Frame-mounted motorcycle fairings offer a unique blend of structural integrity and aerodynamic efficiency for motorcycle enthusiasts and business owners alike. With the growing demand for high-performance motorcycles, understanding the advantages of these fairings becomes essential. This article delves into their benefits, the superior structural integrity they provide, their impact on aerodynamics and performance, the materials used in their construction, and the installation and maintenance required to ensure longevity. Each chapter will elucidate how frame-mounted fairings can elevate your motorcycle business offerings, enhance customer satisfaction, and lead to a more competitive edge in the market.

null

null

Frame-Linked Strength: The Structural Backbone of Frame-Mounted Motorcycle Fairings

Frame-mounted fairings sit at the intersection of form and function, a deliberate design choice that affects speed, handling, and rider comfort. When a fairing is bolted directly to the frame—the bike’s backbone—the structure behind the surface becomes an active part of the chassis, not just a decorative shell. The result is a system that behaves like a single integrated unit rather than a cluster of panels attached to a vulnerable frame. This integration matters most when the rider pushes toward the aero limits of a machine, where stability and predictability are essential. At speed, the air loads the front end and the frame-mounted fairing must resist those forces without flexing or shifting. The fairing staying aligned with the rider’s line of sight, the handlebars, and the front tire is a hallmark of a well-executed frame mount, even as wind pressure grows and road vibrations increase. A robust attachment translates into stability, reduced fatigue, and a more comfortable ride on long stints where wind shear and road chatter can sap focus. The structural integrity of these components is not just a matter of keeping plastics in place; it is about preserving the bike’s aerodynamic intent and the rider’s perception of control. The frame becomes the stage on which the fairing performs, and overall machine performance hinges on how well that stage resists deformation.

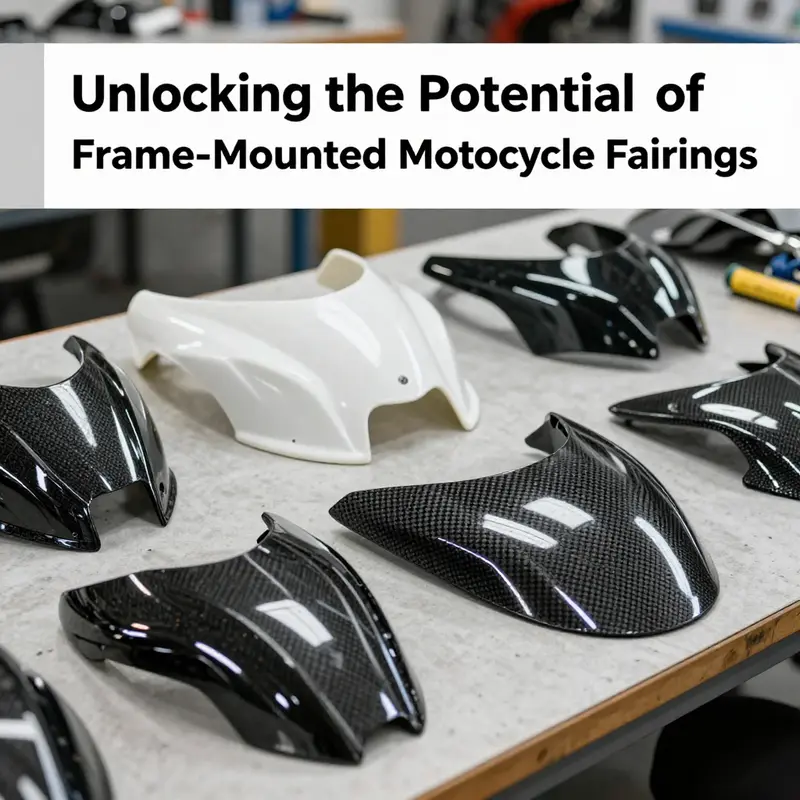

Material choice is the first practical factor in this equation. Common engineering polymers such as ABS, polycarbonate, and fiberglass establish a spectrum of rigidity, impact resistance, and weight. ABS is tough and affordable, offering decent resistance to minor impacts and weathering, which makes it a sensible default for everyday bikes and touring setups. Polycarbonate provides higher impact resistance and clarity, while fiberglass offers a stiffer, lighter option with good fatigue performance at the cost of higher manufacturing complexity and potential repair sensitivity. The choice among these materials is not just about cosmetics; it is about whether the mount can sustain repetitive loads, resist microcracks, and preserve the aerodynamic profile after contact with stones, curbs, or other road hazards.

Even small damage to the fairing skin can ripple into meaningful shifts in performance. A crack may propagate under aerodynamic load, altering surface smoothness and the flow pattern across the front of the bike. The implications extend beyond the dent: mounting points, bulkheads that tie the fairing to the frame, and joints where panels meet are part of a single system designed to resist deformation. When the fairing integrity is compromised, vibration can travel through the mount to the frame, degrading handling response and rider confidence. Maintenance becomes an ongoing discipline that monitors joints, mounting pillars, and the connections that anchor panels to the chassis, ensuring alignment and rigidity remain within design tolerances.

From a design perspective, frame-mounted configurations reflect a philosophy about how a bodywork system should behave under load. Full fairings create a cohesive aerodynamic envelope that shines when the panels resist flutter and seams stay tight through a broad range of throttle and braking inputs. Rigidity from frame-backed attachment helps minimize panel flex during acceleration and deceleration, contributing to a stable wind shield and predictable steering. Semi-fairings, which leave more engine and cooling pathways exposed, trade some rigidity for serviceability and cooling efficiency. The balance between aerodynamic protection and maintenance access guides decisions about stiffening ribs, mounting flange thickness, and cutouts for cooling channels without compromising structural cohesion.

Repairing frame-mounted fairings after a collision or tip-over presents its own challenges. The repair approach often emphasizes maintaining alignment with the windscreen, nose, and edges against the fork crowns and tank. Specific techniques such as controlled heating for gentle straightening can be used on metal frames to restore mounting points, provided temperature control keeps surrounding materials from damage. Aluminum frames demand particular care due to different thermal responses. The post-accident path depends on the deformation extent, available facilities, and the cost-benefit balance of panel replacement versus realignment. The integrated nature of frame-mounted fairings means repairs must consider both cosmetic surface and mechanical reliability of mounting points, ensuring the bike retains its intended stiffness and aerodynamic behavior at speed.

For riders, understanding materials and their limitations translates into informed maintenance choices. Frame-mounted fairings are structural elements as much as aesthetic components. Material durability, mounting hardware quality, and precision fitment determine how well the bike preserves aero profile and tracking characteristics across miles. Regular inspection should target cracks at joints, torque specs on mounting bolts, and consistent panel gaps with the design. If a vibration travels from the front end to the cockpit, the cause may be a loosening mount or a developing crack that compounds under load. Early detection helps prevent drag increase, wind protection loss, noise rise, and potential secondary damage to the frame or engine mounts.

The choice among full, semi, or other fairing configurations should reflect riding style, climate, and maintenance willingness. Full frame-mounted fairings often deliver the strongest aero shield and the most coherent protection, but also bring more panels to align and potentially higher repair costs. Semi-fairings offer easier service and cooling access but may sacrifice some rigidity under gusts and high-speed oscillations. The decision balances aerodynamic performance with practicality and long-term maintenance expectations. To connect theory with practice, consider the practical workflow of selecting, fitting, and caring for frame-mounted fairings: begin with understanding mounting geometry and frame tolerance for added stiffness, then perform precise mounting with alignment cues for headlights and radiator shrouds, and finish with a maintenance cadence that treats the fairing as a living part of the chassis. In this light, material selection, panel design, and mounting strategy cohere into a system that supports safe, stable riding at speed while preserving rider comfort and confidence.

If one seeks additional context on fairing design, materials, and repair standards, authoritative resources and curated guidance remain essential. External references can offer practical, field-tested methods that complement the theory described here.

Frame-Crafted Aerodynamics: Stability, Speed, and the Art of Frame-Mounted Fairings

Frame-mounted fairings anchor to the bike backbone and embody a deliberate philosophy of structural continuity, predictable stiffness, and a clean transfer of wind loads to the chassis. The frame becomes a reference point that preserves alignment between the rider line of sight, the steering axis, and the aerodynamically sensitive front end. When the rider leans into a curve or opens the throttle, the fairing is not merely decorative; it acts as a functional shield and a load path that keeps the front end planted and the rider shielded from wind pressure. The result is a ride feel that remains consistent across a wide range of speeds and road conditions, with fewer surprises as wind shifts or road texture changes.

Rigidity is the first consequence of direct frame attachment. By tying the fairing to the frame, engineers reduce flex that can occur when fairings hang from engine mounts or connect mainly to the fork assembly. Flex at aerodynamic loads can cause misalignment, tug on the bars, and a fluttering sensation that erodes rider confidence. A frame mounted system distributes loads along a single structure rather than letting them be absorbed by multiple mounting points. The rider notices steadier steering response and a more stable line through bends, a subtle but real performance gain for sport and sport touring builds.

Airflow around the front end improves as rigidity increases. With the fairing fastened to the frame, the shape can guide air smoothly along the bike, reducing separation and downstream turbulence that would add drag and buffeting. The rider experiences smoother wind pressure across the torso and head, lowering fatigue on long rides and keeping the cockpit quieter. The practical upshot is better air to surface interaction: less drag, more efficient thrust, and a more favorable engine power use at highway speeds. On track, cleaner air around the rider and steadier load on the front suspension arise as the bike dives and rises with brake input and corner exits.

Frame mounted designs unlock opportunities for active or semi active aero elements such as small winglets or carefully contoured fins that generate downforce at high speeds, pressing the front wheel into the pavement and resisting lift that becomes more pronounced as winds gust over the bike silhouette. When designed with proper scale and balance, these features complement rider input rather than fight it, contributing to a more planted front end at high speeds and less front wheel chatter on rough pavement.

Trade offs include weight, access, and maintenance. Frame mounted fairings tend to add weight and can complicate engine removal and fairing replacement after a crash. Access to the engine and related components can be more restricted by surrounding panels and mounts, demanding careful alignment during removal and reinstallation. The result is potentially higher repair costs and longer service times, though the benefit is improved stiffness and aerodynamic clarity that payoff on speed and stability.

Material choices shape stiffness, weight, impact resistance, and cost. ABS shells offer durability and cost effectiveness; fiberglass sits between ABS and carbon; carbon fiber delivers superb stiffness to weight but carries higher fabrication and repair considerations. The material choice influences the frame stiffness perception, the noise and vibration transmitted to the rider, and the ease of panel repair. It also interacts with production realities such as tolerances and light cavities alignment and the way the fairing load path aligns with the frame under racing or touring loads. Across these options the goal remains the same: anchor the front end shaping around a frame anchored load path that supports a clean repeatable aerodynamic profile while staying durable at speed and in long distance exposure.

Designers seek to harmonize aerodynamics with rider protection and weather shielding without compromising cockpit access or mechanical work. When frame mounted fairings are executed with care, riders enjoy wind protection with a cocoon like sense of enclosure that still allows ventilation and visibility. The panoramic effect of a well integrated fairing can transform long rides into something more efficient and less fatiguing. From a riding psychology standpoint the sensation matters as much as physics: a bike that feels welded to its wind inspires confidence and a calm mind to focus on line choice throttle control and lean angle.

Riders evaluating frame mounted systems should align with goals such as track days high speed stability long highway comfort and ease of service. If modularity and price sensitivity predominate a more modular engine centered approach may seem appealing, but even in that case the frame mounted option remains a strong baseline for stability and wind management. For those who want an accessible catalog of mounting ready options and real world panel fitment across models a practical starting point is to explore the Honda fairings collection at the link shown for reference: https://www.summitfairings.com/collections/honda-fairings

Frame mounted aerodynamics represents an integrated approach where wind is guided by a chassis designed to speak with air rather than shout over it. The result is a bike that feels lighter at speed, a ride that remains smooth, and a rider experience that stays precise and intuitive. As materials science and computational design advance, frame mounted solutions are likely to extend to more models and riding styles, always with the same guiding philosophy: aerodynamics as a fundamental element of the chassis rather than an afterthought.

Frame as Framework: How Frame-Mounted Fairings Shape Strength, Speed, and Style

Frame-mounted fairings are not merely cosmetic shells strapped to a motorcycle; they are an integral part of the machine’s aerodynamic and structural grammar. When a fairing is anchored to the frame—the bike’s central spine—it becomes part of a unified, rigid system. That rigidity matters because it dampens the flex that otherwise accompanies high-speed air loads and road vibration. With the frame as the primary load path, the fairing shares in the chassis’s stiffness and resonance characteristics, so wind forces do not twist or momentarily separate the shell from its intended profile. The rider’s experience follows: less wind buffeting, reduced noise at velocity, and a steadier, more predictable front end. It is not just about keeping the fairing in place; it is about preserving the aerodynamics that the rider relies on for efficiency, stability, and control. In practice, this translates into a more confident ride at the edge of performance, whether the motorcycle is carving canyon roads in a sport setting or cruising a long highway with a loaded tank and luggage. The frame-mounted configuration also harmonizes handling characteristics, helping to maintain a balanced weight distribution and reducing stray stresses on engine mounts that could otherwise cascade into chassis fatigue. The trade-off, of course, is a more involved installation and more complex, potentially higher-cost repairs if the integrated shell sustains damage. Yet for a rider who seeks precision, consistency, and a poised silhouette at speed, the frame-mounted fairing represents a premium choice that treats the front of the bike as a carefully tuned surface rather than a simple panel cover.

Material choice sits at the heart of this design philosophy, and it frames the practical realities of production versus customization. ABS plastic dominates the landscape because it offers a compelling blend of impact resistance, moldability, heat tolerance, and cost. Its ability to hold complex geometries means designers can craft aggressive lines without sacrificing fit and finish. Moreover, ABS handles engine heat and outdoor exposure well when formulated with UV stabilizers and heat-resistant additives. For mass production and aftermarket kits, this material makes sense: it minimizes warranty headaches while delivering consistent results across a wide range of models and conditions. Fiberglass sits just adjacent to ABS in the value ladder. It introduces greater rigidity and tolerance for sharp aero shapes, often at a modest weight increase compared with carbon fiber. Fiberglass is a favorite for custom builds and serious performance-focused projects where the owner wants a strong shell that can be tuned for specific aerodynamic goals without the extraordinary costs of carbon fiber. The layering and weave options in fiberglass also grant designers latitude in controlling stiffness distribution and impact resistance. Carbon fiber, reserved for top-tier or bespoke applications, delivers the most favorable strength-to-weight ratio. The stiffness of carbon fiber translates into crisper handling, with the fairing contributing less inertia during gusts and steering inputs. Weight savings matter in high-speed dynamics: every gram shaved from unsprung mass and front-end inertia can translate into more immediate throttle response and quicker corrections through corners. The downside is clear: carbon fiber comes with higher material costs, longer lead times, and the need for skilled layups to maintain consistent thickness and edge integrity. This is not merely about weight savings; it is about predictable crash behavior and repair economics. When a concussion of heat, impact, or abrasion strikes a frame-mounted fairing, the repair bill often reflects the material choice as much as the structural repair. ABS might permit swifter, cheaper panel replacement; fiberglass may demand careful reshaping and reinforcement; carbon fiber could push the bill higher yet again, especially if the damage affects the internal layups that carry the stiffness to the edge. Across these choices runs a common thread: the material must work in concert with frame-mounted geometry, tolerances, and fastener systems to maintain the intended aerodynamic surface and rider comfort. The combination also shapes the perception of quality and the long-term durability of the fairing. For riders who want a practical framework for decision-making, a thorough resource on choosing the right type of fairing provides a structured approach to weigh cost, weight, durability, and aesthetic impact against the rider’s goals. The bottom line is that the material system is not an afterthought; it is the counterpart to the frame’s rigidity, and together they define how the bike slices through air and how it feels when the road piles on the miles.

The integration story continues with the geometry of attachment. A frame-mounted fairing relies on dedicated brackets, standoffs, and aligned interfaces that link to the frame’s planes. Because the frame handles the main loads—torque, braking forces, and the periodic shocks of pavement—the mounts are designed to transfer those forces cleanly into the chassis while preserving the fairing’s alignment. When the joints are stiff and well-braced, the aerodynamic surface becomes a single, predictable shape rather than a mosaic of panels that can flex independently. The aerodynamic consequence is not merely reduced drag; it is consistent, controllable flow across the surface of the fairing, so the nose of the bike maintains its intended stance under wind gusts and steering input. The rider benefits through steadier steering response, improved high-speed stability, and a quieter cockpit. However, the precision required for frame mounting elevates the maintenance discipline. Tight tolerances, meticulous bracket alignment, and careful inspection of mounting points on the frame are standard practice to prevent chafing and heat buildup that could degrade performance over time. The entire system is only as strong as its weakest link, which is why the assembly sequence, torque specifications, and the sequence of operations during assembly matter as much as the aesthetic layout of contours. The interdependence of form and function here is not rhetorical; it is the evidence that the rider feels when the fairing holds its line through a set of sweeps and the wind presses evenly against a stable, confident silhouette. A well-executed frame-mounted arrangement also doubles down on a sense of unity between rider and machine, reinforcing the all-important feedback loop that tells the rider precisely how the bike is responding to inputs and changing air conditions. In practice, the frame-mounted philosophy is most visible in the way its design language translates into the catalog of parts that enthusiasts chase as a coherent set rather than isolated pieces. The visible result is a front that looks carved, a profile that appears to be sculpted from the same body as the frame, and a ride that feels like a deliberate extension of the chassis rather than a separate shell. This is the experiential promise of frame-mounted systems, a promise that is visible in every carefully engineered joint and every line that flows from the nose to the fairing’s tail. For a concrete taste of how such systems are expressed in catalogs and parts ecosystems, explore the Kawasaki fairings collection, where frame-mounted concepts translate into a defined design language and ride feel.

Repair and maintenance realities are a natural counterpart to this design logic. Because the fairing shares load paths with the frame, damage can require more coordinated repair work than a simple cover that clips on and off. A cracked panel may necessitate replacement or careful reshaping to preserve alignment with other panels and with the frame’s own reference planes. This is not merely cosmetic alignment; it is crucial for maintaining predictable airflow and the front-end mass balance. Technicians will check bracket wear, fastener threads, and the condition of the anchor points to ensure the fairing remains securely fastened and that the geometry remains consistent after service. When a frame-mounted system is well maintained, damaged sections can be replaced without compromising the rest of the assembly, preserving the original aerodynamic profile and the intended rider experience. The economics of this approach reflect a broader philosophy: invest in robust mounting interfaces, use materials capable of withstanding repeated stress, and implement a maintenance routine that minimizes the risk of creeping misalignment. Practically, this means torque checks, bond-line inspections, and timely bracket replacements as part of regular service intervals. A thoughtful maintenance regime keeps the system aligned and preserves the anticipated ride quality over thousands of miles. The payoff is clear: a front-end that remains stable, a windscreen that stays clear, and a cockpit that feels harmoniously integrated with the bike’s frame.

From the rider’s seat, comfort and performance are inseparable when the frame is the structural backbone. Frame-mounted fairings’ primary job is to manage how air flows over and around the rider, shaping the pressure field that forms around the torso and arms. At highway speed, a stiff and well-fitted shell reduces flutter and minimizes vibrations that would otherwise travel through the handlebars or into the chest and shoulders. The aerodynamic layout also influences rider fatigue over long days in the saddle: smoother air, less buffeting, and a quieter environment translate into better focus and longer, more enjoyable miles. The rider’s perception of a chassis’s stability, especially when the wind shifts or the road surface changes, becomes more positive when the frame acts as a predictable, supportive structure for the fairing. In this context, the design choices—how deeply the fairing screens the rider, how the air sweeps across the body, where the intake ducts lie, and how the shell mates with the frame—are all part of a deliberate strategy to create a coherent riding experience. It is a strategy that rewards those who value the subtle differences that turn a good ride into a confident, controlled one. The internal logic is straightforward: frame mounting binds the fairing to the bike’s core, and that binding yields predictable behavior under load, gusts, and high-speed transitions. To appreciate the practical implications of these design choices in a real-world setting, one can peruse the Kawasaki fairings collection, which offers a tangible illustration of how frame-mounted systems translate into distinct handling and aesthetics.

External resources can sharpen the understanding of these trade-offs and help riders weigh their options more clearly. For a practical overview, consult the Motorcycle Fairing Guide: How to Choose the Right Type. https://www.motorcyclefairingguide.com/how-to-choose-the-right-type

Frame-Mounted Fairings: Precision, Stability, and Maintenance for the Motorcycle Frame

Frame-mounted motorcycle fairings sit in a unique position within the world of bodywork. They are not merely cosmetic shells or decorative shields; their attachment to the frame—the bike’s structural backbone—dictates how the machine behaves at speed, under load, and across long miles of highway and backroad rhythm. The design philosophy favors rigidity and stability, because when a fairing is anchored directly to the frame, it gains a degree of resistance to flex that can dramatically influence aerodynamics, rider comfort, and even handling. The result is a complete system where the shell, air, and rider move more as a single, harmonized entity. This is not a marginal advantage. At higher speeds, the air exerts substantial forces on every surface, and any flex in the fairing can disturb the smooth flow of air around the machine, creating buffeting, wind noise, and unwanted mechanical chatter. By tying the fairing directly to the frame, engineers achieve a predictable boundary for the airflow, which translates into steadier stability, cleaner separation of turbulent pockets, and a quieter, more controlled ride through fast sweepers or long, straight stretches alike. Through this interconnectedness, riders often notice that the bike feels more planted when heading into gusts or minor road imperfections, a sense of coherence between rider input and chassis response that fosters a more intuitive riding experience.

The full fairing configurations that typically ride in tandem with frame-mounted support structures are designed to enclose not just the front of the machine but also the upper torso of the bike: the headlight cluster, the upper portion of the fuel tank, the radiator area, and the adjacent engine contours. This level of coverage does more than reduce drag. It creates a compact developmental surface that helps balance downforce with the bike’s weight distribution, which can influence throttle response and acceleration characteristics, particularly under sustained speeds or during rapid lane changes. The materials chosen for these assemblies—high-impact ABS plastic, fiberglass, and, in high-performance builds, carbon fiber—reflect a hierarchy of needs: impact resistance, rigidity, and weight management. Each material offers a distinct set of benefits. ABS provides durability and impact resistance suitable for daily riding and occasional track sessions. Fiberglass offers a middle ground with good stiffness-to-weight ratios and relative ease of repair. Carbon fiber pushes the envelope on weight saving and rigidity, albeit at a higher cost. Across these choices, the goal remains consistent: to deliver a shell that resists fatigue, maintains precise fitment, and endures the rigors of wind, debris, and temperature swings without deforming or loosening.

A frame-mounted configuration relies on the alignment between the fairing’s inner geometry and the bike’s frame geometry. Precision matters here because even small misalignments can alter airflow paths, introduce micro-vibrations, or interfere with control operations. The installation process, therefore, centers on a tight sequence: selecting compatible components, preparing a clean, undisturbed mounting zone, and carefully securing brackets that anchor the fairing to the frame or the fork area. The brackets themselves are engineered to distribute load across multiple points, reducing peak stress on any single fastener and helping with predictable hard mounting through years of riding. The tolerances built into these components are not cosmetic details; they are the practical language that ensures fairing fitment remains consistent across a bike’s life and through the inevitable vibrations of the road.

In practice, the installation begins with compatibility verification. The rider or technician confirms that the chosen frame-mounted fairings align with the specific model and year. This step is essential because the frame, the steering head, and the dash-mounted controls create a constellation of potential interference points. Once compatibility is established, preparation follows: organizing the toolkit, charting the correct torque settings, and ensuring that every bracket, spacer, and fastener is clean and free of corrosion or grit. The first physical action is to secure the mounting brackets to the frame or fork area. This step is where torque becomes more than a guideline; it becomes a safety requirement. Bolts must be tightened to manufacturer-specified torque to prevent loosening under vibration, gusting wind, or aggressive riding. The next stage is to position the fairing body on the brackets with deliberate care, aligning the contours to the bike’s lines. Precision at this stage matters as much for aerodynamics as for rider visibility and control clearance. A misaligned fairing can create localized turbulence, increase drag, and even affect the rider’s line of sight or access to essential controls. Finally, the fairing is secured with the fastening systems supplied—whether cam-locks, quick-release mechanisms, or conventional fasteners—being careful to snug each point without over-tightening, which can crack or distort the plastic or composite material.

After installation, a comprehensive inspection becomes part of the routine. A quick but thorough check for play or wobble is essential: the rider should gently push on the fairing from multiple angles to confirm it remains aligned and rigid. The system should not interfere with the handlebar movement, rider vision, or access to switches and dials. In the weeks following installation, especially after long rides, it pays to recheck the mounting hardware for any signs of loosening, distortion, or corrosion. The goal is not only safe operation but long-term durability; frame-mounted fairings depend on stable fastening that can withstand road shear, speed-induced loads, and the occasional off-race road encounter.

Maintenance for frame-mounted fairings stresses similar discipline. Regular cleaning is straightforward but important. A mild soap and water solution is typically sufficient to remove road grime, tar, and insect deposits that can degrade the surface over time. Harsh abrasives or aggressive solvents should be avoided, as they can dull finishes or degrade coatings. The long-term aesthetic and functional integrity of the fairing hinges on surface protection; applying a UV-protective wax or sealant designed for plastics helps slow the fading and cracking that sunlight can cause. The hardware itself deserves frequent attention. The mounting bolts, washers, and brackets should be inspected periodically—particularly after exposure to heavy rain, salt, or wide temperature swings—for signs of loosening, corrosion, or wear. Any looser fasteners should be tightened to the correct torque specifications without delay to maintain the system’s integrity. In the same breath, one should guard against the onset of material fatigue by looking for hairline cracks near mounting points and around the edges where loads concentrate. When such signs appear, it is prudent to consult technical documentation or a qualified technician before attempting a field repair. The integrated nature of frame-mounted fairings means that repairs and replacements are often more complex and, in some cases, more expensive than on simpler, non-integrated bodywork. This cost reality reinforces the value of careful installation, meticulous maintenance, and a proactive approach to part life, especially for riders who push their machines toward track-day performance or long-distance touring with aggressive winds.

From the rider’s perspective, frame-mounted fairings deliver a tangible sense of purpose. They contribute to a stable platform for the entire machine, enabling more predictable behavior at speed and a cleaner, quieter cabin experience for the rider. They also support a cohesive look that communicates intent: a bike designed to slice through air with minimal interruption and to reward the rider with a smooth, controlled ride. Yet this premium comes with a responsibility to maintain fitment and finish. The job is not simply to bolt a shell on a frame and call it a day; it is to preserve a carefully engineered interface between machine and air, so the vehicle remains predictable, responsive, and durable over thousands of miles of riding.

For riders who want to explore specific aftermarket options without compromising the integrity of the frame, there are established resources and communities that discuss compatibility and installation nuances in depth. This approach highlights a practical path: prioritize matching the mounting points and contour alignment before selecting a shell, since the frame and the bracket system determine how well the fairing behaves under load. Integrating a new panel set is not simply about matching a color or shape; it is about ensuring a precise fit to the frame and a seamless connection to the existing aerodynamic boundaries. As with any significant aftermarket modification, following manufacturer guidance and employing the correct torque specs, protective finishes, and inspection routines will help realize the full benefits of frame-mounted protection and performance.

Final thoughts

Frame-mounted motorcycle fairings present a strategic advantage for motorcycle business owners by enhancing both performance and rider experience. Their structural integrity and aerodynamic properties lead to quieter rides and improved handling, catering to a market that values both aesthetics and function. Understanding the materials and installation processes involved not only helps in providing better service but also position businesses favorably within a competitive landscape. Investing in high-quality frame-mounted fairings can translate into higher customer satisfaction and repeat business, making them an essential component in any modern motorcycle offering.