Metric motorcycle fairings are vital components that enhance performance, rider comfort, and the overall aesthetic appeal of bikes. Specifically designed for metric motorcycles—primarily Japanese models such as the Kawasaki Ninja, Honda CBR, and Suzuki GSX-R—these fairings serve multiple functions, from improving aerodynamic efficiency to protecting riders from the elements. As we delve into the core aspects of motorcycle fairings, this article will break down their aerodynamic benefits, rider protection elements, and types of fairings available, while also shedding light on manufacturing dynamics within the industry. Each chapter offers a comprehensive look at fairings, providing business owners with essential insights to make informed decisions in their offerings.

Riding the Wind: The Aerodynamic Mastery of Metric Motorcycle Fairings

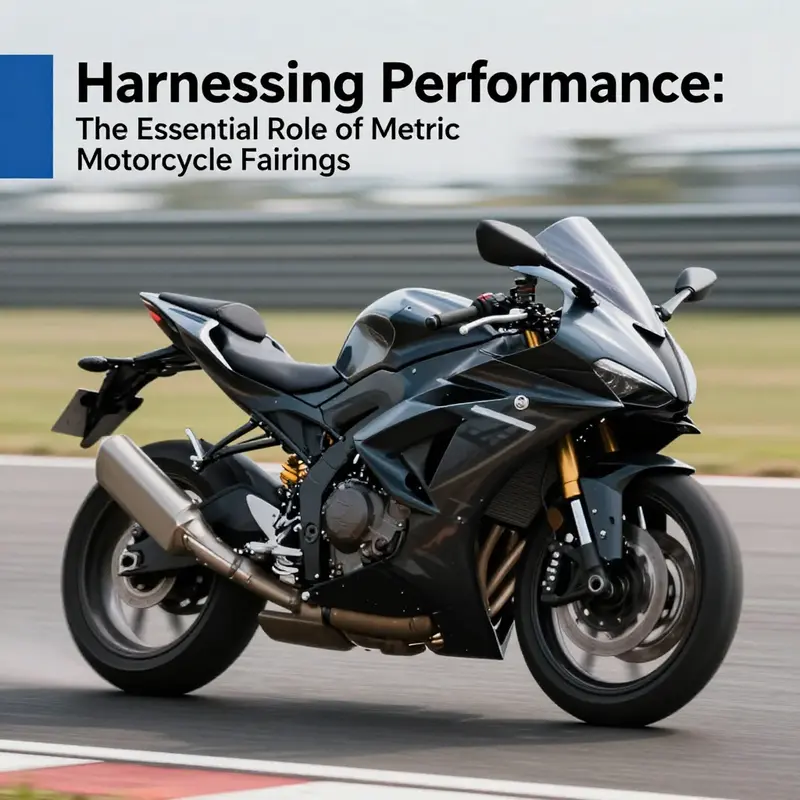

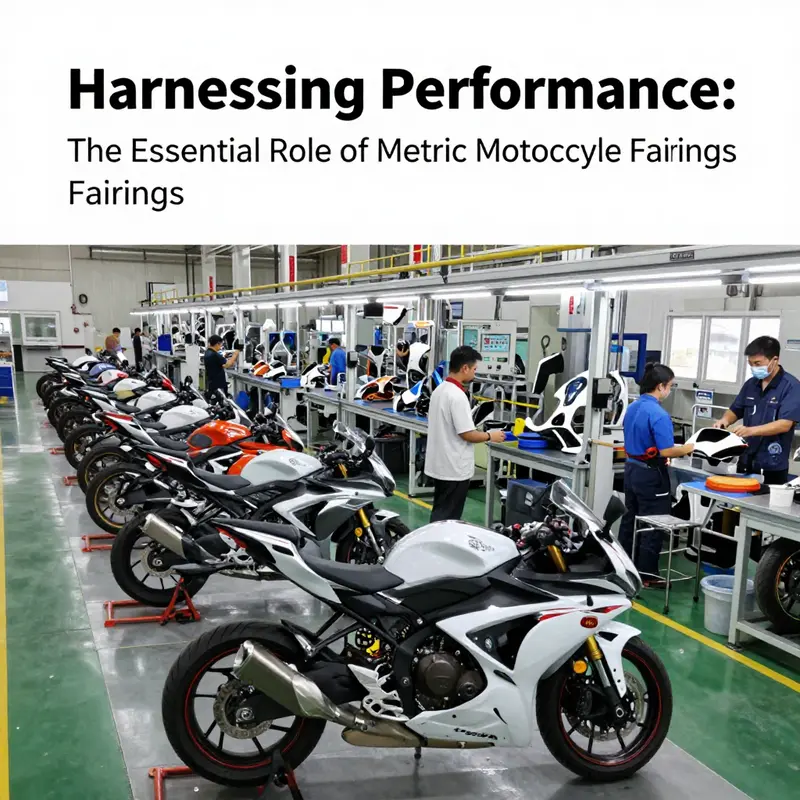

The fairing on a metric motorcycle is more than a cosmetic shell; it is a carefully engineered surface that shapes the air and, with it, the bike’s behavior at speed. In modern sportbike design, aerodynamics is a language the chassis speaks fluently. The lines carved into the bodywork of machines built for the Japanese market—think iconic machines from brands that define metric sportbikes—are not accidental. They are the result of an ongoing conversation between physics, rider comfort, and the machine’s intended use. When a rider leans into a highway straight or threads a track’s apex, the fairing is the invisible partner that translates speed into stability, efficiency, and confidence. It is the sculpted skin that makes power usable, and it does so with a precision that emerges only after years of testing, wind-tunnel work, and real-world feedback from racers and daily commuters alike. To understand this dynamic, one must look at what aerodynamic efficiency actually encompasses and how fairings are designed to optimize it across a spectrum of riding styles and conditions. The goal is not simply to slice through air; it is to choreograph the air so that the bike’s mass, engine output, and rider inputs work in harmony rather than in resistance to each other. This is the essence of metric motorcycle fairings—an intricate fusion of form and function in which every contour, cutout, and vent has a reason rooted in the physics of flow, pressure differentials, and boundary layers. When a rider climbs aboard and the engine comes to life, the fairing becomes a kind of aerodynamic language, telling the wind where to go, where to slow, and where to accelerate. The most dramatic benefits show up at higher speeds, where drag becomes a limiting factor and even small improvements in profile yield meaningful gains in efficiency and stability. Yet the same shapes that reduce drag also influence comfort. Wind pressure, turbulence, and buffeting interact with the rider’s body, and a well-designed fairing can minimize fatigue over long rides by smoothing the air’s wake around the rider. In practice, this means a fairing must balance several competing demands: clean separation of the boundary layer to prevent large wakes, targeted pressure distribution to maintain stability, and enough airflow to keep cooling systems effective without creating unnecessary drag. Across metric bikes—from the most track-focused Ninjas and CBRs to the sport-touring legs of the family of fairings—the pursuit is a profile that brings the air into a respectful partnership with the motorcycle rather than a relentless adversary. The journey toward aerodynamic efficiency begins with the geometry of the surface itself. A well-designed full fairing encases the front end and often extends along the sides to cleanly sweep air around the rider and the engine. The shape must minimize flow separation, which can create turbulent wakes that rob stability and raise drag. In many modern designs, engineers employ sharp transitions, carefully placed chines, and converging lines that guide the air smoothly from the leading edges to the trailing edges. The result is a reduced coefficient of drag, a lower frontal area when projected in the direction of travel, and a smaller overall drag area, commonly expressed as CdA—a product of the drag coefficient and the frontal area. For riders on long highway routes, even a modest reduction in CdA translates into less engine work per mile, yielding improved fuel efficiency and a calmer engine note at sustained speed. For track enthusiasts, the same reductions contribute to steadier cornering at high velocity, where disturbances in the air can upset chassis equilibrium and force micro-adjustments that degrade lap times. The interplay of geometry, material, and mounting accuracy determines how well a fairing performs in real life. It is here that design features such as vented ducts, intake ramps, and, in some high-performance configurations, winglets or small appendages, enter the story. Vented ducts are not merely aesthetic touches; they are aimed at controlling pressure differentials around the radiator or intercooler, helping to manage cooling margins as speed increases. This matters intensely on high-performance machines where sustained acceleration can push cooling needs to the edge. Winglets, conceptually borrowed from automotive aero, act to generate a subtle downforce that helps hold the front end down in the absence of heavy downforce from a rear wing. In practice, winglets are implemented with caution to avoid adding parasitic drag. Their effect is most noticeable at elevated speeds and during aggressive cornering, where the extra stability translates into more predictable handling and the rider’s confidence to push further into a corner or hold a line on a fast straight. The material that forms this aerodynamic skin exerts a second, equally important influence. In earlier days, ABS-plastic fairings offered a robust, affordable solution with enough rigidity to maintain a fair profile under ordinary loads. Today, the choice of material is more nuanced. Carbon fiber provides an excellent strength-to-weight ratio, allowing engineers to push the envelope with slender, aggressive contours that minimize weight while preserving stiffness. This makes the fairing capable of being shaped with high precision, reducing parasitic drag without compromising integrity. Fiberglass remains a durable, cost-conscious alternative that still supports advanced geometry, while high-quality ABS blends offer a consistent surface finish and predictable impact resistance. The ultimate objective is to shape a surface that can be manufactured with consistent tolerances, fit precisely to a given frame and engine configuration, and perform under the wide range of speeds and conditions a rider experiences. In this sense, fairings are a manufacturing and supply chain challenge as much as an aerodynamic one. The global production landscape for metric fairings is heavily Asia-centric, with Chinese facilities playing a pivotal role thanks to sophisticated tooling, scalable production lines, and strong supplier networks. The chain from raw material to finished shell involves resin systems, reinforcing fibers, and painting or coating processes that demand stringent quality controls. For a rider installing aftermarket fairings, the alignment with the bike’s original frame, mounting points, and radiator layout must be exact; a slight misalignment can introduce rubbing, gaps that disrupt clean airflow, or even interference with the engine heat management system. Reputable manufacturers and aftermarket suppliers emphasize fitment testing, sample verification, and clear communication about model applicability. The consequence of a well-executed fitment is a seamless surface that preserves the intended airflow path and ensures that the rider can maintain high-speed efficiency without unintended turbulence. Because most metric fairings target a specific model or family, compatibility matters as much as materials and shape. A track-focused full fairing built for a model like a legendary sportbike family can deliver maximum aerodynamic advantage, while a sport-touring or street-oriented option must still prioritize clean airflow but with an emphasis on reducing fatigue and improving rider protection at everyday speeds. This is where the distinction between full, half, and quarter fairings becomes meaningful. Full fairings enclose the bike’s front end and sides, delivering the most dramatic drag reductions and often the strongest wind protection for the rider. Half fairings strike a balance by protecting the cockpit and upper fork region, leaving the lower engine and chassis more accessible for maintenance and cooling. Quarter fairings, while lighter and more minimal, lend an aesthetic edge and a slight wind deflection that some riders appreciate on retro-inspired builds or cafe racers. These choices depend not only on the rider’s priorities but also on how the rest of the motorcycle is configured for aerodynamics. The research thread on aerodynamic performance in two-wheeled vehicles reinforces the idea that geometry can shift vehicle dynamics in meaningful ways. Academic work has demonstrated measurable gains in both efficiency and stability stemming from optimized fairing geometry, a finding that resonates with high-performance riders who push for every incremental improvement. The same studies show that high-end materials, when used to realize refined shapes, contribute to better energy management at speed by reducing inertial losses and enabling more linear throttle response as air loads shift through corners and transitions. For the everyday rider, moderate improvements in profile can still yield meaningful benefits. A well-chosen fairing improves comfort by shielding the rider from wind pressure and turbulence, reducing fatigue on long commutes and weekend rides. It also contributes to a more stable riding experience in gusty conditions, where a strong, well-shaped surface helps to keep the bike on a predictable path with less steering correction. The practical takeaway for riders who are new to fairing upgrades is to consider fitment accuracy and the intended use. If you ride primarily on highways at sustained speeds, prioritize a design that emphasizes clean flow and effective cooling, even if it means a slightly larger windscreen or different mounting approach. If the goal is weekend track days, you will likely appreciate full-body coverage with refined airflow channels and perhaps venting strategies that suit the cooling demands of high-rev operation. For those exploring the aftermarket landscape, a good starting point is to examine model-specific offerings that illustrate how designers have balanced the aerodynamic demands with the bike’s engine, frame, and suspension geometry. A practical example is the Kawasaki Ninja ZX-14R family, where aftermarket fairings demonstrate how fitment and contouring can preserve the bike’s legendary handling while sharpening its aerodynamic profile. For a concrete reference to current options that reflect this balancing act, consider exploring the Kawasaki Ninja ZX-14R fairings (2012-2021) collection, which showcases a range of full-body solutions designed to maintain structural integrity and aerodynamic efficiency while offering a canvas for personal styling and team branding. Kawasaki Ninja ZX-14R fairings (2012-2021). The essence of this discussion is that the right combination of contour, material, and mounting accuracy turns a fairing from a decorative shell into a functional aerodynamic system that enhances speed, stability, and rider comfort. It is tempting to view fairings as a modular add-on, but in truth they are a core element of the motorcycle’s geometry. When designed with a clear understanding of flow separation, pressure distribution, and the interaction with the rider’s body, fairings unlock performance that would otherwise be limited by drag, turbulence, and heat management. This is especially true for metric bikes that straddle the line between race-ready performance and everyday practicality. Even among more moderately priced options, the gains in aero efficiency can be substantial enough to justify the investment, particularly for riders who accumulate long hours in the saddle. The best fairings are not the lightest or the most aggressively sculpted in isolation; they are the ones that harmonize with the bike’s chassis, engine, and rider posture. The modern landscape also emphasizes the integration of aerodynamic efficiency with advanced cooling strategies, including carefully placed ducts and vents that channel air to radiators and intercoolers without creating an excess of drag. In this sense, aerodynamic optimizing is as much about managing heat as it is about reducing drag. The result is a riding experience that feels smoother, faster, and more controlled, with less fatigue and greater confidence when the road opens up. For enthusiasts who want to go deeper, the field offers a robust body of research and testing that integrates wind tunnel data, computational fluid dynamics simulations, and real-world track and highway feedback. A representative line of inquiry in the literature includes studies on aerodynamic kit design for two-wheeled motorcycles, which highlights how geometry, materials, and installation precision converge to produce measurable improvements in stability and efficiency. In parallel with these findings, contemporary fairing designs in production and aftermarket ecosystems continue to push toward greater alignment with vehicle dynamics while remaining mindful of weight, durability, and maintenance considerations. This ongoing refinement is visible not only in the most performance-oriented builds but also in sport-touring and touring configurations where rider comfort is paramount. The story of metric motorcycle fairings, then, is a story of wind and physics translating into tangible riding benefits. It is about understanding how shaping air can free power and reduce fatigue, and it is about recognizing that every contour has a reason rooted in the complex dance of flow around a moving object. It is about knowing when to accept a little compromise in aesthetics for a bigger win in handling, or when to choose a design that favors cooling and protection for daily riding while still preserving the bike’s aerodynamic edge. For those who crave technical insight balanced with practical guidance, the literature and industry practice offer a coherent path: select a fairing that matches the bike’s geometry, choose materials that balance weight and stiffness, ensure precise fitment to maintain the intended airflow patterns, and recognize that modern designs often fuse performance with visual identity. The result is not simply a faster bike; it is a more composed, comfortable, and engaging ride, whether one is navigating a long highway stretch, mastering a track, or weaving through urban corridors. For readers seeking deeper design and testing perspectives, one can consult peer-reviewed work that analyzes how an aerodynamic kit alters the dynamics of a two-wheeled vehicle, a study that aligns with the practical principles described here and offers additional technical detail on airflow management and performance outcomes. External resource: https://www.researchgate.net/publication/354782942Designandanalysisofanaerodynamickitforatwo-wheeled_motorcycle

Guardians of the Line: How Metric Fairings Protect Riders Without Compromising Speed

The fairing is often the most overlooked guardian on a sport bike, yet on metric motorcycles it stands as a finely tuned shield that blends protection with performance. When a rider leans into a turn at speed or slices through a gust along an open highway, the fairing works invisibly to keep the rider’s focus on the road ahead. Beyond its sculpted lines and the bold sport silhouette, the fairing represents a deliberate balance between protection, aerodynamics, and practicality. It is not merely a shell meant to turn heads; it is a functional interface that connects the rider to the machine, shaping how the bike behaves in wind, rain, debris, and even the occasional spill. The protective value of metric fairings emerges from a careful synthesis of material science, structural engineering, and ergonomic consideration. The result is a component that can reduce fatigue, improve comfort, and lower the chance of a mechanical cascade triggered by environmental exposure or impact. In this sense, rider protection is not a secondary benefit but an integral outcome of how the fairing is designed and engineered for metric motorcycles.

Wind is the most pervasive variable a rider faces. At highway speeds, a continuous blast of air sweeps across the chest, shoulders, and helmet, gradually eroding warmth in chill conditions and magnifying discomfort in rain or mist. A well-designed fairing acts like a layered shield, diverting airflow away from the rider’s torso and head while guiding it along smoother contours. This redirection reduces wind fatigue, which can impair reaction time and concentration. Personally tailored to the rider’s posture, the fairing also minimizes buffeting and noise, allowing the rider to maintain a steadier headset level and a clearer line of sight. The result is not only a more comfortable ride but a safer one, because the rider can sustain focus longer during long commutes or spirited sessions on a track where every fraction of a second counts. When weather turns inclement, the shielded area makes a tangible difference. Water droplets are less likely to sting the face, and rain that would otherwise be forced into gaps or around the hands finds a more predictable path, improving grip and visibility. These benefits accumulate over hours of riding, translating into better decision-making and reduced risk of misjudgment on slick pavement.

The protective function extends well beyond wind and rain. A metric fairing serves as a sacrificial outer layer that absorbs and dissipates energy in the event of a fall or collision. A crash is never desirable, but when it occurs the outer shell can take a portion of the impact that would otherwise transfer to more expensive, fragile components housed deeper inside the bike. The fairing’s energy-absorption role is a product of both thickness and material choice. Thermoformed plastics or composites, often selected for their impact resistance and rigidity, can crack or peel away in a controlled manner, creating a diverting cushion that safeguards the engine casing, radiator, wiring harnesses, and the instrument cluster from direct trauma. This protective buffer not only limits immediate repair costs but also reduces the likelihood of secondary failures that could leave a rider stranded or in need of more extensive maintenance.

Material science underpins the protective promise of metric fairings. A typical full or semi fairing might employ high-impact resistant ABS or advanced composites such as carbon fiber-reinforced polymers. ABS offers a favorable balance of toughness, resilience, and cost, providing more forgiving impact characteristics and easier repair or replacement in the field. Carbon fiber, conversely, delivers superior stiffness-to-weight ratios and excellent impact dispersal, albeit at a higher cost and with different repair considerations. The choice between these materials, and their specific layups and thicknesses, directly affects how the fairing performs during an impact: how energy travels through the panel, where it is absorbed, and how much force is transmitted to mounted brackets and the bike’s frame. For riders who track their bikes or ride aggressively on winding roads, the blend of stiffness and energy absorption becomes a determinant of how confident the machine feels when pushed to its limits. Conversely, for riders prioritizing ease of maintenance and lower ownership cost, a more forgiving resin or composite that protects critical systems while offering simpler repair can be the wiser selection.

Protection also takes the form of shielding essential systems that are vital to safe operation. Headlights, instrument clusters, engine casings, and wiring are vulnerable to moisture ingress, vibration, and small debris kicked up by tires. A well-fitted fairing not only shields these components from direct strikes but also minimizes the depth of drag-inducing air currents that can accelerate wear on seals and connectors over time. When the fairing is designed with proper seals, embedded weatherproofing, and robust fasteners, the rider benefits from longer service intervals and steadier sensor readings, which contribute to more reliable performance and improved rideability in challenging conditions. The integration of these protections requires meticulous fitment, because any gap or misalignment can create a micro-environment where moisture collects or where vibrations propagate more readily through the chassis. In practice, this means that the quality of manufacturing, the precision of fit, and the reliability of mounting hardware all become important riders’ safety features, even if they remain mostly unseen during a polished Sunday cruise.

The balance between protection and weight is another essential consideration. A heavier fairing may deliver more substantial impact resistance or superior aerodynamic shaping, but it can also introduce nontrivial mass that affects handling and acceleration. In metric motorcycles, engineers strive to optimize the weight premium by using advanced composites and strategic internal stiffening. The goal is to preserve the lightness that characterizes modern sport bikes while extending the protective envelope. This trade-off is central to the rider’s experience: a bike that feels planted at speed, with a fairing that resists flutter and flex, communicates a sense of control. Yet any additional weight must be justified by clear gains in protection and durability. The design philosophy often favors integrated solutions—fairings that wrap around subtle reinforcements and protective channels, rather than stacking layers of material that add mass without enhancing impact performance. In daily riding, the fairing’s weight may become less noticeable, but in the dynamic context of track days, even a few extra ounces can influence stability and cornering confidence when the tires scream for precision.

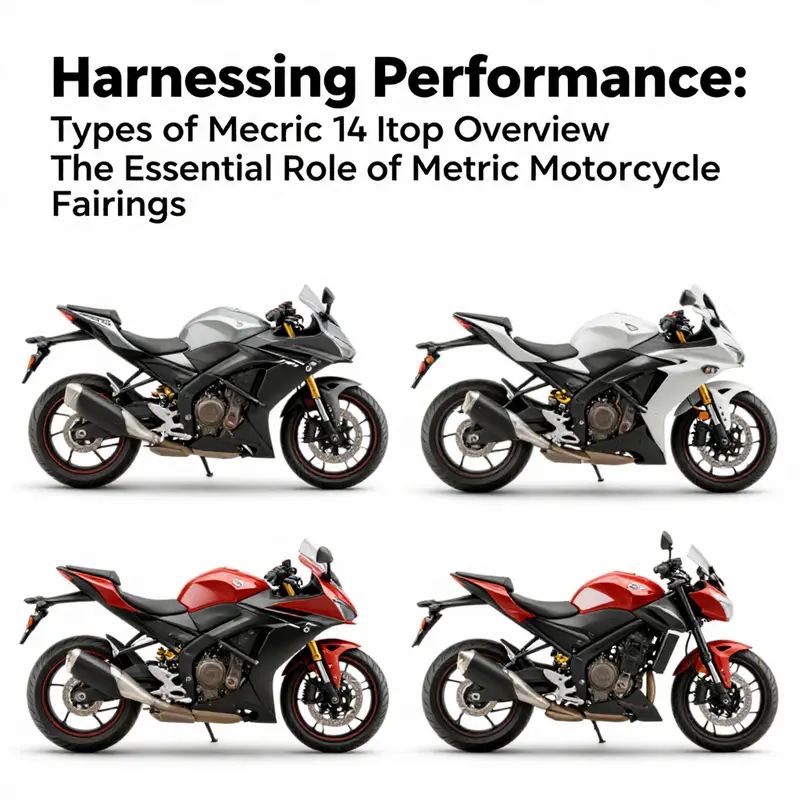

Looking at fairing types reveals how protection is tailored to different riding priorities. Full fairings maximize aerodynamics and frontal protection, creating a seamless shield from wheel to windscreen and wrapping around the upper half of the engine, then tapering toward the belly to minimize drag. They are the natural choice for riders who spend long hours on fast-paced highway stints or who demand maximum protection during track sessions. Half fairings, by contrast, preserve upper visibility and access to the engine’s upper region while offering essential protection for the rider’s chest and shoulders and for the instrument panel. They balance aerodynamics with easier maintenance and cooler engine access, a practical compromise for sport-tourers who represent a blend of comfort and performance. Quarter fairings, the most minimalist option, serve more as stylistic accents or strategic wind deflection rather than as primary protection, and they are often found on retro-inspired builds or boutique projects. The careful choice among these configurations reflects the rider’s priorities: full protection for endurance or racing contexts, or a lighter, more approachable setup for everyday sport riding. It is important to remember that protection does not end with the fairing itself. The mounting system, the alignment of gaps, the presence of gaskets and seals, and even the way the fairing integrates with the windscreen and mirrors shape how effectively the rider is shielded from external forces. A poorly aligned fairing can create turbulent pockets that magnify fatigue or stray air into the rider’s line of sight, undermining the intended safety advantages.

In practice, the protective value of metric fairings is inseparable from the rider’s technique and riding environment. Skilled riders learn how to leverage the fairing’s aerodynamics to reduce wind fatigue while maintaining clean air through corners and straights. They also recognize the trade-offs between protection and accessibility: a highly enclosed fairing might offer superb wind shielding but can complicate quick checks of controls or quick access to the steering head area for maintenance. The best solutions marry protective performance with practical serviceability, ensuring that a rider can inspect, repair, or replace damaged sections without disassembling half the bike. In this light the fairing becomes a legacy component that endures beyond the paint and composite, contributing to the bike’s longevity and the rider’s safety across diverse riding styles and conditions.

Ultimately, the protective promise of metric fairings rests on a holistic approach that blends materials science, structural design, and rider-centric ergonomics. The most effective fairings are those that anticipate real-world use: wind and weather, debris, minor impacts, and the rigors of extended riding. They are crafted not as mere cosmetic upgrades but as integral safety features that help the rider stay focused, comfortable, and in command of the machine. As the sport motorcycle ecosystem continues to evolve, the principle remains steady: protection that preserves speed, and speed that reinforces protection, through a well-engineered fairing system that respects both rider and machine.

External resource for deeper standards and safety benchmarks: https://www.motorcycle.org/standards/fairing-safety-performance/

The Anatomy of Metric Motorcycle Fairings: Crafting Speed, Shielding, and Style

Fairings on metric motorcycles are more than decorative shells. They are active participants in how a machine moves through air, how a rider breathes through weather and wind, and how a machine communicates its purpose to onlookers. When you stand back and consider the whole package, the fairing becomes a study in balancing physics, rider comfort, and visual storytelling. The term metric, in this context, points to a lineage of sport-oriented machines that prize precision, fit, and performance. But the real driver behind any fairing is a simple equation: reduce drag without compromising control, protect the rider without masking access to the machine, and maintain the integrity of vital systems in a harsh riding environment. The result is a carefully engineered component that serves several intertwined roles, each depending on the others to deliver a coherent riding experience on the highway, the twisty road, or the race circuit.

At the heart of the discussion lies aerodynamics. Full fairings envelop the front end and sides of the bike, creating a smooth silhouette that slices through air with minimal separation. The shape channels airflow around the rider and engine, cutting turbulent wake behind the rider to lower overall drag and improve stability at higher speeds. This is especially valuable on long highway stretches or high-speed track sessions, where even small reductions in drag can translate into meaningful gains in speed and sustained efficiency. Beyond the numbers, the fairing’s contour is a tactile cue of intent: it tells the rider to lean into the wind, to trust the bike’s lines, and to feel the bike’s efficiency in the turn of the throttle. Yet full fairings also demand attention to weight and maintenance. The more surface area and mounting points a fairing has, the more there is to inspect, repair, or replace after a mishap. This trade-off is not merely functional; it shapes the way a bike behaves in a corner, in a gust, or after a rock strikes the surface on a rural road.

Semi-fairings, often described as half-fairings, strike a balance between comprehensive protection and practical accessibility. They cover the upper front and the instruments, sometimes shielding the headlight, dash, and upper fork area, but leave the lower engine sides exposed. The upside is a lighter assembly that’s easier to service and repair. The downside is a more limited aerodynamic envelope and less wind shelter for the rider’s torso and arms. Semi-fairings appeal to sport-touring riders and commuters who want some wind protection without committing to the protective heft of a full fairing. They are a pragmatic solution for riders who demand a blend of ride quality, ease of maintenance, and cost efficiency. Importantly, the semi-fairing’s value is also in its adaptability: a design that can be upgraded over time with additional panels or different windshields to tailor wind management for changing climates or riding styles, without necessitating a complete rework of the front end.

Minimalist or quarter fairings represent a different design philosophy. These designs minimize coverage, focusing on wind deflection rather than full rider protection. They often serve aesthetics, weight reduction, and air management for particular riding regimes or retro-inspired builds. In contexts where every gram matters or where maintenance access is a priority, minimalist fairings can offer meaningful advantages. They underscore a broader point: fairings are not monolithic. They are a spectrum of choices that reflect how a rider uses the bike, what they value in weight, and how they perceive the wind as an ally or an adversary.

Material science adds another layer to the discussion. Metric fairings frequently employ high-impact resistant plastics or advanced composites, with ABS and carbon fiber among the most common choices. ABS provides toughness, impact resistance, and a degree of flexibility that helps absorb minor shocks and vibrations. Carbon fiber, by contrast, brings stiffness and a dramatic weight reduction, attributes that pay off on track days where every gram counts and where the rider’s feedback through the handlebars matters. The trade-offs between these materials extend beyond weight: stiffness, cost, repairability, and the way a panel behaves after an impact all influence the lifecycle cost of a fairing. The modern practice in manufacturing also brings a collaborative push between design engineering and supplier ecosystems. A well-conceived fairing must integrate with the bike’s electrical harnesses, headlights, instrument clusters, and excitingly, with fasteners and mounting points that hold up to repeated vibrations and temperature cycles. In practice this means that the fairing is not simply a sheet of plastic but a carefully engineered assembly designed to tolerate the rigors of real-world riding, with precise fitment tolerances to minimize gaps, rattles, and wind noise.

The safety dimension of fairings often goes unappreciated in casual conversations. In the event of a slide or a slide-and-crash scenario, the fairing can act as a sacrificial layer that absorbs a portion of kinetic energy and mitigates damage to more sensitive components beneath. This protective role, while not a substitute for proper riding gear and responsible riding behavior, is a legitimate aspect of design. The panel’s energy-absorption characteristics, its crack propagation behavior, and how it distributes impact across a panel can influence repair costs and the post-incident maintenance a rider faces. It is a reminder that materials, geometry, and mounting integrity matter not just for daily riding comfort, but for the bike’s resilience in unpredictable moments on the road or track.

Beyond functional performance, fairings carry a strong visual language. The large, flat surfaces of modern fairings offer an expansive canvas for color, texture, and branding. The aesthetics are never incidental: the lines, the angles, and the contours convey speed and intent even when the bike is stationary. For many riders, the fairing is a primary identity marker, a way to express personal taste while signaling a rider’s commitment to a particular riding philosophy—be it track-ready precision, long-haul comfort, or a street-fed, cafe-culture stance. The interplay between form and function thus becomes a storytelling device: the fairing speaks of purpose through its shape, its finish, and its fit with the rest of the bike’s visual language.

Where production meets procurement, the realities of manufacturing and supply chains shape what is possible in fairing design. The global landscape remains heavily weighted toward Asia, where scale, infrastructure, and supplier diversity enable a broad range of materials, finishes, and fabrication techniques. Regions with established plastics tooling, carbon fiber layup, and composite molding capabilities can deliver fairings that meet exacting tolerances and durable finishes. The choice of a supplier extends beyond price; it encompasses the predictability of lead times, the ability to honor material specifications, and the consistency of coating and paint compatibility with the bike’s color system and weather exposure. For aftermarket fairings aimed at metric machines, the emphasis falls on compatibility and fitment accuracy. A well-made aftermarket panel should align with the fairing stay geometry, the mounting hardware, and the rider’s perception of gap tolerances and panel alignment under cornering and wind forces. In this sense, the purchasing decision blends engineering diligence with practical logistics: supplier reliability and your ability to verify quality through sampling, testing, and real-world fit checks are as important as the raw material properties themselves. This is why many riders and shops lean toward suppliers who can provide sample panels for fitment checks and who maintain quality control standards aligned with international safety benchmarks.

For riders seeking a practical pathway through the proliferation of options, a fairing choice is rarely about chasing the newest material trend. It is about harmonizing fitment with the bike’s geometry, weight, wind management, and serviceability. Full fairings offer the greatest aerodynamic gains and weather protection, but they demand careful attention to weight, maintenance access, and the complexity of repairs after a fall. Semi-fairings deliver a compromise, enabling better maintenance access while preserving meaningful wind and weather protection. Minimalist designs remind us that sometimes less is more: a lighter, simpler package can enhance responsiveness and style for riders who relish a lean, streamlined character. The decision, ultimately, hinges on how the rider intends to use the bike, the environment in which it will be ridden, and the availability of skilled technicians who can assess fit and finish across the entire front end. An informed approach also includes considering the material mix and the supplier’s track record for consistent color, texture, and tolerances across multiple production batches. If a rider expects frequent changes or color updates, the predictability of paint work and surface finishes becomes part of the ongoing ownership experience.

To help anchor these choices in a practical frame, riders often consult catalogs and catalogs of compatible panels that match their bike’s geometry and mounting conventions. A straightforward starting point is to explore a broad catalog that groups fairings by coverage type, while offering easy access to the hardware and mounting kits that support reliable installation. From a user’s perspective, the key is to verify that the panel lines up with the bike’s frame contours, aligns with the instrument cluster, and creates a cohesive, seamless silhouette when viewed from the side. Fitment accuracy also translates to the rider’s tactile experience: fewer gaps, steadier air pressure against the rider’s chest, and a sense that the bike’s front end is a unified, well-tuned structure rather than a patchwork of parts. These considerations underline the fairing’s role as an integrated system rather than a standalone cosmetic element.

In the broader ecosystem of metric motorcycles, the fairing’s dynamics are inseparable from the bike’s overall performance profile. The fairing’s performance can influence handling characteristics by shaping the wind force vector that acts on the rider’s body and by altering the perceived stability at high speed or in gusty conditions. The rider’s interaction with the fairing—how it directs airflow toward or away from the chest and arms, how it channels light and visibility, and how it blends with the bike’s instrumentation—becomes part of the riding sensation itself. For those who derive fascination from the craft behind speed, the fairing is a tangible demonstration of how engineering disciplines—materials science, fluid dynamics, mechanical design, and industrial production—converge to create machines that feel effortless to ride yet are the product of careful, collaborative design work.

If you want to explore a practical entry point into this landscape, consider starting with a broad, generic catalog that highlights the range of coverage options, rather than chasing a specific brand or model. This approach helps riders assess how much protection they want, how their riding style dictates maintainability, and how the front end contributes to the bike’s overall balance. It also serves as a reminder that the right fairing is not a single solution but a family of designs that can be functionally adapted as needs evolve. For riders and shops alike, the goal remains constant: to harmonize aerodynamic efficiency, rider protection, and serviceability within a cohesive front-end architecture that respects the bike’s form and the rider’s experience. As technology continues to advance, new materials and manufacturing techniques will broaden the spectrum of choices, enabling even more precise control over drag, weight, and impact resistance while expanding the possibilities for color, texture, and branding—without compromising the rider’s comfort or the machine’s reliability. For a practical starting point on finding a generic catalog that helps compare these dimensions, you can explore a dedicated fairings catalog here.

External reading for deeper context on fairing types and their industrial impact can be found here: https://www.motorcycleperformancejournal.com/types-of-motorcycle-fairings-and-their-industrial-impact

null

null

Final thoughts

In summary, metric motorcycle fairings play a critical role in enhancing both the performance and safety of motorcycles while providing necessary protection against environmental elements. With a variety of options available, including full, half, and quarter fairings, it is essential for business owners to understand the unique benefits of each type to meet riders’ diverse needs. Furthermore, recognizing the manufacturing and supply chain dynamics can aid in sourcing high-quality fairings that align with market demands. By investing in quality fairings, businesses can not only enhance rider experience but also offer products that reflect the cutting-edge technology and style that define the motorcycle industry.