Custom motorcycle fairings represent both a functional and aesthetic upgrade for two-wheeled vehicles, essential for business owners looking to differentiate their offerings in a competitive market. This guide explores the intricate structure and composition of these fairings, the innovative materials and manufacturing processes involved, and the myriad of applications available for personalized designs. From understanding the structural benefits that fairings provide to selecting the best materials for durability and style, this comprehensive overview will empower businesses to make informed decisions in the custom fairings market.

在空气动力与个性化之间起舞的曲线:定制摩托车整流罩的结构与组成

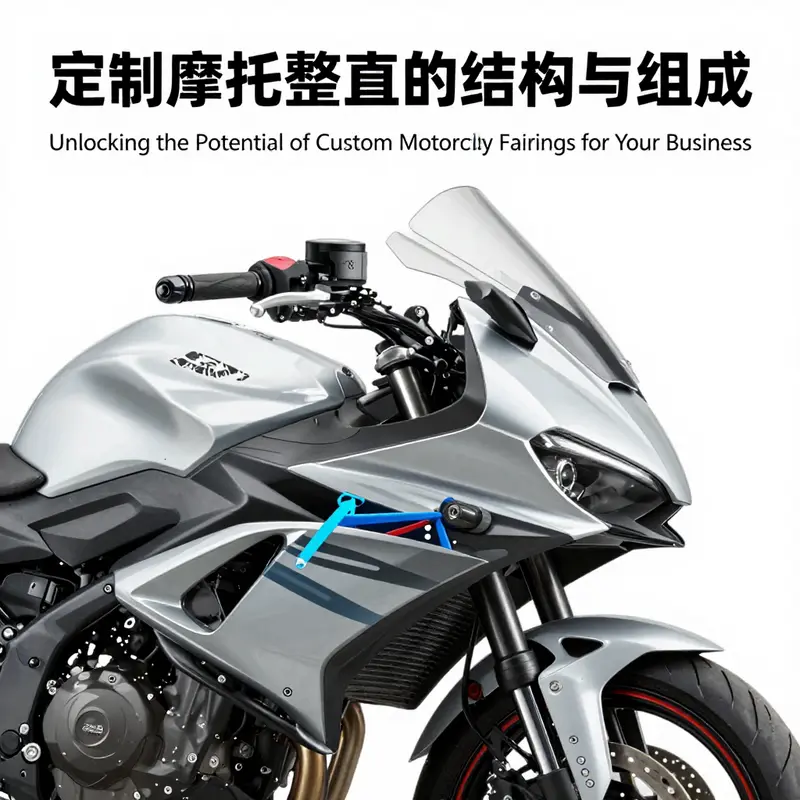

定制摩托车整流罩的结构与组成,远比一个简单的外壳更为复杂与精巧。它是工程与美学的交汇点,是空气在车头周围被引导、分流、再重新组织的载体,也是车主个性表达的载体。一个设计精良的整流罩,能够在不牺牲外观个性的前提下提升气动效率,降低风阻,改善高速稳定性,同时为整车的散热、灯光、传感器等系统提供可控的氛围与空间。要理解它的结构与组成,需从材料的选择、制造工艺、功能性设计、与整车系统的集成这几大核心出发,再把这些要素编织成一个连贯的整体。只有当每一块面板、每一道缝线、每一个连接点都履行着自己的职责时,整流罩才真正成为“中枢件”,而非单纯的装饰件。

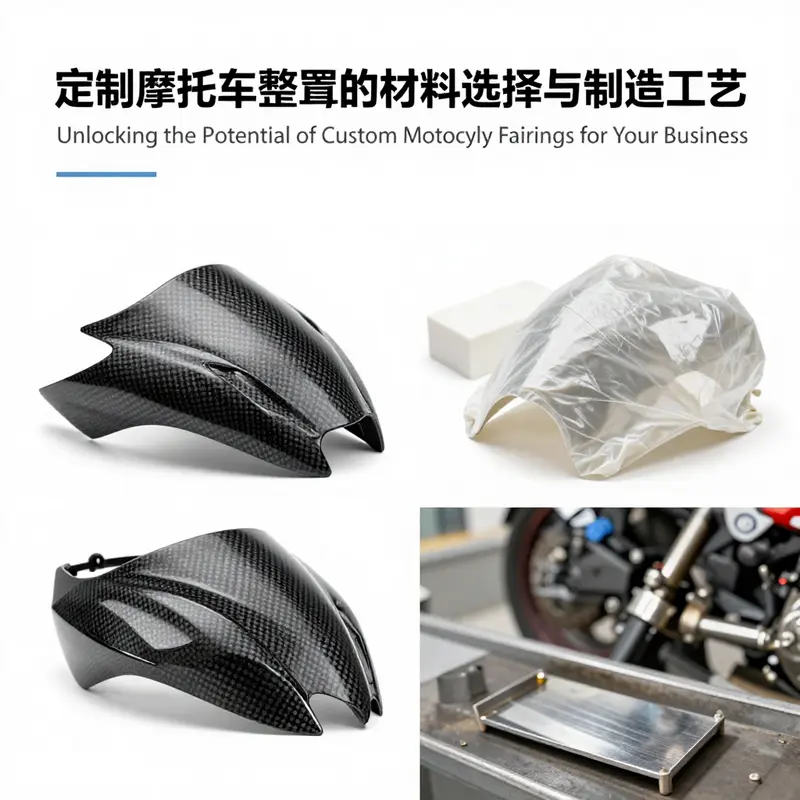

材料是第一道门槛,也是决定性能走向的根本因素。在定制领域,常见的材料组合大多建立在三大主材之上:铝合金、碳纤维与ABS/PC等热塑性材料的复合系统。铝合金以其卓越的强度、耐热性与可塑性,在高端定制车身上得到广泛应用。通过数控加工(CNC)或精细手工锻造,铝合金能够实现复杂曲面和无缝连接的设计语言,提供优越的结构刚性,同时具备良好的热传导性能,便于与发动机与制动系统的热环境协同工作。碳纤维则以重量极轻、比刚性更高著称,成为追求极致性能的改装方案常见的首选。碳纤维的高模量和低密度,使整流罩在高速行驶中的风洞效应更易被掌控,空气阻力减小,车辆的敏捷性和操控性得到显著提升。然而,碳纤维的成本与制造难度也较高,需要更复杂的工艺与严格的质量控制。ABS与聚碳酸酯(PC)的组合则以成本效益和冲击韧性见长,广泛用于日常骑行和中端改装件。PC+ABS的复合材料具备良好的抗冲击性、耐热性和可塑性,适合大面积成型、快速原型验证以及量产化生产。对高性能需求与日常使用场景的权衡,往往会在不同区域采用不同材料的叠层或拼接来实现最优解。

制造工艺则是材料优势转化为实际形态的关键环节。多数定制整流罩通过真空袋压成型、真空辅助树脂传递成型(RTM)或注塑等工艺实现。这些工艺的核心在于控制树脂的浸润、固化方向与表面光洁度,使成品具备优良的表面光泽、平整度和尺寸精度。真空袋成型在碳纤维与高强度复合材料的应用中尤为常见,它能实现薄壁结构的高强度化,同时减少蜂窝状结构的缺陷和应力集中。对于金属如铝合金的整流罩,常通过CNC加工或手工锻造实现高度精确的外形与无缝连接,再配合表面处理工艺提升耐腐蚀性与视觉效果。制造过程中的关键不仅在于成形本身,更在于后续的表面处理与涂装工艺。高质量的抛光、底漆、-middle层涂层以及透明清漆,不仅提高视觉层次感,还为抗紫外线、耐磨、抗划伤等实用特性提供保护。

从功能性设计角度来看,现代定制整流罩的目标不仅是“看起来酷”。它在空气动力学开口、导流槽、通风口等方面被精心布局,以实现气流的有效引导和发动机、制动系统以及机油冷却器的热管理。前方的进气口和两侧的导流口常被设计成与进气系统的压力场匹配的形状,确保冷却空气能顺利进入发动机舱,同时减少对前轮与悬挂系统的干扰。某些高级设计甚至在整流罩内部嵌入导风板、可调节导流结构或气流分配通道,以在不同的驾驶情境下调整气动特性。这些设计不仅提升功能性,也为外观带来更具科技感的线条与肌理。

无缝、极简的外观也是整流罩设计的重要趋势之一。所谓“无扣件”理念,强调尽量减少外部可见的连接点,使面板表面呈现连续、流动的曲线。这需要高度精准的模具、严格的容差控制,以及在连接区域采用高强度粘接剂、金属束紧件与必要的机械螺栓的组合,以确保在长期使用中的结构稳定性与震动耐受性。除此之外,整流罩还并非单纯的外壳,它往往承载甚至隐藏一部分部件,如某些车型将后续的仪表线束、灯组或摄像头支架设计成与整流罩一体的结构,以实现外观的整体性与功能的一体化。这种设计语言要求工程师在早期的概念阶段就考虑到后续维护与扩展性,确保日后对部件的替换、升级或维修不会对整体结构造成过多干扰。

在连接与集成层面,整流罩并非孤立存在。它需要与车架、油箱、副车架及前叉等关键部件实现精准对接。这就要求在制造与组装阶段对孔位、对齐、公差、以及固定方式有严格控制。某些个性化设计会以更加紧凑的体量去包覆前叉下部,甚至将车把的固定与整流罩的上沿做成一体化结构,以获得“驾驶姿态的纯净感”。与此同时,整流罩在热环境中的表现也被放在同等重要的位置。发动机与前部制动系统往往产热较高,因此冷却通道的设计、与通风口的协同工作变得至关重要。良好的热管理不仅提升发动机效率,也有助于延长贴膜、涂层与材料本身的寿命,避免因长期高温而导致的色彩退化或材料脆化。

个性化表达与工艺美学在整流罩的设计里占有重要位置。定制的核心价值之一便是将车主的审美偏好、品牌风格与个性化符号融入到实体结构里。材料表面的纹理、碳纤维的纹路、涂层的色彩深浅、以及图案的局部雕刻都能成为个性化表达的载体。手工打磨、局部手绘、金属雕刻、甚至在表面嵌入微型招牌,都可能出现在顶级定制作品中。质量好的整流罩不仅在视觉上有冲击力,更在触感、光泽度和耐用性上展现出高水平的工艺水准。

从维护与耐用性的角度看,整流罩的改装件往往需要在日常使用、长期风雨侵袭及路面碎石的冲击之间取得平衡。碳纤维部分若遭受外力撞击,修复往往比替换更具挑战性;而ABS/PC基体则在冲击、耐划方面表现更为优越,便于修复与更换。涂层与表面处理是延长寿命的重要环节,尤其是在紫外线照射强烈、温度波动频繁的环境中,合适的涂层能显著降低表面起泡、褪色、龟裂的风险。与之相伴的是对材料的耐腐蚀性、耐化学性以及耐高温性能的综合评估,确保整流罩在长期使用中仍能保持结构强度与视觉美感。

在购买与评估阶段,理解这些结构与工艺要素尤为关键。合格的定制整流罩应具备明确的车型匹配、明确的材料信息、清晰的制造工艺说明以及可追溯的质量标准。对于追求极致个性化的骑士,来自独立工作室的手工定制往往提供从三维建模到喷漆的全流程服务,能够以更高的自由度实现独一无二的外观与结构优化。对普通日常骑行者而言,选择以经济性、耐用性和易维护性为导向的组合则更具现实意义。无论选择哪种路径,最重要的是确保整流罩的轮廓、边缘、接缝与固定点在与整车的对接处保持一致性,以确保安装的顺畅与长期使用中的稳固性。

在市场与材料的组合中,来自不同的供应链与制造工艺的方案往往具有相似的目标——在提升空气动力性能的同时,保留或强化个性表达。这就要求在选择时不仅要看表面的外观效果,更要深挖结构细节、材料层级、加工精度、涂装工艺与维护便利性等方面的综合表现。对于希望在视觉和性能之间取得最优平衡的买家而言,熟悉材料差异、工艺特点及其对耐久性与维护成本的影响,是做出明智选择的前提。

要把这些要素转化为实际决策时的可操作性,可以从综合视角出发:首先明确你的使用场景与预算,再评估你对重量、强度、热管理与美学的优先级。其次对比不同材料在相同几何形状下的实际表现,如同等条件下碳纤维件的重量与刚性是否真的满足你的高速稳定性需求,或ABS/PC件是否更符合日常骑行的耐用性与维修便利。再次考察制造工艺对表面质量与尺寸公差的影响。最后,关注安装与维护的实用性——包括可访问的维修点、可替换的边缘件、以及保养涂层的可持续性。

在实际采购信息的获取上,许多定制件的可用性、匹配性与售后服务也会成为决策的重要组成部分。市场上的定制件往往以不同程度的模块化来实现对多车型的覆盖,但这也意味着实际贴合的精度、边缘的平滑度与结构的韧性会有所差异。对有需求的读者而言,除了关注材料与工艺,还应重点考察供应商的样件对比、试装体验和售后保障。为了帮助读者把握购买的方向,可以参考带有实际适配性与成交信息的权威参考渠道,结合自身车型实际情况做出综合评估。

在文本的这一段落里,若你希望获取对比性的材料视觉与工艺呈现,可以观察材料叠层的纹理与光泽在不同光照下的表现。对于那些追求极致视觉效果的定制件,碳纤维纹理的清晰度、表面涂层的深浅度、以及整体光泽的均匀性都直接影响到最终的观感与耐用性。作为一个可操作的参考,在材料层叠与表面处理方面的表现通常与上述述设计原则密切相关。若你愿意进一步了解市场上对车型匹配的实际案例与设计思路,可以从具有广泛车型覆盖的定制件系列中寻找灵感,观察不同材料组合在同一几何轮廓上的表现差异。

若你想快速了解某些具体的选项与案例,以下内部链接提供了一个起点,便于你从更实际的角度审视材料选择与制造工艺的差异: Honda fairings。这一链接展示了包含多种型号与外观风格的定制整流罩系列,能帮助你把理论转化为实物对比与灵感积累。

最后,选购与评估的过程并非孤立的技术问题。它也需要理解你对车体整体调性与长期维护成本的取舍。在快速发展的定制领域,新的材料组合、表面处理技术与制造工艺不断涌现。因此,开阔视野、持续学习并与专业匠人沟通,是实现“结构/性能/美学三位一体”的关键。对于希望在下一步实现更高水平自定义的读者,本文提供的结构与组成知识框架,将帮助你在面对不同供应商与方案时,做出更具信息量、更具自信的选择。

外部资源参考:若你愿意深入了解一个具体的定制案例在结构与工艺上的实现,可以参考以下权威英文来源的报道,以获得对同类设计在实际工艺层面的直观认识:https://www.bikeexif.com/2022/05/fmc-storm-a-jet-fighter-inspired-custom-motorcycle/

空气中的材料学:定制摩托车整流罩的材质与制造工艺

In the world of custom motorcycle fairings, what you feel first is not just the look but the way the part behaves when the bike is pushed into a corner or opened up on a highway. The chapter you are about to read traces a single through-line: the materials chosen and the way those materials are formed into finished shells determine how a fairing translates aerodynamic theory into real riding experience. It is a story of lightness and strength, of how resin or polymer blends negotiate heat, wind, and impact, and how skilled manufacturing turns a raw sheet or a carbon weave into a seamless cover that fits a specific chassis with exacting precision. The conversation begins with materials and moves through processing, finishing, and functional integration, always with the rider’s needs in view. Every decision—from resin chemistry to molding pressure—affects performance: the speed that a fairing can sustain at a given airspeed, the fade resistance of paint, the way panels respond to heat in mid-summer, and the touch of the surface to the gloves of the rider after hours on the road. This chapter stays focused on the core idea that materials and processes are not afterthoughts but the core language through which design talks to performance.

First, consider the most common families of materials used for custom fairings. Engineering plastics, particularly blends of ABS and polyamide, have become standard because they offer a practical balance of stiffness, toughness, and processability. ABS/PA blends deliver more heat resistance and dimensional stability than pure ABS, especially when heat cycling is part of the riding environment. The blend’s rigidity supports clean, sharp radii and snug panel fits, which matters when fairings must snap onto a frame with minimal gaps and predictable seal lines. The presence of glass fiber reinforcement or mineral fillers can further tailor stiffness and heat deflection, a feature riders rarely see but feel when the fairing returns to rest after a long ride. These materials are well-suited for mass customization because they lend themselves to high-volume processes like injection molding, where tight tolerances and repeatability are critical. Yet even these robust plastics face limits. In sustained high-temperature exposure, the surface can creep, and over time UV exposure may alter color and gloss. So designers who chase a long-lasting finish often pair the base material with UV-stabilized coatings or pigments that resist fading, while keeping the base resin formulation intact to avoid cracking or delamination.

Transparency and aesthetics introduce another set of material choices. For fairings that aim to be semi-transparent or visually striking with light transmission, PMMA (acrylic) and PC (polycarbonate) are the usual suspects. PMMA is renowned for optical clarity and a hard surface that takes a gloss well, making it ideal for tinted windshields or decorative transparent sections. PC, on the other hand, excels in impact resistance. It can absorb a more aggressive impact without cracking, which is valuable for riders who expect their fairings to tolerate stones or road debris in a high-speed environment. The trade-off is that PC—while tough—can be more prone to scratching than PMMA unless properly coated or treated. When designers merge PMMA and PC in composite layers or use them for separate sections of a panel, they can achieve both the clarity of PMMA and the toughness of PC, with careful surface finishing to maintain gloss and resistance to abrasion. The choice between these materials is rarely a simple one; it depends on whether the priority is lightweight transparency, pristine optical quality, or maximum impact resilience.

Alongside these plastics, carbon fiber and other fiber-reinforced composites occupy a privileged position in high-performance builds. Carbon fiber brings stiffness and a dramatic weight reduction that translates into improved stiffness-to-weight ratio and potentially sharper steering response in cornering. But carbon fiber requires a different manufacturing philosophy. The process typically involves resin transfer molding (RTM) or hand lay-up followed by curing, sometimes under vacuum to remove air pockets and optimize resin distribution. The result is a panel whose weave—and therefore its stiffness distribution—can be tuned across the panel by adjusting the weave pattern, the number of plies, and the layup orientation relative to the bike’s geometry. These manufacturing steps are not just about strength; they also influence finish quality. A well-executed RTM layup can produce a striking, smooth surface that accepts paint with minimal filler, reducing the amount of sanding and finishing labor. Yet the cost and time to produce carbon fiber fairings are higher than mass-produced ABS/PA shells, and the technician’s skill level becomes a dominant variable in the final result. The decisions here are about where performance gains justify the additional manufacturing complexity and cost, and where a well-chosen plastic with a smart finish can deliver most of the advantage at a lower price.

Between plastics and composites lies a spectrum of manufacturing processes each with its own signature of precision, finish, and economy. Injection molding remains the workhorse for many fairing components because it provides consistent dimensional accuracy, repeatable surface finish, and the ability to mass-produce complex geometries with relatively short cycle times. It is particularly well suited for standard engineering plastics and for panels with simple contouring that aligns with the frame and mounting hardware. For more organic shapes, integrated features, or highly customized aesthetics, other routes come into play. Hand lay-up or resin transfer molding (RTM) offers designers the freedom to tailor the layup to match the real-world loading paths that the fairing experiences. In a hand lay-up, layers of fabric or mat are placed by hand, resin is added, and the composite cures in a carefully controlled environment. RTM, by contrast, injects resin into a closed mold with pre-placed reinforcement. Both approaches demand meticulous control of resin content, laminate thickness, and cure conditions to achieve a smooth surface, predictable flex, and a reliable bond with integrated features such as air vents or mounting bosses. The choice between injection molding and composite molding is not merely about cost. It is about matching the intended ride experience to the manufacturing rig that can reliably deliver it at scale or in custom one-offs. It is also about post-processing realities: the surface finishing of a molded plastic shell may require different sanding, priming, and clear-coating steps than a carbon fiber panel, where the resin-rich surface can be polished to a glass-like sheen but demands careful attention to avoid print-through or micro-cracking in the resin.

Surface finishing is where material science meets artistry. A fairing’s look matters as much as its airworthiness, and how a surface handles UV exposure, impact, and abrasion is a direct result of the finishing sequence. Clear coats must be compatible with the base resin to avoid yellowing, peel, or micro-blistering. Color matching becomes a test of pigment distribution across a complex geometry where thickness varies, heat affects cure, and ambient conditions influence flow during paint application. In practical terms, this means that the final appearance depends as much on the curing strategy and booth environment as on the polymer selection. Designers often implement multi-layer coatings with UV absorbers and clear layers that resist micro-scratches, while also considering self-healing or self-cleaning properties as optional refinements for riders who log a lot of miles in sunlit conditions and dusty roads.

But the story of materials and processes is incomplete without acknowledging how integration with other motorcycle systems shapes the final product. An aerodynamic shell does not operate in isolation; it must accommodate mounting points, inset hardware, and features such as ventilation ducts, LED arrays, or camera mounts if the build style calls for it. When fairings incorporate such integrated features, the design must anticipate loads and thermal pathways. Carbon fiber skins, for example, can be engineered with rib structures that optimize stiffness while keeping weight down, but the interfaces to the aluminum frame or the existing bodywork must be treated with careful bonding and sealing strategies to prevent differential movement that could lead to paint cracks or gasket leakage. Plastics may require extended dwell times in curing ovens or post-cure heat treatments to relieve residual stresses that show up as warping under temperature changes. The presence of vents and cooling channels adds another dimension: if a vent face is too soft or a channel is poorly sealed, air leaks can degrade aerodynamic efficiency and even introduce unwanted noise at high speed. In all cases, the designer’s goal is to create a synergy where material properties, manufacturing methods, and the rider’s practical needs converge in a single, reliable product that looks coherent, performs predictably, and ages gracefully.

The decision matrix for materials and processes also has a cost dimension. A high-performance carbon fiber shell can deliver exceptional stiffness and weight savings, but the price tag will be significantly higher than a well-executed ABS/PA fairing with a smart finish. For riders who commute daily or who prize durability in a budget-conscious package, a robust engineering plastic with a proven fabrication route can deliver nearly maximum benefit for a much lower total cost of ownership. Conversely, for showpieces or track-focused builds where every gram matters and the rider is willing to pay for the most refined finish and the smallest possible wind-induced drag, composites may be the right choice. In all cases, a well-informed user considers not only the initial cost of the material and process but also the long-term maintenance needs, repairability, and the ease with which a damaged panel can be replaced or repaired. In a market where customization is a core value, the choice between a more economical injection-molded shell and a high-end carbon fiber composite becomes a narrative about how the rider wants to connect with the machine: through affordability and practicality, or through a statement of craftsmanship and performance.

When it comes to the practical workflow of choosing materials and processes, there is a repeating logic that riders and builders can follow. Start with the riding context: daily commuting, weekend cruising, track days, or a blend of these. Then map the environmental conditions: heat exposure, sunlight, UV, humidity, and potential road debris. Next, align this with the expected mechanical loads: mounting rigidity, panel stiffness under load, and vibration responses. With this triad in mind, select a material family that provides the needed performance envelope: the plastics for cost and ease of manufacturing, the transparent or translucent options for a particular aesthetic, and the composites for weight-saving and stiffness when budget allows. Finally, choose the manufacturing route that supports the design intent at the required scale. Injection molding for mass-market items that require precise tolerances; RTM or hand lay-up when the geometry is complex and customization is high; and surface finishing that reinforces the intended appearance and nominal longevity. The beauty of this approach is that it aligns the engineering discipline with the rider’s ambitions, making the material itself a design tool rather than a mere component. The result is a fairing that does not just cover the bike but actively supports the speed, feel, and confidence that the rider seeks.

In the broader ecosystem of customization, sourcing and procurement are not afterthoughts. The material choice often drives supplier selection, as some shops excel in high-volume, uniform ABS/PA runs with rapid turnaround, while others specialize in carbon fiber composites and custom RTM processes that can deliver one-off panels with bespoke contours and finishes. A rider who values precision fit and a consistent finish across multiple panels may gravitate toward a studio that can handle 3D modeling, integrated hardware planning, and a printed color specification across the entire set. The logistics of such a project can be as demanding as the design: ensuring that each panel aligns with mounting points, tolerances, and the rider’s preferred colorway requires meticulous coordination between engineers, fabricators, and painters. Even the finish layers—primer, base coat, clear coat, and any special coatings—play a role in long-term durability, given factors such as weather exposure, abrasion from gloves and seat hardware, and the inevitable micromovements that occur as the bike rides over varied road surfaces.

A chapter-length theme that often emerges in conversations about materials and processes is the balance between performance and practicality. Carbon fiber may offer the ultimate in stiffness and lightness, but it is also more expensive and more challenging to repair. ABS/PA blends can deliver excellent toughness with relatively simple repair strategies, making them a sensible choice for riders who want to maintain or replace a fairing without specialized tooling. PMMA and PC can deliver optical clarity and impact resistance in different combinations, enabling designs that are both functional and visually arresting. The important point, though, is not to chase a single property in isolation but to design for the whole ride—the panel that survives heat, impact, and sun while delivering the airflow required for stability and speed. In practice, this means an integrated design approach where materials, process workflows, and surface finishes are developed together, not sequentially. The result is a fairing system that feels like a unified extension of the motorcycle rather than a separate add-on, with predictable performance across a spectrum of riding conditions.

For readers who want to explore how these choices translate into real-world options, it helps to think about the purchasing landscape as a spectrum as well. On one end, there are mass-market, injection-molded fairings that emphasize fit and economy, produced with consistent finishes and broad model compatibility. On the other end, there are artisanal, hand-crafted composites whose beauty lies in the craft, the precision of layups, and the bespoke fit that only a skilled technician can guarantee. In between, a range of hybrid solutions—engineered plastics reinforced with fibers, or laminated panels with protective coatings—offer performance benefits without the full cost of carbon fiber. The ongoing challenge for builders and riders alike is to assess which point on this spectrum aligns with the intended use, the rider’s budget, and the willingness to accept maintenance and repair realities that come with any material choice. The era of fairings as purely cosmetic additions is long gone. Today, they are active parts of a system—sensors, airflow management devices, and aesthetic canvases—that demand thoughtful material science and disciplined manufacturing.

Should you be considering a purchase or a bespoke build, a practical way to navigate this complexity is to anchor choices to a few core criteria: compatibility with the motorcycle’s frame geometry, the required stiffness and impact resistance, surface finish expectations, and the total cost of ownership over time. The right answer for one rider might be a robust ABS/PA shell with a strong protective clear coat, while another rider might embrace a carbon fiber composite with a tuned layup that matches a particular aerodynamic philosophy. The point is not to select a single material in isolation but to design a fairing system with a consistent logic that respects the bike and the rider as a single entity. As you move from concept to prototyping to production, keep the conversation between material science and manufacturing engineering alive. When those conversations align, the result is not merely a shell but a precise instrument of speed and style.

To bridge this chapter with what comes next, think of the flow from concept to fit as a collaborative dance among designer, material specialist, and fabricator. The next chapter will explore how to evaluate supplier quality, how to judge the suitability of a material for a given riding context, and how to balance customization with reliability. It will also consider practical steps you can take to verify fit and plan for maintenance, so the dream of a perfectly tailored fairing becomes a durable, ride-ready reality. If you want a quick entry point into model-specific options and ready-made configurations, a useful resource for exploring model-compatible fairings across a broad range of chassis is the Honda fairings catalog from a popular supplier platform. For example, you can browse a dedicated collection that aggregates model-specific panels and full fairing sets to gauge available geometry and mounting interfaces before committing to a bespoke design. Honda fairings collection.

External resource: As you widen your search beyond the mid-market and custom studios, you will encounter marketplaces that host a spectrum of sellers offering full fairings with varying guarantees. A widely used reference page aggregates listings and shows verified fitment, past transactions, and customer feedback, which can help you establish a realistic baseline for pricing, lead times, and fit confidence. This page serves as a practical orientation for the purchasing journey and provides real-world context to the material and process choices discussed above. Access it here: https://www.ebay.com/sch/i.html?nkw=Motorcycle+Full+Fairings&sacat=0&LHTitleDesc=0&odk=Motorcycle+Full+Fairings&LHComplete=1&LHSold=1&LH_PrefLoc=1

风线与个性:定制摩托车整流罩在性能与美学之间的旅程

当风从前方涌来,整流罩不再只是一个装饰性的外壳,而是一位安静的引导者,在高速行驶中把空气的力量转化为可控的稳定与更高效的驱动。定制摩托车整流罩的世界,正是在这个看不见的边界上展开。它不仅让车辆的前脸更具工艺感,更通过精准的气流控制,影响着整车的空气动力学表现、声学体验以及骑行者的舒适度。许多爱好者在改装时把“看起来像”与“跑起来就像”的差距缩短,把个人偏好与技术潜力整合在一起,这正是定制整流罩的核心魅力所在。空气动力学效益,往往通过减少正投影面积和优化气流分布来实现;这并非玄学,而是对风的语言的一次精准解码。对长途骑行者而言,风阻的降低不仅意味着更平稳的高速巡航,还意味着燃油效率的提升和油门响应的线性化。这些改善,往往在长时间的骑行中体现得最为明显,因为风的作用是持续的、不可忽视的。更重要的是,整流罩通过降低风噪,改变头盔与躯干之间的空气相互作用,降低头盔在高速状态下的抬升风险,减少风吹动骑行服和身体姿态的干扰。这样的舒适性提升,虽然看不见却能直接转化为更稳定的操控感与更专注的驾驶体验。正是在这一点上,定制不仅仅关乎美观,更关乎安全性与持久性。 效率与体验的叠加,往往来自材料的选择与制造工艺的精准把控。市场上常见的定制整流罩多采用碳纤维或聚碳酸酯(PC)+ABS复合材料。碳纤维以其极高的强度重量比,成为高性能跑车改装的偏好选择。轻量化的同时,刚性和耐疲劳性得以保证,能在高速变道、急加速和风洞测试的极端条件下保持形状的稳定性。然而,碳纤维的成本与加工难度也更高,制造周期通常较长,且对工艺要求更严苛。相对而言,PC+ABS复合材料以价格友好、抗冲击能力强、耐日常使用的特性,成为更多日常骑行者的实际选择。它们通常通过真空袋压成型或注塑成型实现批量制造,表面光滑度与尺寸精度在现代工艺条件下已经足以达到高要求的安装配合。每一种材料的选用,都是在“轻量、强度、成本、可维护性”之间做出的权衡。制造工艺方面,真空袋压成型不仅能实现复杂外轮廓的均匀固化,还能在表面形成细腻的光泽纹理,便于后续喷涂和涂装。注塑成型则在大批量生产中体现出成本与一致性优势,确保同一批次的部件在接口、螺栓孔位和边缘轮廓上保持一致性。专业厂商通常会在生产前进行3D建模和数值仿真,验证气流分布、压力分布以及缝隙间的密封性,确保成品在安装后不会产生不必要的副作用。正是这种从设计到生产的闭环,使得个性化改造既可实现“独一无二”的视觉效果,又能在机械层面保持可靠的安装和长期使用的稳定性。 窗口般的外观之下,整流罩的应用场景并非单一。个性化定制成为许多车主与改装工作室共同追求的目标,既包括对外观的创新,也涵盖对功能的扩展与整合。外观层面,设计师会结合色彩科学、材料特性和纹理工艺提供多样化选择。闪粉、渐变色、金属质感涂层、哑光与亮面的对比、以及浮雕式纹理等,都成为表达个性的手段。更进一步,市场上已经出现了2D贴花与3D浮雕相结合的方案,让徽标、线条和符号在不同光照下呈现出层次感。这种逐层叠加的设计语言,既能在街头风格、赛道风格与经典复古之间找到平衡,也能将骑手的生活态度和美学偏好融入到车身的每一道弧线中。 当设计走向可定制的深度时,整流罩的功能性也随之扩展。一些更高阶的定制品内部可能嵌入LED灯组,用于增强夜间可见性,或通过灯光轮廓强调前脸的空气动力学线条。还有的在内部留出摄像头支架、雷达感应装置或其他传感设备的安装位置,使整流罩不仅仅是外观的改造,更成为“科技与个性并存”的载体。对于那些执着于一体化美学与现代感的骑手,这样的集成设计提供了新的可能性:在不影响整车结构的前提下,保持系统化的整合与整洁的线缆布局。 实现如此丰富的定制,涉及到不同程度的车型匹配能力。厂家和工坊通常会与设计师、工程师密切合作,确保新外壳能够与现有的骨架、进气口、缆线走线和整车风道相互协调。更为关键的是,定制往往强调“精确匹配”,也就是说,安装时需要对接车身的螺栓孔位、边缘夹角和前后风道口的几何关系。在这一点上,汽车工程中的公差管理和表面处理工艺显得尤为重要。即使是看起来简单的安装,也需要对原始蒙皮与新整流罩之间的对位、密封和固定方式做出详细评估。对于追求极致贴合的用户,完全手工定制成为一种艺术实践。设计师会采用3D扫描、数字建模、样件打样、逐步修正的流程,直至最终的喷涂层在形状、厚度与光反射上达到理想效果。这种从虚拟模型到实体部件的全过程,既考验材料学的深度,又考验美学设计与机械工艺的协同能力。 在购买与实现层面,尽管渠道多样,但质量始终是决定成败的关键。高品质的定制整流罩通常具备精确的车型匹配、良好的表面光洁度、均匀一致的涂层以及稳定的结构连接性能。为了避免购物中的盲点,很多买家会寻找具有“车型精确匹配”证明的全套整流罩,确保安装后不会出现干涉或重新加工的情况。考虑到不同骑手的使用环境,耐久性、抗冲击性、耐候性能也是评估的重要指标。某些工坊还提供从3D建模到喷涂的一站式服务,帮助客户在一个统一的工作流中完成定制需求,减少沟通成本和二次加工的风险。 这种一站式服务的价值,远不止于表面的完工时间缩短。它还能确保颜值与功能的长期稳定性,因为在一个集成式流程中,设计师会在初期就考虑到长期维护、清洁和防护的便捷性。这包括如何在日常清洗中保护表面涂层、如何在气动边缘处避免积尘,以及在极端天气条件下维持边缘部位的密封性。用户若将改造视为一项长期投资,这种全链条的设计与制造安排,将显著提升整体的使用体验与二手保值率。 与此同时,市场在持续扩展个性化表达的边界。除了传统的色彩与纹理,越来越多的定制方案开始关注功能性细节的微调,例如在前后端部位加入可调导流板、开口与通风口以更好地管理发动机舱冷却空气、负压区域的气流引导以及在高风速场景下对舱口的防水设计。这些改动不仅提升了冷却效率,还能在特定赛道或路况下提升操控稳定性。从骑士的视角出发,个性化并非只是一种审美宣言,更是一种“对生活方式的物理表达”。选择哪种材料、哪种涂装、哪种导流结构,往往与日常骑行的地形、气候、使用频率和个人偏好紧密绑定。对一些人来说,定制整流罩是让车成为“移动的自我表达”的方式;对另一些人而言,它是对疲惫工作周后追求专注与激情的仪式感。正因如此,选择合适的合作伙伴尤为重要。系统的评估应涵盖材料性能、制造工艺、装配匹配、涂层耐久性、维修与保养的便利性,以及售后服务的可及性。不要被花哨的表面所迷惑,真正的价值在于整流罩与车体之间的协同效应——气流被重新组织、声音被优化、热管理被改善,而所有这些都以可维护的长期性为前提。 若要把这一切落地到实际的改装计划中,骑手应当从最基础的需求出发,清晰地界定期望值:你想要提升的是高速巡航的稳定性,还是更强调城市与山路之间的灵活转变?是偏好更强的视觉冲击,还是希望整流罩在不同光线下呈现出独特的质感?在对答案有清晰认知的前提下,便能更有效地与设计师沟通,缩短来回试验的次数,并在预算范围内实现最具性价比的组合。对于希望在现有车系上实现个性化改造的人来说,选择一个既能保留原有安全性,又能实现风格升级的方案,尤为重要。此类方案往往要求严格的尺寸与接口兼容性,因此更值得投资于专业的定制工作室或具备完整设计与制造能力的厂商。为了帮助读者在这个领域做出更明晰的选择,以下给出一个简要的行动蓝图:第一步,明确使用场景与长期目标;第二步,筛选材料与工艺,权衡重量、成本与耐久性;第三步,评估安装的可行性与未来维护的便利性;第四步,与设计师共同制定视觉与功能的优先级清单;第五步,进行小批量试产与实地试驾,以确认气动、噪声和操控在实际路况下的表现。通过这样的流程,定制整流罩可以从一个单纯的外观改造演变为一个全面提升骑行体验的系统工程。 作为对这一主题的进一步参考,读者还可以访问专门汇集不同车系整流罩集合的页面,以获得车型匹配与安装细节的直观感受。此类资源通常会提供按车型筛选、按接口对位、以及按涂装风格的快速选择,帮助你在海量选项中快速定位到最契合你需求的方案。对于想要更深度探索的读者,务必在选择前对比多家车间的样件与喷涂工艺、售后保障和长期维护方案,以确保未来的改造效益与使用体验都能够达到预期水平。 若要了解在现有车系中的具体实现,可以参考 Summit Fairings Yamaha collection 的系列集合。该页面汇集了多种风格与配置,帮助读者直观地看到不同纹理、色彩与导流结构在实车上的效果,便于在自己的预算与期望之间做出更清晰的权衡。 在讨论定制整流罩的选择时,别忘了市场中还有丰富的渠道与服务形态。除了直接购买现成或半定制的部件,也有越来越多的专业工作室提供从3D建模到喷涂的一体化服务,甚至为某些车型提供完全手工定制的解决方案。这种全流程的个性化,虽然成本更高,但能实现真正意义上的“无缝对接”和“肖像级别”的视觉与功能统一。对写实需求而言,这样的投资往往在长期使用中得到回报,因为你得到的不是单一部件的提升,而是整车气动轮廓与外观语言的一体化改造。 在这一旅程的尾声,值得强调的是,定制整流罩并非一次性的外观改造,而是一种持续的探索。随着新材料、新工艺的出现,新的风洞数据和使用场景的出现,个性化的表达将会持续扩展。对于热爱探索与创新的骑手来说,这既是一次关于美学的自我表达,也是一次对技术边界的试探。通过对材料、工艺和设计语言的综合考量,你可以让爱车在风线之间写下属于自己的故事——一个风的线条被你重新诠释的故事。 外部参考资源: https://www.motorcyclepartswarehouse.com

Final thoughts

Custom motorcycle fairings provide a powerful tool for business owners aiming to enhance their product offerings. By investing in high-quality, tailored fairings, businesses can improve the performance and aesthetic appeal of motorcycles, catering to a diverse clientele. Understanding the structure, material options, and potential for personalized designs is crucial for making strategic decisions in this sector, ultimately leading to increased customer satisfaction and loyalty. Embracing the custom fairing trend is not just a choice; it’s a business necessity in today’s competitive market.