Introduction

Motorcycle fairing grommets might seem like small components, but they play a pivotal role in securing and preserving motorcycle fairings. These rubber or plastic inserts act as vital vibration dampeners, ensuring the integrity and aesthetic appeal of the motorcycle’s bodywork over time. For business owners in the motorcycle aftermarket and repair sectors, understanding the technological features, economic implications, and brand-specific nuances of fairing grommets unlocks significant opportunities. This knowledge equips businesses to source the right parts, optimize inventory, and meet diverse customer demands effectively. The following chapters will unravel the technical construction and benefits of these grommets, analyze their economic and market factors, and highlight model-specific considerations that influence purchasing and sales decisions.

Tables of Contents

Chapter 1: Technological Features of Motorcycle Fairing Grommets

- Material Composition and Durability: The Backbone of Fairing Grommet Performance

- How Vibration Dampening Enhances the Technological Integrity of Motorcycle Fairing Grommets

- Engineering Precision: How Perfect Fit and Compatibility Enhance Fairing Grommet Performance

- Streamlined Installation and Weatherproof Durability in Motorcycle Fairing Grommets

- Precision Engineering and Advanced Functionalities in Motorcycle Fairing Grommets

Chapter 2: Economic and Market Aspects of Motorcycle Fairing Grommets

- Balancing Cost and Value: How Motorcycle Fairing Grommets Influence Maintenance Budgets and Resale Prices

- Navigating Demand and Supply Trends: Consumer Drives Shaping the Fairing Grommets Market

- Balancing Quality, Safety, and Market Value in Motorcycle Fairing Grommets

- Global Trade Dynamics and Geopolitical Factors Shaping Motorcycle Fairing Grommet Markets

- Advances in Materials and Customization Driving Economic Growth in Fairing Grommets

Chapter 3: Brand and Model Specific Motorcycle Fairing Grommets

- Precision Engineering Behind Brand-Specific Motorcycle Fairing Grommets

- Economic and Market Dynamics Shaping Brand and Model Specific Motorcycle Fairing Grommets

- Navigating Geopolitical Challenges in Supply Chains for Motorcycle Fairing Grommets

- How Brand-Specific Fairing Grommets Shape Rider Identity and Community Culture

- Ensuring Genuine Fitment: Authenticity and Sourcing of Brand-Specific Fairing Grommets

Chapter 1: Technological Features of Motorcycle Fairing Grommets

1. Material Composition and Durability: The Backbone of Fairing Grommet Performance

Motorcycle fairing grommets rely primarily on materials like rubber and silicone, valued for their elasticity and resilience. These materials absorb vibrations and mechanical stresses, preventing cracking or loosening of the fairing panels. Rubber offers excellent cushioning and resistance to UV rays, moisture, and temperature fluctuations, ensuring long-term outdoor durability. Silicone shares these protective traits with added chemical resistance and performance across broader temperature ranges. Some grommets incorporate tough plastics such as ABS or Nylon, which bring enhanced wear resistance, albeit with reduced flexibility compared to elastomers.

Durability extends beyond material choice to include environmental resistance. Grommets must withstand continuous road-induced vibration, harsh UV exposure, moisture, and temperature shifts without losing elasticity or becoming brittle. Many designs blend reinforced or composite plastics to achieve the balance of strength and flexibility, guarding against mechanical failure.

Additionally, corrosion-resistant stainless steel fasteners often complement the grommets. These fasteners uphold secure mounting and hinder corrosion within assembly points, contributing to the sustained reliability of fairing attachment systems. The synergy between robust fairing materials and these flexible, weather-resistant grommets forms the foundation of a stable, long-lasting motorcycle exterior. For more insight into quality fairings and compatible components, explore reliable resources such as the Summit Fairings blog.

2. How Vibration Dampening Enhances the Technological Integrity of Motorcycle Fairing Grommets

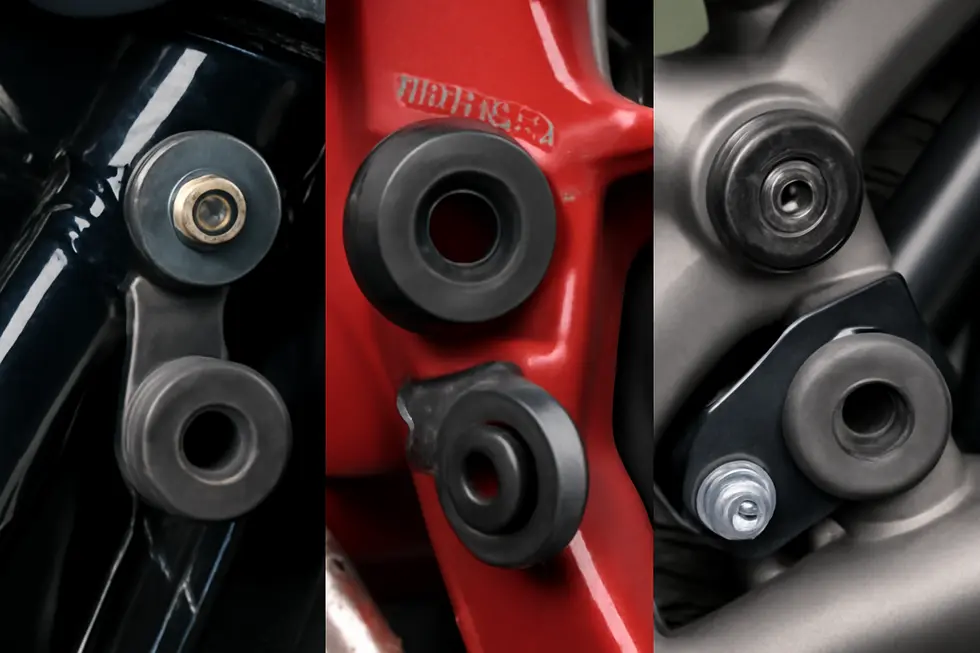

Motorcycle fairing grommets utilize advanced vibration isolation technologies to protect fairing panels from constant engine and road vibrations. Typically crafted from high-quality rubber or silicone elastomers such as EPDM, these materials offer exceptional elasticity and energy absorption. This flexibility creates a cushioning barrier that prevents direct contact between the fairings and the motorcycle frame, effectively minimizing harsh vibration transfer and related mechanical stress.

Manufacturing processes, including precision compression molding, produce custom-shaped grommets tailored to specific mounting points. This ensures an exact fit that maximizes vibration damping and shock absorption, preserving both the structural integrity and aesthetic finish of the fairings. As vibrations are isolated at these junctions, riders experience less fatigue and reduced noise, significantly enhancing overall comfort.

The integration of these elastomeric components plays a crucial role in extending the lifespan of fairing panels, mitigating the risk of cracking or loosening from prolonged exposure to vibration-induced wear. By absorbing shock and dampening vibrations, these technologies create a more durable, reliable solution that maintains the seamless fit and smooth appearance of motorcycle bodywork.

For those interested in exploring the latest advancements in quality motorcycle fairings and components, Summit Fairings offers comprehensive insights into durable and effective fairing solutions.

3. Engineering Precision: How Perfect Fit and Compatibility Enhance Fairing Grommet Performance

Motorcycle fairing grommets require precision engineering to ensure a flawless fit and seamless compatibility with specific motorcycle models. This exactness is vital because these small components secure fairing panels tightly to the frame, preventing unwanted movement that can cause wear or damage. The dimensional accuracy of grommets matches the mounting holes and fastening hardware according to strict tolerances, enabling a stable connection with no rattling or misalignment.

Beyond physical stability, precision fit directly enhances vibration isolation by maintaining tight contact, which minimizes stress concentrations on the fairings. This helps preserve both the structural integrity and aesthetic flow of the motorcycle bodywork. Compatibility means grommets complement the unique curves and mounting systems of different fairing designs without requiring modification, simplifying installation and promoting longevity.

Technological advances in materials and manufacturing—such as custom-molded rubber compounds and CNC-machined components—support these attributes by delivering durability alongside accurate geometry. The result is that riders benefit from secure, visually cohesive fairings that resist loosening over time, ultimately reducing maintenance needs.

For more insights on fairing components and fitment, explore our detailed articles on motorcycle fairings at Summit Fairings.

