Tail fairings are essential accessories for modern motorcycles, offering significant advantages that appeal to both performance-minded riders and aesthetic enthusiasts. By integrating cutting-edge materials and designs, these components not only improve aerodynamics and fuel efficiency but also elevate the motorcycle’s overall look. Each chapter delves into specific aspects: Chapter One examines how tail fairings enhance performance through better aerodynamics; Chapter Two discusses the various design and customization options available; and Chapter Three explores the economic factors influencing tail fairing production and the current market trends, providing a holistic understanding of these vital motorcycle accessories.

Tail Fairings in Modern Motorcycling: Aerodynamics, Protection, and Style

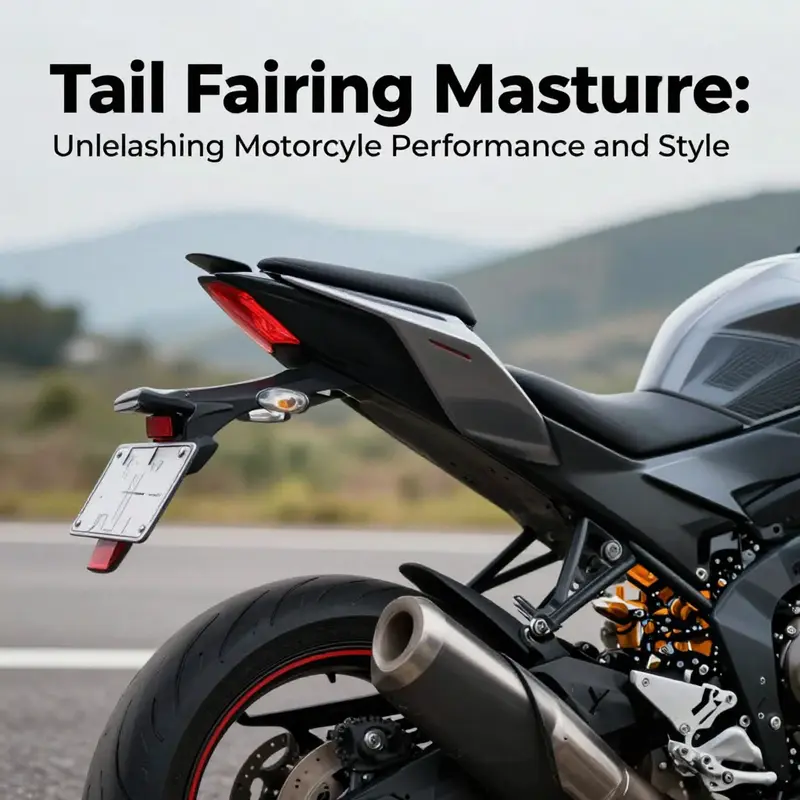

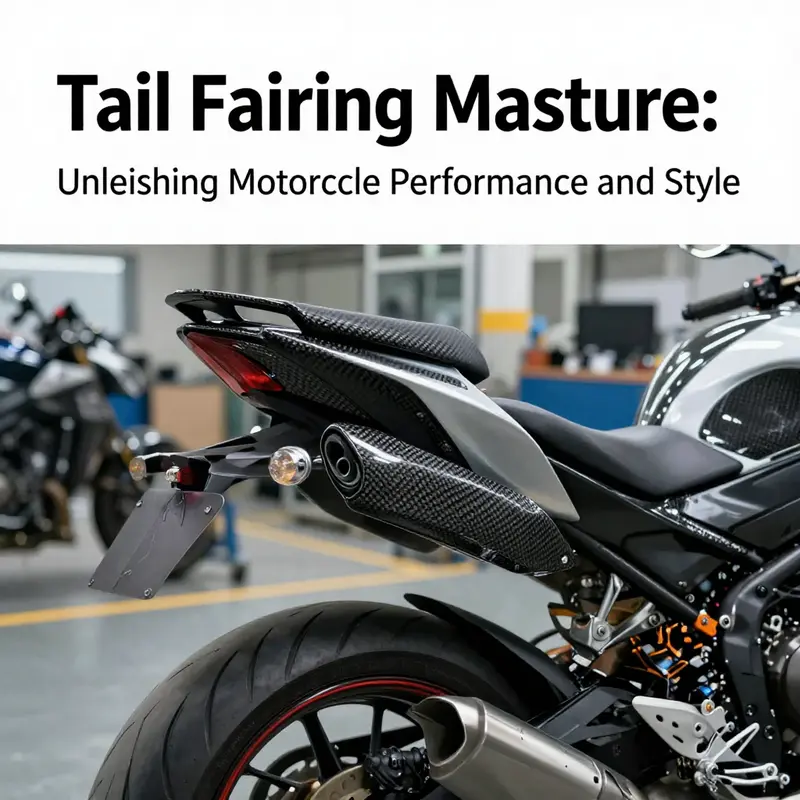

The tail of a motorcycle is more than a cosmetic flourish or a simple containment for the seat and taillight. It is a carefully engineered interface where aerodynamics, structure, and aesthetics meet in a single, integrated form. A tail fairing, in its many configurations, performs a disciplined set of tasks that echo the demands of speed, efficiency, and rider comfort. By shaping the airflow behind the rider and around the rear wheel, tail fairings reduce drag, stabilize the machine at speed, and contribute to smoother wind pressure against the rider’s torso. When a tail fairing is well designed, its influence is not merely cosmetic; it translates into practical benefits such as improved fuel economy on long highway stints, reduced rider fatigue on extended sessions, and a more cohesive silhouette that emphasizes the bike’s purposeful lines. This is why tail fairings have moved from being optional add-ons to near essential components in both performance-focused builds and showroom-oriented street machines. The implications ripple through the bike’s handling, weight distribution, and even the perception of speed itself, making the rear end a strategic playground for engineers and riders alike.\n\nThe aerodynamic role of a tail fairing begins with the recognition that the rider and seat do not exist in isolation. The rider creates a high-pressure wake downstream, and the tail fairing acts as a structured drag-reducing surface that directs this wake away from the vulnerable undercarriage and wheel path. In high-speed cruising, where the rider’s body may present a blunt obstacle to the airstream, the tail’s shape encourages a cleaner separation of flow and helps manage turbulent pockets that would otherwise induce buffeting or slow the overall stability of the chassis. A well-executed tail profile can also influence the pressure distribution near the rear of the bike, reducing the tendency for the tail to lift or to experience flutter in gusty winds. Even on machines designed for aggressive riding, the rear fairing contributes to a sense of planted confidence, giving the rider a feeling of control that is reinforced by the machine’s steadier windswept stability. In practical terms, the drag reduction translates into measurable gains—slightly lower engine load at highway speeds, less fuel burned to overcome wind drag, and minute, but real, improvements in range. That is not to say a tail fairing will magically overhaul a bike’s performance envelope, but it does create a more favorable aerodynamic canvas upon which the engine and chassis work together.\n\nThe materials chosen for tail fairings reinforce the aerodynamics while preserving or enhancing strength and lightness. Carbon fiber has become the benchmark for those chasing top-tier performance, thanks to its stellar strength-to-weight ratio and its ability to hold finely tuned airfoil shapes under load. When carbon fiber is employed, fairings can be engineered with an exquisite balance of stiffness and flexibility to withstand road chatter and minor impacts without compromising the aerodynamics or finish. Yet carbon fiber is not the only viable option. High-strength fiberglass or advanced composites can offer excellent impact resistance at a lower cost, while still enabling precise, pre-drilled fitment and robust surface finishes. The choice of material then informs the manufacturing approach. Autoclave curing, for instance, enables the layup to achieve near-void-free laminates with tight tolerances, producing a surface that mirrors the intended aerodynamic contour with minimal need for corrective work after molding. Hot pressing and other resin-rich methods also have their merits, offering rapid production cycles and consistent results when scaled to aftermarket volumes. The resulting tail fairing must not only blend into the bike’s lines but also resist environmental exposure—UV, rain, and road salt—without suffering color degradation or micro-cracking that could undermine the finish.\n\nBeyond the raw materials, the fidelity of fit and the precision of the aerodynamic profile are driven by meticulous tolerances. A tail fairing pre-drilled for mounting and designed to match the bike’s native bodywork creates a factory-like integration, preserving the aesthetic language of the stock design while yielding tangible performance gains. Precision fitment matters for a cohesive look and for the fairing’s aerodynamic role. A gap or misalignment can act like a small wingtip, introducing unpredictable turbulence. This is why quality control around the assembly of tail fairings—down to surface texture and edge radius—is as critical as the shape itself. When manufacturers pursue OEM-grade standards, they often adopt rigorous quality-management frameworks that echo automotive norms. Certifications and process controls signal that the tail fairing’s performance is reproducible under the stresses of real-world riding conditions, from smooth highway stretches to bumpy backroads and race-track heat. The sense of reliability that comes with a well-made tail fairing is not just about the look; it is about predictable behavior, repeatable aerodynamics, and the rider’s confidence in the machine.\n\nThe functional story of tail fairings also embraces protection and practicality. A rear fairing serves as a shield for the critical components tucked beneath and around the tail section. Debris kicked up by the rear wheel, weather exposure, and minor impacts from road debris can all take a toll on the exposed rear structure. A properly designed fairing provides a sacrificial layer that helps extend the life of the underlying frame and components. In addition, tail fairings often incorporate or accommodate features such as mounting points for luggage carriers, license plate holders, or integrated lighting and reflectors. These features are not merely conveniences; they contribute to the overall system integrity. When integrated thoughtfully, a tail fairing can offer lightweight storage solutions or mounting points that preserve the bike’s center of gravity and maintain the clean, uninterrupted lines that matter for both aerodynamics and aesthetics. Riders who undertake longer trips or who enjoy track days value the combination of protective coverage and the capability to add practical accessories without interrupting the fairing’s curvature or its airflow-guiding function.\n\nThe aesthetic aspect of tail fairings should not be dismissed. The rear of a motorcycle is seen as a punctuation mark, a finishing flourish that communicates speed, precision, and intention. The tail’s geometry—whether it curves smoothly into the seat area, taps into a sharp trailing edge, or employs subtle spoilers or scoops—has a direct impact on the eye and on the perceived performance of the machine. The surface finish plays a part as well. Glossy, matte, or satin textures interact with light to emphasize the film-like quality of the air’s surface as it flows along the fairing. Color options and surface treatments are not mere vanity; they let riders align the bike’s appearance with their personal style while keeping the aerodynamic contour intact. A tail fairing that respects the bike’s original design language—and adds subtle cues of speed without compromising silhouette—achieves the most convincing balance between function and form. The best examples of tail fairings do not shout with loud shapes; they whisper through clean lines, consistent edge radii, and careful transitions from the main body to the tail that preserve the visual cohesion of the whole motorcycle.\n\nFor riders who crave high-performance upgrades, the narrative becomes a study in weight management and surface accuracy. Full carbon fiber tail fairings offer the most dramatic gains in lightness and stiffness, enabling sharper handling through lower inertia in the rear. The lower mass affects not just acceleration but also the way the bike behaves when mid-corner weight transfer occurs and the tail fairing contributes to the total angular momentum of the bike. The stiffness of the carbon laminate supports an accurate aero profile even when the bike is pushed near its limits, ensuring that the intended airflow pattern remains stable under load. Manufacturing choices like autoclave curing contribute to part consistency, so every fairing mirrors the same thickness, curvature, and surface tension across batches. The result is a tailored, race-ready feeling that a rider can perceive in the way the bike boots out of corners and into acceleration with a minimal loss of energy to drag. This is the essence of premium performance in tail fairings: the marriage of a light and stiff structure with a design that respects and enhances the machine’s indigenous aerodynamics.\n\nYet performance is not the sole driver of tail fairing decisions. Riders who value long-distance comfort and reliability may opt for fairings that emphasize durability, weather protection, and pragmatic mounting options over extreme lightness. In these builds, fiberglass-reinforced composites or resin-rich boards can offer a resilient, cost-conscious alternative that still respects the bike’s aesthetics. The difference in ownership experience is tangible; a fairing built to withstand repeated zipping through wind and rain while remaining stable and easy to clean demands only routine maintenance rather than rework after a season of rough use. The choice between materials, and the attention to finish quality, ultimately reflects how a rider envisions the bike’s role: as a highway companion, a track-day partner, or a statement of personal style. In each case, the tail fairing is not a separate accessory; it is a crucial element of the machine’s equilibrium, a component that affects the rider’s sense of gravity, speed, and control while meeting the practical realities of road conditions and weather exposure.\n\nThe aftermarket landscape around tail fairings has grown to accommodate a wide spectrum of riders, from budget-conscious enthusiasts to meticulous builders chasing perfection. Market availability is broad, with various manufacturers offering different shapes, finishes, and installation approaches. The choices can be shaped by the rider’s goals—whether seeking a near-OEM look, a race-ready profile, or a unique aesthetic that signals a rider’s identity. For some collectors and track enthusiasts, the option to source a tail fairing from suppliers that emphasize autoclave-cured carbon fiber and precision-fit components becomes a value proposition that blends performance with a high-quality surface finish. For others, a more affordable fiberglass option that can be quickly swapped during maintenance cycles or after a track day may be more appropriate. In either case, the tail fairing is a fundamental mechanism that shapes how a bike interacts with air, how it looks when parked, and how it feels once the rider is on the move.\n\nThe integration of tail fairings with other components of the bike’s bodywork is a delicate orchestration. Designers aim to preserve the factory feel—where lines, junctions, and edge radii flow as a single design language—while creating clear improvements in airflow management. The result is not a tabula rasa replacement but a refined evolution. When issued as a complete system, a tail fairing complements the tail section, the tail light, and the rear fender, producing a net effect on aerodynamics, weight distribution, and the rider’s silhouette. In this light, tail fairings can be viewed as a form of advanced charioteering, where every contour is chosen to optimize the ride. The rider then experiences the result as reduced fatigue, steadier handling at high speeds, and a sense of riding within a precisely tuned machine rather than a generic bike with a cosmetic add-on. The artistry lies not only in the curvature but in the disciplined approach to construction, alignment, and finish that makes the tail fairing look like an integral part of the original design rather than an afterthought.\n\nFor readers exploring real-world options, the landscape offers a spectrum of choices. The broadest lessons come from recognizing that the tail fairing is both an engineering and design problem. It requires careful consideration of material properties, manufacturing capabilities, and the intended riding context. Whether the goal is to preserve a pristine showroom look, to chase measurable aerodynamic improvements, or to build a rugged, weather-ready touring machine, the tail fairing serves as a focal point where function meets form. In the end, the decision rests on balancing performance, cost, and visual integration with the bike’s overall character. The tail fairing, properly executed, is not a mere enclosure; it is a statement of intent—about speed, efficiency, protection, and personal expression—carried forward by the rider into every mile of road and every fraction of wind it faces.\n\n[Kawasaki-Ninja-ZX-14R-Fairings-2006-2011] discussion of high-end carbon fiber tail fairings has become a benchmark in the performance segment, and while the precise models and numbers may vary, the underlying engineering philosophy remains consistent: a lightweight, aerodynamically tuned rear surface can meaningfully influence the bike’s behavior at speed. Within this framework, the tail fairing emerges as a critical component—one that pilots the intersection of air, chassis dynamics, and human will. The ongoing evolution in materials science, manufacturing accuracy, and finishing processes promises continued gains, inviting riders to rethink the rear end not as a bystander to speed but as an active accelerator of it. And while the market will keep offering new shapes, textures, and finishes, the core principle endures: a tail fairing that respects the airflow, reinforces protection, and honors the visual language of the bike will always stand as a hallmark of thoughtful engineering and refined riding experience.\n\nFor readers seeking additional context on how tail fairings sit within the broader spectrum of motorcycle accessories, you can explore related developments in the aftermarket ecosystem and how these components interface with other bodywork elements. The ecosystem thrives on the intersection of wind tunnel-inspired design, practical protection, and the desire for personal expression, which together drive ongoing innovation in tail fairing technology and its application across rider communities. An understanding of these dynamics helps riders choose products that not only fit their bike but also enhance the ride, yielding a coherent, efficient, and visually compelling machine that performs as well as it looks.\n\nExternal reference for further exploration: https://www.aliexpress.com/popular/pillion-passenger.html

Shaped for Style and Speed: Designing and Personalizing Tail Fairings on Modern Motorcycles

A tail fairing is more than a simple cover for the bike’s rear. It is a visual statement and a functional partner that completes the machine’s silhouette while contributing to the way air flows around the rider and the chassis. In the world of motorcycle aesthetics, the tail section is where design language, engineering intent, and rider identity converge. A well-crafted tail fairing reads as an extension of the bike’s line work, echoing its personality from taillight to tail cowl, and it does so with a precision that blends form with performance. The result is not only a look but a felt experience—the way light catches the surface, the way the curve reveals itself in motion, and the sense of air meeting a carefully sculpted edge rather than a blunt appendage. This chapter invites you to travel through the aesthetics of tail fairings, to see how raw materials, finishes, and customization options translate into a rider’s personal narrative without losing sight of the subtle aero logic that sits beneath the eye-catching surface.

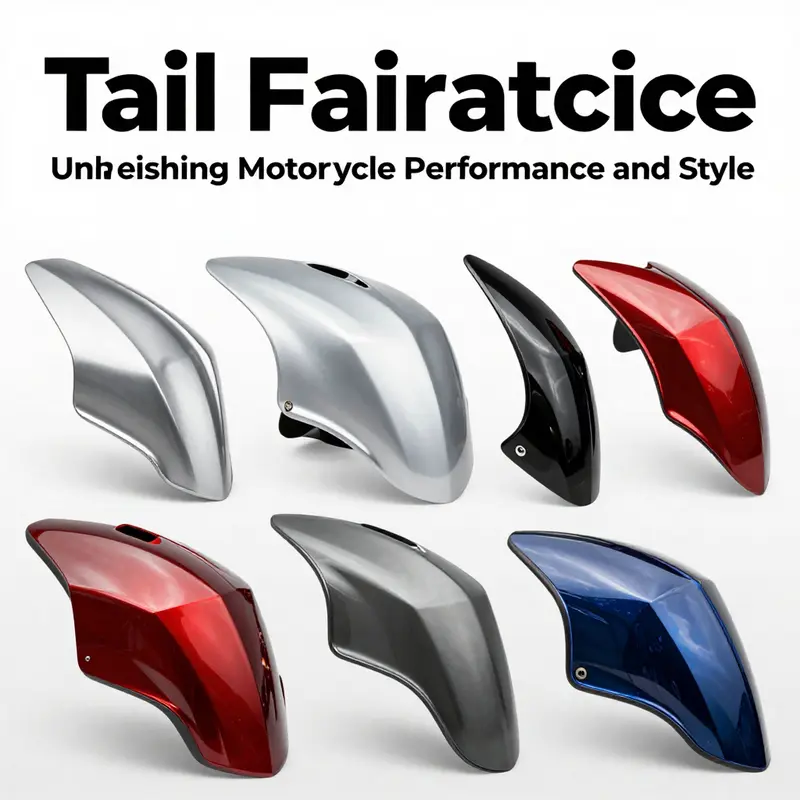

Material choices are the first language of tail fairing aesthetics. Carbon fiber, with its characteristic weave and light weight, has become the preferred material for riders who want a blend of rigidity and sculpture. Its natural sheen and texture invite close inspection, and the way it catches light can elevate a bike’s presence on the street or on the track. But carbon is not the only path to style. High-strength plastics like ABS remain popular for their impact resistance, manufacturing flexibility, and glossy or matte finishes that can be tailored to a wide spectrum of color and texture. The tactile feel of a well-finished ABS tail is almost as important as its color: a fairing that responds with a satisfying snap when the rider runs a gloved finger along its edge signals that the product has been engineered with care. Different manufacturing routes also influence the final aesthetic. Autoclave curing for carbon parts, for example, yields a smooth, uniform surface with fewer resin-rich blemishes, while hot-press methods for fiberglass or composite blends can deliver sharp lines and a tactile rigidity that reads as precision craftsmanship. The choice of material and process becomes a design decision in itself, shaping not just how a tail fairing looks, but how it ages, how it feels under the touch, and how it holds up as wind, heat, and road grime accumulate.

Beyond the material, the geometry of the tail fairing writes its own story. Designers work to create an aerodynamic profile that invites the eye to follow a single, uninterrupted path from the rear edge of the seat to the tail tip. A smooth, continuous curvature can emphasize a sportbike’s lean proportions, while a more angular shell can reinforce a race-inspired aggression. The profile is influenced by the bike’s original architecture, but skilled customization allows the tail fairing to extend that architecture in new directions. Some riders favor minimalist, tight forms that echo the bike’s stock language, while others opt for more dramatic, sculpted rear bodies that exaggerate the sport lineage and give the silhouette a sharper, more assertive bite. The goal is to achieve a cohesive integration—so the fairing does not feel like a borrowed add-on but a natural extension of the motorcycle’s anatomy. This visual cohesion is what makes a tail fairing look as if it belongs to the machine rather than as if it has been bolted on afterward.

Color, coating, and surface texture are the most immediate levers of personality. A color-matched tail can pull the whole bike into a single tone, offering a quiet, elegant update that respects a factory look while delivering a refined uniqueness. Matte finishes tend to soften edges and convey a modern, understated vibe, while glossy coatings heighten contrast and depth, making the contours pop under showroom lighting or street dusk. Satin finishes strike a balance, leaning toward durability while preserving the subtle play of light across the panel’s surface. The surface texture is not merely decorative; it can influence perception of size and proportion. A satin or gloss sheen can accentuate a long, uninterrupted line, whereas a textured finish adds a tactile note that can feel more robust and race-ready. Subtle decals or skin-like graphics can be integrated as well, providing a touch of personality without overpowering the bike’s overall architecture. Though these elements are frequently pursued for personal expression, they also have practical implications: certain coatings can resist road grime more effectively, and color choices can influence heat absorption in hot climates, providing small but meaningful comfort gains during long rides.

Integrated lighting has emerged as a compelling intersection of aesthetics and utility. LEDs embedded in tail fairings offer a contemporary look that signals modern, high-visibility appeal and can accentuate the tail’s lines when riding at night. Lighting details—whether clean strips along the edge or discrete clusters that illuminate the fairing’s inner geometry—can be tailored to align with the motorcycle’s lighting language. The result is a more cohesive nighttime presence that remains faithful to the bike’s identity while enhancing rider conspicuity. When lighting is woven into the tail’s design, it is essential that the electrical routing and heat management are treated as design considerations, not afterthoughts. A well-integrated lighting solution reads as deliberate engineering rather than a patchwork improvement, contributing to a sense of completeness and craftsmanship.

The conversation about aesthetics inevitably meets performance when the topic turns to airflow and stability. A tail fairing’s contours influence the wake that forms behind the rider, shaping how air flows along the bike’s rear half. A clean, well-contoured rear can reduce turbulent eddies, which in turn contributes to smoother handling and reduced buffeting at higher speeds. The visual drama of a racing-inspired tail often mirrors its aerodynamic intent: a straked, sculpted rear that looks fast even when the bike is parked may signal a deeper aerodynamic philosophy at work. Yet the real gains are nuanced. For most riders, the top speed uplift from a tail fairing is modest, but the subtle improvements in airflow can translate into steadier stability during corner exits, gentler wind pressure on the rider, and more predictable behavior in gusty conditions. Aesthetics and aerodynamics thus converge: the tail fairing becomes a visual cue to the rider’s confidence in handling and a practical ally in control.

In practice, choosing a tail fairing is an exercise in balancing aesthetics, compatibility, and protection. For any rider, a tail must fit the machine’s frame lines, align with mounting points, and clear other components such as the seat and exhaust. The pre-drilled holes and standardized mounting interfaces that come with many aftermarket options are not mere conveniences; they are design features that preserve the bike’s integrity and maintain predictable, repeatable fitment. When a tail fairing is designed with precise tolerances, installation becomes a confident process rather than a guessing game, and the likelihood of rattles or misalignment drops considerably. Compatibility across model years and variants is a practical concern as well. The best designs anticipate the evolving geometry of modern motorcycles, offering a snug fit that respects the rider’s sense of quality and the bike’s aerodynamic intent.

Aesthetics, however, is not a solitary pursuit; it thrives in a broader customization ecosystem. For riders who want a deeper bond with their machine, tail fairings open a doorway to bespoke identity. The customization journey often begins with a clear design intent—whether a desire for a race-inspired, aggressive stance or a refined, classic silhouette. Then comes the practical side: selecting materials with the right balance of weight, rigidity, and finish; choosing a colorway that harmonizes or deliberately contrasts with the rest of the bike; and deciding whether to incorporate graphic elements or a subtle, monochromatic scheme. The integration of color and texture must consider the rest of the bike’s palette—the tank, fairings, rims, and even the seat stitching—to build a unified, intentional look rather than a collection of disparate parts.

The customization ecosystem extends beyond raw materials and color. High-end, purpose-built tail fairings often come with engineered carbon fiber structures, meticulously aligned panels, and a level of fitment that feels OEM-like. These premium pieces may incorporate advanced manufacturing techniques and quality controls that align with automotive industry standards, signaling a seriousness about both performance and aesthetics. For riders who crave the highest level of integration, customization can touch on the very microdetailing of the tail’s internal geometry, ensuring a seamless transition between the rider’s line of sight and the tail’s silhouette. Customization may also touch on practical features: integrated LED lighting that matches the bike’s signaling system, or pre-masked finishes that accept dye-based colors for a consistent color saturation across multiple panels. Each option adds a layer of personality, turning a functional component into a canvas for self-expression while staying faithful to the bike’s provenance and design language.

The process of selecting and implementing a tail fairing is deeply personal and technical at the same time. For some riders, the path begins with a broad survey of available shapes and textures, imagining how these shapes will interact with the bike’s existing lines. For others, the journey is more programmatic: they measure mounting points, confirm hardware compatibility, and evaluate the finish’s resistance to UV light and road exposure. In all cases, the relationship between aesthetics and engineering remains central. A tail that looks stunning but interferes with seat removal or service access quickly loses its appeal; one that fits perfectly and complements the lines while offering protective benefits from debris and weather becomes a lasting addition. The interviewer and the importer in the customization chain may also weigh the long-term maintenance implications: carbon fiber tails require careful cleaning to avoid micro-scratches that can dull the finish, while ABS-based tails may require periodic refinishing to preserve gloss or to maintain a uniform matte look.

The cultural pull toward personalization is partly driven by the desire to articulate riding philosophy through appearance. A rider who aches to exude a track-ready stance may gravitate toward sharper lines and exposed surfaces that emphasize technical prowess and speed. Another who seeks a more refined, almost boutique aura might opt for a tail with a subdued colorway and a smooth, almost sculpture-like surface that communicates restraint and attention to detail. In both cases, the tail fairing becomes a focal point—the first thing an observer notices when the bike sits still and the last element they notice as it moves away. This is not vanity divorced from function; it is a holistic approach where aesthetics and performance evolve together, ensuring that the tail fairing contributes to the bike’s story on every ride and every gaze.

For readers who want to explore further, a wealth of options exists in the aftermarket landscape, with frames and shells designed to preserve the bike’s overall geometry while allowing a high degree of customization. The best options offer precise fit and a sense of coherence with the bike’s original design language, rather than creating a visual disconnect. This coherence is what sustains a rider’s sense of pride in the machine and in the lonely hours spent tuning every line and finish. At a practical level, the tail fairing also plays a protective role. Road debris, minor impacts, and weather exposure all challenge the rear of the motorcycle. A well-designed tail fairing shields the attachment points and the underside, preserving the integrity of the seat, tail lights, and electrical harness. The combined effect of aesthetic precision and functional protection elevates the tail fairing from a cosmetic feature to a strategic component in the bike’s overall performance and longevity.

For those who wish to dive into the world of options with a ready-made sense of community, there are routes to explore. Online showrooms and forums often reveal real-world fitment experiences, detailing what works on which chassis, where particular curves align with stock lines, and how a given finish holds up under months of exposure. The knowledge embedded in these communities helps prospective buyers set realistic expectations about fit, color matching, and durability. It also underscores an important point: tail fairings are not one-size-fits-all. They require thoughtful selection, accurate measurement, and sometimes a willingness to accept a degree of customization to achieve that perfect look. The payoff is a bike that not only moves through the environment with greater certainty but also communicates, with a single glance, the rider’s intent and personality.

In closing, the tail fairing is a powerful interface between aesthetics and engineering. It is a canvas for color, texture, and light; a shield against the elements and a whisper of aerodynamic intent; a statement piece that can make a bike look as fast as it feels. The most successful tail fairings honor the machine’s original proportion and spirit while offering a controlled degree of personality. The result is a coherent, compelling presence that stands up to close inspection and daily use alike. For those drawn to the idea of a more personalized silhouette, exploring the Honda fairings collection presents a curated gateway into design languages that emphasize integration, craftsmanship, and a shared philosophy of performance through form. This path invites riders to consider how a single component can translate a riding philosophy into a visible signature, one where every line, color, and surface texture becomes part of a larger dialogue between rider, road, and machine.

To learn more about a curated selection that aligns with this approach, consider exploring the Honda fairings collection, which gathers a spectrum of shapes and finishes designed to harmonize with a broad range of chassis while inviting personal expression. This approach reflects a broader trend in modern motorcycling: the tail fairing as a sophisticated design instrument that respects heritage, embraces contemporary materials, and welcomes customization as a route to a unique riding identity. The conversation around tail fairings thus extends beyond mere surface decoration; it is an invitation to participate in a culture that values precision, aesthetics, and practical performance in equal measure. For readers seeking a tangible starting point on the journey, it is worth examining how a well-chosen tail fairing can align with a rider’s aesthetic goals and how its finish, texture, and lighting can fuse into a legible, expressive silhouette when the bike sits at rest or glides by at speed. With the right combination, the tail becomes not just a shell but a signature—the mark of a rider who understands that beauty in motion derives from the careful orchestration of form, texture, color, and light.

External resource for further reading and visuals can be found here: https://www.amazon.com/Tail-Rear-Cover-Fairing-CBR1000RR-R/dp/B08N5XQJ9Y

Riding the Margin: The Economics, Materials, and Market Pulse Behind Tail Fairings

Tail fairings are often treated as the finishing touch on a motorcycle’s silhouette, a detail that can look like vanity and performance braided together. Yet behind their smooth curves lies a complex interplay of costs, materials, processes, and consumer expectations that moves with the same velocity as the bikes they dress. In this chapter, we explore how tail fairings—from the lightweight carbon fiber shells favored by speed-focused riders to the more economical fiberglass or reinforced polymer variants—are shaped by a suction of market forces, technological advances, and shifting tastes. The tail section is not merely a rear panel; it is a performance amplifier that affects aerodynamics, fuel efficiency, stability at high speed, and the perceived value of a machine. When we talk about the economics of tail fairings, we are really tracing a map of the broader motorcycle parts ecosystem. It is a story about how material choices, manufacturing methods, and customization options converge to determine price, lead times, reliability, and the pace at which new designs reach riders’ hands. In this sense, tail fairings serve as a revealing proxy for the health and direction of the entire sector that builds, buys, and personalizes sport and performance motorcycling.

The market backdrop against which tail fairings operate has grown more dynamic in the last decade. The global motorcycle market, valued at roughly $140 billion in 2023, has been projected to rise to about $175 billion by 2029. This expansion is driven not only by a rebound from pandemic-related disruptions but also by a renewed interest in personal mobility as a flexible transportation option. Within this broader pie, the fairing segment—encompassing rear, tail, and under-tail designs—benefits from a twin pull: the desire for speed-oriented aerodynamics and the appetite for fresh aesthetics that allow riders to express identity through their machines. Within the fairing submarket, the growth trajectory is particularly buoyant. Market analyses forecast a Compound Annual Growth Rate (CAGR) of around 11.7% from 2025 to 2030 for the fairing category itself, a rate that signals expanding production lines, more sophisticated supply chains, and increasing consumer willingness to invest in performance- and appearance-focused upgrades. For designers and manufacturers, these numbers translate into opportunities to push premium materials and advanced manufacturing techniques deeper into mainstream bikes while simultaneously broadening the range of products for touring and commuter riders who still want protection and style but at a lower price point.

Material selection is arguably the most visible economic hinge for tail fairings. The trade-off between carbon fiber, fiberglass, and reinforced polymer composites is driven not only by raw material costs but by the weight savings, stiffness, and impact resistance each option affords. Carbon fiber is the icon of performance—low density, high strength, and excellent stiffness-to-weight ratio—yet it carries a premium price tag driven by material costs, layup complexity, and curing requirements. Autoclave curing, specialized resins, and careful layup schedules add up to higher capital and operating expenses, even before factoring in the costs of precision-fitting molds and quality testing. Fiberglass and reinforced polymers offer compelling value, delivering robust performance at a more accessible price while still enabling aerodynamic shaping and finish quality. For many riders, the choice is not simply about the initial outlay but about the cumulative value over the life of the bike: lighter weight sustains acceleration and fuel efficiency, while a design that reduces drag can improve handling stability at high speeds and during long-range riding. The premium placed on carbon fiber in high-performance builds is a signal of value rather than a simple price tag; it communicates a willingness to pay for performance, brand prestige, and long-term perception of quality. Beyond material type, the finish and surface treatment—gloss versus matte, texture, and color options—carry their own cost implications and consumer appeal. Custom finishes, protective coatings, and precision-cut color accents can elevate a tail fairing from a mere component to a signature element of a rider’s identity, widening the premium potential for manufacturers and aftermarket suppliers alike.

Manufacturing efficiency is another critical axis shaping the economics of tail fairings. The move toward automated fabrication, improved injection-molding techniques, and more consistent curing processes has enabled manufacturers to scale up production while preserving tight tolerances and high finish quality. For premium carbon fiber components, the autoclave or other high-pressure curing methods can deliver consistent resin distribution and fiber alignment, driving down rejection rates and improving repeatability—factors that have a direct impact on unit costs and margins. For more economical variants, advances in reinforced polymers and improved hand layup processes coupled with efficient curing cycles can shorten lead times and reduce energy consumption, which in turn helps to balance the higher material costs associated with carbon fiber. The result is a spectrum of manufacturing strategies that align with the target market segment: race-focused, highly engineered tail fairings that maximize aerodynamic efficiency and brand equity; and more cost-conscious options that still offer a tailored look and solid protection for everyday riding. Each approach has a different cost curve, and manufacturers frequently blend strategies to meet demand while maintaining quality.

The economic narrative also turns on supply chain resilience and regional specialization. A period of widespread logistics disruption—ending up not with a bang but a series of delays and cost escalations—highlighted how disruptions in transport, raw materials, and labor can ripple through the tail fairing value chain. In response, many producers have rebalanced their supplier networks, seeking both closer proximity to key markets and more diversified sources of carbon fiber, resins, and reinforcement materials. This diversification helps reduce vulnerability to single-sourcing risks and can shorten production cycles, even as it sometimes raises unit costs temporarily during the transition. As manufacturing hubs evolve, so do the economics of customization. Regions with established tooling ecosystems and skilled labor for composite fabrication tend to command efficiency advantages, while others may compete through lower wage costs or proximity to raw material streams. In all cases, the emphasis is on delivering consistent quality at scale, because even small deviations in fit or finish can translate into warranty costs and reputation considerations that affect margins over the life of a model launch.

Customization remains a powerful driver of the tail fairing market. Modern riders increasingly seek designs that reflect personal taste as much as performance. The ability to choose finishes—ranging from gloss to satin—along with color cycles and surface textures, allows tail fairings to become expressive components of a build. This trend has clear economic implications. Customization supports higher price points, longer lead times, and more complex supply chains, but it also broadens the addressable market by inviting riders who may be price-sensitive on base models but willing to invest substantially in a visually distinctive shell. The premium value of carbon fiber is often reinforced by customization options that enhance branding and perceived exclusivity. Conversely, semi-fairings and mid-range designs address touring and commuter segments by offering substantial protection with a more sustainable price tag. In this context, market dynamics favor a diversified catalog: a core line of high-performance fairings for track and sport use, complemented by broader collections that emphasize reliability, durability, and cost efficiency for daily riders. The economic implication is straightforward: a broader product mix supports steadier production volumes, reduces seasonal demand swings, and gives distributors and retailers more stable revenue streams across cycles of new model introductions and mid-cycle refreshes.

From a consumer behavior perspective, the willingness to invest in tail fairings correlates with the perceived return on value. Riders who prize high-speed stability, quick lane changes, and reduced fatigue at speed are drawn to lighter, stiffer composite shells that minimize wind resistance and reduce buffeting. Those benefits translate into measurable performance improvements, which can justify premium pricing in the minds of buyers and in the equity valuations of brands that hold reputations for engineering precision. Yet the value proposition extends beyond outright performance. A tail fairing that harmonizes with the bike’s lines and color story can significantly influence resale value and overall perceived quality. This phenomenon explains why the tail fairing segment has attracted attention from aftermarket specialists who emphasize precise fittings, OEM-grade or near-OEM-grade standards, and compatibility with a wide range of models. When a tail fairing is designed with modular mounting points and standardized pre-drilled holes, installation complexity drops, and the return on investment—measured in faster installation, fewer damaged parts, and less downtime—appears immediately in the total cost of ownership for the rider. In such cases, the economics favor not only the initial purchase but also the longer-term maintenance and upgrade cycle that riders undertake in response to evolving tastes and performance goals. To underscore the breadth of the ecosystem, many retailers and builders curate catalogs that demonstrate how tail fairings can be integrated into different machine families, illustrating how a single design language can cross several model lines while preserving fit and finish. A practical manifestation of this approach can be seen in the way tail fairings are presented in brand catalogs and online collections that organize parts by compatibility and aesthetic theme. For example, riders can explore a dedicated Kawasaki fairings collection that showcases how tail section design harmonizes with others pieces to maintain a cohesive look and performance profile across a model family. Kawasaki fairings collection illustrates how a tail fairing can be positioned as both a functional performance upgrade and a visual signature enhancer within a broader customization strategy.

The competitive landscape also shapes the economics of tail fairings. The aftermarket has grown into a robust channel that complements OEM offerings, enabling riders to source race-ready or street-legal, race-inspired tail sections outside traditional dealer networks. This dynamic supports faster response to shifting tastes and model updates, while also pressuring manufacturers to refine production workflows to accommodate shorter lead times without sacrificing quality. In parallel, the rise of online marketplaces and direct-to-consumer models has nudged the industry toward greater transparency around materials, dimensional tolerances, and fitment guarantees. For manufacturers and suppliers, this creates a pressure to invest in rigorous quality management systems and traceable production records—areas where OEM-grade standards become critical selling points. In practice, achieving ISO/TS 22163 or IATF 16949 alignment signals a commitment to a predictable, repeatable, and safe production process that resonates with both distributors and end users seeking reliability and warranty protection. These quality frameworks help stabilize margins by reducing post-sale costs and reinforcing trust with partners across the supply chain, from raw material suppliers to finish-out retailers.

Economic breadth also emerges when considering the broader ecosystem in which tail fairings live. The motorcycle fairing market, as a category, benefits from shifts in consumer preference toward sport-inspired aesthetics and aerodynamic efficiency. The trend toward semi-fairings, which offer a middle ground between full protection and light weight, has created a niche that appeals to touring and commuter riders who still value wind protection but require lower upfront costs and easier maintenance. This duality enriches the product portfolio and supports more resilient pricing strategies. From a macroeconomic standpoint, the tail fairing segment reflects how manufacturers balance premiumization with accessibility. When market demand stabilizes, producers lean on automation and process optimization to protect margins and maintain component quality, even as raw material prices fluctuate. This balancing act is the essence of how tail fairings move through cycles of price sensitivity, innovation, and consumer aspiration. The result is a durable, if occasionally volatile, economic backbone for a segment that sits at the intersection of performance engineering and personal style.

In sum, the economic story of tail fairings is about more than the price tag attached to a single component. It is about how a small, carefully engineered piece connects to large-scale dynamics: material science costs that reflect weight, stiffness, and manufacturing complexity; production efficiencies born from automation and optimized curing; and a consumer market that rewards both athletic performance and distinctive, personalized appearances. The tail fairing sector reflects the broader truth of modern motorcycling—innovation is priced, but it is priced with an eye toward scale, reliability, and the rider’s sense of identity. As the industry continues to invest in carbon fiber capability, advanced resin systems, and automated fabrication techniques, the price ladder will likely flatten at some points as efficiencies compete with premiumization, while it will rise at others where premium materials and bespoke finishes win the loyalty of enthusiasts. The challenge for manufacturers and retailers is to maintain a coherent value proposition across a diverse rider base, ensuring that the economics of design, fit, and finish translate into real-world benefits that riders feel every time they twist the throttle. For those who seek a deeper dive into the market forecasts and industry trends framing these decisions, external analyses provide a structured view of how the motorcycle fairing market is expected to evolve in the coming years: https://www.mordorintelligence.com/industry-reports/motorcycle-fairing-market

Final thoughts

Understanding the multifaceted role of tail fairings in motorcycle design reveals their critical importance to performance, aesthetic appeal, and market viability. As business owners in the motorcycle industry, embracing these advancements can propel product offerings and satisfy an evolving customer base. The blend of aerodynamic benefits, custom design options, and economic insights equips you to make informed decisions that enhance both your product lineup and your competitive edge.