In the world of motorcycle customization and protection, vinyl wrap has emerged as a favored choice among enthusiasts and business owners alike. This innovative solution not only enhances the aesthetics of motorcycles but also serves as a robust protective layer for delicate fairings. Through this article, we delve deep into every aspect of vinyl wraps for motorcycle fairings—from materials and benefits to installation practices and maintenance strategies. Each chapter builds a comprehensive understanding that enables business owners to appreciate the versatility, value, and care necessary for offering vinyl wrapping services. By the end, you’ll be equipped with insights to elevate your service offerings in the motorcycle market and fulfill your customers’ desires for both beauty and protection.

Wrapped for Velocity: A Deep Dive into Materials and Mastery for Motorcycle Fairings

A motorcycle is as much a statement of purpose as a machine, and the surface that tells that story is often a carefully chosen wrap rather than a coat of paint. Vinyl wraps offer riders a way to tailor the bike’s personality, protect delicate finishes, and swap looks without committing to a permanent alteration. The wrap becomes a second skin that can flex with the bike’s architecture, especially on modern fairings that curve and edge with aggressive precision. When done well, a wrap does more than color the surface; it shields from UV fading, micro-scratches, and the tiny abrasions that accumulate on long rides. The best wraps are cast vinyl, a material chosen for a sustained balance of conformability, durability, and clean removal. Cast vinyl’s ability to stretch and settle into complex contours makes it especially well suited to front fairings, side panels, and the rear bodywork that define a bike’s silhouette. It can hold a high-gloss shimmer, a subdued matte, or a textured look that mimics carbon fiber, all while preserving the underlying finish and adding a layer of protection against the elements.\n\nThe choice between cast and calendered vinyl is more than a cost decision; it’s a question of geometry, longevity, and the rider’s expectations for care and maintenance. Cast vinyl is produced by casting the molten material and allowing it to cure slowly, a process that yields superior elasticity and a steady, uniform surface. The result is a wrap that grips the curves of the bike with minimal resistance to edge separation, and it maintains adhesion across a wide temperature range—from bright sun to chilly dawn rides. Cast vinyl typically offers a service life of five to seven years or more, depending on exposure, installation quality, and how aggressively the bike is ridden. This longevity makes it a wise investment for riders who want a premium finish on their machine that won’t require frequent re-wrapping.\n\nCalendered vinyl, by contrast, is produced through a faster rolling process that makes it cheaper and somewhat stiffer. It can perform well on flat or gently curved surfaces, but its rigidity becomes a liability on sharp curves and deep contours common to modern fairings. On complex geometries, calendered vinyl is more prone to bubbling, wrinkling, or lifting at edges, and its lifespan tends to be shorter. While it can suit temporary protection or DIY projects on straightforward panels, most enthusiasts and professionals reserve cast vinyl for full fairing applications where the surface demands a seamless blend with the bike’s lines. The decision is not merely about price; it’s about the predictability of results, the ease of conforming to tight radii, and the absence of compromise on finishing quality.\n\nTo achieve the flawless look riders expect, surface preparation is the unsung hero of a successful wrap. The fairing surface must begin clean and dry, free of oils, wax, and dust that can create micro-bubbles or prevent the adhesive from seating fully. A dedicated prep solution, combined with meticulous wiping and a tack-off to remove any residues, sets the canvas for the wrap. The second pillar is heat, used judiciously to coax the vinyl to follow the fairing’s curves. A professional installer uses a heat gun or infrared source to soften the vinyl enough to lay into creases and around scalloped edges. The process requires steady hands, a clean work environment, and a careful sequence: start with the larger, flatter panels to establish alignment, then work into tighter corners and around protrusions like mirror housings and brake reservoirs. Each panel is squeegeed with controlled pressure to expel air and prevent micro-bubbles, then trimmed along precise edges to ensure a clean seam that adheres evenly and remains forgiving to the removal process later on.\n\nThe practical result of this preparation and technique is not merely a good-looking surface but a wrap that behaves like a factory finish in terms of resilience. Cast vinyl’s adhesion and elasticity help it resist lifting at high temperatures, a common hazard when bikes sit in hot sun during a long ride, or when they’re parked under heat-generating street lamps. Proper installation is essential because even small deviations in contouring can translate into visible irregularities down the line. When done by skilled hands, the wrap remains smooth and consistent across the fairing’s deepest contours and sharp radii, with edges that stay sealed for years. It’s this blend of craft and material that makes wraps a credible alternative to paint for riders who want a non-permanent, reversible, yet durable option.\n\nBeyond the technicalities of material and method, the aesthetic possibilities are a playground of finishes and textures. A high-gloss finish can turn the bike into a sleek, reflective sculpture that catches the eye in every streetlight and showroom glow. Matte options mute the glare and emphasize the bike’s form, giving a stealthy, understated presence on the road. More exotic finishes, including metallic tones and carbon-fiber textures, bring a tactile and visual depth that can mimic more expensive aesthetic packages. The precision of modern vinyl allows the creation of color shifts, two-tone schemes, and gradient effects that can be aligned with the bike’s existing panels or used to emphasize new lines. Selecting the right finish is a balance between color permanence, surface texture, and the rider’s daily use of the bike—whether the aim is a showpiece look or a rugged, race-inspired interpretation that withstands the rigors of time and weather.\n\nCare and maintenance extend the life of a wrap, and sensible habits pay dividends. Gentle washing with mild detergents and soft applicator sponges prevents micro-scratches and preserves the integrity of the adhesive. Avoid harsh solvents that can degrade the vinyl’s surface or soften the adhesive layer. Where necessary, spot-cleaning around edges should be performed with caution, and any aggressive buffing should be left to professionals who know how to preserve the seam integrity. The removal process, when it comes, is a reassuring feature of vinyl wraps. Cast vinyl can be peeled away with minimal risk to the factory finish beneath, provided the wrap was installed with proper surface preparation and care to avoid edge lifting. This reversibility is a compelling advantage for riders who crave the freedom to refresh their bike’s appearance without committing to a permanent color change.\n\nFrom a practical standpoint, several considerations shape a rider’s decision to pursue a wrap. The initial cost is a function of material quality and the complexity of the bike’s panels. A high-grade cast vinyl with a professional installation commands a premium, but the payoff is a longer service life and a finish that remains vibrant under sun, rain, and road debris. In the realm of total ownership cost, the wrap can be a competitive option when compared with repeated paint refreshes or specialized coatings that demand frequent maintenance. It is also important to acknowledge that wrapping requires compatible surface geometry. The more intricate the fairing geometry—the combination of deep grooves, tight corners, and multi-plane transitions—the more advantage a cast vinyl solution provides, and the more likely it is that professional installation will deliver a flawless result.\n\nFor riders who want to explore options for specific fairing families or models, a broad catalog can be a valuable starting point. A link to a collections page that focuses on fairings offers a practical path to visualize how different shapes respond to wrap materials and finishes. This resource can help map the intended look to the physical constraints of a particular bike’s fairing layout, ensuring that color, texture, and gloss levels align with the bike’s geometry and lighting characteristics. collections/honda-fairings, for example, provides a sense of how wrap options map onto common fairing shapes, from broad panels to more intricate assemblies. collections/honda-fairings.\n\nAs riders weigh their options, the decision about whether to proceed with a wrap often centers on how the material behaves in the real world. Cast vinyl is celebrated for its flexibility, its strong adhesion to prepared surfaces, and its ability to maintain color and finish under UV exposure and weather. Its lifelike gloss and depth can rival traditional paint when properly applied, and its ability to be removed preserves the bike’s value and original finish. For enthusiasts who demand both beauty and functionality, vinyl wraps offer an elegant compromise: a protective, aesthetically versatile layer that can be revisited, changed, or removed as tastes—and bikes—evolve.\n\nThe wider ecosystem of wrap materials and finishes underscores a practical truth: in the hands of a skilled installer, cast vinyl unlocks a durable, adaptable alternative to conventional painting. It is not a universal solution for every scenario, but for riders who want a high-grade, long-lasting, and reversible option, it is a compelling choice that respects the inherent beauty and engineering of the motorcycle’s fairing design. In the end, the wrap becomes a story told in color and texture, a narrative of how a rider sees the machine and how the machine carries that vision through daily miles and long rides alike. For those seeking more exhaustive material options, an external resource provides a broader landscape of cast vinyl varieties, metal-inspired finishes, and textural simulations that can complement the careful work of a professional installer: https://www.alibaba.com/wholesale/foil-wrap-sticker-motorcycle.html

Aesthetic Shields and the Edge of Speed: The Protective Power of Vinyl Wraps on Motorcycle Fairings

When riders talk about upgrading a motorcycle, the conversation often centers on horsepower, exhaust note, or aero tweaks. Yet one of the most transformative and practical upgrades happens at the skin of the machine: the fairings. A vinyl wrap on motorcycle fairings is not merely a cosmetic choice. It is a strategic fusion of art and armor, a removable layer that can reinvent a bike’s personality while actively defending its canvas. This dual role makes vinyl wrap a compelling option for anyone who wants to push style without sacrificing the integrity of the original finish. Unlike a repaint, a well-applied wrap sets a reversible path. It can be peeled away to reveal the factory surface beneath, preserving resale value and the pristine look of the underlying material. For a rider who values flexibility—seasonal color changes, sponsorships for a race weekend, or simply a fresh look after a long season—the wrap offers a practical, low-commitment route to express personal identity while maintaining the long-term protection that modern fairings deserve.

The heart of this approach lies in material choice. Cast vinyl, the workhorse of high-quality automotive and motorcycle wraps, brings a suite of technical advantages that align neatly with the complex geometry of contemporary fairings. Cast vinyl’s long-chain structure provides superior elasticity, allowing it to hug sharp radii, tight edges, and deep contours that define modern front ends and side panels. This elasticity translates into fewer bubbles, fewer wrinkles, and a smoother surface that reads as a seamless continuation of the bike’s lines. It resists bubbling even as it stretches to cover a compound surface, provided the installation is performed by skilled hands with the right heat and pressure control. In contrast, calendared vinyl—while more economical—lacks that same degree of conformability. It can perform well on flat or gently curved surfaces, but when a wrap must cover a front fairing with intricate curves or affixed around a rear body line, calendared materials tend to show strain or edge lift over time. The difference is not just about initial appearance; it’s about lifecycle performance on a vehicle that endures wind, vibration, and the grit of road travel.

Preparation is the quiet backbone of a successful wrap. The surface must be pristine, both physically and chemically, before the first sheet is laid down. This starts with a thorough cleaning using a dedicated prep solution that dissolves oils and removes dust flecks without leaving residues. Any debris trapped beneath the film can create whorls, pulling, or micro-bubbles that disturb the visual continuity. After cleaning, a careful inspection for micro-scratches on the fairing surface helps determine whether additional smoothing is required—because even the best vinyl cannot completely erase deep defects. The installer’s toolbox then comes into play: a heat gun or steam source, a high-quality squeegee, and a set of maneuvering techniques designed to coax the film around curves without introducing tension that would lead to lifting later. Proper heat softens the vinyl, increasing its pliability and enabling it to settle into corners and around compound shapes. With cast vinyl, that heat-tension balance is the key to a flawless finish, especially on front fairings where air pressure interacts with the surface at speed.

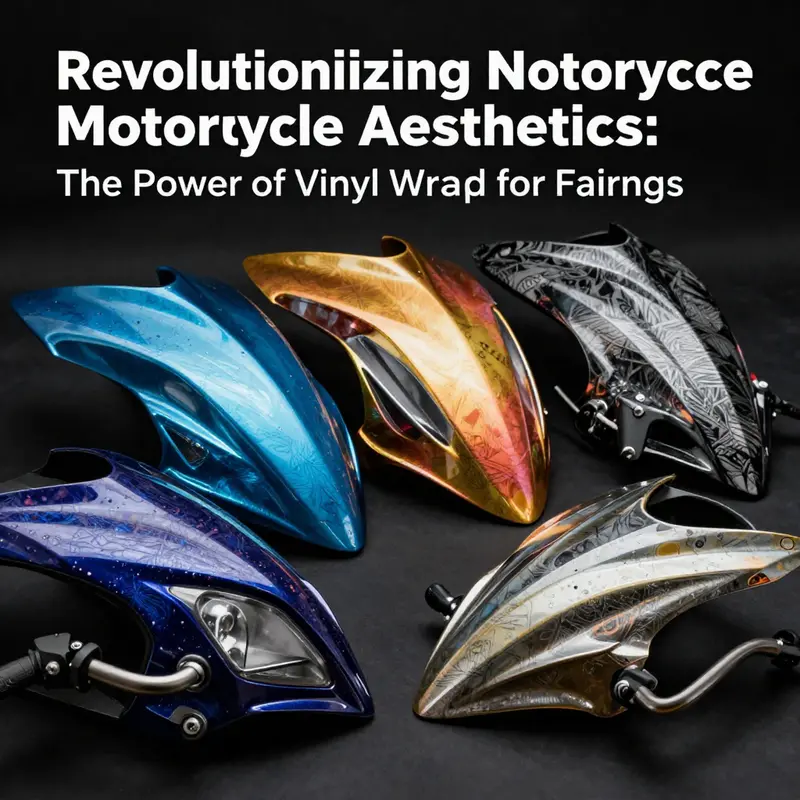

The aesthetic promise of vinyl wraps is correspondingly broad. Riders can pick from an almost limitless palette of colors and finishes. Matte or gloss, carbon fiber textures that mimic woven composites, or chrome-like sheens that shimmer with changing light—these options open a creative runway for personal expression or team sponsorship. The finishes can also be combined in deliberate patterns: racing stripes that accentuate aerodynamics, color blocking that telegraphs a rider’s identity, or even subtle textures that catch the eye without overpowering the silhouette. Because wraps cover the bare paint or primer, they also offer a practical vehicle for experimentation. A rider can cycle through looks—perhaps a bold racing livery for a weekend track day and a subdued, road-legal aesthetic for daily commuting—without the time and cost of repainting each season. A well-chosen wrap can therefore function as a temporary or seasonal garment for the bike, aligning with the rider’s mood, color trends, or race alignments.

Beyond looks, wraps deliver tangible protective benefits. The adhesive layer acts as a sacrificial shield that takes the brunt of minor abrasions, stone chips, and road grime. This is particularly valuable for high-impact areas around the front fender, lower fairings, and the edge lines where debris is often the most aggressive. The protective layer helps preserve the underlying finish, especially when the original paint is delicate or prone to fade under UV exposure. Cast vinyl’s UV resistance is a key feature here; it maintains color integrity longer than many alternative finishes, helping the bike retain that fresh look under sun, rain, and highway miles. The wrap’s resilience also contributes to long-term value. By shielding the fairing panels from micro-marring and the gradual thinning of clear coats, wraps can extend the time between major restorations or repaints, which is a meaningful consideration for riders who ride hard and want to maintain mechanical and cosmetic equity over the life of the bike.

The longevity of a wrap is a function of both material quality and maintenance. A high-quality wrap typically lasts five to seven years or more, depending on climate, riding conditions, and care. Sun exposure and high-heat environments, as well as frequent washing with aggressive cleaners, can shorten that timespan if the wrap is not properly maintained. Routine care should be gentle: mild cleaners, soft cloths, and avoidance of solvent-based solvents that could degrade the adhesive or the surface. When properly cared for, wraps resist fading and edge lift, retaining their color, gloss, or texture for years. It’s also worth noting that the overall life of a wrap is intimately tied to installation quality. Even premium cast vinyl can be undone by poor substrate preparation, improper heat application, or subpar adhesive application. A professional installer trained in automotive and motorcycle wrap techniques is the best safeguard against these issues, ensuring the wrap adheres across all facets of the fairing and remains stable through temperature fluctuations and vibration.

In the lifecycle view, a vinyl wrap introduces a practical pathway to value. It lowers the upfront investment required for a dramatic cosmetic overhaul compared with a full repaint. It also offers the flexibility to refresh the look without the downtime associated with a repaint, reducing the opportunity cost of a weekend on the bench rather than on the road. When the time comes to update or swap designs, the wrap is designed to be lifted and replaced cleanly, often without damage to the factory finish underneath. This reversibility is one of the most persuasive arguments for riders who prize both personalization and resale value. It is also worth mentioning how professionally installed wraps contribute to overall motorcycle reliability. A carefully wrapped fairing retains its aerodynamic integrity, keeping edges crisp and gaps even. The film’s presence does not interfere with mounting points, ventilation intakes, or sensor housings, so the bike maintains its functional performance while wearing a new face.

For riders curious about where to start, the wrap journey often begins with compatible, readily available panels and fairings from established collections. If you are exploring a specific model family, you can begin with a broad catalog of parts to determine how the visual language will translate onto the bike’s geometry. For those interested in a targeted starter point, consider exploring the Honda fairings collection as a baseline to assess how fitted panels and patterns might align with your wrap’s color story and contour flow. This approach can help you gauge how a wrap would interact with your bike’s most defining lines before committing to a full-body wrap, ensuring the final look respects both the bike’s silhouette and the rider’s personality.

Internal linking note: for riders seeking compatible panels to wrap around existing frames, the Honda fairings collection offers a broad starting point. Honda fairings collection.

Finally, the broader context of wrap technology sits within a rising wave of materials science applied to two-wheeled machines. The craft has matured to support wraps that look as if they are painted on, yet retain the non-permanent, serviceable advantages of vinyl. The modern wrap blends color, texture, and tactical protection into a single, practical package. It invites riders to rethink what a motorcycle’s skin can do: shield the surface from the wear of travel, fragrance and form from the caprice of weather, and, perhaps most delightfully, invite the rider to choose a new aesthetic expression with relative ease. In the end, vinyl wrap is more than a cosmetic option. It is an integrated approach to care, performance, and personal storytelling on the move. For those seeking to dive deeper into the technical and practical aspects of high-performance wraps, there is value in exploring external perspectives that detail the benefits and application nuances of vinyl wraps for fairings. External resources can complement this chapter by offering deeper dives into the science of adhesion, heat management, and long-term durability that underpin successful installations on motorcycles.

External resource: https://www.motorcycle-technology.com/vinyl-wrap-fairings-benefits

Precision on Curves: Mastering Vinyl Wrap Installations for Motorcycle Fairings

Every rider considering a vinyl wrap for motorcycle fairings quickly discovers that the real challenge is not color or finish but the installation itself. A wrap is a skin, not a paint job, and its longevity depends on how well it is laid over the bike’s most demanding surfaces. Cast vinyl, the material most recommended for high-end motorcycle fairings, behaves like a second skin: it stretches, conforms, and adheres with a maturity that calendared vinyl rarely achieves. The difference between a wrap that looks factory perfect and one that shows primer through the edges is rarely about pigment alone; it is about the sequence of decisions that begins long before the vinyl touches the fairing and ends only after the last edge is tucked and the surface has cooled. When done by a skilled installer, a wrap can preserve original finishes, shield against UV and micro-scratches, and offer a durable aesthetic that is as expressive as it is protective. The approach to installation speaks to the broader goal of wrapping as a responsible customization—one that respects the bike’s geometry, the rider’s needs, and the long-term integrity of the panels.

Preparation is the silent instructor of the process. The fairing surface must be clean, dry, and free from any contamination that could compromise adhesion. A dedicated prep solution or isopropyl alcohol is used to strip away grease, wax, silicones, and fingerprint residues. Even a faint film left on the surface will become a fault line under the wrap, inviting lifting or premature micro-bubble formation. After cleaning, the surface should dry in a dust-free environment; moisture trapped under the vinyl can lead to clouding or imperfect mating with recessed contours. The surrounding air should be temperate, not extreme, with minimal dust levels to prevent particulates from embedding under the film during handling. The preparation stage is not glamorous, but it is where the wrap earns its reputation for longevity. It also dictates whether the film will lay smooth across a transition from a flat panel to a deeply contoured fairing, where the risk of stretching distortions is highest.

Material choice follows preparation. Cast vinyl is the preferred option for motorcycle fairings because it offers superior stretch and memory. Its flexibility allows it to embrace severe curves, compound angles, and tight radii without bubbling, edge lifting, or cracking. Cast vinyl’s long-term durability—resisting shrinkage and fading under UV exposure—makes it a reliable foundation for a finish that should endure through miles of rain, sun, and road grit. Calendared vinyl, while more accessible, tends to be stiffer and less forgiving on complex profiles. It is more prone to edge lift on sharp edges and aggressive contours, which makes it a less ideal choice for full fairing applications. In practice, the installer evaluates the shape of each panel, then partners with the appropriate cast material in a way that optimizes both appearance and adhesion. The choice has practical implications: a smoother, more consistent color and a wrap that moves with the bike rather than against it.

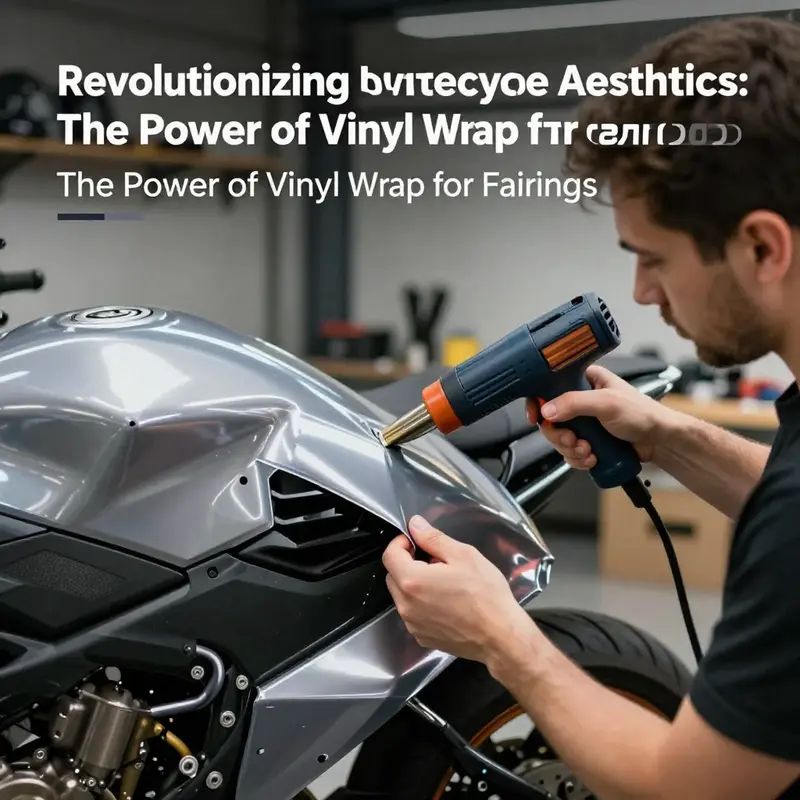

The installation technique unfolds as a choreography of layout, positioning, and controlled shaping. The tools—squeegee, heat gun, utility knife, and optional application tape or transfer film—are extensions of the installer’s hands. Begin by positioning large sections to align with the most visible reference lines or panel boundaries. Application tape can help with precise placement before final adhesion, especially on larger single-piece sections that must maintain symmetry across the fairing. The center-out approach is a time-tested strategy: place the vinyl at the midpoint of a panel and then work outward toward the edges. Consistent pressure with the squeegee pushes out air bubbles and ensures a uniform bond. On curved or deeply contoured areas, brief, cautious heat application becomes essential. A heat gun softens the cast vinyl, allowing it to stretch over a complex contour without overstressing the adhesive. The key is restraint—too much heat or too aggressive pressure can cause silvering, scorching, or adhesive damage that compromises the wrap’s long-term performance. When working around fasteners, air vents, or tight corners, the installer uses the heat to relax the vinyl just enough to tuck it into gaps or under edges, then trims with a sharp utility knife to create a clean, deliberate edge that tucks into the seam rather than peels away from it.

Finishing touches transform a wrapped panel from a good result into a professional one. After the vinyl is laid and all major contours are secured, final trimming is performed with a careful eye for edge management. It is important to leave a small margin beyond the edge to tuck under trim lines or into recesses where possible; this reduces the risk of visible seams and helps keep edges sealed against moisture. The edge work is subtle but crucial. If the wrap meets a panel junction, the installer may run a seam along the interior edge or wrap past the edge and secure with a tight tuck, ensuring a seamless appearance from the rider’s vantage point. Where corners meet, the film should be scored and released in small increments to avoid over-stretching, which can create distortion at the apex of a curve. Once the layout is complete, the surface is allowed to settle. A period of rest after trimming helps the adhesive cure and settle into a consistent bond with the substrate.

Curing and maintenance punctuate the installation as the wrap begins its life on the motorcycle. A curing window—typically 24 to 48 hours in a temperature-controlled environment—allows the adhesive to form a durable bond without sudden temperature shocks that could cause edge lifting. During this time, riders should avoid aggressive washing or exposure to high-pressure streams, which can dislodge marginal edges before the bond has fully cured. When cleaning, mild soap and water are sufficient, and abrasive cleaners or solvent-based products should be avoided to preserve gloss and edge longevity. Routine maintenance becomes a shield against early wear: periodic light cleaning with a soft cloth reduces the accumulation of grit that could abrade the surface, and avoidance of harsh chemicals keeps the color stable and the film intact. Some riders opt for a clear protective overlaminate to boost UV resistance and further prolong the finish, though this adds an extra step in the process and slightly alters the panel’s tactile feel. Either choice should respect the wrap’s documented heat tolerance and adhesive chemistry, ensuring the finish remains consistent as the bike moves through sun, rain, and road grime.

Even with meticulous preparation and execution, an installation exists on a spectrum: from a flawless, showroom-like result to a successful, durable wrap that still reveals the rider’s skill through minor imperfections. Common pitfalls—air micro-bubbles that escape notice until hours later, edge lift at the outer radii, or slight stretch-induced waviness on tight curves—teach important lessons about the sequence of steps and the importance of patience. The best practice is to anticipate where a panel’s geometry will challenge the film and adjust technique accordingly: smaller pieces that reduce tension on a single seam, careful heat management around compound shapes, and deliberate edge trimming that preserves clean lines. These choices reflect the installer’s understanding that wrap installation is not merely about applying a sheet of vinyl; it is about shaping a material to the bike’s anatomy, respecting its curves, and preserving its essence while delivering a fresh look.

For riders seeking a broader sense of how to navigate fairing customization, the ongoing conversation between surface preparation, material science, and technique is helped by established guidance from experienced sources. When exploring options for different model families, you may encounter specific fairing lines that align with particular bikes, such as the Honda fairings collection, which offers panels and styling cues that influence wrap strategies. For a broader catalog, you can explore the Honda fairings collection linked here: Honda fairings collection.

Beyond the hands-on craft, the installation ethos centers on respect for the motorcycle’s original finish and the rider’s evolving aesthetic. Wraps are removable, and the ability to restore to factory paint is a practical advantage for riders who like to experiment with different looks without committing to permanent changes. Cast vinyl’s ability to conform to a bike’s contours with resilience under bending stresses makes it a practical choice for the kind of frequent styling updates riders often desire. The discipline of prep, the elegance of technique, and the care taken in curing and maintenance together compose a narrative about vinyl as a dynamic tool for motorcycle personalization—one that balances artistry with engineering. As the chapter space is limited, the emphasis remains on the essentials: prepare thoroughly, choose the right material, apply with measured precision, finish with care, and maintain with restraint. In doing so, the wrap not only enhances the visual stance of the motorcycle but also extends the life of the fairings by providing a sacrificial, protective layer that is both reversible and recoverable. For those who want a deeper dive into step-by-step demonstrations and expert techniques, external resources exist to guide the curious and the professional alike: Vince’s Vinyl Wrap Academy maintains a comprehensive motorcycle wrap guide that can expand on the practices outlined here. External resource: https://www.vincentvinyl.com/vinyl-wrap-motorcycle-guide

Guarding the Gloss: A Unified Approach to Longevity and Performance in Motorcycle Wraps

A motorcycle’s fairings are a battleground where appearance and protection meet the realities of road chemistry, weather, and constant motion. When riders choose a vinyl wrap as a lasting style and shield, they embark on a maintenance journey that centers on material quality, installation craftsmanship, and disciplined care. The longevity of a wrap on modern fairings hinges on two intertwined factors: the cast vinyl itself and the skill with which it is applied. Cast vinyl, produced by pouring molten vinyl onto a release liner and allowing it to cure, is engineered for precision and resilience. It brings a level of elongation, memory, and edge stability that is especially valuable on deep curves and tight contours—areas that define contemporary fairings. When installed by a professional who understands how heat, pressure, and edge sealing interact, this material can reliably endure for five to seven years or more. In contrast, calendared vinyl—often chosen for budget projects—lacks the same flexibility and habitually performs best on flatter panels rather than full fairings. The practical takeaway is simple: if durability and a consistent, factory-like finish matter, investing in high-quality cast vinyl and a skilled installation nearly always pays dividends in both aesthetics and protection over time.

This reality reframes maintenance not as a chore but as a design principle. A wrap’s lifespan is not merely a matter of the film’s chemistry; it is a function of how surfaces are prepared, how heat is applied during installation, and how the wrap is cared for during riding seasons. Thorough surface preparation remains nonnegotiable. The fairing surface must be meticulously cleaned with a dedicated prep solution to remove wax, oils, and any particulate matter that could become adhesive detents or micro-abrasions under stress. Any remaining dust can threaten adhesive bondlines, especially along compound curves and inside corners where air can become trapped. Proper preparation creates a clean canvas that allows the wrap to conform to the bike’s geometry without creeping or lifting as temperatures fluctuate and as the vehicle experiences vibration.

The installation process itself is where theory meets physics. Cast vinyl’s stretchability is a strength when dealing with the fairing’s three-dimensional shapes, but it is not a license for guesswork. A professional installer uses controlled heat and steady pressure to coax the film into conformity over radii, hollows, and edges. They watch for subtle shifts that could lead to air pockets or micro-wrinkles, particularly near the junctions of side panels and the nose or under the edge lines where UV exposure is intense. Edge sealing is a critical technique that prevents lifting in the long term. When edges are not securely tucked and folded into gap zones, even the best vinyl can peel after a season of sun, rain, and highway spray. The emphasis here is continuity: a seamless wrap remains visually stable and functionally protective, resisting the micro-motions that otherwise crack or lift a lesser install.

Once installed, the wrap’s life is largely defined by environmental exposure and the rider’s care routine. Regular cleaning with mild soap and water keeps grime from working into the film’s surface and avoids the abrasive wear that harsh chemicals or stiff bristle brushes can impart. High-pH cleaners or aggressive solvents can swell or glaze the film’s surface, diminishing gloss and potentially weakening the adhesive over time. Abrasive pads are similarly problematic; even gentle scrubbing can leave micro-scratches that accumulate with road grime. The best approach is a soft microfiber, lukewarm water, and a light touch. For stubborn brake dust or tar, a diluted, non-caustic cleaner designed for automotive finishes, used sparingly, can be followed by thorough rinsing and drying. The philosophy is protective, not punitive: treat the wrap as you would a high-quality clear coat, preserving its clarity and color depth so UV-induced fading and color drift are minimized.

UV exposure itself is a central figure in any discussion of longevity. Cast vinyl resists fading far better than cheaper alternatives, but no wrap is truly immune to the sun’s energy. A long-term strategy combines material choice with practical habits: keep the bike sheltered when idle under a cover that breathes, park away from direct afternoon glare when possible, and consider a protective laminate or top coat if the rider frequently exposes the bike to sun-heavy climates. This additional layer can serve as a sacrificial shield that absorbs some of the environmental stress and can be replaced when the wrap reaches the end of its cosmetic life, simplifying maintenance and restoration.

Riders who seek a balance between cost and durability often weigh the option of lower-grade wraps for temporary protection or flat-panel applications. These can be acceptable for short-term projects or bikes used in environments where a full fairing wrap would be vulnerable to damage, but the realities of contouring and edge behavior make them less ideal for full-fairing coverage. Cast vinyl, especially when matched with a reputable installer and, where appropriate, a protective laminate, delivers a longer service life and a more uniform color response across the bike’s surface. It also affords the rider the flexibility to refresh the appearance with a new color or texture when the time comes.

In practice, longevity also benefits from thoughtful planning around usage patterns. Frequent high-speed exposure, frequent contact with road debris, and aggressive riding in urban environments can accelerate wear. Conversely, a wrap enjoyed as a nightly commuter or a weekend track toy with moderate exposure will perform differently, maintaining its gloss and color more gracefully for a longer period. The key is to set expectations with the rider about the trade-offs. A high-quality wrap is not a one-time cosmetic upgrade; it is a long-term investment in the bike’s appearance and its surface integrity. If the installation was done with attention to edge seals and film orientation, and the rider adheres to a careful cleaning and storage routine, the wrap can maintain its aesthetic and protective value for many seasons.

From a practical perspective, the lifecycle of a wrap also depends on maintenance milestones. For instance, a periodic inspection to check edges and corners after a season of ride-in weather can catch lift early, allowing for timely reheat and resealing. If small wrinkles or edge lift are detected, a professional reheat and compression can re-secure the bond and prevent more extensive repairs later. This proactive approach is often far more economical and visually satisfying than reactive repairs after a larger section begins to peel. It also aligns with the rider’s desire for a bike that looks fresh, with consistent color and gloss across all panels, a factor that becomes especially noticeable at show-and-tell gatherings, photoshoots, or when selling the bike later on.

The conversation about durability ties back to brand and installation reliability, which is why a careful selection process matters. Choosing a material with proven automotive and motorcycle performance characteristics and pairing it with a studio or shop known for meticulous prep and precise heat control is the most reliable path to long-term satisfaction. The goal is not just a beautiful finish but a sustained barrier against chipping, scuffing, UV degradation, and the micro-movements that can undermine adhesion over time. When a rider takes this approach, the wrap remains a resilient layer that preserves factory finishes in new ways, even as styles and textures evolve over the years.

For riders curious about compatible options and a broader range of fairing shapes, the journey often starts with exploring the available fairing collections. A well-considered starting point is to review a curated assortment of fairings that match your bike’s make and model, ensuring the chosen wrap complements the underlying geometry before any material is applied. This alignment helps smooth the transition from stock to wrap and reduces the risk of misfit or edge misalignment during installation. As you compare options, consider how the color, texture, and perceived depth interact with your bike’s existing lines and the lighting you ride under most often. A wrap should accentuate form as much as it enhances protection.

In sum, the longevity and performance of a vinyl wrap on motorcycle fairings rest on the trio of material quality, skilled installation, and disciplined maintenance. High-quality cast vinyl installed by a professional provides the most reliable foundation for a durable, aesthetically consistent finish. Regular, gentle cleaning and mindful protection against harsh solvents, abrasive cleaners, and extreme UV exposure complete the lifecycle equation. When executed with care, the wrap becomes a durable, removable, and visually compelling layer that respects the bike’s original design language while offering the rider freedom to refresh looks as styles and seasons change. This approach positions the wrap not as a temporary fix but as a long-term finishing technique that aligns with responsible care practices and the rider’s evolving sense of speed, style, and protection.

Internal link: For riders exploring compatible fairing options, the Honda fairings collection offers a range of shapes and dimensions that can influence wrap decisions and installation strategies. Explore options here: https://www.summitfairings.com/collections/honda-fairings

External resource: For additional insight into wrap longevity and care routines, a detailed discussion is available at Car Interior, which outlines practical maintenance steps and real-world performance expectations. External reference: https://www.carinterior.com/blog/motorcycle-wrap-how-long-does-a-wrap-last-on-a-motorcycle

Sculpted Surfaces, Shielded Finishes: The Evolution of Vinyl Wrap in Motorcycle Fairings

Riders chase speed, yes, but they also chase identity. In a world where performance has long been measured in horsepower and aerodynamics, the fairing now stands as a dynamic surface where form and protection meet. Vinyl wrap has quietly but decisively transformed that surface. It is more than a color or a pattern; it is a modular layer that can be added, removed, or swapped without compromising the underlying factory finish. The shift from pigment to film signals a broader trend in motorcycle customization: an emphasis on versatility, durability, and practical reversibility. Cast vinyl, in particular, has emerged as the material of choice for modern fairings because it negotiates the road and the curves with a level of fidelity and reliability that calendared vinyl struggles to match. Its flexible, stable nature makes it well suited for the deep contours of a front fairing, the sculpted sides, and the angular retreat of rear bodywork. When applied by a skilled professional, cast vinyl can cling to the most challenging geometries—without the ripple or bubble that might betray a novice hand—and it can maintain its visual integrity for years, typically five to seven or more with proper care and installation. The longevity and appearance of these wraps are not just about aesthetics; they are about preserving the integrity of the bike’s original surface while offering a protective layer against UV exposure, small abrasions, and the daily grind of road debris. The idea of protecting a factory finish while enabling dramatic customization is compelling for riders who want the ability to change the look as readily as a season changes.

The material science behind wrap films explains much of this appeal. Cast vinyl behaves differently from calendared vinyl because it is manufactured with a more uniform polymer structure and a higher inherent memory. This translates into superior conformability when the film is stretched over vents, ridges, and the tight radii that define modern fairings. The film’s dimensional stability means that it is less prone to distortion over time, which is crucial for a surface that experiences rapid air movement at high speed and exposure to intense sunlight. UV resistance is another critical factor. Cast vinyl is engineered to resist fading and yellowing, ensuring a consistent color through years of sun exposure and riding in varied climates. This reliability matters as riders look for visual consistency along with performance.

Yet the benefits of wrap must be earned. The installation process is as important as the material itself. Surface preparation cannot be overstated: meticulous cleaning, the removal of oils, waxes, and residue, and the use of a dedicated prep solution set the stage for a successful wrap. Even the smallest particle or film of grease can cause edge lifting or premature failure at high speeds. Once the surface is prepared, heat becomes a controlled instrument rather than a nuisance. Proper heat softens the cast vinyl just enough to enable it to bend and settle into deep curves, while preserving edge integrity and adhesive strength. Improper heat—too little, too much, or inconsistent application—can create micro-bubbles, wrinkles, or corner lifting that undermines both the appearance and the protection the wrap promises. The process is an art form that combines a technician’s hands, a set of precise tools, and a disciplined approach to timing and patience.

The visual universe of wraps has expanded far beyond its original gloss and matte options. Today, riders can choose from chrome-like sheens, carbon fiber textures, and even color-shifting, iridescent films that change hue with the angle of light and the rider’s viewpoint. These finishes carry practical benefits as well as aesthetic appeal. Some advanced films include scratch resistance and enhanced weather protection, contributing to reduced maintenance and longer intervals between rewraps. The ability to layer patterns and textures offers a way to channel performance cues—like a carbon weave to evoke speed or a metallic hue to emphasize danger on a canyon road—without the risk of permanently altering the bike’s geometry or resale value. A well-chosen finish can also help to hide minor imperfections in the underlying surface, creating a cohesive look that remains faithful to the bike’s lines even as the look evolves over time.

The democratization of wrap technology has contributed to a rising DIY conversation, even as professionals remain the recommended route for high-visibility areas and high-performance machines. The accessibility of DIY wraps has invited riders to experiment with budgets and ideas, to learn the basics of surface prep, alignment, and heat management. But the more complex fairings—where curves meet vents, and panels meet at sharp junctions—still demand the trained eye, a steady hand, and a properly calibrated heat gun. Mistakes in layups, misaligned seams, or premature edge lifting can be costly and time-consuming to correct. What the DIY shift has done, however, is widen the door for the average rider to test ideas, accelerate trend cycles, and push the industry toward more forgiving films and easier application methods. The result is a feedback loop: riders propose looks, manufacturers refine films, and installers translate vision into durable, ride-ready surfaces.

In this evolving landscape, the question for many enthusiasts is not only what they want to wear on their bike, but how those choices fit into a broader maintenance and ownership mindset. Wraps are removable, which is appealing for riders who like to refresh the look with new trends or who want to protect value by shielding the original finish. Yet the decision to wrap should be informed by a pragmatic calculus. The cost of a professional wrap varies with the complexity of the fairing shape, the quality of the film, and the level of customization, including graphics and finishes. The lifetime estimate—five to seven years or longer, with proper installation and care—puts wraps on a similar trajectory to many aftermarket paint options, but with the key advantage of reversibility. The ability to peel away a wrap cleanly, leaving behind a factory-finish surface that remains undisturbed, is a powerful narrative for riders who value future flexibility and resale potential.

From a design perspective, this is where the industry’s innovation cadence is most visible. Films with air-release channels simplify the application by allowing trapped air to escape as the installer squeegees toward the surface, reducing the likelihood of bubbles and ensuring a smooth, continuous wrap along the fairing’s complex geometry. This subtle technical refinement has a disproportionate effect on the rider’s perception of quality. A wrap that lies flat and evenly across a front fairing with a protruding vent or a recessed edge communicates precision and care. The same attention to detail carries through to the color and finish choice. A chrome-like wrap, for instance, demands a reflective clarity that can reveal minor surface flaws if the film is not perfectly contoured to every contour. The carbon textures, when paired with a satin or gloss topcoat, can deliver a convincing illusion of depth and weave that rivals traditional materials, while adding the protective credentials that modern riders expect from their customization choices.

As the market matures, there is also a growing emphasis on trusted, reputable installation and material sources. The consensus among seasoned wrap specialists is that you should treat the fairing as a critical surface, one that benefits from the long-view investment in high-quality film and experienced hands. This approach aligns with the industry trend toward durable, removable finishes that respect the original design language of the motorcycle while enabling fearless experimentation with color, texture, and branding cues—without committing to a permanent paint job. For readers who want to explore how wrap interacts with different fairing geometries, see the Honda CBR1000RR fairings collection (2012–2016).

In sum, vinyl wrap for motorcycle fairings has matured into a credible, high-performance alternative to paint. It offers the versatility to customize, protect, and refresh with a level of ease and reversibility that speaks directly to the modern rider’s lifestyle. The cast vinyl story—its conformability, UV resilience, and long-term stability—tells a pragmatic tale of durability meeting design. The finishes available today—ranging from chrome and carbon fiber to iridescent shifts—expand the aesthetic possibilities without sacrificing the protective purpose of the wrap. And while DIY adoption grows, the professional layer remains essential for ensuring that the wrap performs under wind pressure, heat, and the vibrations that come with high-speed riding. In this ecosystem, the fairing becomes not only a canvas for personal expression but a living piece of protective gear that keeps its edge as it travels through sun, rain, and countless miles of pavement. For a broader market context and technical standards shaping pricing and composition, refer to the industry analysis by Nina Flores. External resource: https://www.nina-flores.com/motorcycle-wrap-industry-trends

Final thoughts

Vinyl wrap for motorcycle fairings stands out as a transformative solution for those looking to enhance a motorcycle’s aesthetic appeal and protect its integrity. As explored throughout this article, understanding the materials, installation processes, maintenance practices, and industry trends offers business owners a comprehensive toolkit to effectively meet customer demands. By adopting high-quality cast vinyl and employing expert techniques, businesses can not only elevate their offerings but also position themselves as leaders in the motorcycle customization market. The potential for growth and customer satisfaction is robust, providing an excellent opportunity for entrepreneurs to excel in this evolving industry.