4. Streamlined Installation and Weatherproof Durability in Motorcycle Fairing Grommets

Motorcycle fairing grommets incorporate advanced features that enhance both ease of installation and resilience against harsh environmental factors. Engineered for a bolt-on approach, these grommets come with comprehensive hardware kits, enabling riders or technicians to mount fairings swiftly without specialized tools. The practical use of silicone spray during installation reduces friction, ensuring the rubber grommets seat properly without damage or excessive effort. This streamlined process supports efficient maintenance and repairs, keeping fairing panels firmly affixed.

Beyond installation, the materials selected for grommets are designed to withstand diverse weather conditions. Durable rubber compounds resist water, dust, and harmful UV rays, preventing deterioration under prolonged exposure. Their flexibility cushions vibrations, helping maintain attachment integrity over time. Surrounding components, including impact-resistant ABS fairing plastics and aerodynamic wind deflectors, complement the grommets’ durability. These parts undergo rigorous testing—such as wind tunnel and fluid dynamics analyses—to confirm they endure operational stresses like wind pressure and temperature fluctuations.

Together, these thoughtful engineering elements ensure motorcycle fairing grommets provide a dependable, long-lasting connection. Their user-friendly installation paired with robust environmental resistance safeguards the form and function of motorcycle fairings even in demanding conditions. For additional insights on fairing components and maintenance, readers can explore expert resources dedicated to affordable motorcycle fairings.

5. Precision Engineering and Advanced Functionalities in Motorcycle Fairing Grommets

Motorcycle fairing grommets embody precise engineering that harmonizes durability, vibration resistance, and seamless integration within the fairing assembly. Crafted from flexible yet resilient rubber or specialized polymers, these components absorb and dissipate vibrations effectively, safeguarding the delicate fairing panels against cracking and loosening caused by road and engine forces. The exacting fit of each grommet ensures stable mounting by matching fairing panel apertures and frame mounting points, which enables straightforward installation while maintaining structural integrity.

Beyond simple vibration dampening, these grommets play an essential role in sustaining aerodynamic efficiency by keeping panel alignments tight and minimizing gaps that might generate unwanted drag or wind noise. Modern designs often incorporate advanced features such as vibration-isolating inserts and locking mechanisms tailored to specific models, enhancing long-term stability and reducing maintenance requirements. Computational analyses alongside rigorous real-world testing guide these innovations to optimize rider comfort and extend fairing lifespan.

This thoughtful integration of advanced materials, exact fits, and functional enhancements elevates motorcycle fairing grommets from mere mounting aids to vital technological components pivotal to the performance and endurance of a motorcycle’s bodywork. For deeper insight into comprehensive fairing solutions, visit Explore the Best Motorcycle Fairings at Summit Fairings.

Chapter 2: Economic and Market Aspects of Motorcycle Fairing Grommets

1. Balancing Cost and Value: How Motorcycle Fairing Grommets Influence Maintenance Budgets and Resale Prices

Motorcycle fairing grommets are a subtle yet impactful component in the economic landscape of motorcycle maintenance. Their low price point makes them an exceptionally cost-effective solution to prevent extensive damage. Typically, these rubber or plastic grommets can be obtained affordably, often costing just a few dollars per kit, which offers a practical way to shield fairing panels from harmful vibrations and impacts that could cause cracks or loosen fittings.

By cushioning the fairings and ensuring a secure fit, grommets reduce the likelihood of expensive repairs or replacements. This protection preserves the structural integrity and appearance, which directly affects a motorcycle’s market value. Well-maintained fairings signal careful ownership and attention to detail, often translating into higher resale value. Buyers tend to favor motorcycles with intact, crack-free panels, as these suggest fewer underlying issues.

Investing in quality grommets not only safeguards the fairing panels but also supports long-term savings by minimizing repair frequency. This balance between low upfront cost and substantial protective benefit makes grommets an indispensable factor in the overall economic equation of motorcycle maintenance. For enthusiasts interested in fairing upkeep and cost considerations, exploring affordable parts and repair kits can offer valuable insights into maximizing both durability and vehicle worth. Visit Summit Fairings’ blog for more details on smart fairing maintenance strategies.

