Introduction

Motorcycle fairings are pivotal in enhancing performance, style, and rider protection. For business owners in the motorcycle industry, understanding the full spectrum of creating high-quality fairings is crucial to delivering value and meeting market demand. This guide walks through the fundamental stages involved in making a fairing, starting with precise design and measurement techniques to guarantee perfect fitment. It then explores material selection and fabrication methods that balance durability, cost, and production scalability. Next, the article delves into professional finishing and painting processes that elevate the aesthetic appeal and longevity of fairings. Finally, it covers mounting hardware and installation best practices to assure secure attachment and rider safety. Each chapter is tailored to provide actionable insights that empower businesses to enhance their manufacturing capabilities and product offerings.

Tables of Contents

Chapter 1: Innovative Design and Precision Measurement Techniques for Motorcycle Fairings

- Harnessing Advanced Technologies for Accurate Design and Measurement in Motorcycle Fairing Fabrication

- Balancing Cost and Precision: Economic Insights into Motorcycle Fairing Design and Measurement

- Geopolitical Dimensions of Precision in Motorcycle Fairing Design and Measurement

- Enhancing Rider Safety and Experience: The Societal and User-Centered Impact of Motorcycle Fairing Design

Chapter 2: Material Selection and Fabrication Methods in How to Make a Fairing for a Motorcycle

- Balancing Performance and Practicality: Choosing the Right Materials for Motorcycle Fairings

- Mastering Motorcycle Fairing Fabrication: Techniques and Material Crafting Essentials

- Balancing Cost, Durability, and Craftsmanship: Economic Insights into Fairing Materials and Fabrication

- Navigating Material Choices and Fabrication Techniques for Durable, Aerodynamic Motorcycle Fairings

Chapter 3: Mastering Surface Preparation: The Key to Flawless Finishing and Painting of Motorcycle Fairings

- Essential Surface Preparation Techniques for Durable and Smooth Motorcycle Fairing Finishes

- Mastering Priming and Paint Application for a Flawless Motorcycle Fairing Finish

- The Essential Dance of Clear Coating, Curing, and Drying for a Durable Fairing Finish

- Expert Polishing and Waxing Techniques to Elevate Motorcycle Fairing Finishes

Chapter 4: Mounting Hardware and Installation Practices for Secure Motorcycle Fairing Assembly

- Choosing and Installing Brackets and Fasteners for a Durable Motorcycle Fairing Mount

- Ensuring Longevity: Protective Care and Material Handling for Motorcycle Fairing Installation

- Innovative Quick-Release Mechanisms and Precision Hardware for Effortless Motorcycle Fairing Installation

- Tailored Mounting Hardware and Installation Techniques for Custom and Model-Specific Motorcycle Fairings

Chapter 1: Innovative Design and Precision Measurement Techniques for Motorcycle Fairings

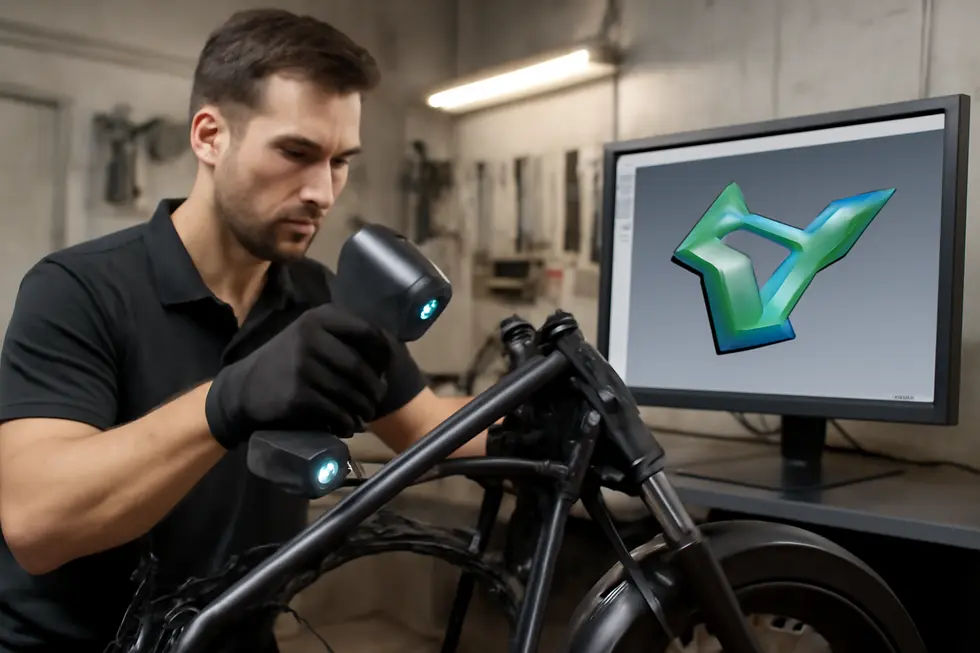

1. Harnessing Advanced Technologies for Accurate Design and Measurement in Motorcycle Fairing Fabrication

Creating an effective motorcycle fairing demands a seamless blend of advanced design technologies and precise measurement techniques. Aerodynamics play a pivotal role; employing Computational Fluid Dynamics (CFD) allows designers to simulate airflow, optimizing the fairing’s shape to reduce wind resistance and turbulence. This scientific modeling not only enhances rider comfort by managing wind impact but also contributes to improved fuel efficiency and stability during high-speed rides. Complementing this, physical wind tunnel testing can validate the aerodynamic benefits, ensuring the design achieves its intended performance goals.

Material choice and fastening solutions integrate tightly with design accuracy. Lightweight, durable composites such as fiberglass or ABS plastic form the base, while precision-engineered, corrosion-resistant quick-release fasteners provide secure, flush mounting points. These fasteners facilitate easy maintenance and fairing removal without sacrificing aerodynamic integrity.

Measurement accuracy is critical to ensure the fairing fits flawlessly to the motorcycle’s frame and interfaces smoothly with components like brake reservoirs, headlights, and instrumentation. Custom-fit designs rely on detailed bracket replacements and mounting point alignment, supported by 3D CAD modeling to simulate real-world assembly and prevent functional interference. Adjustments to cut lines and dimensions accommodate subtle variations across models, exemplifying how technology enables bespoke customization without compromising safety or handling.

This integration of aerodynamic analysis, material science, and precision measurement results in fairings that enhance both performance and rider experience. For additional details on selecting and fitting high-quality fairings, explore comprehensive resources.

For a practical example of aerodynamic refinement through technological design, the Harley-Davidson Batwing fairing illustrates extensive use of CFD to optimize shape and wind flow management.

2. Balancing Cost and Precision: Economic Insights into Motorcycle Fairing Design and Measurement

Designing and measuring a motorcycle fairing with economic efficiency hinges on carefully balancing cost, material choices, and production methods without sacrificing aerodynamic performance. Selecting lightweight yet affordable materials is central; options like vinyl for decals provide durable protection at a reasonable price, while still allowing easy application and removal to reduce future expenses. Moreover, leveraging computational fluid dynamics (CFD) and virtual wind tunnel simulations streamlines aerodynamic refinement, minimizing costly physical prototypes and iterative mold adjustments. This digital optimization approach controls development outlays by predicting airflow behavior accurately before fabrication.

Efficiency in design also involves creating fairings with straightforward assembly and disassembly in mind, which reduces labor costs during manufacturing and maintenance. This design philosophy not only facilitates faster production but also supports sustainability efforts by easing parts recycling and end-of-life processing—thereby helping manufacturers and DIY builders manage long-term environmental compliance expenses.

Modern motorcycle fairing projects, especially those aiming to blend classic aesthetics with contemporary performance, use data-driven measurement tools to deliver precision fit and function while containing costs. Creative use of materials and computational tools means smaller budgets can still achieve professional-quality, aerodynamic fairings. For enthusiasts seeking practical guidance, exploring detailed resources on affordable motorcycle fairings can provide insights into economical design and production methods.

Thus, the interplay of cost-conscious material selection, advanced digital modeling, and design for efficient assembly ensures motorcycle fairings are both effective and economically viable without compromising rider experience or style.

3. Geopolitical Dimensions of Precision in Motorcycle Fairing Design and Measurement

The intricate process of designing and measuring motorcycle fairings carries significant geopolitical weight, influencing global manufacturing dynamics, trade relations, and technological sovereignty. Precise design, including accurate cut lines and metal fitting placements, is essential for ensuring proper fitment and safety. These technical demands empower countries and corporations that develop advanced measurement methods and design innovations to secure leadership in the motorcycle supply chain. This technological control often translates to economic dominance, as proprietary designs and manufacturing expertise create formidable barriers for competitors.

Moreover, the strict precision required for components tailored to specific models fosters heavy dependence on suppliers from certain geopolitical regions. Such interdependencies make supply chains vulnerable during geopolitical conflicts or trade sanctions, disrupting manufacturing continuity and aftermarket parts availability. Design accuracy also directly impacts compliance with international safety standards, which vary by country and shape regulatory frameworks affecting bilateral trade. Consequently, nations with rigorous standards influence design norms and market access globally.

Material sourcing further complicates this landscape, as environmental policies and resource availability differ worldwide. Choices between materials—ranging from chrome-plated steel to composites—are shaped by international resource politics, tariffs, and ecological regulations, all of which ultimately affect fairing durability and environmental footprint.

Together, these factors illustrate how the technical precision in motorcycle fairing design and measurement extends beyond engineering, embedding itself within broader geopolitical strategies. Understanding this interconnectedness is vital for anyone exploring how to make a fairing, as it situates the craft within a global context shaped by technology, trade, and resource governance.

For more insight on sourcing and manufacturing precision related to motorcycle fairings, explore our detailed resources at Explore the Best Motorcycle Fairings at Summit Fairings.

External reference on aerodynamic design techniques: https://www.harley-davidson.com/us/en/about-us/technology.html

4. Enhancing Rider Safety and Experience: The Societal and User-Centered Impact of Motorcycle Fairing Design

Motorcycle fairings are more than aesthetic elements; they profoundly affect rider safety, comfort, and overall performance. User-centered design prioritizes ergonomic fit, adapting fairings to accommodate diverse rider sizes and riding styles. This ergonomic focus improves control and comfort, directly enhancing rider confidence and reducing fatigue on long rides. Measurement precision is vital—accurate fitment ensures the fairing integrates seamlessly with the motorcycle, minimizing vibration and improving structural integrity.

Advanced aerodynamic design, made possible through wind tunnel testing and computational fluid dynamics, reduces drag and enhances bike stability. These aerodynamic improvements not only boost fuel efficiency and top speed but also decrease rider exposure to wind buffeting, promoting safer handling at high speeds. High-quality materials selected through precise measurement techniques contribute to durability and impact resistance, further protecting riders during unforeseen incidents.

Beyond individual benefits, fairing design addresses broader societal mobility challenges. With increasing urban density and aging populations, motorcycles equipped with thoughtfully designed fairings offer an efficient, protective, and accessible transportation alternative. Innovations in sustainable materials and manufacturing processes reflect an inclusive approach, aiming to reduce environmental impact while improving transportation equity.

By integrating careful measurement, ergonomic, and aerodynamic principles, the design of motorcycle fairings plays a pivotal role in improving rider experience and responding to evolving societal needs. For those interested in exploring more about crafting high-quality, precisely measured fairings, resources such as Summit Fairings offer valuable insights and products tailored to user-specific requirements. Further technical details on aerodynamic and ergonomic innovations can be found in this comprehensive review of advanced motorcycle fairing design.

Chapter 2: Material Selection and Fabrication Methods in How to Make a Fairing for a Motorcycle

1. Balancing Performance and Practicality: Choosing the Right Materials for Motorcycle Fairings

Selecting materials for motorcycle fairings requires a careful balance between strength, weight, durability, and fabrication ease. Among popular choices, high-grade titanium alloys and ABS plastic stand out for their distinct advantages. Titanium, particularly Grade 5 (6AL-4V), offers an exceptional strength-to-weight ratio, rivaling steel while weighing 40-50% less. This makes it ideal for fasteners and structural parts where minimizing weight without sacrificing strength is crucial. Additionally, titanium’s corrosion resistance and compatibility with hard, wear-resistant coatings like Diamond-Like Carbon (DLC) enhance longevity and performance, contributing to a premium finish often accented by anodizing for customization.

On the other hand, ABS plastic dominates as the primary material for the main body of many fairings. Its combination of lightness, impact resistance, heat tolerance, and vibration damping makes it well-suited for aerodynamic panels exposed to road stresses. ABS is also highly adaptable in fabrication, compatible with vacuum forming and injection molding, allowing for smooth, paint-ready surfaces that can be customized to match OEM aesthetics or personalized finishes. Cost-effectiveness further bolsters its popularity, especially among aftermarket manufacturers and DIY builders.

The choice between these materials revolves around key criteria: mechanical performance to maintain shape and rider protection; minimizing weight for enhanced handling; resilience against abrasion and environmental factors; ease and cost of fabrication; and the desired visual appeal. By integrating titanium for critical fasteners and supports with ABS for full-bodied panels, builders achieve a well-rounded fairing that excels in function and style.

For further insights into quality fairing materials and options, explore the comprehensive guides found at Discover Affordable Motorcycle Fairings at Summit Fairings.

2. Mastering Motorcycle Fairing Fabrication: Techniques and Material Crafting Essentials

Fabricating a motorcycle fairing demands a meticulous balance between material properties and manufacturing techniques to achieve both strength and style. Materials such as ABS plastic, carbon fiber, sheet metal, and thermoplastics each require distinct fabrication processes tailored to their physical characteristics. ABS plastic is commonly shaped through heated molding, where softened sheets are placed into precision molds and compressed to conform to the desired form. This method offers durability and impact resistance essential for road use. Carbon fiber fabrication, favored for its lightweight strength, involves layering fibers with resin inside molds, followed by autoclave curing under heat and pressure. This process yields rigid, high-performance fairings but necessitates stringent quality control to prevent defects like delamination or resin bubbles.

For metal fairings, often seen on custom cafe racers, thin steel sheets are cut by templates and shaped manually using hand tools such as nylon hammers and sandbags, or mechanically with devices like shrinker-stretchers and English wheels. These techniques allow precise contouring and customization, but depend heavily on artisan skill. Thermoplastics are molded by heat-softening the material, forming it to shape, then allowing it to harden upon cooling, facilitating simplified customization and finishing.

After shaping, fairings require careful finishing to prepare for paint applications. This includes sanding surfaces smooth, applying primer, then multiple paint layers followed by clear coats designed to provide UV protection and resistance against vibration or impacts. Proper trial fitting throughout fabrication ensures exact mounting alignment and secure attachment to the motorcycle frame using dedicated hardware.

These fabrication strategies accommodate a wide range of budgets and skill levels, from professional-grade autoclave-cured composites to hand-shaped metal parts. For further insights on detailed fabrication workflows and tool recommendations, consult specialized resources like the comprehensive carbon fiber manufacturing overview available at Turn1’s site.

3. Balancing Cost, Durability, and Craftsmanship: Economic Insights into Fairing Materials and Fabrication

When crafting a motorcycle fairing, economic factors significantly influence decisions on materials and fabrication techniques. This balancing act involves weighing upfront costs against longevity, repairability, and performance. Fiberglass remains the most budget-friendly choice, favored for its affordability and decent finish. It offers ease of repair, making it accessible for DIY builders who might require touch-ups or custom fitting. However, the trade-off lies in its weight and the necessary refinements like sanding and painting to achieve professional results.

On the other end of the spectrum, carbon fiber delivers unmatched strength and weight savings, directly benefiting performance and aesthetics. Its manufacturing and material costs are considerably higher, often reserving it for enthusiasts prioritizing top-tier quality. Repairs on carbon fiber are more complex and expensive, demanding specialist skills, which can increase long-term expenses.

Fabrication methods also affect expenses. Mass production through injection molding streamlines costs by reducing labor and material waste, making pre-made kits a practical solution for many riders. In contrast, custom fabrication using layup techniques or advanced composites requires skilled labor and specialized equipment, pushing costs upward but allowing unique, bespoke designs.

Shipping costs can surprisingly inflate the overall expense, particularly with bulky fairings sourced from distant suppliers. Thus, local availability or consolidated orders can mitigate these charges.

Ultimately, choosing the right combination rests on intended use and budget constraints. Practical builders often lean toward fiberglass kits for economical yet reliable results, while those seeking performance and exclusivity may invest in carbon fiber options despite the premium price. For a broad overview of affordable and varied fairing choices, exploring affordable motorcycle fairings offers valuable insights.

Further details on pricing dynamics and options can be found through suppliers showcasing wide ranges of materials and fabrication processes, reflecting these economic trade-offs in real market offerings [1].

4. Navigating Material Choices and Fabrication Techniques for Durable, Aerodynamic Motorcycle Fairings

Selecting the right material and fabrication method is pivotal when creating a motorcycle fairing that balances durability, aesthetics, and aerodynamic efficiency. Among the most common materials, ABS plastic excels by combining strong impact resistance, heat tolerance, and vibration damping with ease of shaping. It supports reliable fairings for everyday riders seeking longevity without excessive weight or cost. Fiberglass offers a lightweight alternative with forgiving flexibility, appealing especially to those prioritizing weight savings over the extreme toughness of plastics. For high-end applications, carbon fiber stands out as a premium choice delivering exceptional strength and minimal mass, favored in racing or performance contexts despite its cost.

Fabrication methods directly reflect the chosen material and desired outcome. Injection molding is a mainstream process for ABS due to its precision in replicating complex contours and consistent model-specific fits. This technique produces fairings rapidly and at scale, ideal for aftermarket mass production with repeatable quality. Vacuum forming shapes heated plastic sheets over molds, offering adaptable finishes and robust impact resistance suitable for custom or small-batch fairings. Plastic welding serves as a crucial skill for repairs or small assembly tasks, maintaining structural integrity by fusing plastic components seamlessly.

Crucially, each step must consider the motorcycle’s specific make and model to ensure secure fitment and aerodynamic performance. Proper shaping reduces drag, enhancing speed and stability, while material robustness guards against vibration, heat, and environmental threats. Advances in materials and manufacturing also enable vivid customization options, from OEM-style replicas to weather-resistant finishes that preserve looks over time. These technological and practical considerations collectively ensure that a motorcycle fairing is not just visually appealing but also engineered for resilience and performance.

Explore more on choosing materials and fabrication in our detailed discussion on affordable motorcycle fairings.

Additional technical insights can be found at this external resource on motorcycle fairing molds and fabrication.

Chapter 3: Mastering Surface Preparation: The Key to Flawless Finishing and Painting of Motorcycle Fairings

1. Essential Surface Preparation Techniques for Durable and Smooth Motorcycle Fairing Finishes

Achieving a flawless paint finish on a motorcycle fairing hinges on meticulous surface preparation, which ensures lasting adhesion and a smooth appearance. The process begins with thoroughly cleaning the fairing to eliminate dirt, oils, and grease that impede paint bonding. Using specialized cleaners or degreasers guarantees a contaminant-free base, vital for optimal primer and paint performance. After cleaning, the surface is carefully sanded or abraded to create a subtle roughness that enhances adhesion. The choice of abrasive depends on the fairing material, whether plastic, fiberglass, or carbon fiber, with fine-grit sandpaper typically employed to avoid damaging delicate surfaces.

Any imperfections like scratches, cracks, or dents must be addressed before painting. Techniques such as filling with compatible fillers or V-grooving ensure the surface is uniformly smooth, preventing these flaws from showing through the paint. Once repairs and sanding are complete, the fairing requires another wipe-down with a tack cloth or solvent to remove lingering dust and debris. This step is crucial because even microscopic particles can mar the finish.

Applying a primer tailored to the specific fairing material follows, establishing a consistent base tone and boosting paint adherence. A final degreasing before painting removes any remaining contaminants, setting the stage for paint application. For advanced finishes, some professionals also incorporate protective clear coats and decals, applied with techniques that avoid bubbles and wrinkles. Additionally, cutting-edge options like ceramic coatings demand deeper cleaning and polishing to create an impeccably smooth surface for molecular bonding.

For comprehensive guidance on preparing motorcycle fairings before finishing, refer to the detailed resources available at the Plastic Repair Centre. This foundational preparation phase underpins every step of finishing and painting, ensuring your custom or repaired fairing achieves both durability and visual appeal. Explore more about motorcycle bodywork enhancements through Summit Fairings’ insights on professional finishes.

2. Mastering Priming and Paint Application for a Flawless Motorcycle Fairing Finish

Priming is an essential step to achieve a smooth, professional finish on motorcycle fairings. After repairing any surface damage, start by sanding the fairing progressively—from coarser 180 grit through 240 and up to fine 320 grit—to eliminate imperfections and create a proper texture for primer adhesion. Using a high-build 2K primer, apply two to three even coats with a spray gun, ideally equipped with a 1.8 mm tip, ensuring full coverage without runs. Between coats, a light sanding maintains a flawless surface, enhancing paint bond strength and durability.

Once primed and sanded, fitting the fairing loosely onto the motorcycle allows for final alignment adjustments, preventing flaws during the final assembly. When painting, multiple thin layers are critical; they help avoid sags, runs, or uneven color formation. Each coat should dry sufficiently before applying the next to build depth of color evenly. Following paint application, a clear coat protects the finish and adds lasting gloss, acting as the final shield against environmental wear.

For fairings crafted from plastic or composite materials, thorough cleaning before priming is vital to remove debris, oils, or residues, which can otherwise cause adhesion failure. Plastic welding or repairs may be necessary prior to priming if structural fixes are needed.

This carefully staged process not only achieves aesthetic excellence but also ensures durable protection and longevity for your custom motorcycle fairing. For more on selecting and finishing quality parts, explore insights available at Summit Fairings.

For detailed technical guidance on primer and paint selection and application, consult specialized resources dedicated to automotive and motorcycle refinishing techniques.

3. The Essential Dance of Clear Coating, Curing, and Drying for a Durable Fairing Finish

Achieving a flawless finish on a motorcycle fairing hinges on carefully managing the clear coating, curing, and drying phases. After the base color paint is applied smoothly and evenly, the clear coat becomes the guardian of that vibrant layer beneath. It not only enhances the glossy appearance but also shields the paint from environmental damage and abrasion. Applying this transparent layer consistently ensures that every curve and contour of the fairing gleams with uniform brilliance.

However, the protection provided by the clear coat depends heavily on its curing process—a crucial chemical transformation that hardens the coating and bonds it securely to the base paint. Unlike drying, which is simply the evaporation of solvents, curing solidifies the finish, greatly improving scratch resistance and longevity. Environmental variables, including temperature and humidity, can significantly affect curing times, which may range from several hours up to a few days. Rushing this stage risks compromising the finish, so patience is essential before normal handling or polishing.

Drying between each paint and clear coat layer is equally important to avoid imperfections like runs or cloudy textures. Often, a fine wet sanding between coats smooths micro-roughness and enhances adhesion, typically using ultra-fine grit sandpaper to preserve the surface’s integrity while preparing it for the next layer.

Additional practices, such as meticulous surface cleaning with degreasers before painting and masking off surrounding areas, help secure paint adhesion and maintain clean lines without overspray. Once curing is complete, polishing to a high shine and applying a protective wax or sealant will not only beautify the fairing but also extend its protective qualities.

A comprehensive understanding of these interconnected steps ensures every custom fairing maintains its aesthetic and durability over time. For further insights into these finishing techniques and how they impact fairing quality, explore detailed resources available at your ultimate source for affordable motorcycle fairings.

4. Expert Polishing and Waxing Techniques to Elevate Motorcycle Fairing Finishes

Polishing and waxing are critical finishing stages that transform a motorcycle fairing’s appearance, offering depth, clarity, and durability to its painted surface. The process begins with meticulous cleaning and paint decontamination to remove embedded dirt, oil, and other contaminants that can dull the finish or inhibit adhesion of subsequent products. Following this, a multi-step polishing regimen restores surface smoothness and gloss.

Initial polishing targets deeper imperfections using a cutting compound applied with foam or microfiber pads in overlapping circular motions. This abrasively removes fine scratches and oxidation, evening out the surface while carefully maintaining the paint’s integrity. Once defects are diminished, a finer polish refines the texture, enhancing clarity and luster without introducing micro-marring. Keeping the applicator pad slightly damp aids in smooth compound distribution and prevents streaking.

After buffing away polish residues with a clean microfiber cloth, waxing or sealing the surface is paramount. Wax acts as a protective glossy barrier, shielding the clear coat from UV degradation and environmental corrosives. For longer-lasting protection, polymer sealants or ceramic coatings chemically bond to the clear coat, providing water-repellent, dirt-resistant finishes that simplify cleaning and extend the fairing’s vibrant look. Applying these protective layers every two to three months maintains aesthetics and guards against oxidation.

This polished approach not only accentuates the craftsmanship behind custom or aftermarket fairings but also prolongs their functional lifespan amid riding conditions. For more insights into maintaining and enhancing motorcycle fairings, visit affordable motorcycle fairings at Summit Fairings.

Reference external resource on polishing and waxing techniques: https://www.detailingworld.co.uk/threads/how-to-polish-and-wax.131147/

Chapter 4: Mounting Hardware and Installation Practices for Secure Motorcycle Fairing Assembly

1. Choosing and Installing Brackets and Fasteners for a Durable Motorcycle Fairing Mount

Selecting the right brackets and fasteners is essential to securely mount a motorcycle fairing while protecting its integrity. Model-specific brackets designed to fit particular motorcycle frames offer the best stability and alignment, often crafted from robust materials like powder-coated steel or aluminum to resist corrosion and vibration. Adjustable brackets add versatility, granting approximately two inches of vertical travel and around fifteen degrees of angular adjustment to tailor shield positioning for improved airflow and rider comfort. When installing fairings, employing rubber grommets in bolt holes cushions the plastic or fiberglass material, distributing pressure to prevent cracking. Washers placed behind these grommets further protect the fairing by ensuring bolts tighten against the frame rather than deforming the surface. To avoid damage during mounting, bolts should initially be finger-tightened to allow fine alignment before fully securing them. Over-tightening, especially on brittle composites, risks cracking or distortion and must be avoided. High-performance fasteners, such as titanium quick-release quarter-turn types, combine strength and lightweight benefits. These fasteners typically feature low-profile dome heads for a sleek appearance, enhanced durability from rolled threads and diamond-like carbon coatings, plus anodized finishes in multiple colors. They facilitate rapid removal and installation by engaging existing backing clips, ideal for maintenance or customization requiring repeated access. Overall, prioritizing model-specific or adjustable brackets paired with protective hardware like rubber grommets, washers, and carefully chosen fasteners ensures your fairing remains stable without accidental damage throughout its service life. This methodology balances strength, precision fitment, and rider-focused customization. For further detailed guidance on bracket positioning and wiring clearance considerations, consult comprehensive tutorials such as The Racing Xpert’s instructional video here. To explore a wide variety of compatible mounting components and hardware solutions optimized for motorcycle fairing installation, visit Summit Fairings’ resources at Discover Affordable Motorcycle Fairings at Summit Fairings.

2. Ensuring Longevity: Protective Care and Material Handling for Motorcycle Fairing Installation

Ensuring Longevity: Protective Care and Material Handling for Motorcycle Fairing Installation

Selecting durable materials like ABS plastic is fundamental for motorcycle fairings, offering excellent color retention and resistance to wear. These high-quality fairings often feature multi-layer painting techniques that boost both appearance and durability, ensuring they withstand everyday conditions. To preserve this finish, it is essential to minimize prolonged exposure to direct sunlight, which can cause paint to fade and degrade the material. Parking in shaded areas or using UV-protective motorcycle covers helps maintain the fairing’s integrity over time.

Gentle cleaning routines, employing mild soaps and soft cloths, prevent surface scratches and preserve the glossy finish. Avoiding harsh chemicals or abrasive pads is critical, as these can dull paint and damage the underlying structure. Applying a protective wax layer specifically formulated for motorcycles creates a resilient shield against environmental contaminants and sustains vibrant color depth.

During installation, exact alignment and secure fitting of mounting hardware are vital. Customizable mounting systems allow precise positioning without altering the motorcycle frame, enhancing both aesthetic and functional outcomes. Removable fasteners offer convenience for maintenance but require cautious use, since their holding strength may weaken with frequent removal. Pre-fitting parts and accounting for nearby components—such as brake calipers or heat shields—ensures interference-free assembly, sometimes demanding minor adjustments to fairing edges or foam padding.

Using the correct tools and adhering closely to manufacturer guidelines is crucial to avoid overtightening, which can induce cracks or stress points. Consideration of passenger comfort and shock absorption during rear fairing installation further balances function and style.

For a comprehensive approach to installation and care, practical guidance is available through expert maintenance resources and detailed mounting system instructions, ensuring your fairing remains secure and visually striking.

For more on maintaining a professional look and protection, explore detailed tips at your ultimate source for affordable motorcycle fairings. For installation specifics, see expert recommendations from leading adjustable windshield hardware manuals.

3. Innovative Quick-Release Mechanisms and Precision Hardware for Effortless Motorcycle Fairing Installation

Modern motorcycle fairing installation has evolved significantly through the use of innovative quick-release mechanisms and specialized hardware designed for both convenience and durability. These systems allow riders to easily mount or detach fairings with minimal effort, streamlining maintenance and customization without compromising safety or fitment. At the heart of these advancements are tool-free or minimal-tool locking assemblies, such as spring-loaded trigger locks that ensure solid attachment while enabling rapid removal of windshields or entire fairings. Integrated corrosion-resistant materials like stainless steel and anodized aluminum promote longevity despite exposure to harsh environments.

Adjustability is another pivotal feature, with bracket systems offering vertical and angular tuning options. This adaptability improves rider comfort by optimizing airflow and glare reduction, fostering a more personalized riding experience without permanent modifications to the motorcycle frame. High-performance fasteners crafted from lightweight, strong materials like titanium enhance both aesthetics and endurance. These fasteners often feature protective coatings delivering exceptional hardness and resistance to wear, crucial where frequent removal and reinstallations occur.

OEM-style bolt-on kits with quick-release capabilities blend factory-grade fit and finish with the added benefit of fast, tool-free detachment. This fusion preserves original styling while addressing practical needs during transport or repair. Collectively, these hardware innovations represent a leap beyond traditional fixed bolts, creating a seamless balance between secure mounting and user-friendly operation. They integrate flawlessly with custom or aftermarket fairings, ensuring installation practices remain efficient, reliable, and visually cohesive.

For guidance on choosing matching fairings that complement these advanced mounting solutions, explore comprehensive resources such as the Explore the Best Motorcycle Fairings at Summit Fairings.

4. Tailored Mounting Hardware and Installation Techniques for Custom and Model-Specific Motorcycle Fairings

Effective mounting hardware and installation methods are fundamental to securing motorcycle fairings with precision and durability. Custom and model-specific solutions address the unique contours and frame geometries of different motorcycles, ensuring a seamless fit that maintains both aesthetic appeal and functional integrity. These tailored approaches often begin with brackets engineered specifically for the frame and fairing attachment points unique to various motorcycle models. Such design specificity is crucial for achieving stability and alignment, especially for specialized fairing types like batwing or Road Glide styles, which demand precise interface with their corresponding frames.

In custom builds, fabrication or modification of mounting points frequently becomes necessary, particularly when integrating lightweight and rigid materials such as carbon fiber. Additional components like rubber gaskets or padding often accompany these mounting systems to absorb vibrations and prevent rattling, enhancing rider comfort and preserving the longevity of the fairing assembly. Moreover, color-matched hardware and mounting elements contribute to a cohesive appearance, requiring installers to carefully coordinate installation techniques with visual design goals.

Installation practices emphasize strict torque adherence and meticulous alignment to avoid stress concentrations that could compromise mounting points or material integrity. Vibration-damping solutions play a critical role, mitigating noise and movement during operation. Compatibility considerations extend beyond fit, as specific racing regulations and performance requirements sometimes dictate fairing types and their mounting configurations.

Comprehensive model-specific hardware kits simplify the installation process, reducing guesswork and ensuring compatibility with both the motorcycle and its custom or aftermarket fairing. Combined with careful installation, these solutions guarantee a secure, durable, and visually integrated fairing fit. For detailed techniques and examples, exploring expert tutorials on mounting and installation can provide valuable insight.

For more information on custom fairing options and installation guidance, visit Explore the Best Motorcycle Fairings at Summit Fairings.

Final thoughts

Creating a high-quality motorcycle fairing requires a seamless integration of design, materials, fabrication, finishing, and installation. For business owners, mastering these components translates into superior products that meet consumer expectations for performance, durability, and aesthetics. Accurate design combined with advanced measurement technologies ensures perfect fit and compatibility. Thoughtful material selection and fabrication processes balance cost and quality, whether through fiberglass layups, ABS plastic molding, or innovative 3D printing. Finishing techniques elevate the visual appeal and protect fairings from wear, while mounting hardware and installation protocols guarantee rider safety and product reliability. Appreciating and implementing these essential steps provide businesses a competitive edge to thrive in the dynamic motorcycle aftermarket industry.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined