Introduction

Motorcycle fairings serve both aesthetic and functional purposes, but their durability highly depends on effective heat management. Excessive heat from engines and exhaust systems can cause warping, discoloration, and premature wear, significantly impacting customer satisfaction and warranty claims. For business owners in the motorcycle industry, understanding the critical role of heat shield materials is essential to enhance product longevity and maintain the integrity of fairings. This guide explores three pivotal heat shield materials—foil-coated fiberglass cloth, carbon fiber and fiberglass composites, and aluminized fiberglass fabrics—detailing their unique properties and application benefits. Finally, it addresses the compatibility of these heat shields with common fairing substrates like ABS plastic and fiberglass, enabling informed decisions that protect investments and bolster product quality.

Tables of Contents

Chapter 1: Foil-Coated Fiberglass Cloth as a Motorcycle Fairing Heat Shield Material

- Advanced Heat Reflection and Durability Features of Foil-Coated Fiberglass Cloth for Motorcycle Fairings

- Balancing Cost, Durability, and Performance: The Economic Value of Foil-Coated Fiberglass Cloth in Motorcycle Heat Shields

- Navigating Geopolitical Challenges Affecting Foil-Coated Fiberglass Cloth Supply for Motorcycle Heat Shields

- Enhancing Motorcycle Safety and Sustainability Through Foil-Coated Fiberglass Heat Shields

Chapter 2: Carbon Fiber and Fiberglass Composites for Motorcycle Fairing Heat Shield Material

- Innovations Elevating Carbon Fiber and Fiberglass Composites in Motorcycle Heat Shielding

- Balancing Performance and Cost: Economic Insights into Carbon Fiber and Fiberglass Composites for Heat Shields

- Geopolitical and Supply Chain Influences on Composite Heat Shield Production

- Safety and Societal Impact of Using Carbon Fiber and Fiberglass Composites in Motorcycle Heat Shields

Chapter 3: Aluminized Fiberglass Fabrics in Motorcycle Fairing Heat Shield Material

- Harnessing Thermal Reflection and Insulation: The Science Behind Aluminized Fiberglass Fabrics for Motorcycle Heat Shields

- Balancing Cost and Performance: The Economic Viability of Aluminized Fiberglass Fabrics in Motorcycle Heat Shields

- Navigating Geopolitical and Manufacturing Dynamics in Aluminized Fiberglass Heat Shield Production

- The Transformative Role of Aluminized Fiberglass Fabrics in Motorcycle Safety and Durability

Chapter 4: Ensuring Heat Shield Material Compatibility with ABS and Fiberglass Motorcycle Fairings

- Technological Nuances in Integrating Heat Shields with ABS and Fiberglass Fairings

- Balancing Cost and Performance: Economic Insights on Heat Shield Materials for ABS and Fiberglass Fairings

- Geopolitical Influences on Material Availability and Adhesive Choices for ABS and Fiberglass Fairings

- The Societal Benefits of Optimal Heat Shield and Fairing Material Compatibility

Chapter 1: Foil-Coated Fiberglass Cloth as a Motorcycle Fairing Heat Shield Material

1. Advanced Heat Reflection and Durability Features of Foil-Coated Fiberglass Cloth for Motorcycle Fairings

Foil-coated fiberglass cloth stands out as a dynamic heat shield material for motorcycle fairings due to its unique combination of reflective and structural properties. The aluminized foil surface plays a critical role in reflecting radiant heat away from fairings, which are often crafted from heat-sensitive materials like ABS plastic or fiberglass composites. This reflective barrier significantly reduces heat absorption, protecting the fairing’s shape and finish from warping or discoloration caused by prolonged exposure to hot engine or exhaust systems.

Beyond reflection, the fiberglass backing delivers essential durability and flexibility, allowing the material to conform snugly to the intricate curves of motorcycle bodywork. Its robustness ensures resistance to cracking or peeling, even under the mechanical stresses typical of motorcycle operation. The inclusion of an adhesive backing streamlines installation, enabling precise placement without the need for additional fixtures, and minimizing the risk of damage during application.

This material’s adaptability also allows for easy customization, as riders or manufacturers can cut it to fit specific sections requiring targeted thermal protection around exhaust headers and engine compartments. Compared with other heat shielding solutions such as carbon fiber composites, foil-coated fiberglass cloth offers a cost-effective balance of weight, heat reflection, and ease of use, making it a preferred choice in both aftermarket and OEM contexts.

For those interested in exploring compatible fairing options and complementary accessories, discovering affordable motorcycle fairings at Summit Fairings provides valuable insights into integrating high-performance heat shielding with premium bodywork solutions.

2. Balancing Cost, Durability, and Performance: The Economic Value of Foil-Coated Fiberglass Cloth in Motorcycle Heat Shields

Foil-coated fiberglass cloth offers a compelling blend of cost efficiency and effective thermal protection, making it a smart economic choice for motorcycle fairing heat shields. Its composite structure merges durable fiberglass with reflective aluminum foil, cutting down radiant heat transfer from engines and exhaust systems. This dual-action composition not only shields sensitive fairing materials but also minimizes heat-induced wear and warping, which contributes to longer component lifespans and reduced maintenance demands.

Compared to other high-performance materials, foil-coated fiberglass cloth retains affordability without sacrificing function. Its lightweight nature further adds value by contributing to overall bike weight reduction, which can enhance fuel efficiency and handling—key factors influencing operational costs and rider satisfaction. Manufacturers and aftermarket suppliers favor this material for maintaining quality while controlling expenses, encouraging widespread adoption.

The resulting durability translates into lower repair and replacement frequency, directly benefiting riders with fewer service intervals and less downtime. Market trends in the motorcycle sector reflect a growing preference for such composites, where cost, resilience, and ease of application are crucial. This synergy supports economies of scale, which gradually drives production costs down and spurs innovation.

For those seeking reliable thermal protection that aligns with budget considerations, foil-coated fiberglass cloth stands out. Its economic advantages not only extend the functional life of fairings but also enhance the overall ownership experience. To explore more about motorcycle fairing choices and their impact, consider visiting the ultimate source for affordable motorcycle fairings.

3. Navigating Geopolitical Challenges Affecting Foil-Coated Fiberglass Cloth Supply for Motorcycle Heat Shields

Geopolitical factors play a pivotal role in shaping the production and supply of foil-coated fiberglass cloth, a key material in motorcycle fairing heat shields. The availability and cost of raw materials such as fiberglass and aluminum foil are highly sensitive to international trade relations and regional stability. Trade restrictions, tariffs, and diplomatic tensions between major economies can disrupt supply chains, causing delays or increased expenses for manufacturers producing these specialized materials. For instance, manufacturers often face challenges when sourcing raw materials amid fluctuating import regulations or export controls, which ripple through to impact production schedules and pricing strategies.

Regional manufacturing hubs, particularly in Asia-Pacific, dominate the supply of foil-coated fiberglass cloth due to extensive production capacity and competitive pricing. However, geopolitical tensions in the region have led buyers to pursue diversified sourcing strategies, emphasizing supply chain resilience and certified quality. Meanwhile, European markets focus increasingly on sustainability and regulatory compliance, influencing material choices and creating pressure to adopt eco-friendlier alternatives. These dynamics compel manufacturers and suppliers to constantly adapt to evolving geopolitical landscapes to maintain steady product availability.

Economic pressures triggered by geopolitical developments often translate into raw material price volatility. Rising costs for composite resins and aluminum foil directly impact the manufacturing of foil-coated fiberglass cloth, challenging fairing producers to balance cost and performance. This intricate interplay between global politics and industrial supply underscores the importance of strategic sourcing and agile production management in delivering reliable heat shielding solutions.

For a deeper understanding of related supply chain dynamics, explore detailed insights at the Explore the Best Motorcycle Fairings at Summit Fairings.

4. Enhancing Motorcycle Safety and Sustainability Through Foil-Coated Fiberglass Heat Shields

Foil-coated fiberglass cloth offers a compelling blend of safety, performance, and environmental benefits when used as a heat shield for motorcycle fairings. Its ability to reflect radiant heat protects fragile fairing materials like ABS plastic and fiberglass from warping or deterioration caused by prolonged exposure to high temperatures. This protective effect not only preserves the structural integrity of fairings but also limits heat transfer to the rider, contributing to a more comfortable and safer riding experience by reducing the risk of burns or heat fatigue.

Beyond rider comfort, the material’s durability extends the lifespan of critical motorcycle components by shielding electrical systems and body panels from thermal stress. This longevity helps reduce frequent replacements, which translates into lower maintenance costs and less waste production, aligning with environmental sustainability goals. The lightweight nature of foil-coated fiberglass cloth ensures that its heat shielding capabilities do not compromise motorcycle agility or fuel efficiency.

Economically, it presents a cost-effective alternative to more expensive composites, making advanced thermal protection accessible to a broader range of riders. Its ease of application, often featuring adhesive backing, facilitates installation on diverse fairing shapes, further encouraging its widespread adoption. For enthusiasts seeking quality fairings paired with reliable heat shielding, exploring trusted sources can reveal options designed for both protection and style, enhancing the overall riding experience. More details and options can be found at Summit Fairings’ blog, a reliable resource for affordable and diverse motorcycle fairings.

Chapter 2: Carbon Fiber and Fiberglass Composites for Motorcycle Fairing Heat Shield Material

1. Innovations Elevating Carbon Fiber and Fiberglass Composites in Motorcycle Heat Shielding

Recent innovations in carbon fiber and fiberglass composites have substantially enhanced their application as heat shield materials for motorcycle fairings. Carbon fiber composites now integrate advanced resin systems and hybrid layering techniques, improving not only heat resistance but also structural rigidity with minimal added weight. This makes carbon fiber an excellent choice for riders seeking both performance and aesthetic enhancements. Meanwhile, fiberglass composites continue to evolve through improved weaving patterns and the use of specialized coatings that boost their thermal insulation without compromising durability. These advancements make fiberglass a more accessible and resilient option for shielding fairings, especially in environments where exposure to harsh weather is frequent.

The bonding process has also seen major improvements. Epoxy-based adhesives designed specifically for composite materials now offer stronger chemical bonds and enhanced heat stability. Additionally, novel coatings—such as those involving titanium basalt fibers—reflect radiant heat more efficiently, extending the life of the fairing components they protect. As automated manufacturing techniques mature, including precision fiber placement and optimized curing methods, producing these composite heat shields becomes more cost-effective and consistent in quality.

Looking forward, the integration of recycled composites and eco-friendly resins promises a more sustainable future in motorcycle heat shield materials. These innovations reflect a blend of performance, durability, and growing environmental responsibility. For riders interested in quality and innovation, exploring the best motorcycle fairings available today can provide valuable insight into these material advancements.

2. Balancing Performance and Cost: Economic Insights into Carbon Fiber and Fiberglass Composites for Heat Shields

Choosing between carbon fiber and fiberglass composites for motorcycle fairing heat shields involves weighing both performance and economic factors. Carbon fiber stands out for its remarkable strength-to-weight ratio, delivering exceptional durability and heat resistance that benefit high-performance motorcycles. However, this premium material comes with a substantially higher price tag, often limiting its use to racing or luxury segments where performance justifies the cost.

Fiberglass composites, in contrast, offer a more budget-friendly option without sacrificing essential protective qualities. Its affordability and ease of production make fiberglass the go-to choice for a wide range of riders. While it may not match carbon fiber’s lightness or rigidity, fiberglass provides reliable heat shielding suitable for everyday use and casual riding.

