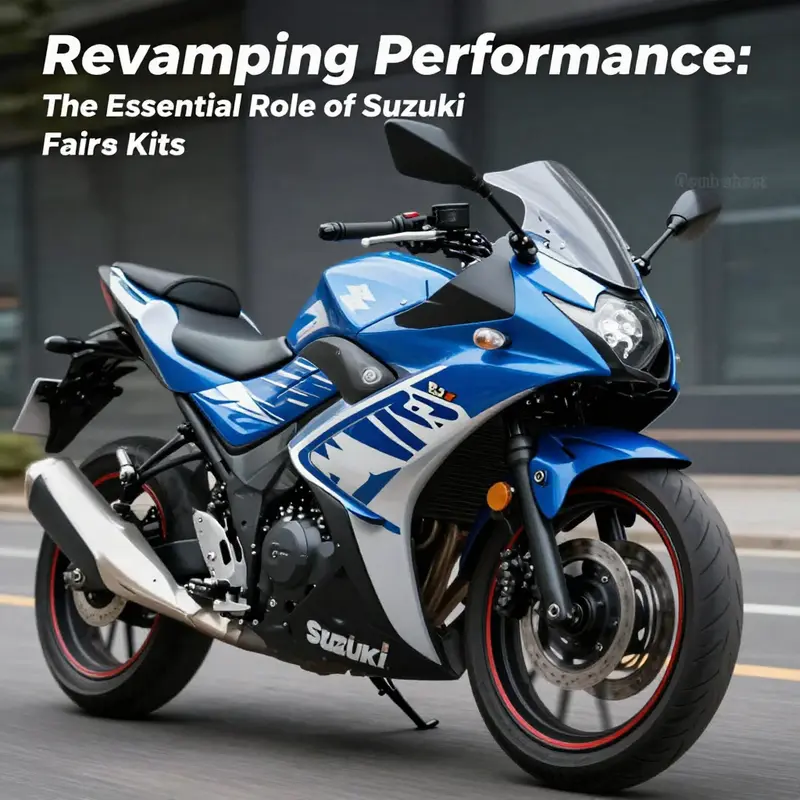

Suzuki motorcycle fairing kits not only revamp the visual appeal of your bike but also significantly enhance its aerodynamics and overall performance. These kits are composed of body panels and other components that seamlessly fit your model, minimizing installation hassles while maximizing style and functionality. Business owners in the motorcycle industry can leverage this information to cater to the rising demand for performance-driven enhancements. This article will delve into the importance of fairing kits, the quality and durability of materials used, and effective sourcing and purchasing methods from trustworthy suppliers to ensure the best options for your clientele.

null

null

Armor in the Wind: The Material Science Behind Durable Suzuki Fairing Kits

Durable fairings do more than just shield the engine from wind and debris; they shape the riding experience in real time. When a rider leans into a long highway curve or threads through tight urban corridors, the material that covers the bike becomes a partner in performance. The chapter that follows threads together how material quality and design durability influence not only aesthetics but also aerodynamics, safety, and long-term reliability of Suzuki fairing kits. It starts with the most common materials—ABS plastic and fiberglass—and moves through the practical implications of their properties, the finishing processes that defend against the sun and the road, and the realities of installation and maintenance that determine how a kit performs in daily life. The aim is to illuminate why some kits feel more factory-like in their fit and finish, while others offer customization latitude at the cost of additional care. In the end, the distinction often comes down to the balance of three values: precise fitment, UV-resistant coatings, and robust construction that remains reliable through miles of riding and weather exposure.

Absorbing sunlight and heat without warping, ABS plastic has become the backbone of most factory-style fairings and many aftermarket variants. Its appeal rests on a mix of toughness, elasticity, and cost efficiency. ABS is renowned for its impact resistance in the face of small road hazards, which translates to fewer cracks when a wheel kicks up a stone or when a rider discovers a late brake line in a corner. The elasticity of ABS also helps it recover from minor deformation, a property that matters when fairings are subjected to occasional drops or minor impacts. UV tolerance is critical in open riding environments; mismanaged UV exposure can cause chalking, chalking can dull color, and fading can reduce the perceived quality of the entire kit. The market has responded by layering color with clear coats that add scratch resistance and extend the panel’s life without altering the underlying structural integrity. These coatings are not merely cosmetic; they are part of the protective system that shields the fairing from fatigue caused by sun, wind, rain, and road salt. A well-applied multi-layer finish also supports paint adhesion and resists micro-scratches that accumulate over thousands of miles. When these coatings are combined with an injection or extrusion process designed to achieve a smooth internal surface, ABS panels can offer a near-OEM silhouette that minimizes the need for bespoke fitting.

From a design perspective, ABS-based kits emphasize precision and compatibility. The molded shape is produced with tight tolerances to align with the bike’s frame points, mounting holes, and edge lines. A kit that adheres to OEM-like standards typically features pre-drilled holes that align with factory hardware and panel contours that mirror the bike’s natural lines. The practical impact of fitment is simple but meaningful: fewer modification steps, reduced installation time, and improved airflow. When the panels align cleanly, the resulting aerodynamics contribute not only to a visually clean silhouette but also to rider comfort by reducing turbulent air near the rider’s chest and shoulders. This is especially significant on longer rides, where even minor drag can amplify fatigue. It also helps protect internal engine components and the radiator shroud from stray debris, since a snug fit reduces exposed gaps where dirt and moisture could accumulate.

Fiberglass, while less common in standard factory offerings, enters the discussion as a material of choice for riders seeking stiffness, customization potential, and lighter or unusually contoured shapes. Fiberglass is intrinsically strong in its rigidity, which can be advantageous for high-speed stability and for creating aerodynamic profiles that push the envelope. The stiffness makes it easier to sculpt complex curves and forms that might be impractical with softer plastics. For advanced riders building track-focused machines or personalized street machines, fiberglass can accommodate aggressive geometries, aggressive fans of aero vents, and intricate detailing that demands precise shaping. Yet, fiberglass is heavier than ABS and more demanding in the finishing process. When a fiberglass panel takes a sharp impact, the risk of cracking increases if the layup is not properly reinforced. Repairs typically require skilled craftsmanship, including careful sanding, resin re-bonding, and careful repainting to restore color match and gloss. Because of its nature, fiberglass demands a finishing discipline that ensures paint adhesion is consistent and uniform across all surfaces, corners, and edges. In practice, fiberglass kits often appear on projects where riders want maximum rigidity or unique aerodynamic features, and where the builder is prepared to invest additional time and expertise into finishing and maintenance.

The choice between ABS and fiberglass is rarely a simple one, because it hinges on the rider’s priorities. Daily riders who value predictable service, lower initial cost, and less maintenance tend to favor ABS-based kits. These panels excel in durability under normal riding conditions, resist fading with UV protection, and support a broad ecosystem of aftermarket fasteners and hardware that ensures reliable mounting. For riders who insist on high rigidity for extreme aero profiles, or who pursue highly customized appearances that require unusual panel forms, fiberglass can be a compelling option. It is essential to recognize that even within the same material family, the quality of the manufacturing process matters just as much as the base resin. A kit fabricated with a controlled lamination process, a balanced fiber-to-resin ratio, and reinforced edges will perform more consistently under heat stress and vibration.

A critical aspect that threads through both materials is the coating strategy. UV resistance is not a luxury; it is a functional requirement that preserves color fidelity, prevents surface chalking, and maintains gloss under sun exposure. Multi-layer clear coats, when properly cured, serve as a sacrificial shield against abrasion and weathering. They also provide a platform for color accuracy and depth that helps the fairing integrate with the rest of the bike’s paint scheme. The clarity and hardness of the clear coat influence scratch resistance and ease of touch-ups after a run through a gravel patch or a stray brush with a branch along a rural road. For ABS, the coating system often needs to be compatible with the substrate to avoid solvent attacks that could soften the surface or cause micro-crazing. In the fiberglass path, coatings must bond to the resin-rich surface and be flexible enough to accommodate micro-movements without cracking, which often requires surface treatments and primer systems designed to optimize lay-down and adhesion. In both paths, the quality of the finish affects not only aesthetics but the long-term maintenance burden; a poor finish invites faster wear, more frequent refinishing, and a higher risk of moisture ingress behind a chipped edge.

The durability story extends to the installation experience. A well-engineered kit minimizes the number of modifications needed for the panels to sit flush. This is not just about the look; it’s about predictable aerodynamics. When panels align with frame lines and with each other, air streams maintain smooth transitions across the fairing, reducing buffeting and the fatigue that can travel through the rider’s wrists and shoulders on long rides. A precise fit also reduces the likelihood of rattling at speed, a byproduct of gaps that catch wind and amplify vibration. The hardware itself—screws, bolts, grommets, and spacers—plays a supporting role in durability. High-quality fasteners resist corrosion, maintain clamping force over time, and avoid haloed rings where a screw head rubs against a sharp edge. On a practical level, a credible kit will come with the correct hardware kit or a reliable reference for replacement parts, which helps riders keep the fairing secure after years of riding through different climates.

The conversation about material quality would be incomplete without addressing the safety dimension. A fairing panel that remains coherent after a minor impact can still protect more sensitive systems, such as internal cabling and the radiator shroud, from exposure to debris or weather. In track environments, where the risk of impact and abrasion is higher, the choice of a stiffer, more damage-tolerant material can influence not only performance but the rider’s willingness to push into corners with confidence. Equally important is the way the panel behaves under heat and sunlight, because extreme heat cycles can lead to warping or flexural fatigue if the lamination and resin systems are not up to the task. A well-made kit will feature a design that distributes stress, including reinforced edges and properly dimensioned wall thickness that helps resist deformation while maintaining the intended aero shape. The overall durability thus becomes a combination of material properties, manufacturing precision, and thoughtful finishing tactics that preserve both form and function over time.

In evaluating a Suzuki fairing kit for durability, a rider can look for several indicators of quality beyond the surface gloss. A kit that advertises an OEM-style fitment usually signals a high degree of precision in the molding and panel geometry. The presence of UV-stable coatings and a multi-layer clear system is another sign of robust protection against sun and weather. The use of heat-shield technology or heat-tolerant resins can indicate a kit designed to withstand higher operating temperatures without softening or warping. For riders who demand customization, the possibility of careful refinishing and color-matching is a bonus, as long as the underlying materials can take the paint and polish without delamination. In contrast, a budget option that promises a perfect look but relies on thin coatings and loose tolerances may save money upfront but could lead to ongoing maintenance costs, misalignment, or recurring repairs.

The broader ecosystem around fairing kits also informs durability expectations. Reputable suppliers emphasize consistent material quality, transparency about coatings, and the availability of compatible mounting hardware. Clear documentation on molding procedures, resin systems, and acceptance testing provides reassurance that the panels are engineered to endure. The best outcomes arise when a kit is designed with the same attention to detail that a factory would apply to a new model—precise fit, UV-resistant protection, and durable construction that gladly bears the rider’s miles rather than demanding constant attention. To connect this idea with practical choices, consider exploring the Suzuki fairings collection to see how current offerings balance form and function across different styling directions. Suzuki fairings collection

In the end, the material quality behind Suzuki fairing kits is more than a technical footnote. It is a hinge point that determines how a rider will experience the bike over the long haul: the smoothness of the airflow, the ease of maintenance, the resistance to weather, and the sense of confidence that comes with a panel that feels integrated rather than bolted on. The best kits honor the rider’s time and ride through a design language that respects the bike’s original silhouette while offering the durability needed for real-world conditions. They achieve this through a thoughtful combination of material choice, manufacturing rigor, and protective finishing. The material decision—the choice between ABS plastic and fiberglass—maps onto a rider’s priorities: practical daily durability and ease of maintenance on one side, or maximum rigidity and customization potential on the other. Either path can deliver a compelling upgrade when paired with careful installation and ongoing care. In this way, the material science behind durable fairing kits echoes a larger truth about motorcycle customization: longevity and performance arise from attention to detail at every stage, from resin chemistry to the final gloss.

For readers seeking deeper technical insight into material properties, consult the MotorCycleTech Journal’s Suzuki fairing material properties guide, which offers a detailed look at the performance metrics discussed here. External resource: https://www.motorcycletechjournal.com/suzuki-fairing-material-properties

null

null

Final thoughts

Investing in high-quality Suzuki motorcycle fairing kits offers not only aesthetic enhancements but also contributes significantly to the performance and longevity of motorcycle components. The choice of materials and design plays a crucial role in optimizing rider comfort and bike functionality. Furthermore, selecting reliable suppliers for these kits ensures that you offer your customers the best available options, enhancing their overall riding experience. By embracing these insights, motorcycle business owners can position themselves as trusted sources in the growing market for performance accessories.