Painting motorcycle fairings with a spray gun is not just a task; it’s a craft that can enhance your business’s reputation for quality and precision. The right techniques ensure that your customers leave with a striking, long-lasting finish, setting your work apart in a competitive market. This guide provides essential insight into the preparation required, masking techniques to protect parts that shouldn’t be painted, selecting and preparing the right paint, and mastering spray application methods. Each chapter is dedicated to these crucial steps, helping your business thrive through outstanding craftsmanship.

Preparation First: Essential Steps Before Spraying Motorcycle Fairings

The foundation of a showroom worthy paint job on a motorcycle fairing begins not with color but with preparation. This quiet work shapes adhesion, texture, and depth. On plastic and curved surfaces, proper prep becomes non negotiable. The aim is to create a surface that accepts pigment evenly, resists chasing dust, and holds gloss over time. In practice, treat every area as a potential fault line and execute a methodical sequence: cleaning, degreasing, scuffing, cleaning again, masking, final wipe, and inspection before any pigment touches the plastic. Begin with cleaning to remove oils, waxes, silicone residues, and road grime. Use a dedicated automotive cleaner for plastics, followed by a lint free cloth. Allow to dry in a dust free zone away from direct sun. Some practitioners finish with a light wipe of isopropyl alcohol to remove the last trace of contamination, but leave no residue that could impair adhesion. The skin should feel clean and dry and reflect light evenly.

Surface preparation is the decisive moment. Sanding is not removal but texture adjustment to create a reliable key for the new paint. Start with a coarser grit in the 800-1000 range to break the glaze and reveal micro-scratches that trap the pigment. Keep strokes consistent and avoid heat build up that may soften plastic. Move to 1500-2000 to smooth the texture and reduce reflections that emphasize flaws. Use damp work to minimize dust and keep the surface cool. Between grit changes, use a tack cloth to lift dust from crevices. Do not skip this step; tiny fibers can ghost under the base coat. If texture remains after the final polish, lightly re-sand at the finest grit and re-tack.

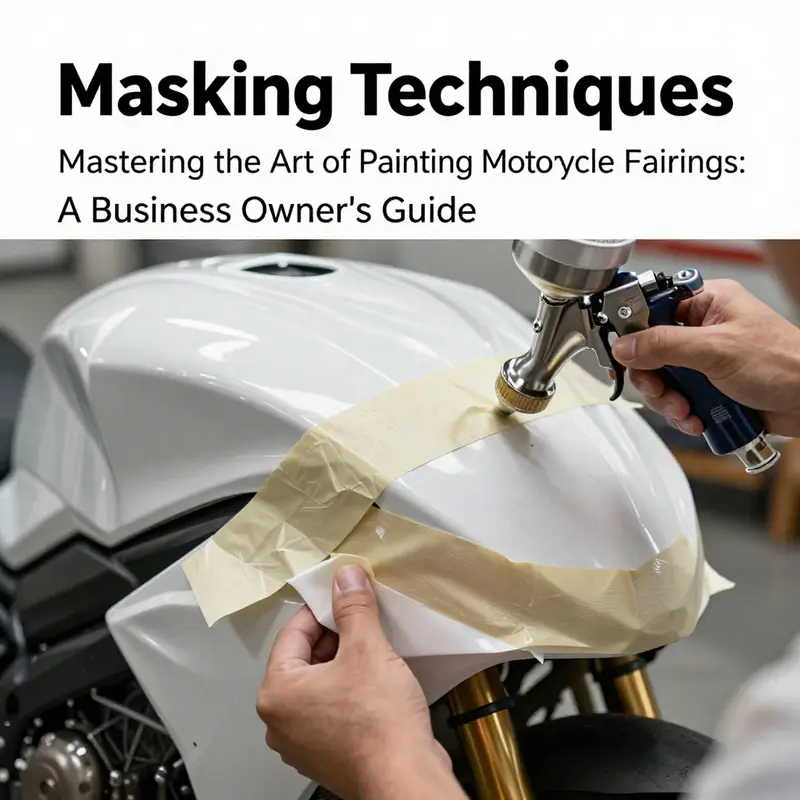

Masking is protection and precision. Use painter’s tape and automotive masking film designed for curved surfaces. Press tape firmly along edges to seal; on complex curves use multiple small pieces. Cover surrounding metal, windshield, and any parts that must stay uncoated. The goal is clean color lines and zero bleed under the base coat.

Final inspection before paint is a formal check under strong neutral light to reveal dust, fingerprints, or scratches. If a defect is found, re-clean, re-sand, and re-tack. Confirm the surface is truly ready for the base coat and that edges are defended.

Optional adhesion promoter can improve bond strength on certain plastics. If used, apply a uniform ultra-thin layer, observe the flash time, and proceed only when fully cured per the promoter guidelines. It adds a margin of reliability for high flex areas and seams.

A practical discipline supports the work: keep the workspace orderly, have tools at hand, and avoid contaminating the clean zone. The sequence is logical: cleaning, degreasing, scuffing, cleaning again, masking, final wipe, inspection. Time invested here reduces waste later and supports a smoother spray.

Finally, use visual references to study how light interacts with curves and how masking decisions affect edge fidelity. References from Yamaha fairings or other collections can sharpen your eye for texture and line before you lay down color. This prep ensures the base coat behaves as intended, with depth, uniformity, and durability that honors the design.

Guarded Edges, Flawless Finish: Mastering Masking for Motorcycle Fairings with a Spray Gun

Masking is the quiet guardian of a flawless paint job. It shields the parts that must stay unpainted while the spray gun works its magic, allowing sharp edges, clean lines, and a finish that looks factory-new rather than home-done. In the studio where motorcycle fairings take on color, masking is not an afterthought but a core step that dictates the overall quality of the result. The goal is simple to state and harder to perfect: every edge where color meets unpainted surface must be clean, crisp, and untouched by overspray or seepage. The masks must hold through several coats, stay in place as the gun sweeps across curves, and release without peeling or lifting when the paint has dried. Achieving that demands a deliberate plan, the right tools, and a calm, methodical rhythm that respects the contours of the fairing as if you were tailoring a suit for a sculpture.

The approach begins well before the gun comes out. A fairy-tine of surface prep, dust control, and layout thinking saves time later and reduces the temptation to rush. Even a small misstep here can show up as smudges, bleeds, or fuzzy edges once the color is revealed. Start with a mock map of the surface. Visualize where color will run, where it must stop, and which components should remain bare. If you plan to keep the bike’s frame visible in some areas or to accent edges with a two-tone design, you will need to segment those zones in your mind before applying tape. A thoughtful plan translates into a cleaner mask, fewer touch-ups, and a more predictable spray pattern.

The tools form the backbone of reliability. A high-quality painter’s tape is essential; you want something that will adhere firmly to plastic, glass, and chrome without lifting when the nozzle passes over at speed. Alongside tape, masking film provides broad coverage for bigger areas, and foam tape can bridge irregular transitions between masked and bare surfaces without squeezing paint into the tiniest creases. For curves and intricate contours common on fairings, custom-shaped templates or pre-cut masking films can be pressed into place with minimal trimming. The aim is to create a belt-and-suspenders system: tape for edges, film for expansive planes, and foam where a gentle transition is needed. Before any tape touches paintable surfaces, ensure the surface is clean and dry. Dust, oil, or moisture trapped between tape and plastic invites adhesion failures and paint creep. The clean-surface rule is non-negotiable; a quick wipe with a dedicated cleaner and a lint-free cloth can save hours of trouble later.

Once the planning is complete and the surface is pristine, masking begins in earnest. The first priority is to protect glass, lights, chrome trims, and delicate hardware. This means laying tape to cover glass panels, shielding reflective surfaces, and sealing edges that meet the body with accuracy. The process itself benefits from patience and attention to the edge geometry. On flat panels, you can press the tape down and burnish along the edge to create a dense seal that resists air and paint bleed. On complex shapes—headlights, vents, or the times when the fairing wraps around the cowling—the same principle applies but with added care. You can run curved strips of tape along the contour, then lay a second strip perpendicular to the first at the edge to anchor the line and prevent lifting under the spray. When curves are tight or deeply recessed, tape should be pressed down in small sections, ensuring every little corner has contact with the surface so the paint cannot slip underneath.

Masking film plays a crucial role for larger areas or when you need to keep the spray contained for longer sessions. In practice, film is stretched over broad planes and trimmed away only where necessary. The trick with film is to keep it taut and smooth, avoiding wrinkles that can trap moisture or create uneven edges under the final coat. Foam tape is particularly helpful when a seam or joint creates a slight step between painted and unpainted zones. The foam cushions the edge, softening the transition and reducing the risk of a high edge that would trap paint or cause buildup along the seam. For technical shapes and curves that resist straight masking, consider custom templates or pre-cut masking films. These tools let you map out precise zones in advance and reduce the risk of overcutting or undercutting the area you intend to expose to color. The idea is to establish a boundary that is predictable and repeatable, especially when you are working on multiple panels or when you are masking the bike in one session with the expectation of returning for additional coats.

The masking step also includes a crucial check after the setup is complete. Good lighting is indispensable. A bright, adjustable light source reveals gaps, edge lift, or paint bleed that might not be visible under ordinary room lighting. A quick retrofit of the masking after inspection often saves you from a crumpled fender or a rework nightmare later. Before you begin spraying, you should also check one more time that the masked areas are completely dry and free of dust. Any moisture trapped under tape or film could cause water-spotting or a pebbly finish once the color is applied. Dust removal becomes part of the masking ritual: use a soft brush or compressed air to remove particles from the surface around the masked edge, never blowing directly at the edge where paint is about to land. The goal is to deliver a barrier that the paint cannot cross and a surface that the gun can glide across without dragging foreign matter into the finish.

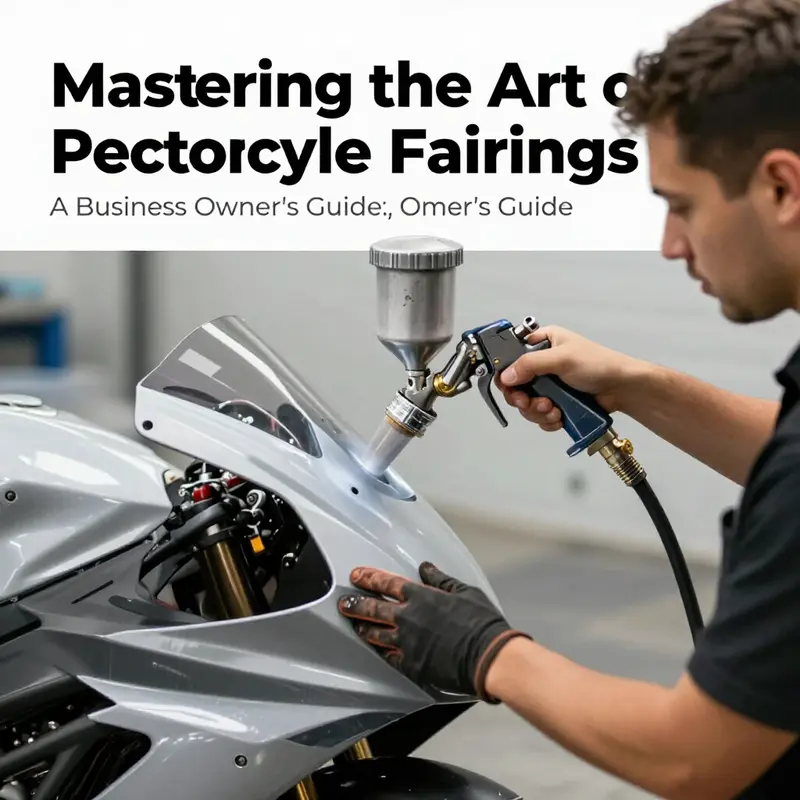

When you are ready to spray, the masking must hold through the entire color sequence. This is where the mask’s integrity is tested by the spray gun’s velocity and the column of atomized pigment crossing the boundary between protected and exposed areas. A practical approach is to keep the masking tight and to work in a well-controlled environment. You want to minimize movement of the mask and avoid abrupt changes in air pressure that could cause edges to lift. If the work area is drafty or subject to airborne dust, you will need to increase the masking’s reliance—more film, additional foam tape at seams, and perhaps even an extra row of edge seals along critical boundaries. It is tempting to rush a masking setup in a busy workshop, but the trade-off is a compromised edge. A patient setup pays for itself in the first coat that lands exactly where you expect it to.

The act of masking also invites a level of craftsmanship that is easy to overlook. It is not simply about covering what you do not want to paint; it is about shaping the path of the color. The line where masked and painted surfaces meet becomes a defining feature of the final aesthetic. A crisp line communicates precision, while a blurred line communicates improvisation. The difference is etched in the tape’s alignment, the film’s tension, and how steadily you burnish along the edge. If the line you are aiming for involves two colors or a color and a clear segment, plan the sequence so that the color boundaries align with the masking edges. You might mask the base color edge rigidly and then carefully apply the second color inside its own defined masking zone. Every transition should read as intentional, not accidental.

In the broader arc of the project, masking is intimately connected to the rest of the painting process. A well-executed mask reduces the risk of over-spray onto the motorcycle frame, engine, or adjacent panels, preserving the integrity of the bike’s overall appearance. It also helps ensure that the final finish is cohesive, with sharp dividing lines that accentuate the fairing’s form rather than blur the shapes into a single, indistinct field of color. When you consider the finished product—the moment when the fairing is mounted back on the bike and the light plays across the glossy surface—the clarity of those edges becomes a quiet testament to the discipline of masking. If you want to explore broader options for the parts you’re masking, you can look at the Honda fairings collection to see how contours interact with flat and curved planes and how masking plays into the final geometry of color and form.

The masking discipline also has a practical, tactile cadence. You lay down the base protection, press and seal edges, inspect under bright light, adjust any misaligned corners, and then move on to the next zone. This rhythm—mask, verify, re-check, mask again if needed—reduces the chance of surprises once the spray booth door closes. You are, in essence, building a safety net that catches all the little issues before they become stubborn flaws. And because masking is about protecting what you want to keep clean and untouched, you should treat every surface with the same respect you afford the paint itself. A good mask is a silent partner in the performance of color, and when you peel it away after the final coat, you should see evidence of careful planning rather than improvisation.

As you progress through multiple layers, masking remains the steadfast boundary that keeps the design intentional. If you are working with two-tone designs or graphics that require precise alignment, masking becomes the invisible guide that ensures the alignment holds across coats. The process does not end with the removal of the tape; it often proceeds to the post-paint workflow, where tiny touch-ups, final edge cleanup, and careful inspection for feathering or bleed may occur. Even minor adjustments—softening a harsh edge with a light pass of cleaner over a newly exposed boundary, or re-burnishing a stubborn corner—can preserve the integrity of the design. The reward for this patience is not just a glossy surface but a sense that every line, edge, and contour has been treated with intention and care.

To deepen your toolkit and broaden your options, consider looking at broader sources for guidance on masking technique and edge control. For a concise, practical overview that translates well into the workshop, you can explore the internal reference to the Honda fairings collection, which demonstrates how masking strategies align with the shapes you are painting. The takeaway is simple: the better your preparation and the more rigorous your edge control, the more confident you’ll feel when you pull the trigger on your spray gun and the color begins to flow in crisp, controlled passes. The masking stage has prepared the ground for that moment when the fairing finally reveals its true color, showing depth, resilience, and a finish that mirrors the precision of the work you poured into every careful edge.

In the end, masking is not merely about keeping paint off areas you don’t want colored. It is about enabling your design, protecting the mechanical and cosmetic components of the bike, and delivering a final result that stands up to UV exposure, weathering, and the wear of riding. It is the quiet craft that makes the loud drama of color possible. And when you step back to view a freshly painted fairing with clean lines, you will recognize that the difference between good and great work is often measured in millimeters of edge fidelity—the small, deliberate decisions around masking that permit the spray gun to tell the story of color without interference. For those ready to broaden the context with real-world examples, the Honda fairings collection offers concrete demonstrations of how masking interfaces with contour and surface, providing a practical reference as you plan your next project.

External resource for deeper tips and techniques on motorcycle fairing painting can be found here: https://www.paintersedge.com/motorcycle-fairing-painting-tips/

Color Confidence: Mastering Paint Selection and Prep for Motorcycle Fairings with a Spray Gun

Choosing the right paint for motorcycle fairings begins long before the spray gun starts moving. It hinges on substrate compatibility, the anticipated environment, and how well the finish will hold up under sun, fuel exposure, and the flex of a plastic shell during movement. The spray gun itself can deliver a showroom gloss, but only if the entire system—paint, primer, and clear—works with the plastic. For fairings, that means leaning into a two‑component polyurethane system designed for plastics, rather than relying on generic acrylics or single‑stage paints that may crack, yellow, or peel with time. A durable result depends on a properly matched paint system that bonds to primed plastic, remains flexible as the panels flex, and resists UV radiation and temperature swings. The choice is not simply about color; it is about a cohesive chemistry that resists the stresses unique to motorcycle fairings. When the wrong system is chosen, you may get good color in the shop, but you will pay for it in the long run with micro‑cracking, dulling, or premature peeling. This is why the decision to use a two‑part polyurethane that is formulated for plastic substrates isn’t just a preference; it is the foundation for a professional finish that survives road life and the test of time.

Material compatibility directly informs the preparation that follows. Plastic fairings respond best when the surface is clean, slightly textured, and primed with a resin that adheres to ABS or polycarbonate. Before any color touches the surface, remove the fairings from the motorcycle to gain full access and to prevent overspray from reaching components that won’t receive paint. A thorough cleaning with a dedicated plastic cleaner or degreaser removes oil, wax, and residues that would otherwise sabotage adhesion. A clean surface is non‑negotiable because every speck of dust or trace of oil found after sanding will reveal itself once the gloss builds. In the same spirit, the sanding step is crucial, but it must be strategic. Start with a coarser texture to remove gloss and create a mechanical key, then progressively refine to a smooth, uniform surface. The aim is not to obliterate the underlying texture but to create a subtle tooth that the primer and paint can bite into. And always finish with a clean wipe using a tack cloth or compressed air to remove fine dust.

Sanding routes matter because they determine the final feel of the paint. A practical path is to begin with a grit that lightly scuffs the existing finish—often a 400–800 range when dealing with plastics that have held a gloss finish or a previous clear coat. Move through finer grits, commonly 800–1200, and in some cases up to 1500–2000 if you’re working with a light color or a panel that requires exceptional smoothness. The key is to sand consistently in one direction on each panel to minimize swirl marks that would later show through the base or the clear. Once sanding is finished, wipe the surface again to ensure no residual dust remains. At this point you can begin the priming process, for which the most important aspect is adhesion—creating a robust bond between the plastic and the subsequent layers.

The priming stage is where plastics meet a real protection plan. A 2K epoxy or urethane‑based primer formulated for ABS or polycarbonate gives you the best balance of adhesion, moisture resistance, and barrier protection. This primer is not merely a color base; it acts as a shield against moisture and chemical attack while providing a uniform, consistent surface for the base color. Allow the primer to cure fully according to the manufacturer’s instructions, then lightly re‑sand to erase any pinholes or imperfections and to create a fresh, even key. This light scuffing, typically in the mid range of a thousand or so grit, is enough to awaken the surface without removing the primer itself. After sanding, clean again with isopropyl alcohol or a similar solvent to remove any residue that might trap dust or hinder adhesion. The goal is a surface that is dry, clean, and uniformly textured, ready to accept color with minimal risk of adhesion failure down the line.

With a solid primer, the painting process moves into color. The base coat, especially when using a 2K system, benefits from a controlled environment and carefully tuned application parameters. The environment plays a decisive role here: a clean, dust‑free area with stable temperature and humidity—typically around 68 to 77 degrees Fahrenheit (20 to 25 degrees Celsius) and 40–60 percent relative humidity—helps the film form evenly and reduces the chance of orange peel or sags. Begin with a test spray on a scrap piece of plastic to dial in your technique, distance, and spray pattern. A general rule of thumb is to hold the gun perpendicular to the surface at roughly 6 to 8 inches (15 to 20 cm) and to apply the color in wet, overlapping passes. The base coat should be built in two to three light coats rather than a single heavy one. Each coat should flash for about 10–15 minutes per the product guidance, until it reaches a tack‑free state but is not fully cured. This flash time allows solvent to evaporate and the film to begin to set so the next coat bonds properly without trapping solvents that could later cause cracking or lifting. Overlap each pass by about 50 percent to ensure even coverage and to minimize thin spots. After each coat, inspect for coverage in good lighting. If you can still see patchy areas or thin spots, apply another coat after the prior has flashed but before it cures completely.

The practical implication of base coating is balance. You want color depth and smoothness without creating heavy film that might crack as the fairing experiences flex. The paint system you choose should support flex and impact resistance while preserving color richness. Once the base coats are in place and have flashed, you can proceed to the clear coat, which seals and deepens the color while providing UV resistance and protection against road hazards. The process for a 2K polyurethane clear is parallel to the base: multiple thin passes, with a controlled number of coats—usually two to three. The clear coat adds depth and a protective layer that resists UV rays and minor abrasion, allowing the metallics or candy colors to pop while remaining robust under sunlight and weather exposure. It is not a cosmetic afterthought; it is the finishing armor that lets the panel keep its gloss under the rough realities of riding and washing, with the flexibility to resist cracking if the fairings flex slightly during operation.

Drying and curing are two different things and both deserve respect. After the final clear coat, let the panel dry for at least 24 hours at room temperature in a clean space before attempting to reinstall or handle the part; however, full chemical cure often takes longer, with many systems achieving their optimum hardness after 7 days. In environments with higher humidity or lower temperatures, cure times can extend beyond the standard guidance, and some brands require longer sits before subjecting the surface to assembly or heavy handling. If reassembly is planned soon after painting, it is worth checking the product’s specific cure window and avoiding any exposure to harsh conditions during the critical early stages. The difference between a glossy, durable finish and one that disappoints often lies in this patience—allowing enough time for the film to reach maximum hardness before subjecting it to the rigors of ride and wash cycles.

After the curing phase, many riders opt for a light refinement to achieve a glassy finish. A very fine wet/dry sandpaper—think around 2000 grit—used with clean water can help erase the tiniest micro‑imperfections and prepare the surface for polishing. A controlled approach here is essential; excessive sanding can cut through the clear and reveal the color, defeating the goal of a smooth, flawless finish. If you proceed with polishing, use a suitable polishing compound and a dual‑action polisher to restore a high gloss without introducing heat buildup that could degrade the film. The objective is a surface that looks flawless in bright light, with a depth that seems to draw you into the color rather than revealing the individual layers beneath. This is the moment where preparation, patience, and technique converge to yield a professional appearance that stands up to daily use.

The discipline of choosing and preparing paint for fairings goes beyond color choice. It includes the quiet art of masking to protect what isn’t meant to be painted and the discipline to test spray and viscosity before committing to the actual panels. Masking is a simple but critical step that protects the frame, engine, lights, and other features from overspray while preserving sharp edges where the paint should stop. Use high‑quality masking tape and paper, apply it smoothly, and over‑lap edges to prevent bleed‑through. The quality of masking is often visible in the final result, particularly on complex shapes or high‑contrast color schemes where the line between painted and unpainted surfaces must be crisp. When you consider the broader ecosystem of parts and color options, you might benefit from exploring a broader selection of fairing styles to understand how different shapes influence the final appearance of the finish. For a sense of fit and form, you can browse the Honda fairings collection and related resources to see how different panels align and how their contours respond to color and gloss in real life. Honda fairings collection.

This approach—careful material selection, meticulous surface preparation, controlled application, and patient curing—creates a dependable route to a professional result. It also opens the door to experimentation with finishes, from solid colors to metallics and beyond, without sacrificing durability. If you keep the process anchored in the fundamentals—cleanliness, adhesion, proper layering, and controlled environment—you will build a workflow you can rely on for future projects. The goal is not simply to paint a panel; it is to create a durable, aesthetically compelling finish that endures the realities of riding, cleaning, and exposure to the elements. For readers seeking a broader context or a concise practical walkthrough of these steps, an external reference offers an expanded perspective on the overall sequence and considerations involved in painting motorcycle fairings with a spray gun: https://www.carinterior.com/how-to-paint-motorcycle-fairings-a-practical-guide/.

The Art and Precision of Spray: Mastering Motorcycle Fairings with a Spray Gun

Painting motorcycle fairings with a spray gun is a study in balance. It blends the predictability of science with the patience of craft. The goal is not merely color on plastic but a durable, glass-smooth surface that can withstand sun, rain, and the road grime of riding. The process begins long before the trigger is pulled and ends long after the last coat has cured to a mirror-like finish. It is a sequence of deliberate decisions—about surface preparation, paint chemistry, tool setup, and technique—that, when executed with consistency, yields a result that looks factory-new and holds up under real-world use. The key is to treat each step as if it were the foundation for the next, because it is. A successful paint job on fairings rests on sound preparation, disciplined application, and careful curing, all performed in a controlled environment where dust, temperature, and humidity are managed with the same care used to mix a flawless base color. The journey from bare plastic to glossy, resistant finish is a gentle orchestration of steps that flow into one another, so the narrative here follows that same river of progress, weaving together practical action with the rationale that keeps the finish reliable and repeatable. To begin, the fairings must be ready for adhesion, and readiness begins with a thorough separation from the bike, a clean canvas, and a surface that will hold the next layers without compromise. Disassembly is more than convenience; it is access, allowing every contour, seam, and edge to receive even attention. When the fairings come off, the next move is cleaning. A dedicated automotive cleaner or degreaser is applied to remove oil, grease, wax, and dirt, followed by a wipe with a lint-free cloth. Cleanliness here is non-negotiable. Any stray film, any smear of oil, or speck of grease can undermine adhesion and later show up as a thin spot or a peel. Once the surface is free of contaminants, light mechanical abrasion follows—sanding—to create the crucial key for the primer and the color. Start with a coarser grit to knock down gloss and any irregularities, then move to finer grits to bring the surface to a smooth, uniform texture. The technique matters as much as the grit you choose. Always sand in one direction to avoid cross-hatching that can cast subtle shadows in the paint or trap dust. After sanding, a tack cloth or compressed air removes the fine dust that would otherwise trap under a coat and cause blemishes. The surface is then primed. Priming plastics is a small but essential science: primers designed for plastics and automotive applications fill micro-scratches, improve adhesion, and establish a uniform base for the base color and clear coat. The primer should be compatible with the selected base color and the subsequent topcoat, so choosing it with the rest of the system in mind matters as much as the color itself. With priming complete and the surface scuffed enough to be hand-slick, the masking stage begins. Careful masking is a quiet art. The aim is to protect everything that must stay unpainted while leaving the fairing exposed where color will land. The right masking tape, properly applied with no gaps or wrinkles, ensures clean edges and prevents bleed. Edges where fairings meet frame or bodywork are particularly sensitive, because any failure to mask here can ruin an otherwise pristine surface. The masking process is often the difference between a professional result and a weekend-by-the-road finish. When masking is done, attention turns again to the paint itself. The choice here is critical. Use a two-part urethane system designed for plastics and automotive use. This choice improves durability, UV resistance, and the long-term resilience of the finish. The base color is mixed with its hardener in the exact ratio specified by the manufacturer. Thorough mixing is essential; stir for at least two to three minutes to ensure uniform chemistry and pigment distribution. After mixing, allow a short pot life—typically ten to fifteen minutes—to keep the mixture workable before it begins to gel. The thinner or reducer is added in the manufacturer’s recommended amount to achieve the correct viscosity for spraying. Testing the mixture on a scrap piece helps confirm whether the spray will lay down evenly on the curved, irregular surfaces of a fairing. The preparation of the paint is only the first half of the equation of success; the environment in which that color is laid down matters just as much. The spraying area should be clean, free of dust, and well-ventilated. Temperature and humidity govern how the film flows and dries, so a stable range—roughly 68 to 77 degrees Fahrenheit (20 to 25 degrees Celsius) with humidity around 40 to 60 percent—helps the paint flow and flash predictably. Direct sun or drafts can compromise film formation, so a controlled, windless space is ideal. Before applying color to the fairing, a test spray on a scrap piece of plastic confirms comfortable gun handling, distance, and spray pattern. This practice spray protects the workpiece from early missteps and allows a precise adjustment of gun settings before the actual job begins. The spray gun itself, typically an HVLP unit for this kind of work, requires few compromises to achieve controlled transfer and minimal overspray. The nozzle often sits in the 1.2 to 1.4 millimeter range for fine finishes on plastics, and the air pressure should be tuned to the paint’s requirements—commonly in the 20 to 30 PSI window. These are not hard absolutes; they are a starting point, adjusted to suit the specific color, the ambient conditions, and the peculiarities of the fairing’s curves. Viscosity is the bridge between the paint and the surface; thinning according to the product’s specification becomes a craft of its own. A scrap test confirms that the viscosity yields a smooth, mist-like spray that lays down evenly without sagging. The distance from nozzle to surface is typically steady, around six to eight inches, and the gun’s motion should be calm and consistent. Movement is essential: it should be a steady, overlapping pattern that covers the surface without creating heavy builds. The wet-on-wet technique—layering semi-wet coats that blend into each other—allows each pass to flow into the last without creating edge lines or thick ridges. Coverage is built in multiple thin coats rather than one heavy application. Two or three light coats are preferred, each allowed to flash for about ten to fifteen minutes before applying the next. The overlap between passes should be about fifty percent so that no area is left under-coated. It’s during these coats that the first signs of depth begin to emerge. A critical but sometimes overlooked step is the light sanding between coats. After the base coats have flashed, a very light sanding with 1500 to 2000 grit is performed to remove micro-imperfections and to provide a smoother surface for the final clear coat. This step should be treated with care—too much sanding can cut through the color or damage the primer; too little can leave a dull finish with visible imperfections. Once the base color has achieved uniformity, the clear coat is applied. The clear coat protects color, adds depth, and provides a UV shield as well as abrasion resistance. The same wet-on-wet technique is used, with two to three thin coats ensuring a steady buildup of gloss and protection. The air and temperature conditions still matter during clear coating, as does the drying time between coats. After the final coat, the piece is allowed to dry at room temperature for a minimum of 24 hours. Full cure is typically achieved after seven days, though some systems permit longer or shorter durations. During curing, the finish hardens and gains the ability to resist scratches and environmental exposure. If any dust or debris has settled onto the surface during drying, a gentle rework may be possible: a very fine wet-sand with 2000 grit can remove minor blemishes, followed by a careful polish. Polishing after cure is a refined art, returning the surface to its maximum luster. A dual-action polisher with a light cutting compound is commonly used to remove micro-scratches and to bring back the shine of the clear. The process is gradual, and the operator should avoid aggressive passes that might burn through the clear or heat the surface beyond its tolerance. The goal is a mirror-like, glassy finish with a uniform highlight across the contours of the fairing. Throughout this journey, discipline in technique is the anchor. The fairing’s curves, edges, and seams demand consistent motion and steady hand control. The gun should be held perpendicular to the surface, with a deliberate rhythm that travels across the contours. The distance should remain constant, and the passes should be evenly spaced to prevent crowding and pooling. The subtle indicators of a successful coat—uniform color, no runs, and an even sheen in well-lit conditions—are earned through patience and practice rather than haste. The practical story here also includes a mindfulness about the environment and the workflow. A dedicated spray booth with proper ventilation reduces exposure to dust and fumes and helps maintain consistent conditions. Preparation of the space, the protection of surrounding components, and the habit of masking can prevent costly mistakes and facilitate a smoother finishing process. The choice of a compatible, well-matched finish is essential for a durable result. The fairing surfaces, with their complex curves and hard-to-reach areas, benefit from a spray gun because the tool’s atomization and transfer efficiency control the paint’s deposition with precision that hand brushing cannot match. The model of the gun—whether its nozzle is the right size for the intended finish, whether the air source is clean and stable, and whether the viscosity remains within the recommended range—does not make the result by itself. Skill and discipline do. A steady routine that begins with clean, dry rooms, continues with careful masking, correct priming, measured mixing, and controlled spray passes, and ends with deliberate curing and thoughtful finishing yields the most reliable results. It is a rhythm, a routine that, when learned, can be repeated with similar outcomes across different fairing shapes and color schemes. For readers exploring a range of fairing options, the Honda fairings collection represents a practical reference point for understanding different contours and mounting considerations. You can explore such options to better visualize how the spray technique adapts to various shapes and angles. Honda fairings collection offers a window into real-world possibilities for color testing, practice panels, and sizing before committing to a full kit. This practical exploration supports the theoretical framework described here by grounding it in real curves and joints that demand careful spray control and edge management. As the narrative of spray technique progresses, it is also valuable to anchor the practice in trusted resources beyond the specific shop. A reputable external guide on spray painting offers broader context—covering atomization, overlap, and curing specifics—without tying itself to any single product line. For readers seeking an external reference to deepen their understanding of spray technique fundamentals, consider consulting established automotive coating guidelines. A widely used resource on spray painting tips provides comprehensive, practical advice on technique, troubleshooting, and best practices. This guidance complements the hands-on process described above and can help refine decisions about thinning, distance, and coat scheduling as you move from theory to practice. External resource: https://www.ppg.com/automotive/paints-and-coatings/technical-resources/spray-painting-tips

Final thoughts

The art of painting motorcycle fairings with a spray gun encompasses several important steps that culminate in a flawless finish. From the initial preparation to the final spray application technique, each element plays a crucial role in delivering a product that meets high standards of quality and aesthetics. By focusing on these practices, business owners can improve customer satisfaction and ensure their services stand out in the marketplace. Consistency, precision, and attention to detail are the hallmarks of a successful operation, paving the way for repeat business and positive referrals.