Material costs are only part of the equation. Effective application depends on adhesives compatible with each composite. Carbon fiber requires specialized epoxy adhesives that establish durable bonds capable of withstanding heat and environmental stresses. Fiberglass benefits from polyester or epoxy resins that ensure sound structural integrity during repairs or installations. Proper surface preparation is crucial in both cases to optimize adhesion and longevity.

Regarding environmental and operational impact, carbon fiber composites typically produce fewer volatile organic compounds (VOCs) during adhesive curing but entail a more energy-intensive manufacturing process. Fiberglass may involve higher VOC emissions unless eco-friendly resins are selected.

Ultimately, the decision between carbon fiber and fiberglass heat shields balances upfront investment with expected performance gains, tailored to the rider’s needs and budget. For a deeper exploration of fairing options that complement these materials, consider this detailed resource on motorcycle fairings.

3. Geopolitical and Supply Chain Influences on Composite Heat Shield Production

Carbon fiber and fiberglass composites are essential in manufacturing motorcycle fairings and heat shields due to their strength, lightweight nature, and thermal resistance. The global supply of these composites, however, faces significant challenges rooted in geopolitical tensions and supply chain complexities. Major producers of carbon fiber, such as Japan and the U.S., dominate raw material availability. Trade restrictions or political friction involving these countries can cause shortages, driving material costs upward and delaying manufacturing timelines. Similarly, sourcing key raw materials for fiberglass composites depends on stable international trade routes; instability in critical regions disrupts delivery and raises prices.

Alongside geopolitical disruptions, supply chain issues like transportation delays and manufacturing bottlenecks further complicate production. Producing carbon fiber and fiberglass heat shields demands precise processes including specialized adhesives and high-quality control. Any disturbance in logistics or ingredient availability can reduce output reliability, impacting motorcycle manufacturers and aftermarket suppliers. These factors elevate costs and can limit the customization or innovation potential for fairings and shields designed for optimal heat protection.

Recognizing these influences is crucial for stakeholders aiming to maintain consistent quality and availability. Addressing supply chain vulnerabilities through diversified sourcing and stronger logistics strategies helps ensure that the advanced materials vital for durable, heat-resistant fairings remain accessible. This enables continued advancement in motorcycle heat shield technology, balancing performance with economic feasibility.

For deeper insights on fairing materials and adhesive methods integral to these composites, visit the blog on expert adhesives for motorcycle fairings.

4. Safety and Societal Impact of Using Carbon Fiber and Fiberglass Composites in Motorcycle Heat Shields

Carbon fiber and fiberglass composites represent a critical evolution in motorcycle fairing heat shield materials, offering distinctive benefits alongside unique challenges in safety and societal contexts. Carbon fiber composites are celebrated for their excellent heat resistance and unmatched strength-to-weight ratio, enabling efficient heat dissipation while minimizing added weight. Enhanced by high-temperature resins, these composites withstand extreme conditions but require vigilant inspection due to potential hidden damage like micro-cracks or delamination after impacts, a risk that could compromise structural integrity. Conversely, fiberglass composites coated with reflective foils provide reliable thermal protection with moderate impact resistance at a more accessible cost, though their adhesive backings may deteriorate under repeated heat cycles, lessening effectiveness over time. Both materials demand careful handling during fabrication to avoid respiratory hazards from dust generation. Beyond safety, the integration of these composites influences societal aspects of motorcycle ownership and manufacturing. Carbon fiber’s premium cost and complex recycling pose challenges to affordability and environmental sustainability, despite its contribution to vehicle lightweighting and performance. Fiberglass composites offer a more economical alternative, yet recycling infrastructure remains limited, affecting their overall ecological footprint. Additionally, the distinctive appearance of carbon fiber can enhance resale value but may attract theft concerns. Judicious selection and maintenance of these composite heat shields are integral to maximizing protective benefits, supporting responsible ownership, and informing industry advancements in sustainable material usage. For more on material options enhancing motorcycle bodywork durability and performance, explore resources dedicated to motorcycle fairings and heat protection.

Chapter 3: Aluminized Fiberglass Fabrics in Motorcycle Fairing Heat Shield Material

1. Harnessing Thermal Reflection and Insulation: The Science Behind Aluminized Fiberglass Fabrics for Motorcycle Heat Shields

Aluminized fiberglass fabrics uniquely combine the thermal insulation of fiberglass with the high reflectivity of aluminum, making them ideal for motorcycle fairing heat shields. The fiberglass component traps heat by limiting conduction, while its porous structure retains air pockets that reduce heat transfer. This intrinsic insulation capability protects sensitive fairing materials like ABS plastic and fiberglass from deformation or damage caused by engine and exhaust heat.

Overlaying this insulating base is an aluminum layer that excels at reflecting radiant heat. Radiant heat, which travels in waves, can quickly degrade plastics and composites without a reflective barrier. The aluminized surface bounces this radiation away, preventing it from penetrating fairing surfaces and keeping surrounding components cooler. This reflective property is vital in the confined spaces near exhaust pipes, where temperature spikes are typical.

Beyond thermal management, aluminized fiberglass fabrics are lightweight and corrosion-resistant, crucial for maintaining motorcycle agility and durability. Their flexibility and adhesive compatibility allow precise application to complex fairing geometries, preserving the bike’s aerodynamic and aesthetic qualities. This combination of effective heat reflection, thermal insulation, and practical usability underpins their widespread adoption as a modern solution for protecting motorcycle fairings.

For motorcyclists seeking durable and efficient heat protection, aluminized fiberglass fabrics offer an advanced balance of function and form. More insights into compatible fairing materials and options can be found when you explore the best motorcycle fairings at Summit Fairings.

2. Balancing Cost and Performance: The Economic Viability of Aluminized Fiberglass Fabrics in Motorcycle Heat Shields

Aluminized fiberglass fabrics occupy a specialized niche in motorcycle fairing heat shields, offering distinct advantages in heat resistance while presenting unique economic considerations. Compared to conventional materials such as ABS plastic and standard fiberglass, aluminized fiberglass commands a higher initial cost, reflecting its superior ability to reflect radiant heat and protect sensitive fairing components. This enhanced thermal protection is crucial where engine or exhaust heat poses a significant risk of warping or degradation, potentially extending the fairing’s service life and improving rider comfort.

Despite these benefits, aluminized fiberglass fabrics are less commonly stocked and available in the market than mainstream options like ABS plastic, fiberglass, and carbon fiber composites. While carbon fiber can match or exceed heat resistance, its premium pricing makes aluminized fiberglass a more attainable solution for specific heat shielding needs. Aluminum, although inexpensive and recyclable, is limited in use due to shaping challenges and labor intensity.

From an economic standpoint, selecting aluminized fiberglass hinges on the balance between its upfront costs and the value of reduced maintenance and replacement frequency. Manufacturers and aftermarket suppliers must weigh budgets alongside performance demands to determine suitability. Its niche availability and higher costs narrow its adoption, yet in applications demanding reliable heat reflection, aluminized fiberglass remains a cost-effective investment.

This nuanced cost-performance relationship highlights why aluminized fiberglass fabrics are integral in targeted scenarios rather than broad general use, aligning with industry trends discussed in resources such as the explore the best motorcycle fairings at Summit Fairings.

3. Navigating Geopolitical and Manufacturing Dynamics in Aluminized Fiberglass Heat Shield Production

The production and supply of aluminized fiberglass fabrics for motorcycle fairing heat shields are heavily influenced by geopolitical and manufacturing factors. Regions with abundant aluminum resources and advanced manufacturing infrastructure, such as China, play a pivotal role in supplying these materials at competitive costs. However, international trade policies and regional tensions can disrupt supply chains, causing delays or price fluctuations that impact manufacturers and consumers alike. High-quality aluminized fiberglass requires precision in coating uniformity and material adhesion, demanding advanced production techniques governed by strict safety and environmental regulations. Balancing cost-efficiency with performance standards is an ongoing challenge within the industry.