2. Navigating Demand and Supply Trends: Consumer Drives Shaping the Fairing Grommets Market

The market for motorcycle fairing grommets is shaped by a dynamic interplay of demand and supply influenced by the preferences of motorcycle enthusiasts and repair professionals. Demand primarily arises from the necessity to replace worn or damaged grommets, as well as from riders seeking aesthetic customization and upgrades. Popular models with dedicated aftermarket support see heightened demand for specific grommet and washer sets, as evidenced by strong consumer engagement on niche online marketplaces. On the supply side, a broad spectrum of manufacturers offers products varying in materials, colors, and finishes, ensuring options that range from economy to premium segments. The presence of both OEM and aftermarket parts creates a competitive environment keyed to quality, compatibility, and price. Consumer preferences emphasize precise fitment and durability, as grommets must resist constant vibration and environmental stressors, while many riders appreciate colored or styled hardware to personalize their motorcycle’s look. This blend of functional necessity and stylistic desire drives brand loyalty and repeat purchases. Regional market patterns further influence availability and marketing approaches, reflecting the diverse global motorcycle community. For those seeking comprehensive restoration or enhancement, exploring tailored aftermarket options can reveal the best balance between cost and quality. More insights into motorcycle accessory trends can be found at Explore the Best Motorcycle Fairings at Summit Fairings.

3. Balancing Quality, Safety, and Market Value in Motorcycle Fairing Grommets

Motorcycle fairing grommets, though small, play a pivotal role in ensuring the safety and longevity of fairing assemblies while influencing market dynamics. High-quality grommets are crafted from durable rubber or plastic compounds that resist environmental wear and mechanical stress, ensuring a secure fit that prevents vibrations and potential panel damage. Using OEM or certified aftermarket grommets guarantees compatibility and adherence to safety standards, which are crucial for maintaining the structural integrity of the fairing system and protecting riders from hazards caused by loose or sharp components.

Economically, buyers face a trade-off between cost and quality. Lower-priced grommets may offer initial savings but often lack thorough safety testing and durability, potentially leading to higher long-term expenses and decreased resale value. Conversely, premium grommets backed by warranties and responsive customer support justify their price by providing reliability and peace of mind. The market also embraces customization trends, where colored or model-specific grommets add personalized appeal without sacrificing function, particularly in niche segments. Ultimately, motorcycles fitted with original or high-quality replacement grommets maintain better aesthetic condition and command superior resale values, reflecting the intrinsic link between product quality, safety, and economic worth.

For enthusiasts and professionals interested in exploring comprehensive options and market insights, expert sources such as those found at summitfairings.com provide valuable guides to navigate the balance of quality and cost effectively.

4. Global Trade Dynamics and Geopolitical Factors Shaping Motorcycle Fairing Grommet Markets

The economic landscape of motorcycle fairing grommets is deeply intertwined with global trade dynamics and geopolitical factors. Centralized manufacturing hubs in East Asia, primarily China and Taiwan, dominate production due to competitive costs and advanced infrastructure. This concentration exposes the market to sensitivities such as tariffs, trade restrictions, and political tensions, all of which directly influence pricing and supply availability. Import duties imposed by major markets in North America and Europe increase costs, forcing manufacturers and buyers to adapt sourcing strategies or absorb higher prices. Moreover, disruptions in global supply chains caused by events like pandemics or logistical bottlenecks can delay delivery of these small yet vital components, impacting assembly lines and aftermarket repairs alike. Regional demand further dictates market trends; areas with vibrant motorcycle cultures spur steady consumption, shaping production volumes and pricing strategies. The competitive aftermarket environment, fueled by affordable alternatives from low-cost manufacturers, challenges OEMs and influences overall market economics. These layered geopolitical and trade considerations create a complex framework that governs the cost, availability, and strategic sourcing of motorcycle fairing grommets. For a deeper look into market trends and sources, readers may explore detailed motorcycle fairings resources that highlight evolving supply and demand patterns.

5. Advances in Materials and Customization Driving Economic Growth in Fairing Grommets

Technological progress in motorcycle fairing grommets has fostered notable economic shifts by elevating product quality and customization options. Enhanced rubber compounds and precision manufacturing methods, including CNC machining, now produce grommets that fit better and resist vibration more effectively. These innovations extend the lifespan of fairings, reduce repair costs, and improve rider satisfaction, encouraging investment in premium aftermarket parts. Customization trends, such as colored grommets tailored to specific models, appeal to enthusiasts seeking both functional and aesthetic upgrades. Moreover, rising standards for motorcycle components, reflected in advanced fairing materials, indirectly boost demand for high-performance grommets designed to complement these improvements. Economically, this technological evolution has carved out niche markets for specialized and OEM-quality grommets, driving competition and expanding consumer choice. The emergence of dedicated suppliers and platforms offering model-specific parts also enhances market accessibility. These factors collectively stimulate growth, positioning the fairing grommet market as an active segment within the broader motorcycle aftermarket industry. For further insights into related motorcycle parts and styles, readers may explore the extensive resources available in Summit Fairings’ blog.

Chapter 3: Brand and Model Specific Motorcycle Fairing Grommets

1. Precision Engineering Behind Brand-Specific Motorcycle Fairing Grommets

Motorcycle fairing grommets tailored to specific brands and models are meticulously engineered to ensure optimal performance and durability. These components are usually crafted from premium-grade rubber or plastic materials that resist environmental factors such as UV exposure, temperature extremes, and mechanical stress. This careful material selection not only preserves the grommets’ flexibility over time but also maintains the integrity of the motorcycle’s appearance.

Exact dimensions and precise fitment are central to the reliability of these grommets. OEM-grade parts are designed to seamlessly align with designated mounting points, eliminating any unnecessary movement that could cause panel misalignment or damage. Such accuracy in sizing prevents rattling, enhances the secure attachment of fairing panels, and contributes to the overall structural soundness of the motorcycle.

Beyond their fundamental role in panel retention, brand-specific grommets excel at reducing vibration. They isolate the fairing from harmful engine and road vibrations, which dampens noise and minimizes the risk of fatigue damage to the panels and fasteners. Additionally, they protect wiring harnesses or cables routed through fairings by cushioning them against sharp edges, preventing wear and potential electrical issues.

Choosing genuine, model-specific grommets thus ensures compatibility, longevity, and effective vibration isolation suited precisely for a given motorcycle. For those interested in superior motorcycle bodywork components, exploring detailed options reveals the value of tailored mounting solutions in maintaining both function and aesthetics. For further insight, see the comprehensive resources at Summit Fairings’ blog.

2. Economic and Market Dynamics Shaping Brand and Model Specific Motorcycle Fairing Grommets

The economic and market landscape of brand and model-specific motorcycle fairing grommets reflects a balance between precision engineering, consumer demand, and brand trust. These grommets, designed for exact fitment, command a price premium compared to generic alternatives, justified by their guaranteed compatibility and durability. Enthusiasts and practical riders alike prioritize verified quality and fit to protect the integrity of their motorcycle’s fairings, often opting for OEM or closely-matched aftermarket options despite higher costs. Simultaneously, the market offers a spectrum of choices—from cost-effective bulk generic parts to specialized, color-customized grommets catering to riders seeking aesthetic personalization. This diversity highlights how consumer segments shape product offerings, blending function with style. Supply chain considerations further impact availability and price, as specialized parts may entail longer lead times or higher shipping costs. Ultimately, the interplay of brand reputation, quality assurance, customization trends, and economic factors creates a dynamic market, where both OEM and aftermarket grommets coexist to meet varied motorcycle maintenance and enhancement needs. For those seeking reliable and tailored solutions, exploring dedicated sources for motorcycle fairings and accessories can be invaluable.

3. Navigating Geopolitical Challenges in Supply Chains for Motorcycle Fairing Grommets

The supply chain for brand and model-specific motorcycle fairing grommets is profoundly shaped by geopolitical factors that influence sourcing, manufacturing, and logistics. Trade policies and tariffs between nations directly affect costs and availability; for example, tariffs on rubber or plastic parts can dramatically increase prices or cause delays, prompting manufacturers to seek more favorable suppliers. Manufacturing hubs concentrated in Southeast Asia and parts of Europe face risks from political unrest or regulatory shifts, which can disrupt production schedules. The dependence on raw materials like natural rubber—sourced mainly from Southeast Asia—and petrochemical derivatives links grommet supply to global energy and political stability. Meanwhile, geopolitical tensions near vital shipping lanes, such as the South China Sea disputes, threaten transport reliability, increasing freight costs and transit times. Compliance with varied international regulations adds complexity to production, requiring manufacturers to adapt material formulations across markets. Furthermore, protecting intellectual property in regions with less stringent enforcement is vital to prevent counterfeit parts compromising brand integrity. Economic sanctions on certain countries further complicate procurement of materials and equipment. Together, these geopolitical dynamics compel brands to diversify suppliers, optimize manufacturing locations, and maintain flexible logistics to secure consistent access to these essential small components. Understanding these influences is crucial for sustaining the reliability and quality of motorcycle fairing grommets across global markets. For a deeper look into maintaining stable supply and part quality, explore brands’ reliance on diverse sources in motorcycle fairing solutions.

4. How Brand-Specific Fairing Grommets Shape Rider Identity and Community Culture

Motorcycle fairing grommets tailored to specific brands and models do more than secure panels; they anchor a deeper connection between the rider and their machine. These exact-fit components uphold the integrity of original designs, embodying authenticity cherished by enthusiasts who view their bikes as extensions of personal and cultural identity. Choosing brand-specific grommets reflects a commitment to heritage and craftsmanship, distinguishing riders who prioritize precision and tradition over generic alternatives.

Beyond individual expression, these components cultivate tight-knit communities united by shared challenges in sourcing and maintaining authentic parts. Forums, social groups, and clubs often revolve around collective knowledge exchanges revolving around such brand-specific details, reinforcing social ties and brand loyalty. This dynamic fosters a culture where expertise and dedication elevate one’s standing within the motorcycling world.

Economically, the demand for these parts supports specialized manufacturers and the aftermarket industry, sustaining niches that emphasize quality and compatibility. Environmentally, precise fitment encourages repair and longevity, reducing waste from ill-fitting or incompatible alternatives.

Ultimately, brand- and model-specific fairing grommets preserve historic motorcycle aesthetics and engineering, strengthening cultural continuity while enhancing community identity. Their subtle presence underscores how even the smallest components are vital threads in the larger fabric of motorcycle culture.

For further insights into maintaining authentic motorcycle components, explore our comprehensive resources on high-quality motorcycle fairings at Summit Fairings.

5. Ensuring Genuine Fitment: Authenticity and Sourcing of Brand-Specific Fairing Grommets

Sourcing brand and model-specific motorcycle fairing grommets demands careful attention to authenticity to ensure durability and precise fit. The most reliable method is obtaining genuine OEM components through authorized dealers or specialized suppliers who provide parts tailored to exact factory specifications. This guarantees the grommets’ material quality, flexibility, and vibration-dampening properties match the original equipment, preserving the integrity of the fairings.

Verification begins with confirming the OEM part number aligns precisely with manufacturer databases. Authentic grommets show consistent material texture and fit without forcing alignment during installation. Customer reviews and detailed product listings from reputable sources also offer vital validation when navigating online marketplaces. Avoiding generic or universal kits minimizes the risk of poor fitment or potential damage to mounting points.

For specialized applications, such as carbon fiber fairings, legitimacy extends beyond part numbers to visual and tactile inspections, ensuring the premium materials used meet expected standards. Prior compatibility checks against your motorcycle’s make, model, and year prevent costly errors.

By prioritizing verified sources and thorough authenticity checks, enthusiasts secure the optimal protection and longevity of their fairings, maintaining both function and aesthetics. To explore a wider range of tailored motorcycle fairings and accessories, visit Summit Fairings’ expert collection.

Final thoughts

Motorcycle fairing grommets, while small and often overlooked, are fundamental components that uphold fairing integrity, protect panels from vibration damage, and ensure secure mounting. Their technological design integrates flexible, durable materials combined with precise fastening systems, delivering functional excellence. Economically, they represent a lucrative segment in the aftermarket, driven by steady replacement demand and preference for OEM-quality parts. Brand-specific grommets further refine this landscape, requiring business owners to maintain detailed knowledge of model requirements to supply the right products. Mastery of these interconnected dimensions offers business owners a strategic advantage in stocking, marketing, and selling these essential parts, ultimately contributing to customer satisfaction and business growth.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined