Introduction

Understanding the materials used in motorcycle fairings is crucial for business owners looking to enhance product offerings and satisfy customer needs. Each material, from ABS plastic to carbon fiber, carries distinctive benefits and applications that cater to diverse market demands. This article delves into ABS plastic, polycarbonate, fiberglass, and carbon fiber, providing insights that can guide your decisions in sourcing and production, ultimately supporting your business strategy and customer satisfaction.

Tables of Contents

Chapter 1: The Integral Role of ABS Plastic in Motorcycle Fairings: Balancing Safety, Performance, and Cost

- Exploring the Resilience and Versatility of ABS Plastic in Motorcycle Fairing Design

- Balancing Cost and Environmental Impact: The Economic Relevance of ABS Plastic in Motorcycle Fairings

Chapter 2: The Superior Impact Resistance of Polycarbonate in Motorcycle Fairing Design

- Unrivaled Safety and Structural Integrity of Polycarbonate Motorcycle Fairings

- Unlocking Cost-Effectiveness and Creative Freedom with Polycarbonate Fairings

Chapter 3: Mastering the Art of Fiberglass: Crafting Custom Motorcycle Fairings for Performance and Style

- Crafting Aerodynamic Elegance: Advanced Techniques in Fiberglass Fairing Fabrication

- Fiberglass: A Trusted Choice for Performance and Customization in Motorcycle Fairings

Chapter 4: The Elite Performance of Carbon Fiber in Motorcycle Fairing Material

- Harnessing the Strength and Style of Carbon Fiber: A Deep Dive into Performance Enhancements and Aesthetics

- The Economic Dynamics of Carbon Fiber in Motorcycle Fairing Material: Balancing Performance with Cost

Chapter 1: The Integral Role of ABS Plastic in Motorcycle Fairings: Balancing Safety, Performance, and Cost

1. Exploring the Resilience and Versatility of ABS Plastic in Motorcycle Fairing Design

The choice of material in motorcycle fairing design is pivotal, not merely for aesthetics but fundamentally for performance, safety, and rider experience. Among the various materials available, ABS plastic—Acrylonitrile Butadiene Styrene—stands out due to its remarkable properties that cater to the rigorous demands of motorcycling. Renowned for its strength and impact resistance, ABS is engineered not just for durability but also for lightweight performance, which is essential for high-speed riding scenarios.

Impact Resistance and Structural Integrity

The driving force behind ABS’s popularity in motorcycle fairings is its impressive impact resistance. When motorcycles engage in high-speed pursuits, the risk of collisions, minor falls, or even road debris impacts increases significantly, necessitating a material that can absorb and dissipate energy effectively. ABS plastic excels in this regard; it has an outstanding ability to absorb significant energy without fracturing, thereby ensuring the rider’s safety and maintaining the motorcycle’s structural integrity. The capacity of ABS to retain its shape and rigidity during stress ensures that the fairing’s aerodynamic profile remains intact. This retention is crucial, as any deformation could adversely affect the bike’s handling and overall performance.

This resilience means that riders have increased confidence knowing that their fairing can withstand the rigors of both everyday use and extreme conditions. Moreover, manufacturers often conduct crash simulations and impact tests to verify ABA’s performance, reinforcing its status as a dependable choice in the industry.

Lightweight Advantages for Performance

Motorcycle enthusiasts appreciate how weight affects performance. An essential characteristic of ABS plastic is its favorable strength-to-weight ratio. This balance allows manufacturers to create fairings that offer substantial durability without significantly increasing the overall weight of the motorcycle. In terms of performance, every ounce counts. A lighter bike not only accelerates faster but also handles more responsively, enhancing the rider’s overall experience. ABS not only reduces the fairing’s weight but also contributes to improved fuel efficiency, offering long-term economic advantages for riders who frequently travel distances.

Moldability and Design Flexibility

The versatility of ABS plastic extends to its moldability. This thermoplastic polymer can be molded into intricate shapes with high precision, creating the opportunity for manufacturers to design sleek, aerodynamic fairings that lower wind resistance. The aerodynamic shapes not only improve the bike’s speed but also contribute to stability at higher velocities, ensuring that riders can maintain control during vigorous riding. Furthermore, the ability to easily paint ABS allows for custom designs and vibrant color options, enabling riders to personalize their motorcycles without sacrificing protective qualities.

Surface Characteristics and Aesthetic Appeal

Beyond mechanical properties, ABS plastic is well-suited for obtaining a superior surface finish. It can be painted and coated with relative ease, ensuring that manufacturers and riders can achieve the desired aesthetic qualities. The nature of ABS allows for vibrant color retention, enabling motorcycles to maintain their visual appeal over time, even when exposed to the sun and environmental elements.

Hybrid Material Applications

While ABS plastic serves as a top material for motorcycle fairings, some advanced designs utilize hybrid applications to enhance performance further. Manufacturers often combine ABS with materials such as fiberglass or carbon fiber at critical stress points within the fairing. This configuration takes advantage of the shock absorption properties of ABS while leveraging the high tensile strength of composites in areas where impact resistance is paramount. The hybrid approach not only improves protection but also can potentially enhance the overall aesthetic of the motorcycle, as carbon fiber is highly regarded for its distinctive appearance.

This blending of materials capitalizes on the benefits of both ABS plastic and other composites, ultimately leading to fairings that are both lightweight and incredibly robust, aligning with the necessitated standards and expectations of modern motorcycle design.

Regulatory Compliance and Assurance

The reliance on ABS plastic for motorcycle fairings has become a recent industry standard, backed by rigorous testing and certification procedures. Manufacturers engage in extensive testing to validate not only the impact resistance of ABS but also its performance under a range of environmental conditions. By adhering to industry standards and undergoing thorough validation processes, ABS components inspire confidence in riders regarding safety and reliability. Riders can trust that the fairing’s capability has been scrutinized under conditions mimicking real-world scenarios—reinforcing safety first and foremost.

In summary, the blend of impact resistance, lightweight attributes, moldability, and aesthetic potential positions ABS plastic as a superior choice for motorcycle fairing applications. Its ongoing evolution in design practices, paired with a commitment to rigorous safety testing, ensures that this material remains indispensable in the ever-evolving world of motorcycle manufacturing. Riders seeking reliable, stylish, and high-performance solutions will continue to find that ABS plastic meets their needs on every ride, whether on the road or the track, making it a cornerstone of modern motorcycle design. For riders considering an upgrade, exploring fairings crafted from ABS, like those in the extensive ranges offered at popular fairing suppliers, can enhance both the look and functionality of their motorcycles.

2. Balancing Cost and Environmental Impact: The Economic Relevance of ABS Plastic in Motorcycle Fairings

The contemporary landscape of motorcycle design is defined by a delicate balance between performance, aesthetics, and cost efficiency. At the heart of this equation lies ABS (Acrylonitrile Butadiene Styrene) plastic, a material renowned for its unique properties that seamlessly link economic viability with the growing need for environmental consciousness in the manufacturing process. ABS plastic has emerged as a favoured choice for motorcycle fairings due to its combination of durability, lightweight characteristics, and relatively low production costs. This subchapter delves into the economic implications of using ABS plastic, alongside its environmental considerations, enriching the discourse on motorcycle fairing materials.

Economic Advantages

The economic appeal of ABS plastic is particularly evident in the motorcycle manufacturing sector. One of its most significant advantages is cost efficiency. The material is known for its ease of processing and ability to be produced through injection molding. This method allows manufacturers to achieve quick turnaround times and efficient large-scale production. Compared to other materials like fiberglass and carbon fiber, which require longer fabrication processes and specialized labor, ABS can be mass-produced at a fraction of the cost. This efficiency not only lowers manufacturing overheads but also translates into competitive pricing for end consumers, making high-performance motorcycles more accessible.

The lightweight nature of ABS also contributes to fuel efficiency, an essential consideration for modern riders. By reducing the overall weight of the motorcycle, manufacturers can create models that offer enhanced performance and reduced energy consumption, fostering a more sustainable approach to motorcycling. Lighter bikes generally feature improved acceleration and higher top speeds, attributes that appeal to both casual riders and racing enthusiasts.

Moreover, the durability of ABS plastic results in lower long-term maintenance costs. Motorcycles with ABS fairings often exhibit better resistance to weather and minor impacts compared to alternatives. This resilience means riders can expect fewer repairs and replacements, solidifying ABS’s role as a practical, cost-effective solution in motorcycle design.

Environmental Impact

Despite its economic advantages, the environmental implications of ABS plastic cannot be ignored. Traditional plastics contribute to considerable waste and pollution, prompting scrutiny and concern within both manufacturing sectors and consumer circles. As the motorcycle industry moves towards sustainability, the use of ABS plastic brings both challenges and opportunities.

Part of the initiative for sustainability includes advancements in recycling technologies. Today, manufacturers are exploring ways to implement closed-loop systems, allowing for the effective recycling of ABS at the end of its life cycle. This practice is increasingly relevant in preserving natural resources and reducing the demand for virgin materials. By incorporating recycled ABS into new motorcycle fairings, manufacturers can diminish their carbon footprint and promote a more sustainable production model.

Additionally, the push towards developing innovative materials that parallel or improve upon traditional ABS continues. Biodegradable composites or eco-friendly plastics are being investigated as alternatives; however, the practicality of performance must be weighed against environmental concerns. While these materials may offer less impact on the environment, they often lack the requisite strength and durability that ABS provides, especially in high-use applications like motorcycle fairings.

Consumer Awareness and Choice

There is a growing awareness among consumers regarding the environmental impacts of their choices, which has begun to influence market trends. Many riders today actively seek motorcycles made with sustainable materials, urging manufacturers to adapt and innovate. Companies that integrate recycling initiatives or invest in alternative materials may find themselves at a competitive edge, appealing not just to a larger demographic but fostering loyalty among environmentally conscious consumers.

Producers of motorcycle fairings must navigate this evolving landscape carefully. While ABS remains a cornerstone material due to its economic advantages and functional attributes, the industry’s collective future may hinge on its ability to adapt to the environmental realities of the 21st century. As market demands shift and technology advances, motorcycle manufacturers will need to evaluate their material choices within the framework of sustainability to ensure they meet consumer expectations while still maintaining performance standards.

Conclusion

The enduring popularity of ABS plastic in motorcycle fairings is a testament to its perfect blend of functionality, performance, and cost-efficiency. As environmental considerations become more prominent in consumer decision-making and manufacturing practices, the motorcycle industry stands at the crossroads of tradition and innovation. Balancing the economic benefits of ABS with the imperative for sustainability will shape the material landscape of motorcycle fairings moving forward. The journey ahead holds significant potential as manufacturers and consumers alike commit to more responsible practices, with ABS continuing to play an integral role in this transformative process. For those looking for options, sites like Summit Fairings offer a range of products that embody both the quality of ABS and the push towards more sustainable practices.

Chapter 2: The Superior Impact Resistance of Polycarbonate in Motorcycle Fairing Design

1. Unrivaled Safety and Structural Integrity of Polycarbonate Motorcycle Fairings

In the dynamic world of motorcycle design, the choice of fairing material plays a pivotal role in ensuring rider safety, particularly in terms of impact resistance. Polycarbonate, a versatile thermoplastic, stands out as an exceptional choice for motorcycle fairings due to its remarkable ability to withstand high-energy impacts. Unlike traditional materials such as acrylic or glass, polycarbonate is engineered to absorb shocks and prevent shattering, making it significantly safer during accidents.

One of the most compelling attributes of polycarbonate is its strength. When a motorcycle experiences a collision or falls, the fairings are often the first line of defense against external forces. Polycarbonate fairings absorb impacts effectively, helping to disperse the energy and reduce the likelihood of cracking or breaking. This characteristic is crucial, especially in high-speed scenarios where the consequences of structural failure can be catastrophic. Riders can feel more secure knowing that their fairings can endure the rigors of the road, providing protection not only to the bike but also to the rider behind it.

Moreover, the safety advantages of polycarbonate extend beyond mere impact resistance. In the event that brief moments of danger arise, such as debris or minor collisions, polycarbonate fairings help mitigate the risk of injury by maintaining their integrity. This aspect of durability is essential for preventing sharp or jagged edges from causing harm. The last thing any rider wants is for a shattered fairing to become a source of injury during a crash or a fall.

In addition to its impact resistance, polycarbonate offers excellent optical clarity. This property allows for unobstructed visibility through the fairing, enabling riders to maintain a clear view of the road ahead. Visibility is a key safety component; with the ability to see freely, riders can respond quickly to changing conditions, whether it be an unexpected obstacle or weather-related challenges. Many manufacturers utilize polycarbonate for windshields and transparent fairing components, underscoring its important role in enhancing visibility while ensuring robust protection.

Furthermore, polycarbonate exhibits excellent resistance to UV radiation, ensuring that the material does not degrade or become brittle over time due to sun exposure. This longevity extends the life of the fairings, contributing to both the cost-effectiveness of ownership and the maintenance of aesthetics. Riders benefit not just from immediate safety but also from an investment that remains visually appealing and structurally sound over the years.

The environmental conditions that motorcyclists frequently encounter—ranging from corrosive elements like salt on the road to intense sunlight—can adversely affect the performance of fairing materials. Polycarbonate is engineered to resist such degradation, thus maintaining its integrity and performance under a variety of circumstances. This resilience is paramount for riders who traverse diverse settings, from urban landscapes to rugged terrains.

In practical applications, the advantages of polycarbonate are increasingly reflected in the designs of modern motorcycles. Premium brands and custom builders alike are recognizing the material’s merit, leading to its adoption in high-performance race bikes and special edition models. As safety regulations become more stringent and the demand for reliability rises among consumers, the use of polycarbonate fairings is likely to gain even more traction in the industry.

The combination of these properties—impact resistance, optical clarity, UV protection, and weather resilience—ensures that polycarbonate not only meets but exceeds the expectations established by conventional materials. Riders who prioritize safety and performance will find that polycarbonate fairings provide an unparalleled balance of strength and visibility, critical factors that contribute significantly to the riding experience.

When considering motorcycle fairings, it is essential to acknowledge the evolving advancements in materials technology. Polycarbonate stands out as an excellent choice, particularly for those interested in enhancing both the aesthetics and safety of their motorcycle. By investing in polycarbonate fairings, riders can enjoy a safer ride, knowing that they are protected by one of the most reliable materials available. For anyone looking to explore the specific applications and options for polycarbonate fairings suited to their motorcycle model, resources such as this collection can provide valuable insights.

As the motorcycle market continues to develop, the significance of materials like polycarbonate becomes ever more apparent. Its unique attributes, focused on safety and durability, play a crucial role in the overarching conversation about rider protection and vehicle performance. By selecting polycarbonate for motorcycle fairings, manufacturers contribute to a safer riding environment while meeting the diverse needs of their clientele.

2. Unlocking Cost-Effectiveness and Creative Freedom with Polycarbonate Fairings

Polycarbonate has emerged as a material of choice for motorcycle fairings due to its notable economic benefits and design flexibility. These aspects make it an appealing option for both original equipment manufacturers (OEMs) and aftermarket customizers, providing advantages that extend throughout the lifecycle of a motorcycle’s bodywork.

Economic Benefits of Polycarbonate Fairings

One of the primary reasons for the increased adoption of polycarbonate in motorcycle fairings is its cost-effectiveness. When comparing it to traditional materials like fiberglass and carbon fiber, polycarbonate often comes out ahead in terms of affordability without sacrificing performance. This is particularly evident in small-scale production scenarios, where the cost per unit can significantly impact overall manufacturing expenses. Manufacturers generally find that polycarbonate not only mitigates the initial cost of raw materials but also minimizes fabrication costs due to its efficient processing capabilities.

The versatility of polycarbonate extends beyond mere cost. Its excellent formability allows for the creation of complex shapes using methods like thermoforming and injection molding. These production techniques help streamline the manufacturing process, reducing both time and labor costs. By allowing designers to create intricate and aesthetically pleasing fairings with relative ease, polycarbonate offers a practical solution for a wide range of customization options. Additionally, during prototyping, the scalability of polycarbonate means that designers can make rapid, iterative changes without incurring hefty financial penalties.

Another key economic advantage of polycarbonate is its durability. Inherent impact resistance means that parts made from this material are less likely to sustain damage during handling, transportation, and installation. This quality not only protects the investment made in manufacturing but also lowers the likelihood of warranty claims and repair costs over the product’s lifecycle. Ultimately, the durability associated with polycarbonate ensures that manufacturers can offer reliable products to consumers, fostering customer loyalty and satisfaction.

Design Flexibility with Polycarbonate

Beyond its economic benefits, polycarbonate shines when it comes to design flexibility. This material provides versatile aesthetic options that can cater to diverse consumer preferences and brand identities. The capability to easily tint, coat, or paint polycarbonate components allows for the creation of a wide range of finishes, from high-gloss to matte and even metallic effects. As motorcycle customization becomes increasingly popular, this means that manufacturers can meet the specific desires of riders who wish to personalize their bikes.

Moreover, polycarbonate lends itself to innovative design elements. Its transparency in clear grades opens up possibilities for integrated lighting and transparent panels that elevate both visual appeal and functionality. For example, many modern motorcycle designs incorporate LED lighting within fairings, and polycarbonate’s clarity allows for such enhancements without detracting from the overall design of the bike. This unique characteristic empowers manufacturers to experiment and push creative boundaries, solidifying polycarbonate’s position as an essential material in contemporary motorcycle fairings.

The lightweight nature of polycarbonate contributes to another significant advantage: improved fuel efficiency and handling, critical elements for motorcycle performance. As riders seek to enhance their bikes’ capabilities, every gram counts. Polycarbonate’s low weight helps in achieving an optimal strength-to-weight ratio, affording greater agility on the road. This is particularly important for racing enthusiasts and casual riders alike, all of whom benefit from lighter fairings that enhance performance.

Additionally, polycarbonate maintains dimensional stability across an expansive temperature range. This factor is vital in ensuring that fairings retain their shape and fit over time, even in harsh environmental conditions. Riders expect their motorcycle components to perform consistently; thus, the stability offered by polycarbonate supports long-term use without worrying about degradation or misalignment.

In conclusion, the robust economic and design advantages of polycarbonate contribute to its popularity as a motorcycle fairing material. This multifaceted polymer stands out for its cost-effective nature, formability, and durability, allowing for innovative designs that meet evolving customer demands. As typical motorcycle compositions continue to incorporate advanced materials, polycarbonate is poised to play a central role, further defined by the ever-changing landscape of motorcycle customization. For those seeking a strategic blend of performance, aesthetics, and affordability in their motorcycle fairings, polycarbonate proves to be an invaluable asset. By simplifying the production process and providing creative opportunities, polycarbonate offers the vital support needed for manufacturers to thrive in a competitive market, as well as for riders eager to express their individuality.

For a closer look at how polycarbonate and other materials are used in motorcycle fairings, visit the selections for various models here.

Chapter 3: Mastering the Art of Fiberglass: Crafting Custom Motorcycle Fairings for Performance and Style

1. Crafting Aerodynamic Elegance: Advanced Techniques in Fiberglass Fairing Fabrication

Fiberglass has emerged as a foundational material in the realm of custom motorcycle fairings, celebrated for its incredible adaptability and robust performance characteristics. Riders and builders gravitate towards fiberglass not only for its favorable strength-to-weight ratio but also for its remarkable capability to be shaped into intricate designs tailored for aerodynamics and aesthetics. This versatility makes it invaluable in custom fabrication, where the quest to push design limits melds with function and identity. Each fairing crafted from fiberglass represents not merely a component but an extension of the rider’s personality, bridging the gap between art and engineering.

The Fabrication Process in Depth

At the heart of creating fiberglass fairings lies a meticulous manufacturing process that begins with the construction of a master model. This initial form is typically crafted from dense foam or clay, presenting the desired contours and complexities of the final bodywork. Once crafted, this model serves as the basis for producing a high-quality mold, often constructed from silicone or fiberglass itself. The mold-making process involves applying a release agent to the master form, ensuring that the fiberglass can be cleanly separated once it cures.

The next phase involves layering fiberglass cloth and resin—commonly, a polyester or epoxy resin system—over the prepared mold. This technique allows builders to create fairings that are not only lightweight but also incredibly resilient. Each layer is meticulously applied, and the resin is catalyzed to initiate the curing process, which hardens the composite into a solid, formidable structure. For high-performance applications, builders often opt for multiple layers of fiberglass, reinforcing areas that experience the most stress, which adds to the fairing’s durability and structural integrity.

Achieving the Perfect Finish

Once cured, the newly formed fairing is sanded to smooth out imperfections and to prepare it for painting. Here, attention to detail is paramount. Techniques such as wet sanding and gelcoat application ensure a flawless surface free from air bubbles or surface flaws. Builders often employ vacuum bagging during the resin application phase to reduce potential air entrapment, a crucial step for achieving the high-quality finish that custom motorcycle enthusiasts demand. In this phase, the attention to detail becomes evident; the aesthetics of a fairing can elevate a motorcycle from merely functional to breathtakingly beautiful.

Cost-Effectiveness and Accessibility

One of the standout advantages of fiberglass in motorcycle fairing fabrication is its cost-effectiveness. Compared to more exotic materials such as carbon fiber, fiberglass presents a financially accessible solution, particularly for DIY builders and small-scale custom shops. Its affordability does not necessarily equate to compromise; fiberglass offers solid performance capabilities, making it a pragmatic choice for many custom projects. Moreover, the tools required for fiberglass work are often readily available in most workshops, inviting enthusiasts to explore their creativity without significant financial barriers.

For the DIY enthusiast, the satisfaction of creating a personalized fairing from scratch fosters a deeper connection to the motorcycle. The ability to repair or modify fiberglass parts easily further encourages experimentation. In contrast to rigid metals or the more complex carbon fiber, fiberglass can be sanded, reshaped, and repainted with relative ease, making it user-friendly for those keen on learning and evolving their skills.

Safety and Precautions

While the allure of fabricating custom fiberglass fairings is strong, it is crucial to acknowledge safety considerations throughout the process. Fiberglass fabrication does entail certain risks; inhaling fine fiberglass dust or fumes from resin can pose health hazards. Builders must prioritize their safety by utilizing respirators, protective eyewear, and gloves. Proper ventilation in the workspace is also vital—ensuring that harmful particles and fumes dissipate away from the fabricator can significantly reduce health risks involved in the process. Training in safe handling of fiberglass materials and resin can further enhance safety.

The Convergence of Functionality and Identity

Ultimately, the significance of fiberglass in motorcycle fairing production transcends cost and technical attributes. Each fairing tells a story—an expression of individuality, performance aspirations, and artistic vision. The custom motorcycle culture thrives on the notion that each bike is unique, and fiberglass facilitates this philosophy effortlessly. Whether shaping a low-profile fairing for aerodynamic advantages or creating a flamboyant design for visual impact, fiberglass allows builders to explore and deliver their vision effectively.

Embarking on the journey of customizing motorcycle fairings with fiberglass is not just about performance enhancement; it is also about crafting joy into the ride. From the initial conception of a design to the final application on a finely tuned machine, each step enriches the rider’s experience, cultivating a deeper appreciation for the art of motorcycling.

As you consider the future of your motorcycle’s bodywork, remember that fiberglass is not merely a functional choice—it is an avenue through which creativity, innovation, and personal expression blend effortlessly. Explore the vast array of fiberglass options, and embark on a project that showcases your individuality and passion for two-wheeled engineering. For a glimpse into various options, you may want to check fairings tailored for specific models like those in the Honda CBR series or Yamaha’s collection. This diversity allows a rider’s vision to materialize into a tangible, exhilarating ride.

2. Fiberglass: A Trusted Choice for Performance and Customization in Motorcycle Fairings

Fiberglass is a highly regarded material within the realm of motorcycle fairings, particularly noted for its dual advantages of economic viability and performance enhancement. As riders continue to seek customizations that not only elevate the aesthetics of their bikes but also improve functionality, fiberglass presents an appealing proposition that balances both aspirations. Its application ranges from bespoke builds to competitive racing, showcasing versatile adaptability.

One of the foremost benefits of fiberglass is its lightweight nature. In motorcycle design, reducing weight is crucial as it directly impacts handling, acceleration, and overall agility. By replacing heavier metallic components or solid plastics with fiberglass, motorcycles can achieve a significant weight reduction. This change not only results in improved performance metrics—such as increased speed and better fuel efficiency—but also enhances rider control and maneuverability, especially in demanding riding conditions. Therefore, for bikers who crave speed and responsiveness, fiberglass fairings provide the ideal solution without the downsides often associated with heavier materials.

Moreover, fiberglass brings an unmatched design flexibility to the table, making it a prime candidate for custom builds. Unlike traditional metals or more rigid plastics, fiberglass can be molded into intricate shapes and aerodynamic contours. This feature allows custom fabricators to create one-off designs that are both unique and functional, vastly differing from the standardized forms found in mass-produced parts. The capacity to produce complex shapes means that designers can optimize airflow around the bike, thereby reducing drag and increasing stability at higher speeds—a fundamental aspect for racers who seek every advantage in competition. Ultimately, this moldability not only fulfills functional roles but also allows the creation of artistic, eye-catching designs that reflect the rider’s personality.

From an economic perspective, fiberglass is also appealing due to its cost-effectiveness. Compared to high-performance alternatives such as carbon fiber, fiberglass provides a budget-friendly option without sacrificing structural integrity or performance. This makes fiberglass particularly attractive to DIY builders and small manufacturers who are looking to create high-quality custom parts while remaining budget-conscious. The balance of affordability and quality empowers a wider scope of enthusiasts and professionals alike to explore custom fairing designs or upgrades without breaking the bank.

The molding and prototyping capabilities of fiberglass further enhance its appeal in custom applications. Fiberglass can be easily worked with using hand molds and resin, enabling rapid prototyping and modifications as needed. This agility in the manufacturing process allows builders to experiment and refine their designs on the go—an essential factor in the custom motorcycle world where preferences can change quickly. By facilitating quicker iterations, fiberglass ensures builders spend less time on revisions and more time on the road enjoying their creations.

Further adding to its advantages, fiberglass exhibits notable durability and weather resistance once cured. Many riders expose their motorcycles to various environmental conditions, from harsh sunlight to rain and road debris. Fairings crafted from fiberglass not only stand up well under such stressors but also retain their shape and performance over extended periods. This durability means fewer repairs and replacements, ultimately resulting in enhanced longevity for custom builds and investment protection for existing motorcycles.

In a landscape populated with different material options—from lightweight carbon fiber to robust aluminum—fiberglass serves as a middle ground that impeccably merges performance, economic sense, and aesthetic freedom. Because of its versatility, fiberglass has established a solid reputation within the motorcycle community, finding its place in both street-legal custom builds and high-performance racing prototypes. Notably, the material can be painted to match vibrant color schemes, providing the opportunity to create visually stunning fairings that reflect the owner’s style while preserving performance characteristics associated with more utilitarian designs.

The application of fiberglass is not limited to a particular segment of motorcycle riding. From the competitive racetrack to the weekend cruiser, fiberglass fairings have been embraced across various riding communities. Racing teams frequently implement fiberglass to achieve optimal aerodynamic performance, while hobbyists may choose it for their bespoke custom projects, drawing attention to the vibrant and creative potential it offers. This duality illustrates how fiberglass is not simply a material choice but a strategic advantage that can differentiate a motorcycle’s performance capability and visual impact.

In summary, fiberglass remains a cornerstone material for those embarking on custom motorcycle projects, balancing cost, weight, and design flexibility effectively. Its extensive utilization in both the racing and custom markets proves its versatility and reliability. For riders seeking to personalize their motorcycle and enhance performance, turning to fiberglass offers a practical, efficient solution that embodies the spirit of motorcycle customization. The right fiberglass fairings not only define the aesthetic appeal of a motorcycle but also elevate the overall riding experience, ensuring that each bike is as unique as its rider. For more on specific models and collections, check out Summit Fairings’ extensive offerings covering everything from Honda to Kawasaki custom fairings.

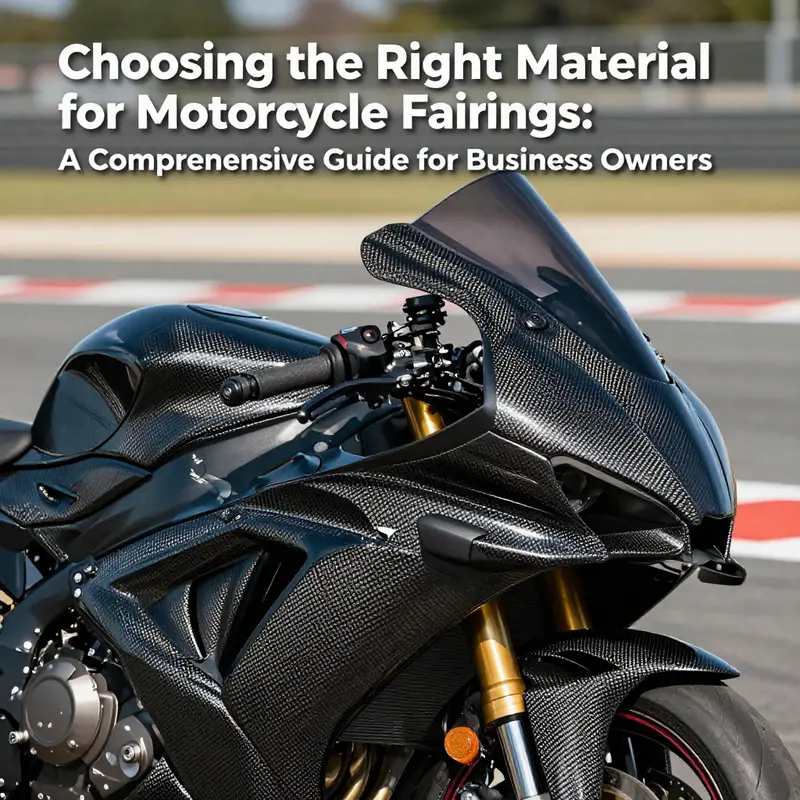

Chapter 4: The Elite Performance of Carbon Fiber in Motorcycle Fairing Material

1. Harnessing the Strength and Style of Carbon Fiber: A Deep Dive into Performance Enhancements and Aesthetics

Carbon fiber has firmly established itself as a premium choice in the world of motorcycle fairings, standing out not only for its remarkable strength-to-weight ratio but also for the aesthetic appeal it brings to high-performance bikes. The advantages offered by this material are multifaceted, providing riders with both enhanced performance and a distinctive visual style that resonates deeply with enthusiasts and casual riders alike.

One of the standout features of carbon fiber is its incredible strength. The composite material comprises tightly woven strands of carbon filaments which are significantly stronger than steel yet weigh considerably less. This exceptional rigidity translates to superior impact resistance, meaning that motorcycle fairings made from carbon fiber can withstand considerable stress during accidents without succumbing to deformation. This characteristic not only provides safety benefits for the rider but also protects critical components of the motorcycle, enhancing overall durability. As riders prioritize safety more than ever, carbon fiber emerges as a material that meets these heightened expectations of risk management on the road.

In addition to its strength, the weight-reducing qualities of carbon fiber contribute significantly to motorcycle performance. Reducing the mass of a motorcycle directly impacts its acceleration and handling, allowing for quicker response during maneuvers, improving braking, and enhancing overall maneuverability. Riders experience decreased inertia on the road, which means better fuel efficiency as well. Exceptional engineering and design can mold carbon fiber into sleek, complex shapes that facilitate optimized airflow, lowering drag. This aerodynamics is particularly crucial in racing scenarios where milliseconds can be the difference between first place and second. Riders equipped with carbon fiber fairings are likely to note significant improvements in their bikes’ handling and stability, essential elements especially revered in competitive environments.

The longevity of carbon fiber is also one of its appealing attributes. Unlike many materials that degrade or corrode over time, carbon fiber maintains its structural integrity even when exposed to harsh environments. Its excellent resistance to fatigue and corrosion enhances the lifespan of the fairings, making them worthwhile investments—despite the higher initial costs associated with carbon fiber components. Riders often view their motorcycles not just as modes of transport but as cherished assets, and carbon fiber fairings ensure these investments are safeguarded against the rigors of time and use.

However, it’s not just performance metrics that make carbon fiber a go-to material; aesthetics play an equally crucial role. The unmistakable woven pattern of carbon fiber delivers a high-tech, sophisticated look that many riders find visually appealing. The glossy finish and the unique texture capture attention, allowing motorcycles to stand out in a crowd. This distinct appearance has earned carbon fiber its share of prestige in motorcycle culture, often regarded as synonymous with luxury and exclusivity.

Customization possibilities further enhance the allure of carbon fiber fairings. Builders and enthusiasts can choose from a variety of finishes—whether clear-coated for a polished effect or matte for a more understated vibe—allowing riders to tailor their bikes according to personal taste. Some manufacturers even offer carbon fiber fairings infused with colors, enabling a unique blend of style that matches individual rider aesthetics. This customization factor promotes not only personal expression but also a deeper connection between the rider and their machine, fostering a sense of identity.

The craftsmanship involved in creating carbon fiber parts is another aspect driving their appeal. Producing carbon fiber components is labor-intensive, often requiring skilled artisans to master the weave, layup, and cure processes. The dedication to quality and the meticulous attention to detail bolster the reputation of carbon fiber as a luxury material. For many riders, owning a motorcycle adorned with custom carbon fiber fairings symbolizes not just a passion for riding but an appreciation for exceptional craftsmanship and engineering excellence.

Market trends indicate a gradual evolution in the accessibility of carbon fiber components. Advances in technology and manufacturing processes have led to a decrease in production costs, making high-performance materials like carbon fiber more attainable for a wider range of consumers. As carbon fiber continues to permeate various tiers of motorcycle models, it remains closely associated with cutting-edge design and the pinnacle of engineering prowess in the industry. This trend indicates a shift in the average rider’s accessibility to advanced materials, fostering an environment where performance and style can converge even in more mainstream motorcycle offerings.

In conclusion, carbon fiber’s advantages in both performance and aesthetic appeal continually position it as the premium choice for motorcycle fairings. As newer riders stepping into the sport and seasoned hands alike with an eye for detail opt for carbon fiber, it is clear that this powerful composite material is not merely a passing trend but a fundamental aspect of modern motorcycle design. The combination of unparalleled strength, lightweight characteristics, and stunning visuals ensures that carbon fiber fairings will remain in high demand, captivating both purists and thrill-seekers alike. Riders seeking a balance of form and function can find their answer in the premium nature of carbon fiber, solidifying its place at the forefront of motorcycle materials. For those interested in exploring how carbon fiber enhances various models, you can find an excellent selection of high-performance fairings tailored for brands such as Honda, Yamaha, and Suzuki at Summit Fairings.

2. The Economic Dynamics of Carbon Fiber in Motorcycle Fairing Material: Balancing Performance with Cost

Carbon fiber, increasingly recognized as a cornerstone material for high-performance motorcycle fairings, epitomizes the delicate balance between premium quality and economic implications for manufacturers and consumers alike. With an exceptional strength-to-weight ratio, carbon fiber excels in enhancing the performance and aerodynamics of motorcycles, making it a sought-after choice for racing and elite models. However, the economic ramifications of utilizing this material cannot be overlooked, as they create complexities influencing both market dynamics and consumer accessibility.

The allure of carbon fiber begins with its remarkable physical properties. Its unique composition provides a superiority in tensile strength and significantly reduces the overall weight of motorcycle fairings—a critical factor for performance motorcycles where every ounce shed can contribute to improved speed and handling. Furthermore, carbon fiber exhibits impressive durability, resistant to fatigue and environmental degradation, which ensures longevity and maintains the aesthetic quality over time. This resistance to wear and tear complements an aesthetic appeal that many riders find irresistible, presenting not just functional benefits but also enhancing the motorcycle’s visual appeal, thanks to its sleek, high-tech finish.

Despite these advantages, the economic implications of incorporating carbon fiber into motorcycle fairing material are multifaceted. The cost of production ranks high on this list; the intricate processes involved—including the precise weaving of carbon strands, resin infusion, and high-temperature curing—lead to elevated manufacturing costs. Unlike the simpler processes used for ABS plastic or fiberglass, carbon fiber requires specialized equipment and skilled labor, thus driving up the prices of motorcycles outfitted with this material. Consequently, even though manufacturers can market these motorcycles as high-performance vehicles, the production costs can cause retail prices to soar, limiting this technology’s reach into the broader market.

Also significant is the market positioning associated with carbon fiber motorcycles. Typically, these bikes are found in the premium segment, marketed as exclusive products that cater to enthusiasts willing to invest in superior performance. This exclusivity, whilst appealing to a certain demographic, inadvertently creates a barrier for wider consumer access, thus concentrating market demand among affluent consumers and limiting mass-market adoption. Consequently, manufacturers face a challenge of balancing the costs associated with carbon fiber while appealing to a more budget-sensitive audience.

So, how do manufacturers respond to the high costs of carbon fiber production? Through pricing strategies designed to justify these expenses. By emphasizing performance features and the premium nature of carbon fiber in marketing campaigns, manufacturers aim to establish a perceived value that aligns with the higher price points. It’s a strategy that plays a dual role: enhancing brand image while also tapping into the exclusivity that often accompanies high-end performance motorbikes. When positioned as status symbols, carbon-fiber-finished motorcycles can command prices that not only cover production costs but also contribute to substantial profit margins.

This delicate pricing model does not come without its challenges. The high costs may dissuade potential buyers, particularly those looking for a balance between quality and affordability. Moreover, with advancements in motorcycle technology and engineering, the competition in the market becomes fierce. Manufacturers must not only innovate but do so in a cost-effective manner that allows them to maintain profit margins without alienating a broader consumer base.

One of the crucial aspects influencing the future viability of carbon fiber in the motorcycle industry is the technology advancement in manufacturing processes. Innovations such as Automated Fiber Placement (AFP) and Resin Transfer Molding (RTM) are paving the way toward more economical production methods. These advancements promise to reduce costs and enhance manufacturing efficiency over time, potentially allowing carbon fiber to transition from its niche in high-performance motorcycles into more mainstream models, making it an appealing option for mid-tier motorcycles as well.

Additionally, the theory of economies of scale emerges as a potential game-changer for carbon fiber utilization in motorcycles. As demand increases and production capacity expands, costs are expected to decrease, which may lead to broader adoption of carbon fiber in varied motorcycle models. The development of recycling methods for carbon fiber could further bolster this trajectory, presenting an environmentally sustainable option that appeals to modern consumers increasingly focused on green technologies.

It’s clear that while carbon fiber represents the apex of engineering and aesthetics within motorcycle fairing materials, the associated economic dynamics pose unique challenges. Yet, as the industry adapts with innovative manufacturing methods and the potential for shifting market perceptions, carbon fiber may very well straddle the line between luxury and accessibility in the coming years. Embracing the resilience of market forces will be key to adapting to the evolving needs and preferences of consumers, ultimately redefining how motorcycle enthusiasts experience performance on two wheels.

For those looking to explore the extensive options available in motorcycle fairings, including applications of different materials, consider browsing selections like Honda CBR fairings.

Final thoughts

In summary, selecting the right material for motorcycle fairings is paramount for business owners aiming to meet customer requirements and enhance their product offerings. Each material serves specific needs—ABS plastic remains popular for its affordability and durability, polycarbonate offers enhanced safety, fiberglass provides versatility for customized designs, and carbon fiber exemplifies premium performance. By understanding these materials, you are better equipped to make informed sourcing decisions that align with market demands and elevate your business.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.