Introduction

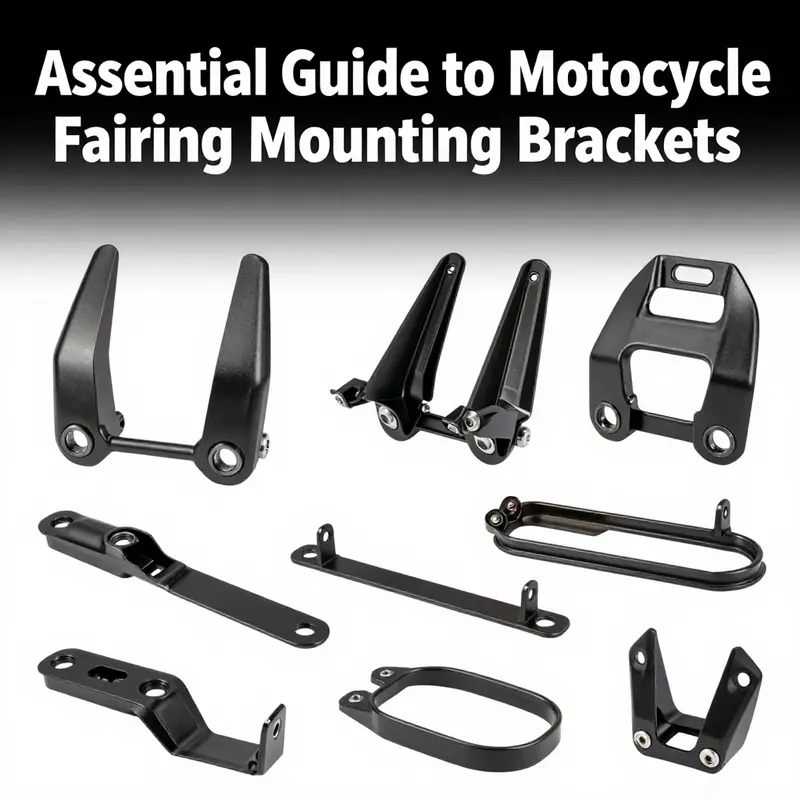

Motorcycle fairing mounting brackets are critical components that ensure the fairing is securely attached to the motorcycle’s frame, improving both aesthetics and functionality. Designed specifically for durability and resistance to the elements, these brackets play a vital role in minimizing vibrations and wind resistance during riding. As a business owner in the motorcycle industry or aftermarket accessories, understanding the intricacies of fairing mounting brackets—from their design specifications to installation practices and available aftermarket options—can significantly enhance customer satisfaction and operational efficiency. This article will delve into key aspects: the specific design specifications that dictate the suitability of brackets for various models, best practices for installation and maintenance, and the broad range of aftermarket options available for customization or replacement. Each chapter aims to equip you with essential knowledge to make informed choices that enhance your product offerings and customer experiences.

Tables of Contents

Chapter 1: Material Innovations and Applications in Motorcycle Fairing Mounting Brackets

- Understanding Material Choices in Motorcycle Fairing Mounting Brackets

- Essential Design Elements: Mounting Points and Fitment of Motorcycle Fairing Mounting Brackets

- Ensuring Structural Rigidity and Load-Bearing Strength in Fairing Mounting Brackets

Chapter 2: Ensuring Stability and Safety: The Comprehensive Guide to Installing Motorcycle Fairing Mounting Brackets

- Mastering the Art of Installing Motorcycle Fairing Mounting Brackets

- Vigilant Maintenance Techniques for Motorcycle Fairing Mounting Brackets

- Navigating Installation Challenges: Troubleshooting Common Problems with Motorcycle Fairing Mounting Brackets

Chapter 3: Navigating the Landscape of Motorcycle Fairing Mounting Brackets: Challenges and Solutions

- Evaluating Fitment and Installation Considerations for Aftermarket Motorcycle Fairing Mounting Brackets

- Prioritizing Safety in the Selection of Aftermarket Fairing Mounting Brackets

- Enhancing Motorcycle Performance and Visual Appeal with Aftermarket Fairing Mounting Solutions

Chapter 1: Material Innovations and Applications in Motorcycle Fairing Mounting Brackets

1. Understanding Material Choices in Motorcycle Fairing Mounting Brackets

The material composition of motorcycle fairing mounting brackets plays a fundamental role in the overall performance, durability, and aesthetic appeal of the motorcycle’s fairing system. Given the substantial forces that motorcycles encounter while in motion—ranging from vibrations and impacts to varying weather conditions—selecting the right material is crucial for ensuring safety, stability, and longevity.

Among the most widely utilized materials for motorcycle fairing mounting brackets, ABS plastic (Acrylonitrile Butadiene Styrene) is perhaps the most prevalent choice. Its remarkable strength-to-weight ratio makes it exceptionally suited for the demands of motorcycle applications. ABS plastic is not only light but also boasts excellent impact resistance, allowing these brackets to endure the shocks and vibrations inherent in everyday riding. Furthermore, ABS can be molded into intricate shapes, making it a versatile option for manufacturers looking to create customized designs that fit specific motorcycle models seamlessly. This adaptability has led to its popularity in both original equipment manufacturer (OEM) parts and aftermarket modifications, ensuring that riders have access to reliable options for both new builds and restorations.

In contrast to ABS, aluminum alloys are favored for high-performance mounting brackets due to their superior strength combined with low weight. This characteristic is particularly beneficial on sport bikes and touring motorcycles, where performance is paramount. Aluminum brackets are often anodized, enhancing their corrosion resistance, which is crucial considering the exposure to rain, dirt, and other elemental factors. The aesthetic aspect of aluminum—its sleek appearance—makes it a preferred choice for models that prioritize style as much as performance. The decision to use aluminum also reflects a trend in motorcycle design toward reducing weight without compromising structural integrity, allowing for an exhilarating riding experience without burdening the motorcycle with unnecessary mass.

Steel is another common material employed in the production of motorcycle fairing mounting brackets, often seen in heavy-duty applications. Although heavier than both ABS and aluminum, steel’s exceptional strength makes it ideal for applications requiring maximum load-bearing capacity. This durability is particularly appreciated by those who may subject their motorcycles to more strenuous conditions, such as off-road riding or long-distance touring. Steel brackets are frequently coated or powder-coated to provide additional protection against rust and wear, ensuring that they maintain both their structural integrity and appearance over time.

The choice of material for motorcycle fairing mounting brackets is not merely about immediate performance. It also speaks volumes about the longevity and reliability of the motorcycle itself. For instance, when these brackets face the rigors of road vibrations, temperature fluctuations, and environmental exposure, the quality of material directly influences the overall reliability of the fairing system. Poorly constructed or incompatible mounting brackets can lead to alignment issues, increased wind noise, or, in the worst scenarios, compromised safety due to loose or damaged fairings. Therefore, when considering aftermarket upgrades, it is vital for riders to select mounting brackets that are compatible with their motorcycle model and that align with product specifications provided by manufacturers.

Understanding these materials goes beyond a mere academic discussion; it translates into practical implications for every rider. Riders might find that a well-designed fairing not only enhances the aesthetic appeal of their motorcycle but also contributes to improved aerodynamics and wind protection, which further enhances the riding experience. Thus, those considering replacement parts should conduct an informed assessment of both material options and brand reputation. For example, purchasing replacement fairing mount brackets from reputable manufacturers such as Harley-Davidson guarantees a product that adheres to standardized material and design specifications, often being backed by warranties that provide additional reassurance regarding product quality and performance durability.

In this context, it’s also worth considering recent advancements in material technology. The motorcycle industry has seen innovations that blend traditional materials with modern composites, creating brackets that meet the evolving demands of motorcycle enthusiasts. While conventional materials like ABS, aluminum, and steel continue to be pillars of mounting bracket design, new composites can offer unique benefits such as increased flexibility or reduced weight. Understanding and adapting to these innovations can play a crucial role in customizing a motorcycle to achieve not only performance but also individual style preferences.

As riders seek to enhance their motorcycles either for restoration purposes or performance improvements, examining material compositions in the context of fairing mounting brackets reveals a complex interplay of technology and design philosophy. Utilizing the right material fosters a connection between performance and aesthetic appeal, ensuring that the bike delivers on both fronts. Whether opting for ABS plastic for its cost-effectiveness, aluminum for performance or aesthetics, or the robustness of steel, riders can find polarities in materials that suit their distinct riding styles and preferences. Embarking on this material exploration underscores the value of informed decision-making, ensuring that each component assembled contributes to an overall experience that defines the joy of motorcycling.

For those interested in aftermarket modifications, seeking out compatible mounting brackets tailored specifically for their motorcycle model is paramount. Riders can explore various options through specialized resources, such as those available within dedicated fairing collections, ensuring that they find the perfect fit and material composition for their needs.

2. Essential Design Elements: Mounting Points and Fitment of Motorcycle Fairing Mounting Brackets

Motorcycle fairing mounting brackets serve as the unsung heroes of motorcycle design, expertly crafted to secure the fairing—those sleek, aerodynamic structures that not only enhance the bike’s appearance but also promote optimal performance. When considering the mounting points and fitment of these brackets, it becomes apparent that their design is not merely functional but also essential for the aesthetic integrity and operational stability of the motorcycle.

Mounting Points

The mounting points on motorcycle fairing mounting brackets are meticulously designed to provide an anchor between the fairing and the motorcycle frame. These points are placed at critical junctions such as where the upper fairing connects to the main frame or where stay brackets link to the handlebar stem. The strategic positioning of these mounting points ensures that weight is evenly distributed across the fairing structure, minimizing potential stress and enhancing stability. Proper load distribution is vital in preventing vibration or misalignment that can occur during dynamic riding conditions.

Most motorcycles have specific mounting configurations dictated by their design. For example, high-performance sport bikes often showcase mounting points that facilitate lower riding positions, enhancing aerodynamics, while dual-sport configurations might prioritize versatility and functionality. This diversity emphasizes the importance of designing each bracket according to the distinct characteristics and performance demands of various motorcycle models.

Fitment

While mounting points play a crucial role in the overall design, fitment is equally important. Each bracket is tailored to the exact specifications of specific motorcycle models, whether it be a Honda, Yamaha, or Suzuki. This specificity includes exact bolt patterns, precise hole diameters, and alignment features necessary for both original equipment manufacturer (OEM) and aftermarket fairings. The aim is to facilitate swift installation without compromising performance or safety.

Incorrect fitment can lead to various complications such as increased noise due to air gaps, which can detract from the riding experience. Moreover, improperly fitted fairings might result in decreased safety—loose or damaged fairings could detach from the motorcycle while in motion, posing severe risks to both the rider and surrounding traffic. Hence, choosing fairing mounting brackets that are specifically designed for a motorcycle model is crucial.

Motorcycle enthusiasts keen on customization need to prioritize fitment when exploring aftermarket fairings. Each motorcycle model, like the Honda CBR1000RR, or the Yamaha YZF-R6, will have distinct dimensions and specifications related to fitment. This makes it essential for riders to consult not only the product descriptions but also the technical specifications provided by manufacturers.

Installation Guidance

To ensure seamless compatibility, manufacturers provide installation guidance tailored to their specific mounting brackets. Comprehensive instructions typically outline vital steps such as the correct torque for bolts or the sequence for attaching different components. For example, the RIFLE Fairing Installation Guide includes detailed directives on bracket placement, such as how to accurately remove the top triple clamp pinch bolts and secure the top brackets at 90° or 120°. These angles are critical for ensuring proper alignment and optimal fairing stability.

Furthermore, the installation guides highlight best practices for maintenance and upkeep to prevent issues that may arise from wear and tear. Regular checks not only extend the lifespan of the brackets and fairings but also improve safety for the rider.

Importance of Material Choice

An often-overlooked aspect of the mounting points and fitment is the importance of material choice. Brackets made from durable materials such as aluminum or reinforced plastics exhibit excellent resistance to corrosion and wear. Furthermore, these materials are engineered to absorb vibration, which minimizes stress on the fairing itself while optimizing the overall riding experience. Riders interested in upgrading their motorcycle may find that choosing lightweight yet sturdy materials enhances both performance and handling. This is especially important in off-road or racing situations where conditions can be more demanding.

Quality and fitment should never be underestimated; low-cost substitute parts may lead to compromised safety or performance. Some brands like Harley-Davidson offer replacement fairing mount brackets—they not only ensure fitment but often come with warranties that bolster the rider’s peace of mind.

Conclusion

In summary, the mounting points and fitment of motorcycle fairing mounting brackets represent a harmonious blend of precision engineering and aesthetic considerations. Ensuring that these components are properly designed, compatible, and installed is vital for achieving both the desired performance and appearance of the motorcycle. Riders who invest time in understanding these specifications will not only enjoy a more reliable riding experience but will also enhance their motorcycle’s overall performance and longevity.

For those looking to explore specific motorcycle fairing options, selecting the right montoing kits tailored to your model, such as those offered for the Honda CBR1000RR, can be a critical step towards ensuring a perfect fit and finish.

3. Ensuring Structural Rigidity and Load-Bearing Strength in Fairing Mounting Brackets

Motorcycle fairing mounting brackets serve as vital elements in the structural framework of the bike, tasked with maintaining both rigidity and load-bearing capacity necessary to secure the fairing—an essential component for aerodynamics and rider comfort. The integrity of these brackets not only affects the aesthetic appeal of the motorcycle but also its performance and safety during operation. As riders push their machines to higher speeds, the demands on these mounting systems become increasingly significant, highlighting the importance of careful design and material selection.

Design Specifications

At the heart of a reliable fairing mounting bracket lies the careful consideration of materials. High tensile strength and exceptional fatigue resistance are paramount to withstand the dynamic forces encountered on the road. For instance, high-grade steel is often utilized for its robust mechanical properties; on the other hand, high-performance motorcycles, like the Yamaha YZF-R1, employ advanced aluminum alloys to create brackets that boast both low weight and formidable strength. These materials ensure minimal deflection during riding and resistance to wear and tear from environmental exposure.

Any compromise in material quality can lead to performance issues. The BMW K1600B exemplifies this approach, as its brackets made from premium aluminum alloy achieve a perfect balance between strength and the ability to handle vibrations and thermal expansion across diverse conditions, cementing the integral nature of proper material selection in the bracket’s design.

Load-Bearing Capacity and Stress Distribution

Load-bearing capacity is a critical aspect of fairing mounting brackets that cannot be overlooked. Engineers meticulously calculate the maximum load each bracket must bear under various riding conditions, ensuring that stress is evenly distributed across attachment points. Under high-speed conditions, the forces acting on a motorcycle increase significantly, impacting the fairing and consequently the bracket. If the brackets are misaligned or poorly equipped to handle these forces, the risk of structural failure rises, leading to potential detachment of the fairing and severe safety implications.

Brackets are typically designed in such a way that they distribute loads uniformly, preventing localized stress concentrations that can lead to material fatigue. This attention to load distribution is part of an intricate design process aimed at creating components that perform reliably over time, thereby maintaining the overall structural integrity of the motorcycle.

Compliance and Testing Protocols

Ensuring the safety and durability of fairing mounting brackets necessitates adherence to industry standards set forth by organizations such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE). Compliance with these rigorous standards affirms that manufacturers have met the minimum quality and performance requirements, further underscoring their commitment to safety. Non-compliance not only jeopardizes rider safety but can also result in severe financial and reputational losses for manufacturers.

To validate their designs, manufacturers conduct extensive testing of fairing mounting brackets through a variety of protocols. These include vibration tests that simulate the operating environment of the motorcycle, assessing how well the brackets will perform under conditions of mechanical stress. Load tests are imperative as they measure how brackets respond to both static and dynamic loads, offering insight into their resilience and potential failure points.

Environmental tests also play a critical role in determining the brackets’ longevity. These tests expose the materials to extreme temperatures, changes in humidity, and exposure to various chemicals, all of which can affect the performance and durability of the brackets. This comprehensive testing creates a safety net for both manufacturers and riders, ensuring that the final product can withstand the rigors of real-world usage.

Conclusion

In summary, motorcycle fairing mounting brackets encapsulate a blend of engineering diligence and material science, focused on delivering the structural rigidity and load-bearing strength required to support the fairing effectively. Each bracket must be designed with precision, taking into account the dynamic forces experienced during operation. As riders seek to enhance their experiences through customization or performance modifications, understanding the role and specifications of mounting brackets becomes essential.

When choosing aftermarket fairings and their corresponding brackets, it is crucial to select components specifically engineered for compatibility with the motorcycle model, ensuring both safety and performance are not compromised. Riders can explore a plethora of options, such as those offered for various models like the Honda CBR1000RR, which exemplify the intricate relationship between design choice and motorcycle performance.

Quality and fitment remain paramount in this domain, where the right specifications can lead to a smoother ride, improved aerodynamics, and heightened safety on the road.

Chapter 2: Ensuring Stability and Safety: The Comprehensive Guide to Installing Motorcycle Fairing Mounting Brackets

1. Mastering the Art of Installing Motorcycle Fairing Mounting Brackets

Installing motorcycle fairing mounting brackets is not merely a task; it is an essential aspect of motorcycle maintenance that directly impacts the vehicle’s performance, aesthetics, and rider safety. Proper installation ensures that the fairing, which serves both protective and aerodynamic purposes, is securely and effectively attached to the motorcycle’s frame. This comprehensive guide details a step-by-step installation process based on best practices and manufacturer recommendations, suitable for a variety of motorcycle models.

Preparation: Setting the Stage for a Successful Installation

Before diving into the installation process, preparation is key. Start by gathering the necessary tools and materials. You will typically need hex wrenches, usually 4mm or 5mm, a reliable torque wrench for precise adjustments, cleaning cloths to wipe down surfaces, and lubricants like silicone grease or specialized thread lubricant to ensure smooth operation and prevent corrosion.

Safety measures are paramount; always place the motorcycle on a stable stand to avoid any movements that could lead to injury or damage while working. If you’re replacing existing brackets, ensure to carefully remove the current fairing and all relevant fasteners. Inspect these components to assess if they need replacing or repairing, as the longevity of your new installation will depend on the integrity of existing parts.

Step One: Installing the Top Bracket – The Keystone of the Structure

The installation process begins at the top bracket, often considered the most vital point of attachment due to its role in maintaining the upper structure’s alignment. First, locate and loosen the top triple clamp pinch bolts positioned typically above the handlebars. This action enables you to adjust and fit the new bracket effectively.

Selecting the correct angle for the bracket is crucial—most installations permit either a 90° or a 120° angle. The 90° bracket fits compact designs best, while the 120° bracket accommodates larger fairings or additional components, providing more space. Once you’ve chosen the appropriate angle, insert the selected bracket into the designated space, ensuring it aligns properly with the frame.

Using the torque wrench, tighten the top triple clamp pinch bolts to the manufacturer’s specified torque value. Usually, this ranges from 25-30 Nm. Avoid over-tightening, which risks damaging the materials, especially if they are aluminum or carbon fiber, as structural integrity is vital for maintaining the fairing’s safety during operation.

Step Two: Securing Side and Bottom Brackets – Achieving a Balanced Hold

Once the top bracket is secure, it’s time to focus on the side and bottom brackets. This step is all about positioning. Place each bracket in its specific location according to your motorcycle’s fairing design specifications. Be vigilant for interference points that could affect the installation; potential obstructions include the fuel tank, footpeg positioning, and even the wiring harness—ensure these elements are clear and unimpeded.

Initial positioning should involve hand-tightening all fastening bolts of the brackets. This allows for keep the brackets in place without fully locking them down just yet. Come around to check the alignment of the fairing from all angles. An effective installation depends on the correct edge gaps, creating a professional look and ensuring that the part will perform reliably at various speeds and conditions. If the fairing appears slightly off, minor adjustments to the bracket positions can rectify this, enhancing the flush fitment crucial for both performance and aesthetics.

Finally, once you confirm all alignments are correct, use your torque wrench to systematically tighten all bracket bolts. Applying torque in an even manner helps in preventing wobbliness or uneven pressure points that could weaken your installation over time.

Step Three: Inspection and Proving the Setup with a Test

With the brackets securely installed, the next phase is thorough inspection. Look closely to confirm that all components are correctly positioned with no loose or misaligned parts. Quality control at this stage can save you from more extensive repairs down the line.

Performing a function test is equally important; start the engine and listen for unusual noises or vibrations that could indicate improper mounting. Taking the bike for a short ride can provide insight into the fairing’s stability under various road conditions, reflecting on its alignment and overall effectiveness.

If your fairing has a waterproof design, consider conducting a spray test to validate its sealing capabilities—an essential factor for riders in varied weather conditions. This simple check can prevent future issues that stem from ineffective seals, which could lead to electrical problems or corrosion in critical components.

Expert Tips for Optimal Installation

While the above steps outline a thorough installation process, consider a few expert tips to enhance your experience. First, refrain from unnecessary drilling unless modifications are explicitly required. Drilling can compromise the structural integrity of both the frame and the fairing, negating warranties and leading to costly repairs. Secondly, for those new to motorcycle maintenance or handling high-value fairings, it may be wise to seek professional installation. Skilled technicians possess specialized knowledge that can ensure your installation meets the highest quality standards.

In conclusion, mastering the installation of motorcycle fairing mounting brackets not only enhances the motorcycle’s visual appeal but significantly contributes to its performance and safety. Through careful preparation, precise installation, and thorough inspection, riders can confidently enjoy their motorcycles knowing they have taken the essential steps to secure their fairings effectively. For specific models and detailed installation diagrams, consulting manufacturer guides is always recommended as they often offer tailored advice that can vastly simplify your installation experience.

For additional components such as fairings that complement your motorcycle model, consider checking out compatible options at specialized retailers to enhance your ride’s aesthetic and functional aspects.

2. Vigilant Maintenance Techniques for Motorcycle Fairing Mounting Brackets

Motorcycle fairing mounting brackets play a pivotal role in securing the fairing to the motorcycle’s frame, creating a streamlined configuration that enhances both aerodynamics and rider safety. Within the demanding environment of motorcycle riding, these brackets must endure constant vibrations, pressures from wind, and potential impacts from the road. Therefore, establishing and adhering to a comprehensive maintenance regimen is not merely recommended; it is essential for the true performance and longevity of the motorcycle.

Regular inspections of the mounting brackets should be a fundamental part of every rider’s maintenance schedule. This practice should occur at least once every few rides, particularly after long journeys or when the bike has encountered challenging weather conditions. Look for signs of wear, such as cracks, bends, or loosened bolts, that might compromise the integrity of the brackets. Pay careful attention to corrosion, especially if you frequently navigate through rainy or salty environments. Corrosion can significantly weaken metal components over time, leading to failures that could jeopardize your safety on the road. Identifying these issues early can prevent more serious problems down the line.

In conjunction with inspections, it is crucial to regularly check the tightness of the bolts and nuts securing the brackets. Using a calibrated torque wrench, confirm that everything is tightened to the manufacturer’s specified settings. This is not a trivial task; over-tightening can strip threads or deform the brackets, while under-tightening may result in loose fairings—both scenarios can lead to decreased performance and increased risk while riding. Many riders overlook the importance of torque specifications, but adhering to these guidelines is critical for maintaining the structural integrity of the fairing installation.

Cleaning also contributes significantly to the longevity of mounting brackets. Dirt, grime, and road salt can accumulate and hasten the onset of corrosion despite the toughest materials used in bracket construction. Utilize a simple mixture of mild soap and water to gently clean all components regularly. After washing, ensure everything is thoroughly dried to prevent moisture from fostering rust. While routine cleaning may seem trivial, it is a proactive step in safeguarding the functional life of your fairing brackets.

An additional line of defense against potential maintenance challenges is the application of an anti-seize compound or thread locker. These materials are typically suggested by manufacturers and help prevent issues with bolts becoming seized due to corrosion over time. When applying these compounds, a small amount is usually sufficient; it acts as a barrier against moisture and can facilitate easier disassembly during future maintenance. Note, however, that not all applications may require this—check the guidance included with the fairing or the specific hardware. As the old adage goes, an ounce of prevention is worth a pound of cure, and this rings particularly true regarding component longevity.

For those who frequently ride in environments characterized by wet or variable weather conditions, thorough inspection of auxiliary components is equally vital. Installations such as fog light mounting brackets, which may attach to the same areas as the fairing brackets, are often overlooked. These components should not only be securely fastened, but also regularly assessed to ensure that they do not contribute to undue stress on the mounting system. By managing all connected systems, riders can maintain optimal operation and reduce the likelihood of unexpected failures.

In addition to performing these routine checks, it is prudent to consult the manufacturer’s maintenance guidelines specific to your motorcycle model. Many motorcycle manufacturers provide detailed manuals that contain vital information about bracket care, including appropriate torque values and suggested cleaning products. This documentation can also list compatible aftermarket parts should replacements become necessary, a key factor especially for those modifying their motorcycles with new fairings or brackets.

The aim of diligent maintenance practices is not only to enhance performance but also to ensure overall safety while riding. Motorcycles operate in a finely balanced state, and every component—from engine to mounting brackets—plays a role in preserving this harmony. Inadequately maintained fairing brackets can lead to performance disadvantages such as noise increases that affect the riding experience and, more critically, structural failures during operation.

By consistently applying these maintenance practices, riders not only elongate the service life of their fairing mounting brackets but elevate their bike’s reliability, enhancing their overall riding experience. Each preventive action contributes to safer riding, underscores the importance of attention to detail, and ultimately leads to an enriched relationship with your motorcycle.

In summary, engaging in vigilant maintenance techniques for motorcycle fairing mounting brackets leads to greater safety, performance, and longevity. From routine inspections and checks to a meticulous cleaning regimen, these practices champion an approach that prioritizes both reliability and rider safety on the road, making them invaluable not just for the motorcycle but for the experience of riding itself. In this vein, for those seeking to explore high-quality fairings compatible with their motorcycles, a trusted source for additional information can be found in our detailed collection of Honda fairings at Summit Fairings.

3. Navigating Installation Challenges: Troubleshooting Common Problems with Motorcycle Fairing Mounting Brackets

Motorcycle fairing mounting brackets play a pivotal role in ensuring the functionality and aesthetics of a motorcycle’s bodywork. However, the installation and maintenance of these components can often present challenges that riders need to address proactively to maintain both safety and performance. The journey of navigating these challenges can be significantly simplified by understanding the common issues, their causes, and effective solutions that can enhance the longevity and durability of fairing mounts.

One prevalent issue encountered by motorcycle enthusiasts is the occurrence of loose or misaligned brackets. Riders may notice vibrations, unwelcome noises, or even the risk of detachment while riding. Such problems typically stem from improper torque application during installation. Using substandard fasteners can further exacerbate this issue, as lower quality materials are less capable of enduring the forces experienced on the road. To mitigate this concern, it is crucial to use a torque wrench to ensure bolts are tightened according to the manufacturer’s specifications. This attention to detail, combined with the careful alignment of all components before final fastening, can greatly enhance the installation’s integrity. Furthermore, periodic inspections should be conducted to check for wear or deformation in the brackets that could lead to future issues, where any damaged components can be replaced promptly.

Another challenge that motorcycle riders face is corrosion and rust. Such deterioration not only compromises the structural integrity of the brackets but can also lead to catastrophic failures under stress. This issue frequently arises due to prolonged exposure to high humidity environments or road salt, which can accelerate the degradation of metal components. To combat corrosion, applying protective coatings, such as anti-corrosion grease or a layer of paint on metal surfaces, can provide an essential barrier against environmental elements. Riders should also make it a habit to conduct regular inspections during routine maintenance to catch early signs of rust, ensuring that such issues are addressed long before they can escalate into safety concerns.

Additionally, inadequate load distribution represents another significant challenge to the performance of fairing mounting brackets. The symptoms of this issue may manifest as stress fractures or failures over time, particularly in cases where aftermarket accessories extend beyond the original design specifications. This problem usually results from putting excess strain on mounting points due to modifications made to the motorcycle. Riders who seek compatibility with their aftermarket fairings must ensure that the chosen mounting brackets are appropriately rated for the additional load. Implementing supportive measures, such as welding additional support brackets, utilizing higher-grade materials, or redistributing weight evenly across the motorcycle frame, can effectively address load distribution challenges. For instance, using 5mm thick angle steel for reinforcement can significantly enhance the stability of the fairing assembly, thereby prolonging the lifespan of all related components.

Lastly, the impact of vibration-induced fatigue is a common concern, especially for those who enjoy aggressive riding or frequent excursions on rough terrain. Over time, vibrations can degrade bracket performance and lead to a loss of structural integrity. To minimize this risk, it is advisable to incorporate vibration-dampening materials, such as rubber bushings, between the fairing and the bracket. These materials help absorb shocks and vibrations that would otherwise put stress on the mounts. Implementing secure connections without any play in the system is vital, as it significantly reduces long-term wear and enhances the performance of the motorcycle’s fairing assembly.

When tackling these installation and maintenance issues, it is essential for riders to consult official service manuals or reliable technical resources provided by motorcycle manufacturers or certified repair organizations. By doing so, they can ensure that all practices align with the original specifications—serving not only to maintain the aesthetic appeal of their motorcycles but also to safeguard their safety as they navigate the roads.

Overall, addressing common issues surrounding motorcycle fairing mounting brackets can lead to safer, more efficient riding experiences. Whether through understanding the risks of misalignment, combating corrosion, ensuring proper load distribution, or mitigating vibration-related challenges, riders who take a proactive approach can significantly enhance the performance and longevity of their motorcycles. Keeping a keen eye on the details during installation and maintenance will undoubtedly pay off, resulting in a well-fitted, stable, and aesthetically pleasing motorcycle that stands the test of time. For riders looking to explore fairings for various motorcycle models, resources like Summit Fairings can be invaluable for ensuring compatibility and quality, thereby further simplifying the journey of customization and improvement for motorcycle enthusiasts.

Chapter 3: Navigating the Landscape of Motorcycle Fairing Mounting Brackets: Challenges and Solutions

1. Evaluating Fitment and Installation Considerations for Aftermarket Motorcycle Fairing Mounting Brackets

When it comes to enhancing motorcycle aesthetics and aerodynamic performance through aftermarket fairings, the importance of selecting the right fairing mounting brackets cannot be overstated. Riders pursuing modifications typically confront a myriad of fitment and installation challenges. Whether sourcing universal kits or specific model components, understanding how these factors influence the riding experience is crucial.

The Appeal of Universal Fit Kits

Universal fit kits have emerged as a popular solution for those looking to enhance their motorcycle’s fairing attachment. One of the primary advantages of these adjustable brackets is their adaptability to a diverse array of motorcycle makes and models. Using universal kits can streamline installation processes and bolster fairing stability during rides, effectively reducing the potential for vibration-related issues. These kits often incorporate versatile design features that allow riders to customize the installation attributes according to their unique motorcycle setup.

However, while universal brackets promise a degree of convenience, they are not without their pitfalls. An improperly fitted universal bracket can create stress points either on the fairing or the motorcycle frame. Over time, this misalignment can escalate to significant damage, stressing the importance of compatibility over merely opting for a universal solution. Before proceeding with any installation, it is critical for riders to confirm that the bracket design aligns with the specifications of their motorcycle model and year.

Installation Challenges Insider

Installation is another area rife with potential challenges. Riders may underestimate the complexity involved in securing fairing mounting brackets correctly. Many manufacturers provide installation guidelines, including torque specifications, recommended tools, and alignment techniques; however, following these doesn’t always guarantee success. Each motorcycle’s unique geometries must be accounted for, significantly impacting how well an aftermarket solution fits.

Incorrect installation may not only affect performance but could also void any warranties associated with the motorcycle. Many riders overlook this aspect. For instance, drilling into the frame to accommodate a mounting bracket can lead to significant structural integrity issues, triggering repercussions that extend beyond the current modification. Riders must consider such technicalities to avoid unintended outcomes that may hinder riding safety or performance.

The Warranty Conundrum

One of the most pressing concerns surrounding the installation of aftermarket fairing mounting brackets is their potential impact on the manufacturer’s warranty. Many motorcycle brands enforce strict policies regarding modifications that alter the original specifications. As such, if the installation of aftermarket components compromises the OEM design, warranty claims may be denied, potentially leaving riders with hefty repair bills. For those considering aftermarket solutions, exploring how these adjustments may affect coverage becomes critical.

It’s advisable for riders to contact their motorcycle manufacturer or authorized dealer to understand the implications of using aftermarket parts. Often, manufacturers recognize specific aftermarket modifications that maintain warranty integrity; therefore, doing due diligence can save future complications and ensure peace of mind.

Material Matters

The materials used in fairing mounting brackets are equally significant in determining their durability and effectiveness. Riders should conduct thorough reviews of specifications before selecting components. Ideally, high-strength aluminum or reinforced steel is recommended, as these materials offer enhanced resistance to the dynamic loads and vibrations that motorcycles are subject to on the road. The choice of material can directly correspond to the longevity and performance of not only the brackets but also the fairings they support.

For instance, a robust alloy material can absorb vibrations better than a standard plastic alternative, ensuring that the fairing remains both securely attached and aerodynamically efficient. Riders would do well to prioritize not just cost, but durability, to enhance their motorcycle’s performance over time.

Selecting the Right Design

Beyond just materials, the design intricacies of fairing mounting brackets play a crucial role in performance and safety. Opting for brackets explicitly designed for a particular motorcycle model minimizes the need for modifications, fostering a seamless fit that securely attaches the fairing without introducing additional stress. The right design can prevent long-term wear issues and safety hazards, making it a paramount consideration for riders looking to enhance or restore their motorcycle’s aesthetic and functional qualities.

Finding a perfect fit can feel overwhelming amid the myriad of options available in the market. However, resources such as fitment guides can assist riders in navigating these challenges more effectively. For detailed insights on selecting and installing compatible mounting hardware, the Motorcycle Fairing Bracket Fitment Guide serves as an excellent starting point for riders.

Conclusion

In summary, assessing fitment and installation when selecting aftermarket fairing mounting brackets is paramount for ensuring safety, performance, and longevity. While universal kits offer attractive convenience, the compatibility with specific motorcycle models is crucial for avoiding misalignment and damage. Additionally, materials and design should not be overlooked, as they directly impact riding experience. By prioritizing these considerations, riders can confidently navigate the aftermarket landscape and achieve an optimal balance between performance and aesthetic appeal, ensuring that their motorcycle is not just a mode of transport but an extension of their passion and personality.

2. Prioritizing Safety in the Selection of Aftermarket Fairing Mounting Brackets

When engaging with aftermarket options for motorcycle fairing mounting brackets, an unwavering focus on safety is non-negotiable. These brackets perform the crucial role of securing the fairing—an essential part of a motorcycle’s aesthetic and aerodynamic design—directly to the framework of the bike. Given that any failure in this component could precipitate grave consequences not only for the motorcycle itself but also for the rider and passenger, each decision made in this process must be thoroughly considered.

A foremost consideration when selecting these components pertains to material quality. The durability and strength of a fairing mounting bracket are paramount as they absorb significant dynamic forces, particularly during high-speed riding or when encountering bumps and potholes. High-quality aftermarket brackets are frequently constructed from materials like aircraft-grade aluminum or high-tensile steel, known for their exceptional strength-to-weight ratios and resistance to fatigue. Conversely, brackets made from low-grade plastics or substandard metals may compromise integrity, especially in moments of stress. In this regard, it is prudent for riders to verify that any mounts they consider meet or exceed industry standards for both strength and durability.

Equally vital is the precise fit and compatibility of the mounting brackets with the specific motorcycle model and the intended fairing. Every motorcycle is uniquely designed, with particular mounting points tailored to accommodate original equipment manufacturer (OEM) fairing systems. Therefore, when opting for aftermarket brackets, it is crucial to choose models that are engineered for specific makes and models. The use of incompatible or poorly fitting brackets can lead to misalignment, which not only results in an unattractive aesthetic but can also significantly increase wind noise and the vibration experienced by the motorcycle. Moreover, the risk of detachment becomes a genuine safety concern. Reputable aftermarket manufacturers often provide detailed compatibility charts and installation templates, which can greatly assist in ensuring a correct fit.

Furthermore, the secure fastening and adherence to torque specifications cannot be overstated. A safe installation of fairing mounting brackets demands the correct type and grade of fasteners. Fasteners categorized as Grade 8 or above are preferred for their strength. During installation, using a calibrated torque wrench is crucial to uphold the manufacturer’s recommended specifications. Under-torquing the bolts could allow the brackets to loosen with time, thus increasing the chances of bracket failure. On the other hand, over-torquing can result in stripped threads or potential damage to the motorcycle’s frame, which could lead to catastrophic failure of the fairing structure.

Another key aspect to consider is impact resistance and vibration damping. Given that motorcycles encounter constant wind pressure and vary in vibration levels due to road conditions, fairing mounting brackets must be designed to effectively absorb these forces. Quality brackets mitigate the transfer of harsh vibrations to the fairing, diminishing the risk of cracks or structural failures in the fairing material itself. Advanced designs might incorporate rubber grommets or flexible mounts which not only enhance the installation’s durability but also extend the life of the fairing by reducing the cumulative stress caused by vibration over time.

Lastly, one must evaluate whether the selected mounting brackets comply with safety standards. While there may not be specific regulations encompassing fairing brackets alone, adherence to recognized safety standards by manufactures—such as those set by the International Organization for Standardization (ISO) or the Society of Automotive Engineers (SAE)—serves as an indicator of quality and reliability. Components that do not adhere to such standards may pose a higher risk of failure and could ultimately compromise rider safety.

In conclusion, the pursuit of aftermarket fairing mounting brackets is as much about safety as it is about customization and style. The importance of investing in high-quality materials, ensuring precise fitment, adhering to proper installation protocols, and confirming compliance with safety standards cannot be overstated. Every motorcycle enthusiast should prioritize these aspects above short-term savings or aesthetic preferences. Doing so not only preserves the functionality and appearance of the motorcycle but significantly enhances the rider’s safety on the road. Riders are also encouraged to consult resources, such as the guidelines provided by the National Highway Traffic Safety Administration (NHTSA) on motorcycle safety standards, to better understand best practices for modifications. Committing to these best practices is essential for every motorcycle rider, especially those considering the installation of aftermarket fairings and brackets, and ensures a more enjoyable and safer ride on the open road.

For further exploration of motorcycle fairings and their compatibility with mounting brackets, visiting targeted collections, such as those for Honda, Yamaha, Suzuki, and Kawasaki, can provide valuable insights into making informed decisions that align with the unique specifications of their motorcycle models.

3. Enhancing Motorcycle Performance and Visual Appeal with Aftermarket Fairing Mounting Solutions

Aftermarket motorcycle fairing mounting brackets, such as the popular XFMT Motorcycle Front Fairing Support Bracket Mount Kit, play a crucial role in bolstering both performance and the visual aesthetics of motorcycles. For many riders, making the transition to aftermarket options represents not just a necessary upgrade, but an opportunity to personalize their bike while ensuring optimal functionality.

The construction and design of these brackets are often superior, crafted from high-quality aluminum, which offers an impressive strength-to-weight ratio. This material choice not only ensures the durability of the brackets but also contributes significantly to the overall weight management of the motorcycle. Each bracket typically features a sleek black finish, enhancing the modern look that seamlessly integrates with various motorcycle designs. Additionally, this finish provides a layer of protection against corrosion, ensuring that the motorcycle maintains its fresh appearance over time.

A key component of the mounting kit includes left and right fairing supports, which promote balanced support for the fairings. This symmetry not only contributes to a polished, factory-finished aesthetic but also serves a functional purpose. Uneven mounting can lead to misalignment, which not only detracts from the bike’s appearance but can also affect aerodynamics and performance.

When it comes to performance enhancements, the role of aftermarket fairing mounting brackets extends beyond mere aesthetics. These components provide secure fitment for essential accessory systems, such as tip-over protection. This added feature serves as a safeguard for the motorcycle’s front end and fairings during minor crashes or when the bike leans unexpectedly on uneven surfaces. A solid, well-designed mounting bracket minimizes movement, leading to reduced vibration and consequently enhancing rider comfort and safety across a range of riding conditions.

Moreover, the engineering behind these brackets often takes into account the provisions for various riding styles and bike modifications, catering to both urban street riding and high-speed maneuvers. The secure placement of the fairing helps manage airflow, reducing turbulence that can cause unwanted noise and instability at higher speeds. Riders can then navigate their motorcycles with greater confidence, knowing that their fairings—secured by high-quality brackets—are less likely to loosen or shift in unpredictable conditions.

For riders who are keen on individualizing their motorcycles, style plays a significant role. Aftermarket fairing mounting brackets elevate the visual aspect of a motorcycle. They allow riders to achieve a number of looks, from aggressive street bike aesthetics to sleek touring designs. The polished allure of robust aluminum combined with innovative designs can significantly amplify the motorcycle’s appeal, ensuring it stands out in a crowd. This visual enhancement often goes hand-in-hand with the character of the motorcycle, allowing owners to express their unique style and riding preferences.

Selecting the right aftermarket fairing brackets goes beyond mere compatibility. Riders must consider the integrated design features that can streamline the installation process, often including thorough installation instructions and the required hardware. For successful installation, attention to detail is paramount. Incorrectly mounted brackets can lead to major issues such as wind noise, fairing vibration, or even safety concerns due to loose fittings. Many manufacturers are cognizant of these challenges and provide warranties alongside their products, underscoring their commitment to quality.

Furthermore, the availability of replacement brackets caters to those who might damage original components during a ride or maintenance. Having access to quality replacements not only alleviates the downtime associated with repairs but also ensures that the motorcycle remains in peak operational condition. Providers such as established motorcycle accessory brands offer these replacement parts, often with extensive customer service support to guide riders through compatibility and installation.

In the realm of aftermarket options, compatibility is essential. Riders are encouraged to utilize mounting brackets specifically tailored for their motorcycle model, as universal parts may not deliver the desired fit or performance. Models such as those from Honda, Yamaha, and Suzuki have dedicated aftermarket options designed to complement factory fairings and accessories while enhancing overall functionality. For instance, those exploring options like the Honda CBR series can find specifically designed fairings and mounting solutions that align perfectly with their motorcycle’s unique geometry.

In conclusion, opting for aftermarket motorcycle fairing mounting brackets is a worthwhile investment for riders seeking to enhance performance and aesthetics alike. With thoughtful engineering and specialized designs, these components do not only improve stability and strength but also contribute significantly to the overall ride experience. For engaged motorcycle enthusiasts, bettering their machines with high-quality mounting solutions fosters a harmonious blend of safety, suitability, and individual style, ultimately allowing each ride to be as thrilling as it is visually captivating.

Final thoughts

Motorcycle fairing mounting brackets play a vital role in ensuring that fairings are securely attached to the motorcycle, which is critical for both aesthetics and safety. Understanding the design specifications, installation processes, and availability of high-quality aftermarket options can empower businesses in the motorcycle industry to offer valuable insights and products to their customers. As this article has highlighted, attention to detail in each of these areas not only enhances performance but also reinforces rider confidence on the road. By investing in quality parts and maintaining proper installation practices, businesses can ensure customer satisfaction and fuel loyalty in a competitive market.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.