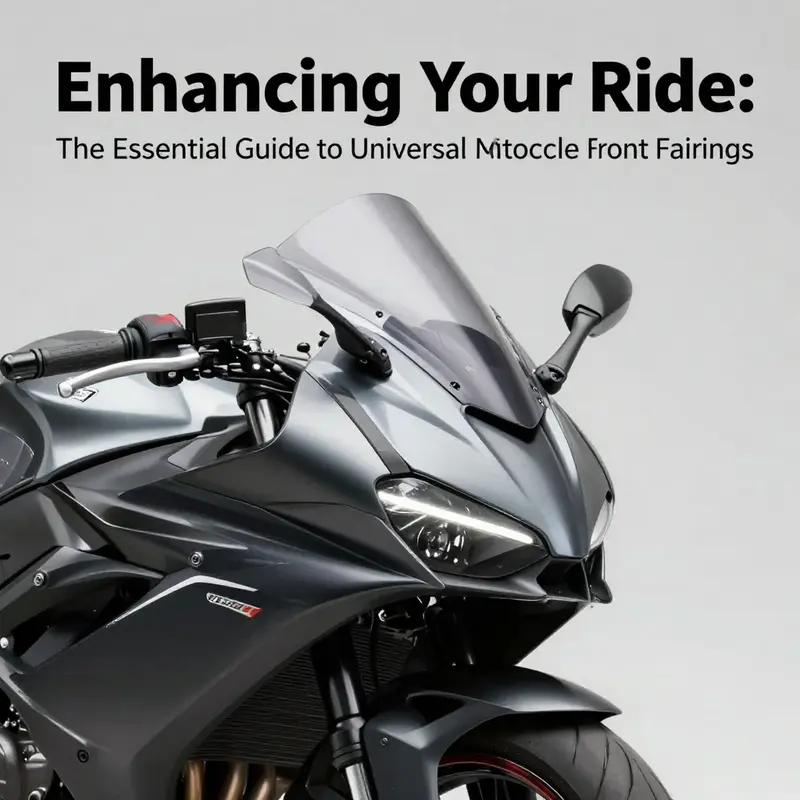

Universal motorcycle front fairings have become essential accessories for riders seeking improved aesthetics, performance, and comfort. Designed to fit various models, these aftermarket solutions cater to a diverse customer base. This guide delves into the critical aspects of universal front fairings, highlighting their design and materials, aerodynamic benefits, installation considerations, market trends, and potential innovations. Understanding these facets enables business owners to make informed decisions about incorporating these products into their offerings, ensuring relevance and competitiveness in a dynamic market.

null

null

Streamlined Power: How Universal Front Fairings Shape Stability, Speed, and Rider Comfort

The front of a motorcycle is the point where air becomes a constant conversation, a canvas on which aerodynamics writes its most immediate statements about stability, efficiency, and comfort. A universal front fairing, designed to fit a broad spectrum of models, is not merely a cosmetic upgrade; it is a deliberate intervention in the way air behaves around the bike at speed. Crafted from durable materials such as ABS, these fairings embrace a balance between rigidity, weather resistance, and flexibility. The result is a streamlined silhouette that guides airflow with a purpose: to reduce drag, minimize turbulence, and domesticate the wind that otherwise ricochets off the bike and into the rider’s body. In essence, a well-executed universal fairing becomes a partner in the ride, shaping the relationship between machine and environment through careful geometry and robust construction.

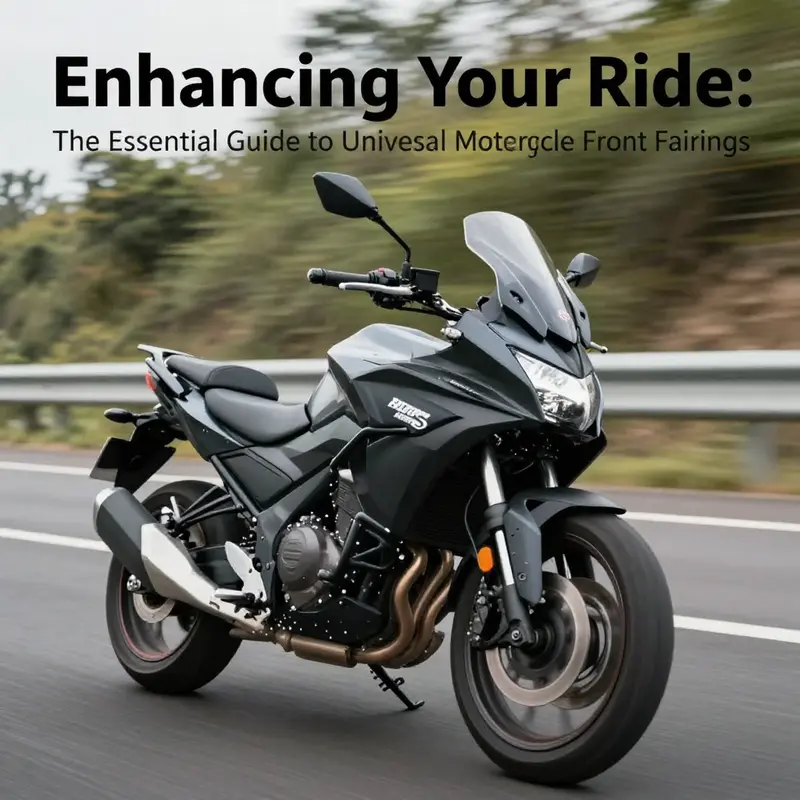

To understand the aerodynamics at play, imagine the motorcycle as a bluff body entering a fluid stream. The fairing’s primary function is to sculpt the path of that stream as it reaches the front and sides of the machine. By introducing a smoothly contoured surface, the fairing channels air more efficiently over the front wheel and down the sides, reducing abrupt pressure changes that generate lift or erratic gusts. The goal is to lower the coefficient of drag, a measure of how readily air resists the bike’s progress. The lower this value, the less thrust is wasted in overcoming air resistance. Riders experience this as improved efficiency and a greater sense of control, especially at highway speeds where wind forces become prominent and fatigue can creep in as wind buffeting compounds over long distances.

A fairing designed for a wide range of bikes faces the challenge of versatility without sacrificing the precision of airflow. The batwing-inspired or streamlined profiles commonly found in universal options are not just stylistic choices; they are aerodynamic decisions meant to tame the wind. The fairing’s side contours, lower edges, and the angle of the windscreen or its integrated shield all contribute to how air splits and reattaches around the machine. When air reattaches smoothly behind the rider, wind noise and helmet buffeting diminish. The rider perceives a quieter cockpit and less intrusion from turbulence, a factor that translates into reduced fatigue on endurance rides or long commutes, where hours in the saddle can otherwise take a toll on concentration and comfort.

The performance implications extend beyond comfort. Reducing drag does not simply free up horsepower in a direct sense; it lowers the energy the engine must supply to maintain velocity against air resistance. This, in turn, can improve fuel economy. The relationship among drag, engine power, and efficiency is nuanced, because a fairing can also alter cooling dynamics by modifying how air flows to engine intakes or radiators if the design includes small air channels. In some universal configurations, subtle intake ducts and vents are integrated with the fairing to assist engine cooling without creating additional drag or turbulence. These features demonstrate how modern universal fairings merge form with functional airflow management while preserving a sleek, cohesive appearance.

High-speed stability is perhaps the most tangible riding benefit of a well-proportioned front fairing. At elevated velocities, air pressures become more pronounced, and any asymmetry in airflow can translate into a tendency for the bike to wrestle with gusts or crosswinds. A properly fitted universal fairing helps smooth the pressure distribution across the front of the bike, reducing the likelihood of sudden lift or uncommanded steering inputs. The riding experience at speed becomes more confident, with the rider relying on the bike’s chassis and the fairing’s aerodynamic envelope rather than fighting a turbulent air environment. This stability is especially meaningful for touring or sport-touring setups, where riders may spend hours in steady, fast cruising, where small improvements compound into meaningful reductions in rider strain and micro-adjustments.

Compatibility considerations are intrinsic to achieving these benefits. Universal fairings are designed to accommodate a range of handlebar diameters and mounting schemes, commonly including 22 mm, 25 mm, and 28 mm bars. The practical upshot is a broader fitment window, reducing the barrier to adopting a performance-minded aesthetic without committing to a model-specific part. Yet compatibility is not merely about diameter; it encompasses mounting hole patterns, clip-on extensions, and bracket kits that promise a secure, rigid fit. The better the alignment with the bike’s forward geometry, the cleaner the airflow and the more precise the steering feel at speed. Pre-cut mounting points and adjustable hardware help tailor the fit, ensuring that the fairing sits true to the machine’s silhouette rather than sagging into a misaligned or gap-filled aftermath. The subtlety of fit often determines whether the wind’s impact is felt as a gentle flow or a disruptive gust.

Material selection and finishing have a direct impact on aerodynamics and durability. ABS plastic is a common choice for universal front fairings because it offers a favorable combination of stiffness, impact resistance, and weather tolerance. UV-resistant coatings help guard against sun fade, ensuring that the fairing remains visually sharp even after prolonged exposure to sunlight. The weather protection system is not merely about resisting rain; it involves maintaining a smooth surface over time so that texture or micro-scratches do not trip the flow or create micro-turbulence. A fairing that remains glossy or retains a uniform matte finish contributes to consistent airflow, whereas a roughened or chalky surface can alter boundary layer behavior and degrade aerodynamic efficiency. The surface finish thus matters as much as the fundamental shape in sustaining performance across the life of the installation.

From an ergonomic perspective, the rider’s experience of wind is about more than the absence of buffeting. A fairing that elegantly channels air away from the chest and shoulders can lower wind noise perceived by the rider’s ears and helmet. This acoustic aspect of aerodynamics matters in real-world riding, where sustained exposure to wind at highway speeds can become fatiguing and distracting. The end result is not only a quieter ride but a more focused cockpit environment that helps the rider maintain situational awareness and ride safely for longer periods. The combined effect of reduced wind pressure and calmer acoustics is a freer head space for line of sight, helmet ventilation, and overall comfort, which, in turn, supports better riding posture compliance and reduced muscle tension.

Integrated features in modern universal fairings demonstrate how efficiency and function can coexist with aesthetics. Some designs provide mounting points for headlights and indicators, enabling a cohesive front-end solution without requiring a patchwork of separate components. In other cases, lightweight breathers or air intakes are subtly included to assist engine cooling or to manage the boundary layer around the intake area. These elements must be harmonized with the fairing’s primary role of air management; if they protrude or disrupt the smooth flow, they can undermine the aerodynamic gains. The orientation and sizing of these features demand careful consideration during the design and installation process, balancing the rider’s visibility, the bike’s electrical needs, and the aerodynamics of the overall package.

The discourse around universal fairings would be incomplete without acknowledging the practical realities of fitment and use. The assumption that one fairing can perfectly match every model is tempered by the reality that some bikes present distinct front-end geometries, fairing mounts, or windscreen elevations. A thoughtful universal design acknowledges these nuances and offers modular mounting solutions, aligning with varied cockpit angles and rider preferences. A skilled installation often involves a measured approach: verify mounting points, check alignment at several swing-arc positions, and ensure there is no contact with the radiator shroud, footpegs, or levers during full steering lock. The installation experience itself becomes part of the performance equation, for if fitment is ambiguous or insecure, the aerodynamic gains are overshadowed by rattles, gaps, or flutter at speed.

It is valuable to view universal front fairings not as a single replacement piece but as a gateway to a broader understanding of how air interacts with a motorcycle. The chapter’s focus on aerodynamics and performance should be seen as a gateway to deeper technical exploration, including how these fairings influence the bike’s overall efficiency envelope. Real-world testing varies with riding style, bike weight, wind direction, and speed, yet the underlying physics remains consistent: shaping the front-end profile carefully reduces drag and stabilizes the flow, which translates to measurable gains in efficiency and ride quality. For riders curious about model-specific implications, exploring a model-relevant collection can illuminate the nuances of fit and alignment across compatible bikes. For example, the yamaha-yzf-r1-fairings-2009-2012 collection serves as a reference point for understanding how universal patterns translate to particular silhouette constraints, while still reaping the untreated aerodynamic benefits of a well-designed front fairing. See the yamaha-yzf-r1-fairings-2009-2012 collection to gain practical context and model-aware insights: yamaha-yzf-r1-fairings-2009-2012 collection.

From a design philosophy perspective, the value proposition of universal front fairings rests on the idea that performance and appearance can advance together. A front fairing that looks purposeful and rides with confidence often signals a broader attention to the machine’s overall efficiency and rider comfort. The aesthetic of streamlined form resonates with riders who seek both performance and a clean, integrated look. The result is a front end that communicates capability and poise, a visual cue that the bike is optimized for aerodynamic harmony as much as for aggressive styling. The rider, sensing this precision, tends to ride with a smoother throttle hand, a more balanced posture, and a greater willingness to embrace longer stretches of highway or twisting road with less fatigue and more immersion in the ride.

The journey through aerodynamics and performance benefits of universal front fairings converges on a simple, powerful idea: when airflow is guided rather than fought, the whole motorcycle behaves better. Drag is trimmed, stability is enhanced, and rider comfort follows. The chapter’s exploration underscores that the best universal fairings do not merely cloak the bike in a sleek shell; they act as a dynamic interface between rider, machine, and environment. They make the wind an ally to performance, rather than an adversary to fatigue. They invite riders to pursue longer rides with confidence, to push a little further into a corner, and to experience speed as a refined, controlled phenomenon rather than an unpredictable gust. The aerodynamic logic is clear, the engineering rationale persuasive, and the riding experience more connected when the front end succeeds in shaping the air’s path as deliberately as the rider shapes the road ahead.

External reference for a deeper technical perspective on fairing-driven performance can be found here: https://www.motorcyclecruiser.com/motorcycle-aerodynamics-how-fairings-improve-performance. This resource provides a detailed overview of how fairings influence drag, stability, and efficiency, complementing the practical insights discussed here. For readers seeking model-specific context or additional options, the broader catalog of universal fitment solutions can be explored in related collections.

Perfecting the Fit: The Installation Realities of Universal Front Fairings Across Motorcycles

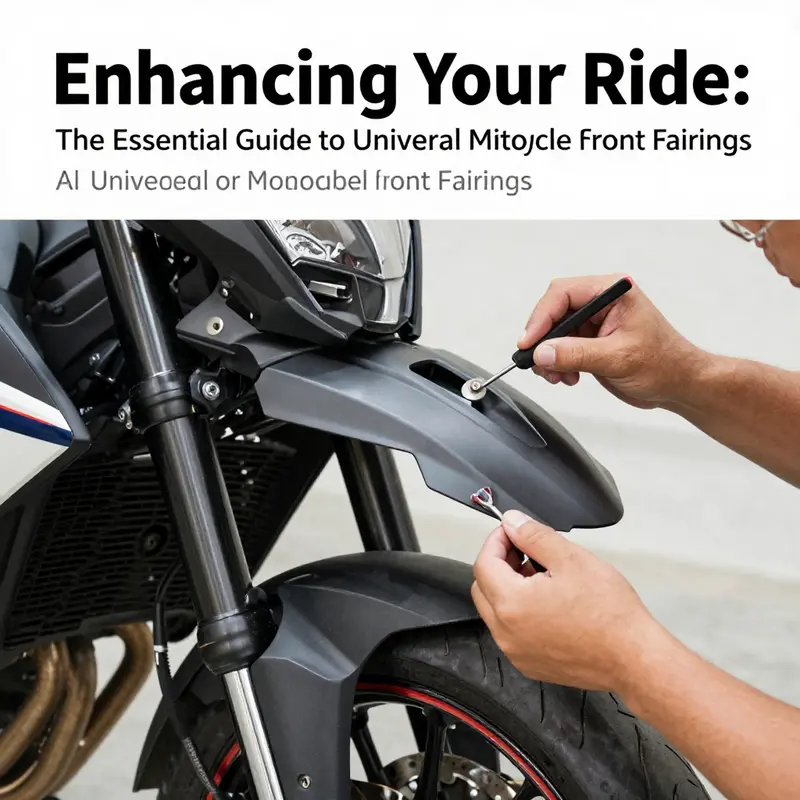

A universal front fairing promises a broad, practical upgrade—a single component designed to bridge a spectrum of models, rider preferences, and weather conditions. Yet that very universality introduces a discipline of fitment that model-specific parts rarely demand. This chapter explores the installation realities that sculpt performance, safety, and aesthetics when a rider chooses a universal kit. The core premise is simple: these fairings are built to accommodate many bikes, but they must be coaxed, trimmed, and routed with care to honor each bike’s unique geometry, control layout, and mechanical systems. When approached with a methodical mindset, a universal front fairing can deliver a balanced blend of wind management, visual coherence, and long-term durability that feels tailor-made even when the component was designed for a wide audience. When you embark on installation, start with a plan that treats fitment as a multi-point puzzle rather than a single alignment task. The first piece of that puzzle is alignment with the mounting points. Unlike OEM panels that align with preengineered tabs or frames, universal kits rely on a matrix of potential attachment points, brackets, and adjustable hardware. The rider must map the fairing’s mounting interface to the bike’s existing anchors, then anticipate how vibration, torque, and temperature cycles could affect fasteners over time. Even small misalignments can cascade into uneven gaps along the edge of the fairing, undesirable leaks around seals, or degraded aerodynamics at speed. A measured approach—confirming anchor point spacing, testing fore-aft and side-to-side alignment, and pre-assembling brackets off the bike—reduces the risk of later rework and strain on fasteners. In practice, this means taking time to loosely position the fairing, verify that it sits flush against the headlight aperture if present, and confirm that the top edge aligns with the rider’s line of sight when seated. The fairing’s silhouette should harmonize with the bike’s overall profile, not trap heat or rub against cables. The second major element is the routing of brake lines and electrical wiring. Universal fairings typically require passage for lines and wires through a new structural conduit or behind the fairing’s interior surfaces. This work often involves trimming protective sleeves, re-routing hoses, and carefully feeding wires through brackets or channels to prevent pinching or abrasion. If hydraulic systems are involved in the front brake assembly, care must be taken to bleed the lines after reassembly to remove air pockets that can compromise brake feel. A clean, organized routing plan not only preserves braking performance but also simplifies future maintenance. The wiring plan should anticipate potential adjustments for different accessories—like auxiliary lighting, heated grips, or electronic displays—without forcing compromises that could introduce loosened connectors or exposed wiring. Interference with controls is another critical concern. A universal fairing must coexist with the handlebars, mirrors, and switching gear. If the fairing impinges on bar movement, even minimally, it can alter steering feedback or limit the rider’s freedom to execute maneuvers. This is especially true for motorcycles with staggered or nonstandard clip-on arrangements, where the fairing might clash with riser bolts, clutch/ brake master cylinders, or turn signal assemblies. The installation process benefits from a deliberate check: with the handlebars fully turned lock-to-lock, evaluate every contact point between the fairing and control surfaces. In some cases, small spacers or repositioning brackets are needed to restore clearances without creating new gaps that invite wind-driven flutter at speed. The hardware used to secure the fairing is not cosmetic—it is a lifeline against water ingress, structural shifts, and stress under vibration. The right mix of gaskets, sealants, and fasteners ensures a secure seal around the edges and joints while preserving the bike’s weatherproof integrity. The absence of a robust seal at the joint can allow water intrusion, which, over time, can degrade fasteners, add weight, or accelerate corrosion. Protective films or shields applied to the fairing’s outer surfaces are a practical defense against scratches during handling and installation. ABS plastics, which are common in universal kits, offer impact resistance and weather tolerance, but they can be susceptible to cracking or scratching if treated with abrasive tools or stripped of protective coatings. The installer’s toolset matters as much as the kit itself. Soft tools—such as microfiber cloths for cleaning and nonabrasive spatulas for positioning—help minimize surface damage. When removing or adding hardware, care should be taken to prevent over-tightening, which can warp mounting points or strip threads. If the kit comes with pre-cut mounting holes, use them as anchors for initial alignment; if not, you will likely need to drill or elongate holes to achieve a precise fit. In that context, creating a staged installation process can help manage complexity. Begin with a loose, all-around fit; then progressively tighten a few critical fasteners to hold the fairing in place while you confirm alignment from multiple viewpoints. The stage-by-stage approach guards against a false sense of finality before all clearances and lines are in their final positions. Material composition informs a lot about how the installation will unfold. Most universal fairings are fashioned from ABS or polycarbonate blends, chosen for durability and weather resistance. These materials offer a practical compromise between rigidity and flexibility, which matters during fitment because some flex can help absorb vibration, while too much rigidity can transfer stress to mounting points. Understanding the material’s behavior—how it responds to heat, UV exposure, and impact—helps determine mounting strategies. A fairing that is allowed to flex slightly at speed can reduce crack formation at joints; however, excessive flex may lead to misalignment over time. Protective strategies extend beyond films and shields. Temporary masking during mounting helps prevent scratches on edges; soft clamps and padded brackets minimize contact with fragile surfaces. It’s also wise to consider environmental exposure. If the bike will see rain or road salt, choosing weatherproof gasket materials and ensuring a secure, water-tight seal at the joints becomes essential for longevity. The installation manual provided by the kit’s manufacturer remains an authoritative compass through this process. It outlines step-by-step procedures, tool requirements, and safety checks that are tailored to universal fairing installations across multiple brands and models. While the manual offers general guidance, the true craft emerges in translating those guidelines into a bike-specific plan. A knowledgeable rider will cross-reference the manual with their bike’s service documentation, noting any unique routing or clearance issues that standard universal kits may not fully anticipate. For riders seeking broader context, model-specific fitment forums and catalogs can serve as reference points to approximate the expected alignment and mounting geometry before committing tools to metal. A practical path to progress involves validating fitment across all expected directions of motion. Once the fairing is near its final position, perform a dynamic check: ride-height adjustments, suspension compression, and wheel travel can subtly alter spacing. Even small shifts can appear as contact or rub once the bike is loaded and springing in motion. If trouble arises, revisiting the mounting hardware choices—like the selection of spacers, bracket thickness, or the sequence of bracket installation—can restore the intended geometry without requiring a wholesale redo. The goal is not a rigid, one-size-fits-all assembly but a compatible, robust interface that respects both the bike’s engineering and the rider’s ergonomics. With careful planning and disciplined execution, a universal front fairing can deliver the clean lines and aerodynamic advantages that riders expect, while maintaining the reliability and safety that a rider relies on every time the road opens ahead. The aesthetic payoff—stepped wind deflection, a streamlined silhouette, and a coordinated cockpit look—should not come at the expense of control feedback, braking reliability, or weather protection. In this sense, installation becomes a conversation between the rider, the bike, and the kit—a dialogue that progresses from loose fitment to confident, repeatable mounting, from rough alignment to daily-rider refinement. For those who want to explore how universal designs translate into specific makes and models, the Honda fairings collection offers a reference point for how universal concepts can be adapted to particular chassis and lines, providing a sense of how universal fitment can still honor model-specific aesthetics and engineering. Honda fairings collection can serve as a practical companion when planning transitions from universal components to a more model-faithful presentation. While browsing, it is crucial to keep in mind the broader standards that govern safe, durable installations. External resources outline a consistent, safety-forward approach that aligns with professional best practices in fairing installation. For a more formal, standards-driven path, consult the Motorcycle Mechanics Institute’s installation guidelines, which offer step-by-step procedures, tool requirements, and safety checks tailored to universal fairing installations across multiple brands and models. External resource: https://www.motorcycle-mechanics-institute.com/installation-guidelines-front-fairing/

Between Windshield and Skyline: Trends, Materials, and the Rise of Universal Front Fairings

Universal motorcycle front fairings have moved from niche upgrades to mainstream components that promise both style and substance. In the past, riders seeking a custom look often faced a choice between costly, model-specific parts and makeshift fixes. Today, a growing category offers a more flexible path: fairings designed to fit a wide range of models while delivering measurable gains in aerodynamics, weather protection, and rider comfort. This chapter traces the current market dynamics, the material science behind these parts, and the design philosophies that keep universal fairings relevant across generations of bikes. The story is not just about parts, but about how riders, manufacturers, and retailers collaborate to redefine what a front fairing can do on a motorcycle.

The most consequential trend is the relentless push toward advanced aerodynamics. As riders demand greater stability at highway speeds and lower fatigue on long journeys, manufacturers have embraced streamlined profiles that reduce wind drag and turbulent wake. Rather than simply covering the front of the bike, modern universal fairings are shaped to guide air smoothly around the rider, deflect wind away from the torso, and minimize buffeting on the helmet. The result is a more confident ride at higher speeds, with less rider effort required to maintain a steady line. In practice, this means fairings that employ thoughtful curvature, carefully placed chines, and gradual transitions between the windscreen, the outer shell, and the bike’s fairing gaps. Even small refinements in contouring can translate into noticeable differences in feel and fuel efficiency at cruising velocity.

Material science sits at the core of this evolution. ABS plastic remains a foundational material for its balance of stiffness, impact resistance, and cost. Yet the field has expanded to include high-performance composites and reinforced plastics that push durability without adding excessive weight. Carbon fiber-reinforced matrices are increasingly used in premium lines for their stiffness-to-weight advantages, while advanced engineering plastics offer toughness and UV resistance at a more accessible price point. Both approaches address weather exposure, sun damage, and the daily realities of riding in varied climates. The modern universal fairing often features UV-protected surfaces and weather-sealing concepts that prevent moisture ingress and color fading, extending the life of the component and keeping its appearance consistent across seasons. Sustainability also enters the material conversation. Recyclable resins and redesigned recycling streams are guiding some manufacturers toward lower environmental footprints, aligning with broader industry and consumer expectations without sacrificing performance or durability.

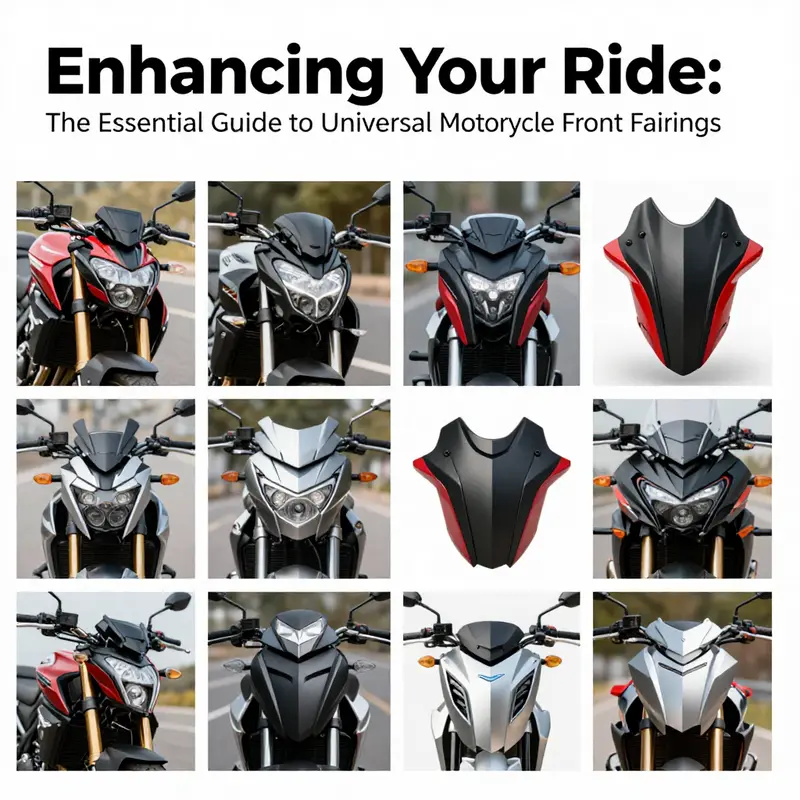

These material choices dovetail with modular design philosophies that have become a hallmark of universal fairings. Rather than a single, monolithic shell, contemporary options frequently incorporate modular components that riders can swap or reconfigure. Clip-on extensions, bracket kits, and adjustable mounts let someone tailor fitment to their bike and riding style without committing to a factory-spec installation. Compatibility with common handlebar diameters—such as 22 mm, 25 mm, and 28 mm—simplifies the mounting process and broadens the pool of compatible motorcycles. Pre-cut mounting holes and standardized attachment points reduce the guesswork during installation, while adjustable mounts offer a measure of fine-tuning for stance, rake, and windscreen height. This modularity is not merely a matter of convenience; it enables a diverse ecosystem in which riders can mix and match to achieve a balanced blend of protection, aero efficiency, and aesthetics.

The rise of customization is another force shaping the market. A growing segment of riders wants a look that echoes a particular era or racing lineage, but they still expect practical benefits like protection from wind and rain. Universal designs respond with retro-inspired silhouettes that nod to classic fairings while incorporating modern fasteners, lightweight composites, and integrated lighting harmonized with the bike’s electronics. Equally important is the demand for clean aesthetics. Universal fairings that minimize visible seams and hidden fasteners tend to be favored by riders seeking a sleek, unified appearance. In this context, the fairing is not only a functional shield but a visual statement that can dramatically alter a motorcycle’s overall silhouette.

Alongside these design aims, accessibility and value continue to drive market growth. The proliferation of online marketplaces and aftermarket retailers has created a more competitive landscape where a broad range of styles—ranging from sport-oriented to retro and streetfighter influences—are readily accessible. This democratizes customization, letting a wider audience explore a personal interpretation of speed and style without the capital investment required for model-specific parts. The result is a dynamic, ever-expanding catalog of options that reinforces the idea that a front fairing can be both functional and expressive. To illustrate the accessibility of curated options, riders often consult collections that group compatible pieces by model families, height, or headlight size, making it easier to pair a universal fairing with a preferred riding configuration. If a reader wants to explore practical coverage options that mirror a particular aesthetic, a quick tour through a dedicated Honda fairings collection can reveal how universal designs are adapted to specific contours while maintaining core functional benefits. Honda fairings collection.

The market’s momentum is also influenced by how manufacturers think about integration with lighting, gauges, and other front-end electronics. A fairing that integrates a light source or offers a clean path for wiring can reduce clutter and simplify the installation. This integration supports a cleaner cockpit and reduces the need for additional mounting hardware. The concept of integration extends to modular windshield systems as well. The ability to swap or height-adjust a windscreen allows riders to tune airflow for different weather conditions or rider heights. This kind of adaptability is especially appealing to newcomers who want a single, reliable platform that can evolve with their riding preferences over time.

From a strategic perspective, universal front fairings occupy an interesting position in the broader motorcycle accessories landscape. They sit between highly specific, model-matched parts and generic, all-encompassing add-ons. That middle ground creates opportunities for brands to emphasize fit accuracy, finish quality, and fit-for-purpose engineering rather than solely chasing the lowest price point. It also invites collaboration with independent shops and custom builders who value precise alignment and bespoke coloration. In other words, universal fairings are not just bolt-on components; they are platforms for customization and expression, capable of transforming a bike’s stance and aerodynamics while preserving the individuality of each rider’s machine.

Market data from industry research suggests that the growth trajectory for the fairing category will continue to ride the momentum of these design and material advances. The sector benefits from a multi-year cycle of product updates, where incremental gains in stiffness, fit, and finish accumulate into noticeable improvements in handling and comfort at speed. As riders increasingly pursue long-haul performance and weekend sport rides, the front fairing becomes a pivotal element for reducing fatigue and enabling a rider to stay focused on the road. The evolving competitive landscape also supports broader access to high-performance options at varying price points, enabling first-time buyers to adopt a universal approach without sacrificing quality.

In summary, the convergence of aerodynamic insight, material innovation, and modular design is reshaping how universal front fairings are conceived and used. The outcome is a flexible, durable, and aesthetically versatile category that speaks to the needs of a diverse riding community. It is a space where science and style intersect, and where careful engineering translates into real-world benefits—less wind on the chest and more confidence in the corners. As riders chart their preferred balance of protection, performance, and personality, universal front fairings offer a pragmatic path forward. For readers seeking a deeper dive into how this ecosystem is organized and where it is headed, the broader market analysis provides a useful frame of reference. External reference: https://www.grandviewresearch.com/industry-analysis/motorcycle-fairing-market

Toward a Smarter, Lighter, and More Modular Future for Universal Front Fairings

Universal motorcycle front fairings have long been a practical, price-conscious way to alter appearance and improve comfort without committing to model-specific parts. Yet the next wave of innovation will push these fairings beyond mere aesthetics or basic wind deflection. The future hinges on integrating intelligence, materials science, and modular engineering into a single, versatile package that can adapt to a rider’s needs, a bike’s architecture, and a changing urban and environmental landscape. Rather than a one-size-fits-all shell, the envisioned fairing of the near future behaves like a living component of the motorcycle, tuned for performance, efficiency, and personal preference. In this broader view, a universal front fairing becomes part of a holistic riding system, capable of adjusting to conditions, weight changes, and cabin-like comfort expectations while still honoring the constraints of aftermarket accessibility and model-agnostic fitment.

The most compelling direction is the emergence of smart fairings. Embedded sensors and compact processing enable a level of feedback and automation that would have seemed futuristic a few years ago. Small pressure and flow sensors embedded in the surface can map true wind angles and turbulence as the bike moves through space. When paired with a lightweight actuator system, these sensors could drive tiny, adaptive panels that alter the shape of the fairing in real time. The rider would notice smoother airflow at highway speeds, reduced buffeting, and more consistent ride quality, even when gusts sweep from the side. The potential extends to temperature and humidity as well. Temperature sensors could trigger vents or micro-vents to moderate the cockpit environment, particularly on longer rides or in urban heat. The same sensors could feed into a rider interface, offering recommendations, such as adjusting the windscreen tilt, seat position, or grip tension, to optimize comfort and concentration. Even more, integrated communication channels could enable the fairing to exchange data with a helmet system or a motorcycle’s main ECU, creating a coordinated response to weather, traffic, or road conditions.

Another promising strand is adaptive aerodynamics. The wind does not arrive in a uniform stream; it trends and ripples around the bike, producing lift, drag, and turbulence that can affect handling and fuel efficiency. With dynamic fairing geometry, the device could reconfigure its silhouette as conditions demand. A streamlined shape for high-speed cruising would yield better straight-line stability, while a broader, more shielded profile could guide air away from the rider during city commuting or windy days. The concept does not imply bulky, moveable fins that compromise strength. Instead, it envisions carefully engineered, lightweight panels that travel along predetermined paths, guided by robust control logic and simple, reliable actuators. The payoff is not just comfort; it is safer, more predictable behavior in variable weather, with less rider fatigue and more stamina for longer journeys. This is especially important when the fairing is designed to fit many bikes; adaptive aerodynamics can compensate for differences in riding posture, wind direction, and motorcycle geometry, delivering a more universal experience than today’s fixed designs.

Material science is already reshaping the practical side of universal front fairings. The drive toward lightweight composite materials is not about flashy performance alone. Reducing mass helps lift, handling, and, for electric motorcycles, range. Modern composites, be they reinforced plastics or fiber-reinforced laminates, offer stiffness and impact resistance while keeping production costs within reach for aftermarket manufacturers. The challenge lies in balancing durability with repairability and end-of-life considerations. Advancements in recyclable resins and matrix materials mean that a fairing can recover value at the end of its life, minimizing waste in a market that increasingly perceives sustainability as a baseline expectation rather than a premium feature. A smart move here is to design fairings around modular, replaceable sections that can be swapped as styles or conditions change, rather than replacing the entire shell. In practice, this modular mindset translates to a fairing that can shed or add segments to alter aerodynamics, weight, or aesthetic, depending on the rider’s daily needs or long-term plans.

Modularity also serves the practical constraints of universal fitment. Pre-cut mounting points, adjustable brackets, and clip-on extension systems facilitate installation across a wide range of models and handlebars. This is not about forcing every bike into a single mold but about providing a flexible interface that preserves structural integrity and safety while allowing riders to tailor a look and function. The modular approach encourages a lifecycle where sections can be upgraded as technology advances or as the rider’s priorities shift—from a sportier stance for weekends to a more laid-back, weather-protective configuration for daily commuting. The design philosophy is to treat the fairing as a browser of options rather than a single static package. This is especially relevant for those who are using an aftermarket fairing in a non-traditional frame or an older platform where full model-specific replacement parts are scarce. In such cases, a modular, adaptive fairing reduces complexity and waste, enabling a broad spectrum of bikes to benefit from improved aerodynamics and comfort without forcing a complete chassis rebuild.

Sustainability is becoming a central criterion in development, not merely a footnote. Sustainable manufacturing practices ranging from material sourcing to end-of-life processing are increasingly compatible with performance goals. The industry is moving toward using recyclable polymers, bio-based resins, and processes that minimize waste during molding and trimming. A fairing designed with recyclability in mind can be disassembled at the end of its life, allowing sections to be remanufactured or repurposed. In practice, this aligns with a circular economy approach: the outer shell could be upgraded in stages as technology and aesthetics evolve, rather than discarded in full. For riders concerned about environmental impact, this translates into real-world value: longer-lasting visors that can be refreshed with new skins or panels, less scrap, and a reduced carbon footprint over the life of the accessory.

Electric motorcycles intensify the argument for aerodynamic precision. With limited range as a constraint, any gain in efficiency, however small, counts toward practical usability. CAD/CAE tools enable engineers to model airflow around an entire motorcycle-plus-fairing system with high fidelity. These simulations show how subtle changes in fairing geometry affect drag, laminar vs. turbulent flow, and ultimately energy consumption. The upshot is fairings that are not just shield components but integral contributors to range and performance. The onus falls on designers to translate these computational insights into manufacturable products that can be installed on a wide variety of bikes without compromising safety or liability. In this context, universal fairings are not a compromise but a platform that harmonizes aerodynamics, rider protection, and practicality across diverse bike architectures.

All of these threads, smart sensing, adaptive aerodynamics, advanced composites, modular construction, sustainable protocols, and EV-friendly design, must be anchored in real-world usability. The best solutions empower riders to install, adjust, and upgrade without specialized tools or technical expertise. They respect the cockpit ergonomics of different bikes, ensuring that the fairing does not impede instrument visibility, handlebar reach, or clutch and brake operation. They also acknowledge weather resilience: UV-stable coatings, water resistance, and materials that resist sun fade and cracking over time. And they recognize the broader ecosystem of aftermarket support, where compatible mounting kits, brackets, and extension pieces enable a truly universal front fairing to serve as a scalable foundation for countless configurations.

In envisioning this future, it is essential to maintain momentum with ongoing learning and cross-pollination between design studios, engineering groups, and end users. The universal fairing becomes not only a protective shell but a collaborative canvas for riders who want to tune form, function, and feel. As innovation accelerates, the line between aftermarket accessory and genuine performance component will blur, yielding products that are simultaneously visually striking, aerodynamically effective, and environmentally responsible. The chapter forward is not a shrunken or simplified future but a richer, more inclusive one where a single, adaptable fairing can accommodate different bikes, climates, riding styles, and times of day. In this vision, universal front fairings are both a practical retrofit and a gateway to smarter, more efficient, and more personalized motorcycling.

For readers who want to explore the broader landscape of aftermarket fairings and how they are evolving in tandem with rider needs, a broader context is available through industry perspectives that examine how fairings are used in the real world and what riders actually value. External resource: https://www.bikeexif.com/2023/11/motorcycle-fairing-in-the-real-world-5-uses-youll-actually/

Final thoughts

Understanding universal motorcycle front fairings is crucial for business owners aspiring to thrive in the motorcycle accessory market. By recognizing their design, aerodynamic benefits, and installation prerequisites, you become better equipped to cater to rider needs and preferences. Furthermore, staying informed about market trends and anticipating future innovations positions your business for success. As riders continue to seek improvements in both performance and aesthetics, universal motorcycle front fairings will remain a focal point for enhancement. Embrace these insights, and watch your business grow.