Introduction

Motorcycle fairing design is a nuanced discipline that demands precision, innovation, and a harmonious balance between aesthetics and engineering. For business owners in the motorcycle industry, understanding the software landscape behind fairing design can unlock opportunities for improved product quality, streamlined workflows, and enhanced customizability. This exploration reveals the range of software tools and methods—ranging from MotoSPEC’s chassis and suspension alignment capabilities to advanced Computer-Aided Design (CAD) platforms for aerodynamic modeling, and the use of reverse engineering through 3D scanning. Each chapter builds on the last to provide a comprehensive view of how these technologies collectively empower businesses to produce fairings that not only meet functional demands but also cater to diverse market tastes and racing specifications.

Tables of Contents

Chapter 1: Integration of MotoSPEC within Motorcycle Fairing Design Software for Chassis and Suspension Alignment

- Enhancing Motorcycle Fairing Design Through Advanced MotoSPEC Integration and Virtual Prototyping

- Maximizing Cost Efficiency and Performance Through MotoSPEC Integration in Fairing Design

- Navigating Geopolitical Challenges in Integrating MotoSPEC within Motorcycle Fairing Design Software

- Societal Benefits of Integrating MotoSPEC with Motorcycle Fairing Design Software for Safer, Customizable Rides

- Efficient Workflows and Methodologies for Harmonizing MotoSPEC with Fairing Design Software

Chapter 2: Advanced CAD Applications for Precision 3D Modeling and Aerodynamics in Motorcycle Fairing Design

- Innovations Driving Precision and Aerodynamic Excellence in CAD-Based Motorcycle Fairing Design

- Transforming Manufacturing and Development Economics Through CAD-Driven Motorcycle Fairing Design

- Global Innovation and Cultural Forces Driving CAD Applications in Motorcycle Fairing Aerodynamics

- Enhancing Rider Experience and Environmental Impact via CAD-Driven Fairing Innovations

- Harnessing Aerodynamic and Structural Simulations Within CAD for Optimized Motorcycle Fairing Design

Chapter 3: Advanced Reverse Engineering and 3D Scanning Integration in Motorcycle Fairing Design Software

- Seamless 3D Scanning Integration for Precision Custom and Replacement Motorcycle Fairings

- Harnessing CAD Software to Transform 3D Scans into Customized Motorcycle Fairings

- Overcoming Precision and Material Challenges in Reverse Engineering Custom Motorcycle Fairings

- Transforming Motorcycle Fairing Production Through Reverse Engineering and 3D Scanning Technologies

- Innovative Technologies and Industry Standards Shaping Motorcycle Fairing Reverse Engineering

Chapter 4: Advanced Software Integration for Aerodynamic Excellence in Race Fairing Design

- Leveraging Specialized Design Software to Optimize Aerodynamics in Race Fairing Production

- Harnessing Specialized Software to Engineer Ground-Effect Aerodynamics in Motorcycle Race Fairings

- Harnessing Computational Fluid Dynamics in Motorcycle Fairing Design for Enhanced Race Aerodynamics

- Harnessing Advanced Design Software to Innovate Materials and Structural Integrity in Race Fairings

- How Specialized Design Software Accelerates and Lowers Costs in Race Fairing Development

Chapter 5: Use of Proprietary and Industry-Standard CAD Tools in Custom Motorcycle Fairing Design Software by Fabricators

- How Industry-Standard CAD Tools Elevate Precision and Durability in Custom Motorcycle Fairing Fabrication

- Material-Driven Precision: How Proprietary CAD Tools Optimize Custom Motorcycle Fairings

- Harnessing Cutting-Edge CAD Technologies for Precision and Creativity in Custom Motorcycle Fairing Fabrication

- Economic and Manufacturing Influence of CAD Software Choices in Custom Motorcycle Fairing Fabrication

- Balancing Innovation, Compliance, and Inclusivity: Societal and Regulatory Dimensions in CAD Software Selection for Custom Motorcycle Fairing Fabrication

Chapter 6: Comprehensive Workflow Combining Multiple Technologies in Motorcycle Fairing Design Software

- Seamless Integration of CAD and CAM for Precision and Innovation in Motorcycle Fairing Design

- Harnessing Simulation and Analysis Tools to Elevate Integrated Motorcycle Fairing Design

- Harnessing Additive Manufacturing to Innovate Motorcycle Fairing Design Workflows

- Economic Benefits of Integrating Advanced Technologies in Motorcycle Fairing Design Workflows

- Cultural Expression and Global Dynamics Shaping Motorcycle Fairing Design Technologies

Chapter 1: Integration of MotoSPEC within Motorcycle Fairing Design Software for Chassis and Suspension Alignment

1. Enhancing Motorcycle Fairing Design Through Advanced MotoSPEC Integration and Virtual Prototyping

The integration of MotoSPEC with motorcycle fairing design software marks a significant technological evolution in chassis and suspension alignment. MotoSPEC’s virtual prototyping enables designers to simulate how modifications to suspension linkages and chassis geometry influence handling and weight distribution without costly physical trials. This real-time feedback loop allows aerodynamic and aesthetic fairing adjustments to be evaluated for mechanical impact immediately. Cross-platform support and precise data export empower seamless collaboration between CAD modeling environments and suspension optimization tools, ensuring aerodynamic performance and mechanical stability coexist harmoniously. Such advancements democratize high-level engineering analysis, enabling both grassroots and professional teams to optimize fairing designs aligned closely with dynamic chassis behavior, enhancing safety and competitive edge. For insights on custom fairings and manufacturing techniques, explore Summit Fairings’ extensive resources.

2. Maximizing Cost Efficiency and Performance Through MotoSPEC Integration in Fairing Design

Integrating MotoSPEC within motorcycle fairing design software streamlines development by enabling accurate simulation of chassis and suspension setups alongside aerodynamic fairing models. This virtual environment drastically reduces physical prototyping, cutting associated costs and time. Early coordination of fairing aerodynamics with suspension geometry enhances product performance while minimizing design iterations. Such efficiency accelerates time-to-market and supports extensive customization without heavy R&D expenditure. Consequently, manufacturers and racing teams benefit from improved profitability and resource utilization. For more on fairing options complementing these design efficiencies, explore the variety available at Summit Fairings.

3. Navigating Geopolitical Challenges in Integrating MotoSPEC within Motorcycle Fairing Design Software

Integrating MotoSPEC into motorcycle fairing design software extends beyond technical innovation, deeply influenced by geopolitical complexities. Protecting proprietary chassis and suspension data requires navigating varying international intellectual property laws, balancing patent disclosures against trade secrecy amid uneven enforcement. Data sovereignty and cybersecurity demands compel developers to architect compliant systems that respect regional privacy laws and guard against cyber threats, including industrial espionage. Moreover, global trade policies, tariffs, and market access affect supply chains, component availability, and regulatory compliance essential for MotoSPEC-enabled designs. Cross-border collaborations and standardization efforts further reflect geopolitical interplay, driving innovation while requiring careful coordination to align diverse legal and commercial environments. This geopolitical landscape critically dictates the development, deployment, and success of integrated motorcycle design solutions in a complex global market.

Read more about exploring the best motorcycle fairings and their design considerations.

4. Societal Benefits of Integrating MotoSPEC with Motorcycle Fairing Design Software for Safer, Customizable Rides

Integrating MotoSPEC with motorcycle fairing design software profoundly influences society by improving safety, performance, and accessibility in motorcycle engineering. This synergy enables precise virtual alignment of chassis and suspension, reducing the reliance on costly physical testing and accelerating innovation. Riders gain safer, more ergonomic motorcycles tailored to diverse needs, while smaller tuners access advanced tools once reserved for major manufacturers. Such democratization fosters inclusivity within motorcycle culture, driving both craftsmanship and technological progress. Ultimately, the fusion of these tools supports not only competitive racing but also everyday riding comfort and public road safety, enhancing the rider experience industry-wide. For more on fairing options, explore unmatched choices in motorcycle fairings at Summit Fairings.

5. Efficient Workflows and Methodologies for Harmonizing MotoSPEC with Fairing Design Software

Integrating MotoSPEC with motorcycle fairing design software demands a refined workflow that synchronizes chassis geometry and suspension data with aerodynamic modeling. Central to this process is standardizing data formats to enable fluid information exchange between MotoSPEC and CAD platforms. Utilizing parametric design techniques within CAD allows adjustments in chassis or suspension parameters to update fairing models dynamically. This iterative approach fosters collaboration among engineers and designers, supported by simulation tools that evaluate performance impacts before fabrication. Continuous feedback, informed by virtual testing or real-world data, ensures progressive alignment of structural and aerodynamic elements for optimized motorcycle design. For deeper insights on fairing design options, explore affordable motorcycle fairings at Summit Fairings.

Chapter 2: Advanced CAD Applications for Precision 3D Modeling and Aerodynamics in Motorcycle Fairing Design

1. Innovations Driving Precision and Aerodynamic Excellence in CAD-Based Motorcycle Fairing Design

Technological innovations in CAD have revolutionized motorcycle fairing design, allowing for precise 3D modeling that merges aesthetics with aerodynamic functionality. Designers use CAD to create custom fits that integrate seamlessly with chassis and suspension, enhancing stability and rider protection. The integration of aerodynamic simulation tools enables airflow optimization, reducing drag while preserving bold styling. Reverse engineering through 3D scanning accelerates design iteration by converting physical parts into editable digital models. Moreover, CAD models streamline manufacturing via CNC and 3D printing, ensuring accuracy and repeatability. This fusion of creative design with engineering rigor supports distinct styles, including culturally unique fairings, while maintaining aerodynamic integrity. Explore more about custom fairing options at Summit Fairings for practical design inspiration.

2. Transforming Manufacturing and Development Economics Through CAD-Driven Motorcycle Fairing Design

Computer-Aided Design (CAD) revolutionizes motorcycle fairing development by enabling precise 3D modeling and aerodynamic optimization that significantly reduce physical prototyping costs and material waste. This digital approach accelerates time-to-market, allowing rapid design iterations and better responsiveness to consumer trends. CAD facilitates seamless data transfer to manufacturing equipment, supporting mass customization without extensive retooling. It also reshapes workforce demands by emphasizing skills in simulation and digital modeling over manual fabrication. These efficiencies lower barriers for smaller manufacturers, intensify competition, and expand high-performance, affordable aftermarket options. This economic impact strengthens the motorcycle industry’s innovation and market adaptability, reflecting a pivotal shift in design and production practices. For further insights on quality fairing options, explore affordable motorcycle fairings available at Summit Fairings.

3. Global Innovation and Cultural Forces Driving CAD Applications in Motorcycle Fairing Aerodynamics

The adoption of CAD in motorcycle fairing design is deeply influenced by a blend of global innovation, material tech advancements, and cultural design trends. Industry leaders invest heavily in 3D modeling to optimize aerodynamics using carbon fiber composites, balancing drag reduction with rider safety. Regional subcultures, such as the expressive Japanese Bosozoku style, shift CAD focus toward bold aesthetics over pure performance. Meanwhile, geopolitical realities affect material sourcing and software access, shaping manufacturing workflows worldwide. Emerging AI integrations further enhance design precision, supported by academic-industry partnerships. This synergy of global forces drives continual evolution of CAD’s role in aerodynamic fairing development, marrying functionality with diverse cultural expression. For insight into practical design resources, explore this ultimate source for affordable motorcycle fairings.

4. Enhancing Rider Experience and Environmental Impact via CAD-Driven Fairing Innovations

The integration of Computer-Aided Design (CAD) in motorcycle fairing development not only refines aesthetics and aerodynamics but also delivers tangible societal benefits and improved rider comfort. Through precise 3D modeling, fairings are optimized to reduce wind resistance, enhancing fuel efficiency and lowering emissions, which supports environmental sustainability. Riders enjoy reduced fatigue and increased safety, as CAD enables incorporating advanced design elements that mitigate wind buffeting and improve stability at speed. Furthermore, CAD empowers customization, fostering personal expression and broadening market appeal. This fusion of performance, safety, and individuality exemplifies the holistic improvements offered by CAD technologies in motorcycle fairing design. For insight into diverse fairing options realized through such innovations, explore resources like discover affordable motorcycle fairings at Summit Fairings.

5. Harnessing Aerodynamic and Structural Simulations Within CAD for Optimized Motorcycle Fairing Design

Computer-Aided Design (CAD) software merges 3D modeling with aerodynamic and structural simulations to elevate motorcycle fairing design. Designers craft detailed fairing geometries within CAD before applying Computational Fluid Dynamics (CFD) to analyze airflow, minimizing drag and enhancing stability at speed. Concurrently, Finite Element Method (FEM) structural analysis tests material stresses and deformation, ensuring durability without excessive weight. This iterative approach refines fairing properties virtually, reducing the need for costly prototypes. Complemented by rapid prototyping techniques, such as 3D printing and CAM, integrated simulation within CAD accelerates development cycles while maximizing performance and aesthetic harmony, supporting a seamless path from concept to manufacture. For more details, explore unmatched choices in motorcycle fairings.

Chapter 3: Advanced Reverse Engineering and 3D Scanning Integration in Motorcycle Fairing Design Software

1. Seamless 3D Scanning Integration for Precision Custom and Replacement Motorcycle Fairings

3D scanning revolutionizes reverse engineering by capturing the precise geometries of existing motorcycle fairings, enabling designers to recreate or customize parts with unmatched accuracy. Scanned models, often processed into watertight meshes, integrate smoothly into CAD software for detailed refinement. This workflow supports adaptations such as segmenting large fairings for additive manufacturing and adjusting features for stronger, lighter components. Beyond exact replicas for replacements, 3D scanning empowers bespoke modifications, helping designers innovate while maintaining fit and function. Such digitization streamlines prototype development and broadens access to rare parts, blending craftsmanship with modern engineering. For detailed insights, explore affordable motorcycle fairings at Summit Fairings.

2. Harnessing CAD Software to Transform 3D Scans into Customized Motorcycle Fairings

CAD software serves as the cornerstone in transforming 3D scanning data into precise, customizable motorcycle fairings. After reverse engineering captures physical fairings as digital models, designers use CAD tools to refine shapes, adjust dimensions, and integrate stylistic elements tailored to unique preferences or functional demands. This flexibility supports the recreation of rare or obsolete fairings and facilitates bold customizations, such as culturally specific Bosozoku designs, by balancing aesthetics with manufacturability. By bridging scanned data and innovative modifications, CAD empowers bespoke replacements and creative enhancements, ensuring motorcycle fairings not only fit perfectly but also reflect personal or cultural expressions. Learn more about the diverse options available in motorcycle fairings at Summit Fairings.

3. Overcoming Precision and Material Challenges in Reverse Engineering Custom Motorcycle Fairings

Reverse engineering motorcycle fairings presents distinct challenges due to their intricate curves, thin-walled structures, and reflective surfaces. Capturing these complexities with high-resolution 3D scanning technologies, such as structured light or laser scanners, enables precise digital replication. To address surface reflectivity issues, temporary matte coatings or multi-spectral scanning enhance data quality. The integration of scan data into CAD models relies on specialized scan-to-CAD workflows that preserve dimensional accuracy crucial for manufacturing. Additionally, advances in lightweight composite materials allow for strong yet thin fairings that meet aerodynamic and structural demands. Iterative prototyping with simulation tools ensures proper fitment on frames, reducing physical trial and error. This approach streamlines custom and replacement fairing production, expertly balancing engineering rigor with design fidelity. For further insights into bespoke fairing styles, explore elite motorcycle fairings.

4. Transforming Motorcycle Fairing Production Through Reverse Engineering and 3D Scanning Technologies

Reverse engineering and 3D scanning enable precise digitization of existing motorcycle fairings, producing accurate CAD models for repair, customization, or reproduction. These technologies excel in capturing complex geometries and mounting points, vital for rare or discontinued parts. By converting scanned data into editable digital models, designers can modify or restore fairings before leveraging 3D printing or traditional manufacturing methods. This approach ensures impeccable fitment, reduces inventory needs, and accelerates delivery, especially benefiting vintage motorcycles where original parts are scarce. Such integration of scanning with CAD streamlines replacing and customizing fairings while balancing aerodynamic and aesthetic demands. Discover more insights on custom motorcycle fairings here.

5. Innovative Technologies and Industry Standards Shaping Motorcycle Fairing Reverse Engineering

Recent innovations in reverse engineering and 3D scanning have revolutionized motorcycle fairing design by enabling precise digital replication of existing parts. These technologies support restoration, customization, and aerodynamic refinement without physical prototypes. Strict certification standards ensure accuracy and reliability in data capture and model integration, fostering trust across design and manufacturing teams. Software advances now blend scanned data with simulation and AI-driven optimization, accelerating development and collaboration. As materials evolve and design complexity grows, adherence to industry protocols remains vital in producing fairings that meet both aesthetic and functional demands. Explore more about motorcycle fairings design and trends at a leading motorcycle fairings resource.

Chapter 4: Advanced Software Integration for Aerodynamic Excellence in Race Fairing Design

1. Leveraging Specialized Design Software to Optimize Aerodynamics in Race Fairing Production

Specialized motorcycle fairing design software enables precise aerodynamic simulations that predict airflow, pressure distribution, and downforce effects critical to race fairings. By modeling complex features like wings and air intakes, this software supports optimization to enhance grip, reduce drag, and improve rider stability during cornering and high-speed runs. Through virtual testing, manufacturers can refine advanced aerodynamic elements—such as ground-effect wings—while minimizing prototyping costs. This computational approach underpins the development of cutting-edge race fairings that meet rigorous aerodynamic demands, ensuring superior performance, safety, and competitive advantage in motorcycle racing. For more on high-performance fairing choices, explore options available at Summit Fairings.

2. Harnessing Specialized Software to Engineer Ground-Effect Aerodynamics in Motorcycle Race Fairings

Specialized motorcycle fairing design software is essential for engineering race fairings that exploit ground-effect aerodynamics. By precisely modeling airflow to create low-pressure zones beneath the bike, these tools enable designers to generate increased downforce that significantly boosts cornering grip and stability at high lean angles. Integration of 3D modeling with computational fluid dynamics (CFD) allows iterative refinement of winglets and side fairings to balance aerodynamic efficiency with regulatory constraints. This software also supports advanced carbon fiber manufacturing, ensuring components combine lightweight strength with aerodynamic function. The result is race fairings optimized for performance gains through strategic manipulation of airflow close to the track, directly enhancing rider control and lap times. For more on innovative fairing options, explore Summit Fairings’ selection of race-ready designs.

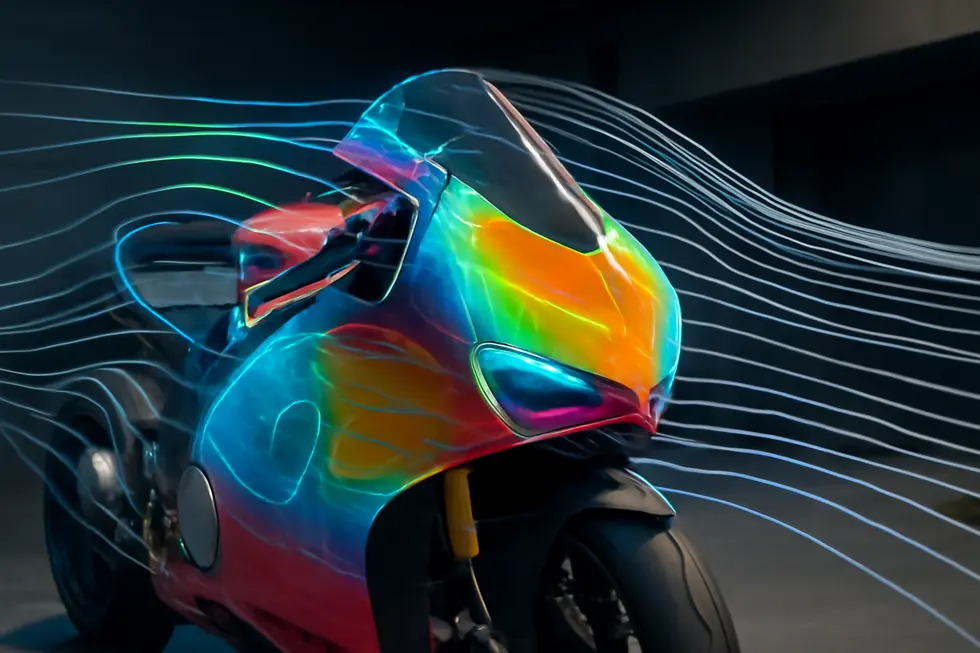

3. Harnessing Computational Fluid Dynamics in Motorcycle Fairing Design for Enhanced Race Aerodynamics

Specialized fairing design software leverages Computational Fluid Dynamics (CFD) to simulate airflow precisely around race motorcycles. This process enables designers to iteratively refine fairing shapes, balancing drag reduction and downforce to boost high-speed stability and cornering. CFD analysis also enhances cooling efficiency by optimizing radiator airflow, critical under intense racing conditions. Integration with advanced materials allows production of lightweight, strong composite fairings meeting both aerodynamic and structural demands. Such software thus drives the creation of race fairings that significantly improve speed, stability, and rider control, essential for competitive race performance.

4. Harnessing Advanced Design Software to Innovate Materials and Structural Integrity in Race Fairings

Specialized motorcycle fairing design software drives innovation by enabling precise aerodynamic refinement and the integration of cutting-edge materials like carbon fiber composites. Utilizing computational fluid dynamics (CFD) alongside structural analysis, designers optimize fairing shapes to reduce drag, enhance downforce, and improve rider stability. This software-guided approach supports advanced manufacturing methods such as layered carbon lay-ups, combining lightness with rigidity. Through structural integration, these fairings not only deliver aerodynamic benefits but also support critical components. Such software-enabled innovations accelerate development of race fairings that excel in performance, durability, and aerodynamic efficiency. For more insights on premium fairing options influenced by advanced design, visit Explore the Best Motorcycle Fairings at Summit Fairings.

5. How Specialized Design Software Accelerates and Lowers Costs in Race Fairing Development

Specialized motorcycle fairing design software accelerates race fairing development by enabling detailed aerodynamic simulations and rapid digital prototyping. Designers can virtually model airflow and structural behavior, integrating features like ground-effect wings and corner sidepods to enhance downforce and stability. This reduces reliance on costly physical prototypes and accelerates iterations. The software also supports advanced materials, optimizing lay-ups for rigidity and weight reduction while minimizing waste, lowering production costs. It facilitates swift adaptation to strict aerodynamic regulations, maintaining competitive performance. This integrated approach streamlines race fairing innovation and cost-efficiency for high-speed stability and grip. For more on custom fairing options, explore these insights from Summit Fairings.

Chapter 5: Use of Proprietary and Industry-Standard CAD Tools in Custom Motorcycle Fairing Design Software by Fabricators

1. How Industry-Standard CAD Tools Elevate Precision and Durability in Custom Motorcycle Fairing Fabrication

The integration of industry-standard CAD software in custom motorcycle fairing fabrication empowers designers to achieve unmatched precision and durability. Detailed 3D modeling within tools like Fusion 360 and SolidWorks allows for exact shaping that preserves unique aesthetic styles while optimizing aerodynamics and structural strength. Simulation features refine design choices, balancing rider protection with visual appeal. These CAD workflows also facilitate seamless transitions to precision manufacturing, ensuring the final fairings fit flawlessly and withstand stress through optimized materials and complex geometries. This holistic approach results in durable, high-performance fairings that embody both craftsmanship and engineering excellence. For deeper insights into stylistic influences, explore detailed Bosozoku fairing designs.

2. Material-Driven Precision: How Proprietary CAD Tools Optimize Custom Motorcycle Fairings

Custom motorcycle fabricators rely heavily on proprietary CAD tools to tailor fairings for materials like ABS plastic, carbon fiber, and composites. These systems enable precise 3D modeling that balances aerodynamics, fitment, and aesthetics while maximizing each material’s strengths—such as reducing weight or enhancing flexibility. By simulating structural stresses and refining thickness and mounting points, designers ensure durability and optimal performance under real-world conditions. Integration with manufacturing workflows also streamlines production, allowing bespoke designs—from race-ready panels to culturally distinctive styles—to meet exacting standards. This material-specific approach elevates both functionality and rider expression in custom builds, showcasing the critical role of advanced CAD in fairing innovation.

3. Harnessing Cutting-Edge CAD Technologies for Precision and Creativity in Custom Motorcycle Fairing Fabrication

The fusion of proprietary and industry-standard CAD tools has revolutionized custom motorcycle fairing design, allowing fabricators to seamlessly blend precision engineering with artistic vision. Advanced software supports detailed 3D modeling, aerodynamic simulation, and integration with complex chassis and suspension modifications, enabling tailored fairings that fit unique mechanical setups. These tools empower designers to create bold aesthetic styles—such as culturally distinctive oversized fairings—while maintaining functional integrity. Moreover, CAD’s role extends beyond design into prototyping and production workflows for both traditional and electric motorcycles. This technological synergy accelerates innovation and enhances customization within the motorcycle fairing fabrication landscape, reflecting a new era of design sophistication. For more insights, explore the best motorcycle fairings at Summit Fairings.

4. Economic and Manufacturing Influence of CAD Software Choices in Custom Motorcycle Fairing Fabrication

The choice between proprietary and industry-standard CAD tools significantly shapes economic and manufacturing outcomes in custom motorcycle fairing design. Proprietary software often demands higher upfront investment but delivers tailored aerodynamic modeling and seamless integration with advanced manufacturing, enhancing precision and product performance. On the other hand, industry-standard CAD tools provide cost-effective, flexible platforms supporting rapid prototyping and diverse fabrication methods like 3D printing, ideal for smaller fabricators and fast iterations. This balance affects scalability and innovation paths: while proprietary tools drive cutting-edge refinement for premium markets, industry-standard tools empower widespread customization with accessible workflows. Understanding these impacts guides fabricators toward solutions aligned with their production scale and market goals. For a deeper dive into custom motorcycle components, explore the best motorcycle fairings at Summit Fairings.

5. Balancing Innovation, Compliance, and Inclusivity: Societal and Regulatory Dimensions in CAD Software Selection for Custom Motorcycle Fairing Fabrication

Fabricators face a nuanced challenge when choosing between proprietary and industry-standard CAD tools for custom motorcycle fairing design. Proprietary solutions offer tailored features that enhance niche creativity yet may restrict collaboration and impose higher costs. In contrast, widely adopted CAD platforms promote interoperability, regulatory compliance, and accessibility, broadening user inclusion and easing file exchanges critical for manufacturing workflows. Equally, cultural expression, such as bold stylistic traditions, depends on flexible design tools that respect safety mandates while supporting distinctive aesthetics. This interplay of societal impact, legal adherence, and economic accessibility shapes the holistic adoption of CAD technologies within custom fairing fabrication.

For further insights into custom fairing design innovations, explore the rich variety available at Summit Fairings.

Chapter 6: Comprehensive Workflow Combining Multiple Technologies in Motorcycle Fairing Design Software

1. Seamless Integration of CAD and CAM for Precision and Innovation in Motorcycle Fairing Design

CAD and CAM technologies unify to transform motorcycle fairing design by enabling detailed 3D modeling alongside automated manufacturing processes like CNC machining and 3D printing. This synergy allows designers to balance bold aesthetics with aerodynamics, rider protection, and manufacturability. Using advanced materials such as ABS plastic and carbon fiber, the integrated workflow supports rapid prototyping and iterative enhancements. The digital continuum from design through production streamlines development, yielding complex, customized fairings that fulfill both functional and stylistic demands. For a closer look at creative fairing styles, explore more about Bosozoku motorcycle fairings.

2. Harnessing Simulation and Analysis Tools to Elevate Integrated Motorcycle Fairing Design

Simulation and analysis tools are vital in merging diverse technologies within motorcycle fairing design workflows. Geometry and suspension simulation ensures fairings complement chassis dynamics and handling by modeling frame and suspension interactions. Using 3D scanning with CAD facilitates precise reconstruction and refinement of fairing shapes for aerodynamic and aesthetic goals. Advanced composite material simulations optimize structural integrity through tailored layups and curing processes. Rapid prototyping via 3D printing accelerates functional validation and customization of lightweight components. Emerging virtual reality tools enable immersive ergonomic and rider interaction assessments. This multidisciplinary approach deepens design accuracy, streamlines development, and enhances fairing performance and style, pivotal for high-quality motorcycle manufacturing. For further insight, explore detailed innovations at https://blog.summitfairings.com/explore-summit-fairings-your-go-to-destination-for-motorcycle-fairings/.

3. Harnessing Additive Manufacturing to Innovate Motorcycle Fairing Design Workflows

Additive manufacturing revolutionizes motorcycle fairing design by enabling rapid prototyping and fabrication of lightweight, intricate components. It complements digital tools like 3D scanning and CAD, allowing precise replication and refinement of custom geometries. This synergy accelerates design iterations, reducing development time and cost while enhancing aerodynamic performance and rider-specific customization. By integrating with composite materials and advanced production methods, additive manufacturing supports durable, complex fairings previously unattainable through traditional techniques. These capabilities empower designers to push aesthetic and functional boundaries, facilitating innovation within a holistic multi-technology design environment. Learn more about diverse fairing options at Explore the Best Motorcycle Fairings at Summit Fairings.

4. Economic Benefits of Integrating Advanced Technologies in Motorcycle Fairing Design Workflows

The integration of CAD, simulation, and manufacturing technologies in motorcycle fairing design significantly reduces development costs and accelerates time-to-market. Advanced material simulations enable lightweight, waste-minimized fairings that improve performance and operational savings. By leveraging aerodynamics and structural optimization inspired by motorsport innovations, manufacturers create premium, high-value products that stand out competitively. Automation through CNC and composite molding further cuts production expenses and enhances repeatability. This holistic approach balances upfront investments with long-term gains in efficiency, product quality, and brand positioning, driving sustainable profitability within the motorcycle industry. For deeper insights, explore an ultimate source for affordable motorcycle fairings.

5. Cultural Expression and Global Dynamics Shaping Motorcycle Fairing Design Technologies

Motorcycle fairing design software not only advances engineering precision but also intertwines with cultural identities and global market forces. Distinct styles like the Bosozoku fairings symbolize rebellion and individuality, using CAD tools to merge artistic expression with functional design. On a broader scale, regions with robust technological infrastructure leverage advanced design software to innovate, influencing global motorcycle trends and trade. This creates a feedback loop where local culture inspires design, and geopolitical access to technology shapes industry competitiveness, fostering a dynamic interplay crucial to modern motorcycle fairing development. For deeper insights, explore the best motorcycle fairings and their evolving styles.

Final thoughts

The effectiveness of motorcycle fairing design software lies in its ability to seamlessly integrate diverse technologies to meet the multifaceted demands of design precision, functional performance, and aesthetic excellence. From the critical alignment of chassis and suspension geometry using MotoSPEC to the detailed 3D modeling and aerodynamic simulations in CAD environments, each tool contributes indispensably to the refinement of fairings. Reverse engineering and 3D scanning provide indispensable flexibility when working with custom and vintage models, ensuring accuracy and customization. Moreover, specialized software solutions elevate race fairing production, optimizing performance through advanced aerodynamic analysis. Fabricators who combine proprietary tools with popular CAD platforms deliver bespoke designs that meet unique client demands. Ultimately, a comprehensive workflow that amalgamates these technologies empowers motorcycle businesses to innovate, optimize, and compete effectively in a demanding market.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined