Introduction

Motorcycle fairings are vital not only for aerodynamics but also for the bike’s aesthetic appeal and rider protection. For business owners involved in manufacturing, retailing, or supplying motorcycle parts, understanding how these components are made is essential for ensuring product quality, customer satisfaction, and competitive advantage. The production of motorcycle fairings is a complex craft that combines precision engineering, advanced materials, and meticulous finishing. Beginning with injection molding of high-grade ABS plastics, the process advances through sophisticated multi-layer painting to ensure durability and style, and concludes with stringent quality control and assembly preparation to deliver flawless parts. Each chapter unfolds these critical stages, offering a detailed insight into the techniques and standards that business stakeholders need to know to excel in this market segment.

Tables of Contents

Chapter 1: Injection Molding in Making Motorcycle Fairings: Materials and Techniques

- Choosing the Right Materials for Injection Molded Motorcycle Fairings: Balancing Strength, Cost, and Performance

- Mastering the Injection Molding Process: Shaping Motorcycle Fairings with Precision and Care

- Unlocking the Technological and Economic Edge of Injection Molding for Durable, Precise Motorcycle Fairings

Chapter 2: Multi-Layer Painting and Finishing in Making Motorcycle Fairings

- Material Science and Surface Preparation: The Foundation for Flawless Multi-Layer Painting on Motorcycle Fairings

- Innovative Coating Advances Enhancing Durability and Aesthetics in Motorcycle Fairings

- The Broader Economic, Societal, and Geopolitical Dimensions of Fairing Finishing Processes

Chapter 3: Quality Control and Assembly Preparation in Making Motorcycle Fairings

- Mastering Quality Control: Safeguarding Material Integrity and Flawless Fit in Motorcycle Fairings

- Mastering Assembly Preparation for Motorcycle Fairings: Adhesive Choices and Surface Conditioning for Durable Bonding

- Precision Manufacturing’s Impact on Quality Control and Assembly Preparation for Motorcycle Fairings

Chapter 1: Injection Molding in Making Motorcycle Fairings: Materials and Techniques

1. Choosing the Right Materials for Injection Molded Motorcycle Fairings: Balancing Strength, Cost, and Performance

Motorcycle fairings rely heavily on the careful selection of materials to meet the demanding balance between durability, aesthetics, and cost-effectiveness during the injection molding process. Among these, ABS plastic stands out as the most widely used material for producing injection-molded fairings. Its popularity stems from its exceptional impact resistance, toughness, and chemical stability which make it highly suitable for the rigors of motorcycle environments. ABS offers a smooth surface ideal for painting, enabling fairings to achieve the glossy, factory-quality finish riders expect. Additionally, its ease of processing and affordability make ABS the preferred choice for OEM-grade parts that require consistent precision and fitment.

While ABS dominates the market, other materials come into play depending on specific performance needs. Fiberglass composites, often consisting of polyester resin reinforced with fine glass fibers, are valued for their lightweight strength and corrosion resistance. These composites provide fairings with enhanced rigidity and chemical durability, though their brittleness requires careful molding and finishing processes. Polyester resin used in fiberglass fairings offers hardness and heat resistance, though UV sensitivity is a concern, necessitating protective coatings for longevity.

For parts demanding superior impact resistance or transparency, such as windshields, polycarbonate is utilized. Though tougher than ABS and excellently resilient to shattering, this thermoplastic is costlier and less common for full-body fairings. At the premium end, carbon fiber composites deliver unmatched strength-to-weight ratios and stiffness but introduce higher production complexity and expenses. Carbon fiber fairings often require epoxy bonding systems that enhance UV stability and chemical resistance.

Selecting a material for injection molding motorcycle fairings involves weighing impact resistance, durability against environmental factors, cost, and weight. ABS remains the most cost-effective, offering a favorable combination of toughness and finish quality for mass production. Fiberglass and carbon fiber allow for weight savings and specialized performance, while polycarbonate suits transparent components needing high toughness.

Understanding these material trade-offs allows manufacturers to tailor fairings to diverse motorcycle styles and rider demands. This foundational knowledge sets the stage for exploring the specific injection molding techniques that transform these materials into precise, high-quality motorcycle fairings. For those interested in exploring various fairing options and material applications, a detailed resource on available choices at Summit Fairings provides valuable insights into modern fairing manufacturing.

2. Mastering the Injection Molding Process: Shaping Motorcycle Fairings with Precision and Care

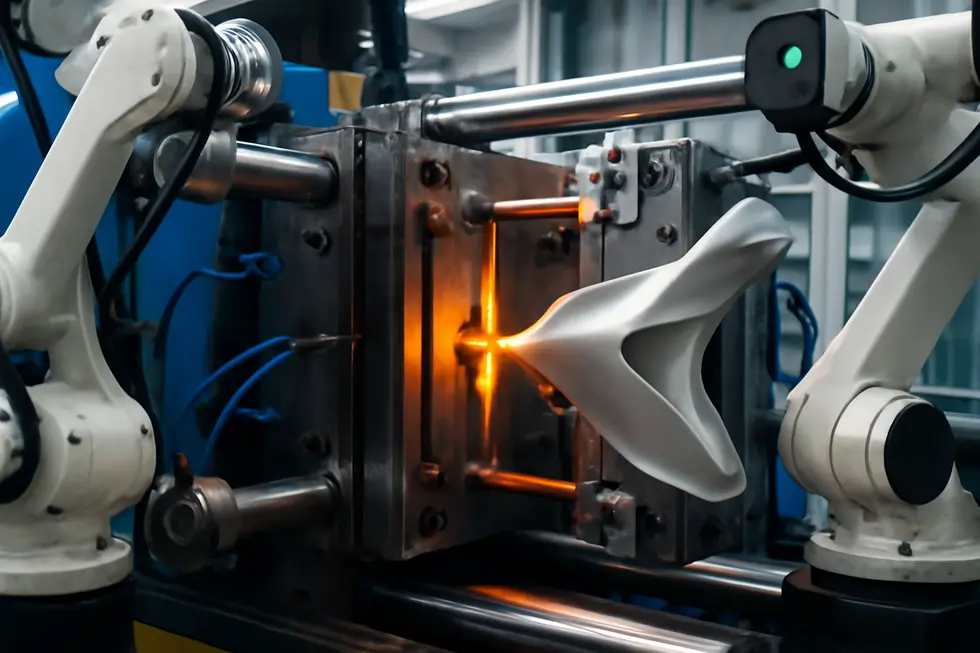

The injection molding process for motorcycle fairings transforms raw thermoplastic pellets, primarily ABS, into precisely shaped, durable components essential for both function and style. This begins with thorough material preparation, where pellets are dried to remove moisture, ensuring the molten plastic remains free of imperfections. These pellets are then fed into the injection molding machine, where temperature control becomes critical. Inside the machine’s heated barrel, the plastic is melted into a uniform molten state, ready for injection.

The molten resin is injected at high pressure into a carefully engineered mold cavity. This cavity not only defines the fairing’s detailed contours but also governs dimensional accuracy and surface smoothness. Achieving consistent flow and pressure during injection helps prevent defects such as warping or voids, which could compromise the part’s fit or finish.

Once the mold is filled, controlled cooling solidifies the plastic, locking in the shape with exact precision. Cooling time and temperature must be balanced to minimize residual stress and maintain surface quality. After solidification, the mold opens, revealing the newly formed fairing. Automated ejection systems, such as pins or robotic arms, carefully remove the part to avoid scratches or deformation.

Following molding, the fairing often undergoes post-processing steps like trimming excess material and preparing the surface for subsequent finishing processes. The ability of ABS to accept multi-layer paint systems hinges on the quality of the molded surface, which must be free of blemishes and precisely dimensioned to allow seamless assembly.

Adhesive bonding techniques complement the process by providing robust yet flexible joins that withstand vibrations and environmental exposure inherent to motorcycle use. Maintaining strict control over processing parameters—temperature, injection pressure, and cooling duration—is vital to achieving reliable repeatability and durability.

This meticulous orchestration of material handling, mold design, and process control ensures final fairings are not only visually appealing but also engineered to endure the road. Manufacturers leveraging automation and precise machinery produce consistent parts that meet stringent OEM-quality standards. For a deeper insight into these efficient, high-quality manufacturing workflows, exploring an expert source like the Explore Summit Fairings blog offers valuable perspectives on OEM fitment and multi-layer paint protection.

3. Unlocking the Technological and Economic Edge of Injection Molding for Durable, Precise Motorcycle Fairings

Injection molding stands as a cornerstone technology in crafting motorcycle fairings, delivering an essential balance of durability, precision, and cost efficiency. This process transforms thermoplastic materials such as ABS into finely detailed, lightweight components that boast exacting tolerances and consistent quality. The ability to repeatedly produce fairings that conform precisely to a motorcycle’s specifications directly supports superior aerodynamic performance, rider comfort, and safety. Such precision ensures that fairings mount securely with exact bolt-alignments, reducing vibrations and optimizing airflow around the bike.

From a technological perspective, injection molding enables rapid production cycles, allowing manufacturers to meet both OEM demands and aftermarket volumes effectively. The versatility of this method permits complex shapes and customized designs, which would be difficult or costly to achieve through traditional fabrication. High-quality ABS plastic processed by injection molding provides robust impact resistance and flexibility, critical attributes that enhance the resilience of fairings under everyday use as well as in minor collisions.

Beyond performance, injection molding brings compelling economic advantages. Large-scale production significantly lowers per-unit costs, making it a financially sustainable solution for both manufacturers and consumers. Unlike manual or alternative molding methods, it generates minimal material waste and reduces labor input, offsetting the initial expense of custom tooling through efficiency and speed. Additionally, the long-lasting nature of injection-molded fairings decreases maintenance and replacement frequency, contributing further savings over the life of the motorcycle. Employing automotive-grade adhesives and coatings in assembly ensures the structural integrity of these components, reinforcing their value.

This combination of technological innovation and economic practicality fosters a manufacturing environment where fairings excel not only in form and function but also in affordability and durability. For those looking to explore reliable and well-crafted motorcycle fairings made through this advanced process, discover affordable motorcycle fairings at Summit Fairings provides valuable insight into widely accessible options enhanced by the benefits injection molding offers.

Chapter 2: Multi-Layer Painting and Finishing in Making Motorcycle Fairings

1. Material Science and Surface Preparation: The Foundation for Flawless Multi-Layer Painting on Motorcycle Fairings

The excellence of multi-layer painting and finishing on motorcycle fairings begins fundamentally with the selection of materials and meticulous surface preparation. Fairings are commonly crafted from composites such as fiberglass, carbon fiber, and ABS plastic, each presenting unique challenges and advantages that influence how the painting process unfolds.

Fiberglass, known for its affordability and light weight, is frequently used in track fairings due to its favorable strength-to-weight ratio. However, it is comparatively brittle, demanding delicate handling during surface preparation to prevent cracking. Sanding must be carefully controlled to avoid damaging its structure, yet it remains essential to create a slightly roughened surface for optimal primer and paint adhesion.

Carbon fiber, recognized for its ultra-lightweight stiffness and premium status, requires specialized attention. Its resin matrix needs compatible adhesives and primers to avoid delamination. Surface preparation here balances the need to create mechanical bonding without compromising the underlying fibers. After painting, carbon fiber fairings particularly benefit from ceramic clear coatings, which enhance scratch resistance and simplify cleaning while preserving visual appeal.

Injection-molded ABS plastic stands as the industry standard for OEM-style fairings. It offers outstanding dimensional accuracy and impact resistance, which supports uniform paint application and contributes to aerodynamic performance. The smooth, consistent surfaces of ABS simplify sanding and priming, enabling multi-layer paint systems to achieve a deep, glossy finish with excellent durability.

The surface preparation sequence is pivotal: starting with thorough cleaning to eliminate any dust, grease, or contaminants that could impair adhesion. This is followed by careful sanding to provide mechanical adhesion points without damaging the substrate. Applying primers tailored to each material seals the surface and creates a foundation for the base coats. Multiple layers of base color are then applied with controlled drying times between each to build richness and uniformity. Finally, clear coats are layered to impart gloss, UV protection, and abrasion resistance; curing conditions like temperature and humidity are tightly managed to ensure finish longevity.

Successful multi-layer painting is thus inseparable from understanding material science and performing precise surface preparation. These steps ensure that the fairings achieve not only visual brilliance but also the resilience required to endure environmental exposure and the rigors of motorcycle use. For those exploring quality aftermarket fairings and their finishes, a resource like the Summit Fairings blog provides deeper insight into materials and paint processes, helping enthusiasts make informed choices that combine style with durability.

2. Innovative Coating Advances Enhancing Durability and Aesthetics in Motorcycle Fairings

The evolution of multi-layer painting and finishing for motorcycle fairings hinges on cutting-edge coating technologies that elevate both protection and visual appeal. Integrating advanced materials with precise application techniques produces fairings that withstand mechanical stress, weathering, and UV exposure while retaining a factory-quality gloss and texture.

Among the most transformative innovations is the use of nanotechnology-based ceramic coatings. These ultra-thin layers bond intimately with the fairing surface, creating a chemical-resistant, UV-blocking shield that combats scratches and environmental contaminants. Their unique self-healing property, triggered by heat, allows minor abrasions to smooth out, preserving clarity and shine. Achieving this flawless finish demands thorough surface preparation, including paint correction, to ensure optimal adhesion and durability.

In parallel, In-Mold Coating (IMC) technology streamlines production by combining injection molding with a reactive polyurethane coating in a single step. This integration yields fully finished fairings directly from the mold, reducing manufacturing time and volatile emissions. The coatings applied through IMC exhibit exceptional wear resistance and allow for intricate design details, creating a blend of functional longevity and aesthetic sophistication.

To complement traditional paint layers, multi-layer adhesive-backed films provide versatile solutions for customization and protection. These films feature advanced adhesives with repositionability and air-release channels that ensure smooth, bubble-free application. They enhance scratch resistance and UV protection while allowing for easy removal or replacement, catering to both full and partial coverage styles.

For fairings utilizing polycarbonate or acrylic substrates, thermally cured hard coatings applied in controlled environments boost impact and chemical resistance, safeguarding both appearance and structural integrity. These coatings are vital to maintaining clarity and toughness, particularly in areas prone to abrasion or mechanical stress.

Additionally, the durability of multi-layer finishes relies heavily on advanced adhesives formulated to balance strength with flexibility. These adhesives endure continuous vibrations and environmental challenges without becoming brittle or losing adhesion. Their resilience to moisture, UV exposure, fuels, and cleaning agents ensures the fairings remain securely assembled and visually pristine over time.

Collectively, these advances reflect a deeper marriage of material science and manufacturing precision in motorcycle fairing production. By leveraging nanotechnology, smart coatings, and intelligent adhesives, manufacturers consistently deliver parts that meet rigorous durability standards while offering superior aesthetic finishes. For those exploring quality options and innovations in fairing finishes, resources like the comprehensive guides provided by Summit Fairings offer valuable insights into the latest techniques and materials.

3. The Broader Economic, Societal, and Geopolitical Dimensions of Fairing Finishing Processes

The multi-layer painting and finishing process in manufacturing motorcycle fairings extends beyond technical craftsmanship, influencing economic, societal, and geopolitical realms in significant ways. Economically, applying multiple paint layers—often up to seven—incurs higher production costs due to sophisticated materials, automated spraying technology, and energy-intensive drying systems. These increased expenses can raise prices for both original equipment manufacturers and aftermarket providers. Consumer demand may shift accordingly, especially in markets sensitive to price changes. Yet, the investment also enhances fairing durability and aesthetic appeal, boosting market value and customer satisfaction through long-lasting, factory-quality finishes.

From a societal standpoint, advanced finishing processes contribute to user safety and satisfaction by producing fairings that better withstand environmental conditions and collision impacts. This durability supports motorcyclists’ confidence and safety on the road. Furthermore, evolving technologies in painting and finishing foster new employment opportunities across manufacturing, design, and quality control sectors, benefiting local economies. However, these innovative methods sometimes increase the cost barrier, potentially restricting access to premium fairings among lower-income riders and highlighting socioeconomic disparities. Additionally, improvements in environmentally friendly coatings and waste reduction measures integrate sustainability into production, reflecting growing societal demands for greener industrial practices.

Geopolitically, the sourcing of raw materials for paints, varnishes, and plastic substrates ties the fairing finishing industry into complex global supply chains. Trade policies, tariffs, and international tensions can directly impact costs and availability, encouraging manufacturers to consider nearshoring or regional supply strategies to mitigate risks. National priorities to secure critical resources and intellectual property influence where and how fairing finishing technologies develop, driving both competition and collaboration among countries. This environment affects talent flows as nations seek expertise while safeguarding their innovation ecosystems.

Understanding these interconnected economic, societal, and geopolitical factors reveals the comprehensive influence that the multi-layer painting and finishing process wields in the motorcycle fairing industry. For further perspectives on industry trends and product options shaped by these dynamics, explore detailed insights on affordable and expertly finished motorcycle fairings.

Chapter 3: Quality Control and Assembly Preparation in Making Motorcycle Fairings

1. Mastering Quality Control: Safeguarding Material Integrity and Flawless Fit in Motorcycle Fairings

Ensuring the integrity and flawless fit of motorcycle fairings requires a comprehensive quality control strategy that goes beyond surface inspections. Quality control begins with choosing materials that align with performance and durability standards. ABS plastic and carbon fiber composites are prevalent, each demanding tailored inspection approaches to preserve their mechanical and visual properties. Adhesives used during assembly must be chemically compatible with these materials to avoid weakening bonds or causing discoloration. Epoxy-based adhesives are favored for their strong, flexible, and weather-resistant qualities, while plastic welding offers a seamless repair option that maintains structural strength without blemishing the exterior.

Dimensional precision is another cornerstone of defect-free production. Fairings must match exact specifications to fit motorcycle frames perfectly. Advanced measuring tools like calipers and laser gauges verify that all molded or machined parts stay within tight tolerances, preventing alignment issues during installation. Alongside dimensional accuracy, surface quality checks identify cracks, warping, or color inconsistencies that can compromise both function and aesthetics. UV and impact resistance of paints and adhesives are routinely tested to ensure fairings withstand harsh environmental conditions over time.

In modern production, 3D-printed jigs and fixtures with integrated reference points help maintain consistent assembly accuracy while streamlining inspection processes to reduce human error. Moreover, integrating third-party or in-house quality audits bolsters defect detection and validates conformity across material properties, dimensions, and packaging integrity before shipment. This thorough scrutiny creates traceability, assuring manufacturers and consumers of the product’s reliability.

Packaging plays a vital role in maintaining quality by safeguarding fairings during transport. Protective films, foam inserts, and thoughtfully designed stacking prevent surface damage and deformation, ensuring the parts arrive in pristine condition.

This rigorous multi-layered approach to quality control combines material science, precise measurement, and diligent handling to produce durable, visually appealing motorcycle fairings. Such dedication ensures that each part meets or exceeds OEM standards, offering riders confidence in both the performance and aesthetic value of their motorcycles. For deeper insights into adhesive selection and material care when handling fairings, exploring detailed resources at Summit Fairings offers valuable guidance.

2. Mastering Assembly Preparation for Motorcycle Fairings: Adhesive Choices and Surface Conditioning for Durable Bonding

Achieving durable, high-quality assemblies in motorcycle fairings hinges on meticulous adhesive selection coupled with precise surface treatment. Because fairings are formed from composite materials such as ABS plastics or fiberglass, the adhesives must be specifically formulated to bond these substrates reliably. Epoxy resins, polyurethane adhesives, and specially designed plastic bonding glues offer excellent mechanical strength while providing resistance to the constant vibrations, temperature fluctuations, and weather exposures that motorcycles face daily.

Surface preparation is equally critical to maximize adhesive performance. The process begins with thorough cleaning to eliminate oils, dust, and contaminants that can impair bonding. Light sanding or abrasion follows, creating a textured surface that significantly enhances adhesive grip by increasing surface area and promoting mechanical interlocking. When working with painted or coated sections, care is taken to avoid damage; generally, only the bonding edges are abraded. Degreasing with appropriate solvents ensures no residual film remains to interfere with adhesion.

Depending on the material and adhesive type, application of primers or adhesion promoters can further improve bond strength, especially important on plastics and composite surfaces where adhesion challenges are more pronounced. This multi-layered approach emphasizes not only chemical bonding but also physical surface modification to achieve optimal results.

In practice, many manufacturers combine adhesives with mechanical fasteners like rivets or screws to enhance overall assembly integrity and resistance to dynamic stresses. Proper assembly technique includes securing the motorcycle on a stable surface, avoiding part movement during adhesive curing, and adhering strictly to manufacturers’ recommended curing times and environmental conditions such as temperature and humidity.

Finally, protecting painted surfaces from scratches during installation requires careful handling and thoughtful assembly sequencing. This attention to detail ensures the fairings not only fit perfectly, as expected from OEM standards, but also present a flawless finish after installation.

For a deeper exploration of assembling motorcycle fairings with professional standards, consider visiting Explore the Best Motorcycle Fairings at Summit Fairings, which offers insight into quality construction and materials.

3. Precision Manufacturing’s Impact on Quality Control and Assembly Preparation for Motorcycle Fairings

The manufacturing process of motorcycle fairings fundamentally shapes the quality control measures and assembly readiness necessary to deliver high-performance components. Fairings begin as raw materials such as ABS plastic, fiberglass, or carbon fiber composites, formed through precisely controlled methods like injection molding, vacuum forming, or composite layup. These processes ensure dimensional accuracy and consistent shape, which are critical prerequisites for achieving seamless fit and finish.

Once formed, each fairing undergoes thorough surface preparation to eliminate imperfections such as air pockets or uneven textures. This stage not only facilitates flawless aesthetics but also ensures optimal paint adhesion during the subsequent multi-layer painting process. Quality control teams rigorously inspect surfaces, correcting any defects before painting, to uphold the durability and visual standards expected from premium motorcycle parts.

Dimensional inspections continue beyond surface quality, with every part measured to verify alignment with design specifications. Defective components are either repaired or discarded, preserving the integrity of the final assembly. This meticulous scrutiny guarantees compatibility with motorcycle frames and adjacent components like lights and indicators, preventing fitment issues during installation.

To streamline assembly, manufacturers utilize specialized jigs and fixtures—often created via advanced 3D printing technology—to hold fairings securely during fastening operations. These manufacturing aids minimize part deflection and alignment errors, ensuring consistent assembly quality and repeatability. Through such precision tooling, fairings maintain their structural strength and aesthetic coherence when mounted.

CNC-machined molds and 3D-printed assembly aids exemplify how cutting-edge technology reinforces this process, improving production efficiency and part reliability. The integration of these advanced methods ensures fairings not only meet aerodynamic and aesthetic requirements but also contribute meaningfully to rider safety and motorcycle longevity.

In essence, the manufacturing workflow—from exact forming through surface finishing to targeted assembly preparation—establishes the foundation for stringent quality control. This system robustly guarantees that each motorcycle fairing fits perfectly, withstands operational stresses, and presents a polished, durable finish worthy of factory standards. For those interested in exploring the range and quality options available, discover affordable motorcycle fairings at Summit Fairings offers insight into expertly crafted products aligned with these high manufacturing standards.

Final thoughts

Manufacturing motorcycle fairings demands a blend of precision engineering, material expertise, and rigorous finishing protocols. Injection molding with ABS plastic ensures each component’s strength and dimensional accuracy, forming the foundation for durable fairings. The subsequent multi-layer painting and finishing process not only enhances aesthetic appeal but also protects against environmental damage and wear, setting aftermarket and OEM fairings apart in quality and longevity. Finally, comprehensive quality control and assembly preparation uphold the standards necessary for a perfect fit and customer satisfaction, ensuring parts integrate seamlessly with motorcycles. For business owners, mastering these interconnected steps is crucial to delivering products that meet market expectations and foster brand reliability. Understanding this holistic manufacturing approach enables informed decisions in sourcing, production oversight, and quality management to excel in the competitive motorcycle accessories industry.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined