polyester resin is popular for its affordability and quick curing, yet it can be brittle under stress. Epoxy resin, though more expensive and requiring longer curing, offers superior adhesion, durability, and is especially suited for structural repairs and bonding with composite materials like carbon fiber. Ensuring compatibility between resin and reinforcement, combined with meticulous surface preparation, not only restores the fairing’s strength and flexibility but also its visual finish. This balanced approach to material and resin selection underpins successful, lasting repairs that meet both functional and aesthetic demands. For deeper repair insights, comprehensive resources are available in dedicated motorcycle fairings guides.

2. Mastering Surface Preparation and Application for Durable Fiberglass Fairing Repairs

Effective fiberglass motorcycle fairing repair depends on thorough surface preparation combined with precise application techniques. Start by meticulously cleaning the damaged area to eliminate all dirt, grease, and loose debris that could hinder resin adhesion. Next, sanding roughens the surface using 80–120 grit, creating an ideal profile for resin bonding while removing any weak or delaminated fiberglass sections to ensure a stable base. Selecting the right fiberglass reinforcement is crucial: fiberglass cloth offers superior strength and smoother finishes for smaller or detailed repairs, whereas fiberglass mat covers larger areas more easily but with a coarser texture. Application begins by applying a resin base, either polyester for cost-conscious repairs or epoxy for superior strength and durability. Carefully layer the fiberglass pieces, fully saturating each with resin before applying the next to build structural integrity. After curing, the repair is sanded smooth and finished with primer and paint to restore aesthetics. This methodical approach safeguards the fairing’s strength and appearance, making repairs resilient and visually seamless. For more insights on motorcycle fairing options, explore affordable motorcycle fairings at Summit Fairings. External detailed techniques can also be reviewed here.

3. Choosing Aftermarket Motorcycle Fairings: Material Insights and Installation Tips

Aftermarket replacement fairings serve as a practical alternative to OEM parts, especially for cost-effective motorcycle bodywork restoration. Commonly made from ABS plastic or fiberglass composites, these parts balance affordability and functionality. ABS plastic offers excellent impact resistance and precise molding, closely replicating OEM shapes for easier installation. Fiberglass aftermarket fairings, while lighter and customizable, require careful repair techniques using suitable resins and reinforcement to restore strength and smooth finishes.

Fitment quality varies, but premium aftermarket kits strive for OEM-level precision through advanced molds, reducing the need for modifications during assembly. Installation involves cautious removal of damaged panels, especially near electrical components, followed by careful alignment of new parts to ensure seamless integration. Painting is often necessary unless parts come pre-finished.

For comprehensive choices and installation guidance, exploring a dedicated marketplace with extensive options can be invaluable for riders seeking both durability and style. Detailed technical resources also enhance understanding of composite repairs.

Find more insights on affordable and quality motorcycle fairings in the comprehensive Summit Fairings blog.

4. Tailored Techniques for Carbon Fiber Repairs: Ensuring Strength and Durability in Motorcycle Fairings

Repairing carbon fiber motorcycle fairings demands a different approach than fiberglass due to the composite’s complex structure and load-bearing function. The key is using two-part high-strength epoxy resins specifically formulated for composites, which offer superior adhesion and heat resistance. Surface preparation involves light sanding and meticulous cleaning to remove contaminants, ensuring the resin bonds effectively. During curing, clamping parts firmly for around 24 hours is critical to achieve maximum structural integrity. Unlike typical fiberglass repairs involving polyester or epoxy resins with cloth patches, carbon fiber requires precision to maintain safety and performance, often necessitating professional intervention. Replacement carbon fiber fairings commonly feature 3K twill weave with UV protective coatings to enhance durability and aesthetics. Post-repair ceramic coatings can be applied safely to improve scratch resistance and ease maintenance without harming the resin matrix. For enthusiasts focused on fiberglass repairs, proper resin choice and curing yield solid cosmetic and minor structural results, but carbon fiber’s unique demands must be respected to preserve the fairing’s strength and longevity. For a deeper exploration of fairing options, visit Explore the Best Motorcycle Fairings at Summit Fairings.

Source: https://www.turn1.com/carbon-fiber-adhesive-guide

Final thoughts

Effective fiberglass repair for motorcycle fairings demands a comprehensive understanding of surface preparation, damage evaluation, resin application, fiber layering, curing, and finishing techniques. For business owners, mastering each step not only ensures structural integrity and aesthetic appeal but also drives customer satisfaction and boosts operational efficiency. Recognizing when to repair versus when to replace parts brings added value and cost-effectiveness to service offerings. Empowering your team with these insights positions your business as a reliable expert in motorcycle care, ultimately enhancing brand reputation and increasing repeat business.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined

RELATED POSTS

View all