Supply chains for these heat shields extend from raw fiberglass and aluminum sourcing to composite fabrication and distribution. Strategic regional production hubs help reduce transportation costs and improve delivery times, directly affecting market responsiveness. Manufacturers often prioritize locations near key markets to ensure reliable inventory flow and to meet stringent heat resistance and durability criteria essential for protecting motorcycle fairings. Understanding these interconnected factors is crucial for maintaining the consistency and longevity of heat shield materials, ultimately safeguarding the fairings from heat damage while preserving aesthetic integrity.

For those interested in exploring deeper insights into motorcycle fairings and their related materials, check out this resource on explore the best motorcycle fairings at Summit Fairings.

4. The Transformative Role of Aluminized Fiberglass Fabrics in Motorcycle Safety and Durability

Aluminized fiberglass fabrics uniquely combine the heat-reflective properties of aluminum with the structural resilience of fiberglass. This synergy creates an exceptional heat shielding material ideal for motorcycle fairings, which are vulnerable to damage from the intense heat generated by engines and exhaust systems. The aluminum layer effectively reflects radiant heat, reducing thermal exposure to the underlying fairing materials, while the fiberglass core provides insulation and mechanical strength. This structural combination ensures not only protection but also durability against environmental factors such as corrosion and weather.

From a practical perspective, these fabrics are lightweight and flexible, allowing effortless conformity to the complex shapes of motorcycle components. Their ease of installation and adhesive compatibility simplify application, reducing maintenance and labor costs. By preventing heat damage such as warping or discoloration, aluminized fiberglass fabrics extend the lifespan of fairings, preserving both functionality and appearance – critical factors for riders who value performance and aesthetics.

Societally, the utilization of these materials enhances motorcycle safety by mitigating risks associated with overheating, which can lead to mechanical failures or reduced control. Their contribution to sustaining optimal engine function indirectly supports environmental efforts by promoting fuel efficiency and lowering harmful emissions. Compared to other materials like carbon fiber or pure aluminum sheets, aluminized fiberglass fabrics balance cost-effectiveness, thermal protection, and flexibility, making them an indispensable choice in the evolution of motorcycle fairing heat shields. For riders and manufacturers seeking a dependable solution, embracing this material aligns with both performance goals and long-term sustainability.

For more insights on premium motorcycle fairings, explore comprehensive options at Summit Fairings.

Chapter 4: Ensuring Heat Shield Material Compatibility with ABS and Fiberglass Motorcycle Fairings

1. Technological Nuances in Integrating Heat Shields with ABS and Fiberglass Fairings

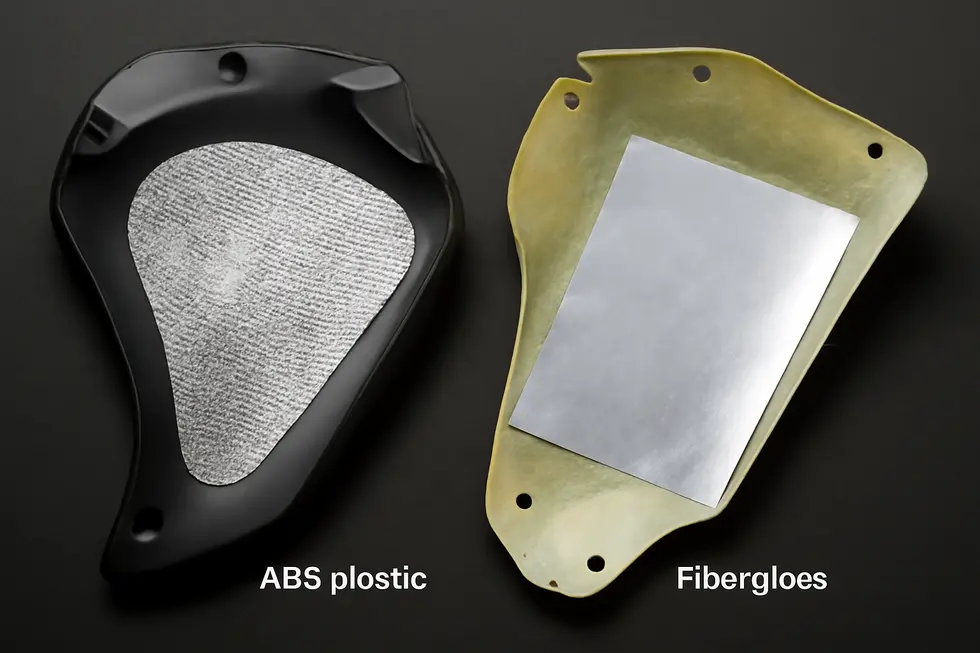

Motorcycle fairings, primarily crafted from ABS plastic or fiberglass, demand careful selection and integration of heat shield materials to prevent thermal damage and maintain durability. ABS offers flexibility and impact resistance but has a relatively low melting point, making it sensitive to excessive heat. Fiberglass, while more heat resistant and lighter, tends to be brittle and vulnerable to cracking under stress. Consequently, heat shields must be tailored to these contrasting properties to ensure optimal protection.

The material compatibility challenge centers on avoiding chemical reactions between adhesive agents and fairing substrates. Adhesives intended for bonding heat shields must neither degrade ABS nor weaken the fiberglass matrix. Typically, two-part epoxy resins formulated specifically for plastics or composites provide the necessary chemical compatibility and physical resilience to withstand vibrations and thermal cycling common in motorcycle environments.

Integration strategies balance thermal performance and mechanical attachment. Heat shields rely on materials like foil-coated fiberglass cloth or carbon fiber composites that reflect or dissipate radiant heat efficiently. Mechanical fastening is often preferred to minimize stress concentration, but when adhesives are used, extensive surface preparation such as sanding and degreasing ensures robust bonding. Moreover, accommodating differential expansion between heat shield and fairing materials is vital to prevent warping or delamination.

Real-world conditions challenge the heat shield system with repeated thermal cycles, vibrations, UV exposure, impacts, and debris. Therefore, selecting adhesives and mounting methods that endure these stressors is critical for lasting protection without impairing the structural integrity of ABS or fiberglass fairings.

For deeper insights into compatible fairing materials and adhesive selection, visit the Summit Fairings blog.

2. Balancing Cost and Performance: Economic Insights on Heat Shield Materials for ABS and Fiberglass Fairings

Selecting heat shield materials for motorcycle fairings involves a careful balance between economic efficiency and compatibility with ABS and fiberglass substrates. ABS fairings are favored for their affordability and impact resistance, making cost-effective heat shield options vital to maintain overall value. Materials such as foil-coated fiberglass cloth with adhesive backing prove economical while offering the necessary protection against heat stress. These shields prevent warping and discoloration without requiring expensive installation or frequent replacement.

Fiberglass fairings, often preferred in performance or racing scenarios, demand heat shields that withstand higher thermal loads and mechanical stress. Although fiberglass is generally less costly than carbon fiber, reinforcing it with durable, heat-resistant shields introduces additional expense. Riders and manufacturers must weigh the benefits of advanced composites and aluminized fiberglass fabrics against their cost to ensure safety and longevity without overshooting budgets.

Adhesive selection also impacts cost compatibility. High-quality two-part epoxy resins provide strong bonds suitable for both ABS and fiberglass but vary in price. Investing in moderately priced adhesives that combine heat resistance with adequate strength can reduce long-term maintenance expenses.

Ultimately, economic considerations require choosing heat shield materials that align with the fairing type while ensuring durability and thermal protection. For riders seeking affordable yet reliable options, exploring a diverse inventory of materials that balance cost and performance is essential. More insights on material compatibility and economic factors can be found in the resource on affordable motorcycle fairings at Summit Fairings.

3. Geopolitical Influences on Material Availability and Adhesive Choices for ABS and Fiberglass Fairings

The compatibility of heat shield materials with ABS and fiberglass fairings extends beyond physical and chemical properties to include geopolitical factors that shape material sourcing and adhesive selection. Trade policies and international relations can restrict access to critical raw materials and specialized adhesives used in heat shield production. For example, supply chain disruptions may limit availability of foil-coated fiberglass cloth or high-grade epoxies essential for secure bonding with ABS and fiberglass surfaces. Environmental regulations adopted in different regions also influence which materials are preferred or permitted, favoring options with lower emissions or recyclable content, thereby affecting manufacturers’ choices. These geopolitical dynamics often dictate cost fluctuations and quality consistency, compelling producers to adapt formulations or seek alternative suppliers to maintain compatibility and performance. Adhesive chemistry is particularly vulnerable to such influences, as access to certain additives or solvents may be limited. Ensuring that adhesives do not degrade ABS plastic’s structure or cause long-term damage to fiberglass requires sourcing reliable, compliant products—sometimes challenging amid shifting geopolitical landscapes. Consequently, manufacturers must navigate an evolving environment of trade and regulation to secure materials that protect fairings from heat without sacrificing durability. Understanding these geopolitical factors is crucial for selecting optimal heat shield solutions that align with both the physical demands of ABS and fiberglass fairings and the broader global material context. For a deeper dive into selecting compatible adhesives and fairing materials, explore more insights at Explore the Best Motorcycle Fairings at Summit Fairings.

4. The Societal Benefits of Optimal Heat Shield and Fairing Material Compatibility

The compatibility between heat shield materials and ABS or fiberglass fairings extends beyond technical performance, carrying significant societal benefits in safety, economy, and environmental sustainability. Ensuring these materials work harmoniously protects riders from excess heat exposure that could cause burns or discomfort, while preserving the structural integrity of fairings. This protection prevents warping, cracking, or detachment, reducing the risk of accidents that might arise from sudden material failures during rides. Economically, compatible heat shields and adhesives increase the lifespan of motorcycle fairings, decreasing the frequency of costly repairs or replacements. Such durability benefits riders, manufacturers, and aftermarket providers by lowering expenses and encouraging innovation within the motorcycle community. Moreover, prolonged part life directly contributes to waste reduction, curbing the environmental impact tied to discarded plastics and composites. Advanced heat shield materials that reflect or resist heat without compromising fairing integrity foster a culture of sustainability. Riders experience safer, more reliable motorcycles while supporting materials that minimize environmental footprints. By reinforcing the connection between material science and user wellbeing, this compatibility nurtures a responsible riding culture valuing longevity, safety, and ecological awareness. For those interested in detailed guidance on selecting materials and adhesives for fairings, resources such as the comprehensive insights found on Summit Fairings offer valuable information on optimizing durability and safety in fairing assembly.

Final thoughts

Selecting the appropriate heat shield materials for motorcycle fairings is a strategic decision that directly impacts the product’s durability, finish, and customer satisfaction. Foil-coated fiberglass cloth offers a flexible, adhesive-backed option that blends ease of installation with reliable heat resistance, making it ideal for many motorcycle applications. Carbon fiber and fiberglass composites provide robust, lightweight solutions that excel in high-heat zones around exhaust systems while enhancing design aesthetics. Meanwhile, aluminized fiberglass fabrics serve as effective radiant heat barriers, protecting the fairing’s base materials without adding bulk. Importantly, understanding how these heat shield materials interact with fairing substrates such as ABS plastic and fiberglass ensures optimal protection without compromising structural integrity. For business owners, this knowledge translates into better product development, fewer repairs, and stronger market reputation. Investing in the right heat shield solutions safeguards fairings, extends product lifecycle, and ultimately maximizes value for both manufacturers and consumers.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined