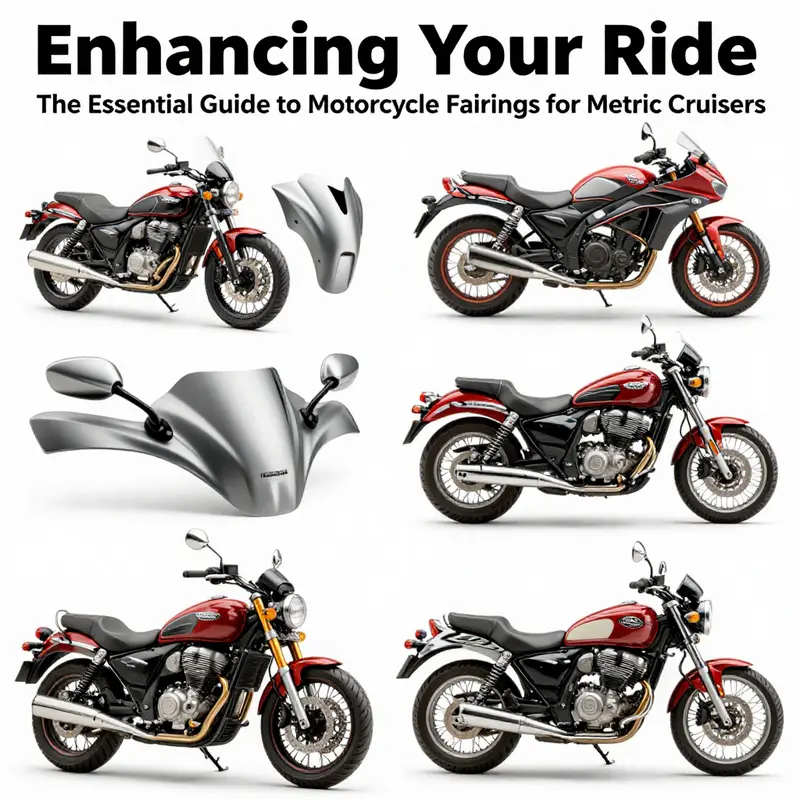

Motorcycle fairings are more than just a visual enhancement; they serve as a functional element that can significantly improve the riding experience, particularly for metric cruisers like the Honda Shadow and Yamaha V-Star. These fairings can transform a bike’s aesthetic appeal while also offering practical benefits, such as wind protection and comfort during rides. This guide delves into the various types of motorcycle fairings available for metric cruisers, their benefits, the materials used in construction, and the latest market trends. By understanding these elements, business owners in the motorcycle accessories industry can make informed decisions that cater to rider demands.

null

null

Riding Light, Riding Forward: How Fairings Transform Performance, Comfort, and Character on Metric Cruisers

Across the spectrum of motorcycles, metric cruisers occupy a space that values relaxed ergonomics, a broad powerband, and a sense of timeless style. The fairing—a panel-driven shield between rider and the road—becomes more than an accessory on these bikes. It is a functional partner that shapes the ride, protects the rider from the elements, and subtly nudges the machine’s personality toward modernity without erasing its retro soul. In this chapter, we explore how fairings for metric cruisers deliver tangible benefits in aerodynamics, comfort, and durability, while also contributing to the bike’s visual presence. The discussion centers on half fairings, the form most commonly adopted by cruisers in this category, and how their alignment with the bike’s posture and engine character yields a balanced, practical upgrade for riders who value long-distance comfort as much as street-ready style.

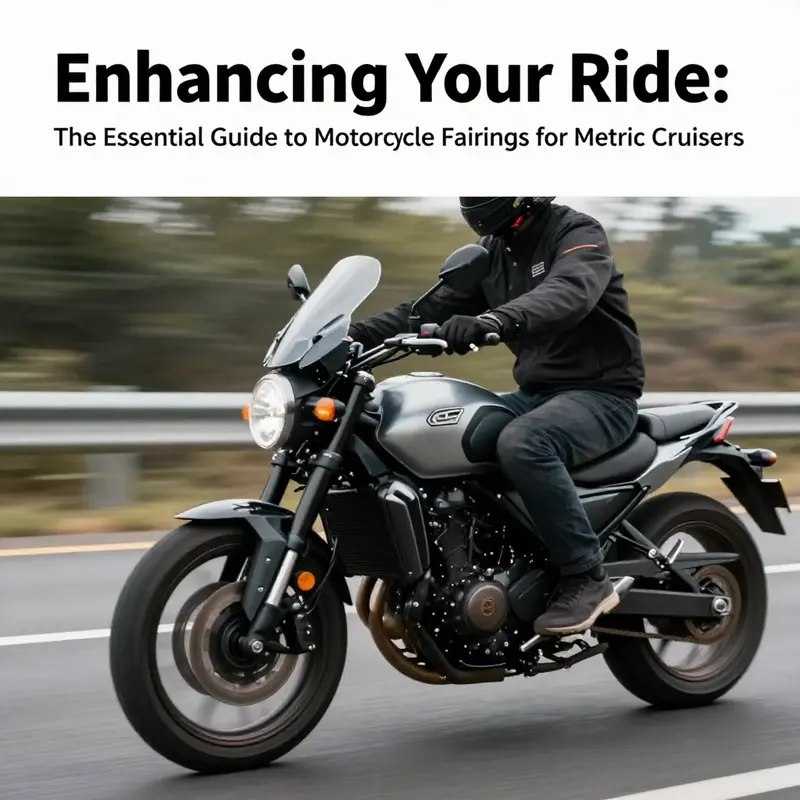

Engineers and designers speak in silences when a rider sits on a cruiser with a proper fairing. The engine’s rhythm, the wind’s whisper, and the bike’s weight distribution all become a single, coherent experience. Metric cruisers typically house large-displacement V-twin engines that reward steady, highway-oriented cruising. The rider’s posture—a relaxed spine, slightly bent elbows, and feet forward—favors a shield that deflects wind at mid- to high-velocity ranges without creating a bottleneck that traps the rider behind a rigid cocoon. This is where half fairings excel. They cover the upper front portion of the bike, from the handlebars to behind the front wheel, and they do so with a light touch that preserves visibility, access to the engine, and ease of maintenance. The result is a wind profile that smooths the rider’s wake and reduces buffeting without the bulk and weight that characterize full fairings.

The aerodynamic argument is straightforward but compelling. At highway speeds, wind resistance compounds with the rider’s own body airfoil. A half fairing disrupts that interaction by directing air over the chest and helmet in a more laminar fashion and by shielding the shoulders from the most direct gusts. The rider experiences less fatigue in the neck and upper back, a factor that matters after hours of steady cruising. The practical upshot is better fuel economy, slightly steadier throttle response, and a more comfortable posture that invites longer trips before fatigue sets in. It’s not only about speed or wind tunnel numbers; it is about creating a ride feel that remains relaxed and predictable as the miles accumulate.

Beyond the open road, weather and road debris present additional reasons to consider fairings. A properly chosen half fairing can deflect rain spray and stone chips that would otherwise sting the hands and forearms or pepper the tank and crash bars. The shield’s height and curvature matter here; the best designs integrate with the bike’s line so they skim past the rider’s visor without creating excessive wind shadow. Liberal angles and curved surfaces help keep rain off the rider’s chest and throttle hand, which in turn reduces the chance of moisture-related grip loss at critical moments. The same principles apply to debris, where the fairing acts as a barrier that can spare paintwork and vital components from minor impacts, especially in less-than-ideal riding conditions.

Visually, the right fairing reinforces the cruiser’s character while signaling a blend of forward thinking and tradition. Batwing and other stylized shapes often emerge in aftermarket catalogs because they satisfy two goals at once: they punch up the bike’s stance with a broad, confident silhouette and they acknowledge the rider’s desire for a modern, protected riding experience. For many riders, the fairing becomes part of the bike’s identity—an element that communicates readiness for long trips and a willingness to engage with the elements rather than surrender to them. This aesthetic alignment is not accidental. It reflects a broader trend where the practical needs of riders intersect with design cues that evoke a timeless, classic look. The net effect is a machine that feels both comfortable and spirited, capable of covering vast stretches with minimal wind fatigue while still turning heads in town.

On the practical side, half fairings are favored for their lighter weight, lower cost, and easier installation compared with full fairings. When a cruiser is already carrying a generator of torque from its V-twin heart, keeping the fairing lightweight helps maintain nimbleness—especially around town, in parking lots, or on narrow country lanes where maneuverability matters. The modularity of many aftermarket options means riders can tailor their setup to their riding habits. A rider who spends long hours on the highway may prioritize a larger windscreen and more extensive side panels for additional deflection, while a commuter or weekend explorer might choose a leaner configuration to maintain engine accessibility and serviceability.

Material choice remains a central consideration in fairing design. ABS plastic and fiberglass are the standard bearers in most mass-market and performance-oriented lines because they balance impact resistance, stiffness, and cost. ABS has the practical advantage of being tough, forgiving when encountering road debris, and relatively simple to mold into complex shapes with consistent tolerances. Fiberglass offers a favorable strength-to-weight ratio and can be shaped with high precision for a clean, integrated look. In premium corners of the market, carbon fiber surfaces reduce weight even further and deliver a distinctive finish that matches the modern aesthetic some riders crave. Across these materials, the story is the same: the fairing is not merely a shell; it is a structural element that must weather wind, rain, UV exposure, and the occasional rock while maintaining proper alignment with the bike’s chassis. This is why manufacturers adhere to rigorous standards of safety, fitment, and weather resistance. The goal is a product that remains reliable through years of highway miles and seasonal riding.

One of the notable advantages of standardized fairing designs is the economies of scale they enable. A shared bolt pattern, mounting hardware, and collaborative engineering allow manufacturers to offer a broader range of options across model years and trim levels. This standardization simplifies aftermarket customization and makes it easier for owners to upgrade or modify their bikes as tastes and needs evolve. The efficiency is not purely economic; it translates into predictable fitment, straightforward installation, and the assurance that a fairing designed for one model will integrate cleanly with compatible chassis and controls. The broader effect is a healthier aftermarket ecosystem in which riders can pursue personalization without sacrificing reliability or safety.

The integration of fairings with the bike’s overall design language is a delicate balance. A half fairing must harmonize with the cruiser’s cues—the curvature of the tank, the line of the handlebars, the silhouette of the exhaust and engine casing—so that the addition reads as a natural extension rather than an afterthought. When done well, the result is a bike that looks more contemporary without losing its classic vibe. The fairing’s edges should echo the bike’s lines, its color and finish should complement the paintwork, and its presence should enhance, not overwhelm, the rider’s view of the road ahead. This alignment matters because it affects rider confidence. A well-integrated fairing can create a sense of cohesion that encourages longer journeys and a more immersive riding experience, the kind of experience that makes a two-hour ride feel like a warm-up for the next leg.

Maintenance considerations round out the practical side of choosing a fairing. Half fairings tend to offer easier engine access than full-body kits, which can simplify routine maintenance such as valve checks and spark plug changes. The modular nature of many aftermarket options means riders can swap out panels or trim pieces without removing the entire assembly, a convenience especially valuable for riders who like to tweak their setups after a few seasons on the road. Cleaning and care follow the same logic: accessible surfaces, fewer hidden fasteners, and straightforward removal for weather protection or color changes. For cruisers designed for long-haul cruising, this accessibility translates into real-world time savings and less downtime when the bike is parked for service.

In terms of a broader riding strategy, fairings support a philosophy of endurance and adaptability. Riders who built their confidence around relaxed, open-road performance will find fairings help maintain a stable, controlled feel as wind conditions shift with the weather, traffic, or altitude. The improvements in comfort have tangible consequences: riders are more likely to extend trips, explore new routes, and return with a sense of satisfaction rather than fatigue. The fairing becomes, in effect, a partner in the journey, smoothing the ride so the rider can focus on the road, the traffic, and the distant horizon.

If you are considering a fairing upgrade, a practical first step is to survey the catalogs that itemize fitment and compatibility across model years. It is important to check the mounting hardware, adjustability, and the potential need for minor modifications to ensure a clean fit with the bike’s frame and controls. As a general principle, a higher-quality fit will yield better wind deflection, less interference with steering inputs, and more predictable behavior at highway speeds. Finally, the aesthetic choice should be considered in tandem with functionality. A fairing should feel inevitable on the bike, not an afterthought or a compromise; it should enhance the ride’s comfort while augmenting the overall style. For a straightforward starting point in exploring options, the collections/honda-fairings page provides a clear sense of how fairings are organized, including how they map to frame compatibility and mounting considerations. collections/honda-fairings.

For readers seeking a broader framework beyond fitment and style, it helps to consult guidance that surveys the aftermarket landscape and offers practical, experience-based recommendations. A respected technical overview emphasizes how to balance the goals of aerodynamic efficiency, rider comfort, and cost, while acknowledging that the most effective solution varies with riding habits, climate, and road conditions. Such guidance notes that half fairings are especially well-suited to metric cruisers because they deliver meaningful wind protection without the bulk that can impede daily usability. This perspective aligns with the observed trends in rider preferences: a majority favor upgrades that improve comfort and durability while preserving the bike’s classic silhouette and easy maintenance access. The emphasis on practical performance—wind deflection at moderate to high speeds, protection from weather, and straightforward maintenance—highlights why half fairings remain a popular choice for many metric cruisers.

In sum, the integration of well-designed fairings into a metric cruiser is about more than cosmetics. It is a considered approach to expand aerodynamic efficiency, raise rider comfort, and extend the bike’s longevity without compromising the cruiser’s timeless identity. With appropriate material choices, reliable mounting standards, and a thoughtful attention to line and proportion, a fairing upgrade can transform a long highway ride into a more enjoyable, less fatiguing experience. It can also signal a rider’s commitment to a balance between tradition and forward movement—a nod to the past while embracing the practicality and resilience demanded by modern, all-weather riding. The result is a motorcycle that not only performs better but also feels more complete, inviting riders to ride farther, more often, with the confidence that their machine is prepared to meet the road head-on.

External resource for broader context on selection and design considerations can be consulted here: BikeRadar—Aftermarket Motorcycle Fairing Guide: How to Choose Right.

The Hidden Skeleton of Style: Materials, Standards, and the Quiet Power of Cruiser Fairings

Cruiser fairings occupy a subtle, almost conspiratorial space in motorcycle design. They do not shout with race-grade lines or track-ready bravado; instead, they whisper through a rider’s experience, shaping the journey with a careful blend of form and function. In metric cruisers—the family of bikes built around relaxed geometry, low center of gravity, and an emphasis on comfort over sheer top speed—the fairing acts as both a windbreak and a canvas. The aesthetic is rooted in a retro sensibility, a nod to long highway horizons and the tactile pleasure of a well-tuned ride. Yet beneath the paint and polish lies a more pragmatic physics: the materials chosen for the fairing, and the standards those materials must meet, determine how a touring mile feels and how reliably a rider can enjoy that mile. The conversation about fairings, then, begins with two questions that continually reappear in engineering discussions and in the daily ritual of maintenance: what are these panels made of, and what rules ensure they stay attached, perform as promised, and keep riders safe when the road turns rough or weather turns capricious?

The most common materials for cruiser fairings sit along a spectrum from economical, impact-resistant plastics to composites whose lightness and stiffness invite careful design. High-impact ABS plastic remains the workhorse for many production fairings. ABS has a proven track record of resisting impact without shattering, a property that matters when a bike is parked in a busy lot or tucked into a windy campsite. Beyond its resilience, ABS is forgiving in molding. It accepts complex contours, which is essential for achieving the softer, more forgiving shapes favored on cruisers. ABS also lends itself to cost-efficient mass production, supporting the broad aftermarket ecosystem that keeps classic-styled motorcycles accessible and customizable. Fiberglass-reinforced composites occupy the other end of the spectrum, trading some cost and weight efficiency for greater strength and an opportunity for more elaborate finishes. The glass fibers reinforce the resin matrix, yielding panels that can stand up to the occasional curb strike or road debris with a bit more reserve. For riders who crave a more bespoke look, fiberglass offers a palette for customization—from sculpted curves to embedded or layered textures that catch light in nuanced ways. Premium options sometimes take a step further into carbon fiber, where the woven geometry of the material translates into a very favorable stiffness-to-weight ratio. The allure is obvious: lighter weight, diminished gyroscopic inertia, and a leaner visual language that aligns with modern performance sensibilities while still nodding to the cruiser’s timeless charisma. In practice, these material choices interact with the bike’s overall balance. A fairing must not feel like a ballast in the wind but a contributor to a cohesive front end. The weight distribution matters if the rider leans into a long sweep or taps the throttle with a firm hand on a windy expressway. The correct blend of materials—ABS for the bulk, fiberglass for custom vigor, carbon for the premium edge—allows designers to tune stiffness, impact resistance, and surface finish without sacrificing the cruiser’s characteristic silhouette.

Cost is never only a number in a construction narrative. It echoes through production planning, consumer pricing, and the long arc of a rider’s ownership experience. ABS is typically the economical choice, enabling manufacturers to achieve consistent quality across a wide range of models and model years. That reproducibility matters because a fairing is not a single, solitary piece; it is a system comprising mounting points, fasteners, brackets, and sometimes a windscreen. All of these components must fit together with a predictable tolerance band. When a manufacturer can rely on a material family with known processing behavior, it reduces variance in part geometry and reduces the risk of misalignment after a heat cycle or a cold start. Fiberglass, while offering opportunities for shaped elegance and surface texture, comes with a different set of costs—primarily materials handling, potential moisture ingress, and a more labor-intensive finishing process. Carbon fiber, though admired for its stiffness and potential weight savings, remains the exception rather than the rule: it is used when the market segment values performance attributes and is prepared to pay for them. The upshot is a tiered ecosystem where mass-market fairings are predominantly ABS, premium or boutique offerings lean toward composites, and the most exclusive pieces flirt with carbon fiber. That spectrum is not just about weight and price; it is also a reflection of ride philosophy. For riders who spend many hours on the highway, the focus shifts toward fatigue reduction and predictable behavior in gusty conditions. The materials chosen for the fairing influence how effectively it deflects wind at cruising speeds, how well it dampens noise, and how the rider perceives the surface texture and finish after years of exposure to sun, rain, and road salt. In this way, the fairing becomes a tangible link between the bike’s core engineering and the rider’s subjective sense of control and comfort.

A second layer of this story concerns standards and compliance. Safety and structural integrity are not optional extras for fairings; they are fundamental requirements that govern how panels are designed, manufactured, and tested. In the United States, the DOT’s FMVSS 216 standard sets explicit expectations for windshields and related fairing components. The core idea is straightforward: windshields and protective components must be made of shatter-resistant material, and they must be securely attached so they cannot detach at speed or under sudden loads. This is not merely about preventing shards in a crash. It reflects a broader philosophy that a fairing, as a moving part of the motorcycle, must remain anchored under a range of conditions—from high-speed air pressure and turbulence to the thermal expansion that accompanies a hot sun and a cold night. The European framework, anchored in ECE regulations, mirrors this emphasis on safety, ensuring that components meet rigorous performance criteria regardless of where a bike is sold or ridden. For riders and technicians, this dual-layered regulatory environment provides a predictable baseline against which materials, shapes, and finishes are judged.

Across both OEM and aftermarket channels, fitment requirements and testing regimes reinforce the notion that a fairing is more than a cosmetic wrap. The geometry of a cruiser’s frame, the position of the rider, and the profile of the fairing must align so that the wind deflection delivers comfort without introducing buffeting or steering instability. This is where independent testing becomes valuable. Custom or aftermarket fairings may undergo a battery of evaluations designed to simulate real-world stresses: vibration resistance to ensure the panel remains intact and attached through the intermittent vibrations of a rough road; temperature extremes to assess material behavior under heat soak and cold contraction; mechanical stress tests to verify fastener integrity and joint durability. The result is a body of evidence that supports claims about performance and reliability, while giving riders confidence that a modification will not compromise the bike’s handling or safety envelope.

In practice, the choice between a full fairing and a half fairing—often called a cruiser fairing—maps directly to a rider’s balance of protection, accessibility, and classic styling. A full fairing can deliver maximum wind protection and aerodynamic efficiency, shaping a streamlined front end that looks purpose-built for long-haul performance. A half fairing, on the other hand, preserves more of the bike’s traditional silhouette while still offering meaningful wind deflection. The windscreen and partial side panels can markedly reduce windblast at cruising speeds, which translates to less fatigue and a clearer line of sight. Maintenance access, too, is a practical consideration: half fairings typically spare more of the engine and frame from removal during routine service, a factor that matters to riders who value straightforward access without sacrificing a tidy, integrated appearance. The decision is not a simple one of “more coverage equals better.” It is a nuanced judgment that weighs weight, cost, ease of installation, and the rider’s typical road profile. In both cases, the materials chosen—whether ABS for base configurations, fiberglass for layered aesthetics, or carbon fiber in select pieces—must cooperate with the fairing’s architectural design, the mounting topology, and the fastener system that secures it to the bike. When these elements harmonize, the fairing becomes a coherent part of the motorcycle’s personality, performing the quiet work of smoothing air flow while preserving the bike’s iconic, unhurried cadence on the highway.

Equally important is the way fairings age, because longevity is a form of virtue in cruiser culture. UV exposure, temperature swings, moisture ingress, and chemical exposure from road treatment all interact with surface finishes and substrate stability. ABS, for instance, can tolerate long-term exposure with proper UV stabilization and a robust paint or clear coat system, but it may become more susceptible to chalking or micro-cracking if the finish is neglected or if the material experiences significant thermal cycling. Fiberglass panels demand careful sealing to prevent moisture diffusion along joints, which can later manifest as surface checking or a dulling of the finish. Carbon fiber, while resistant to many forms of wear, requires attention to resin integrity and protective coatings; without adequate protection, surface abrasion and environmental exposure can reveal the filament weave over time. A well-engineered maintenance routine—gentle cleaning with non-abrasive products, periodic inspection of mounting points, and timely care of any clear coats—extends the life of the fairing and preserves its aesthetic appeal as well as its structural function.

Industry-wide, standardized fairing designs confer significant advantages beyond safety and fit. They enable economies of scale that lower unit costs and foster compatibility across different model years and frame revisions. This standardization does not imply sameness; rather, it reflects a pragmatic approach to modular design: panels that can be swapped or upgraded without necessitating a complete bike redesign. A robust aftermarket ecosystem follows, offering a spectrum of styling options and performance upgrades while respecting the underlying geometry that preserves ride quality. For riders who value customization, the prospect of swapping panels or adjusting the fairing’s proportion becomes a way to tell a personal story on a familiar platform. In this context, materials and standards are not constraints but enablers: they ensure that the visual language a rider selects can be realized without compromising the motorcycle’s structural integrity or regulatory compliance. The result is a marketplace where design freedom and safety accountability coexist, allowing cruisers to evolve with the road rather than simply endure it.

For readers navigating this landscape, the practical takeaway lies in recognizing the interplay between material science and regulatory requirements. ABS may offer a cost-effective baseline with predictable performance under a wide range of conditions, while composites unlock higher degrees of customization and refined aesthetics. The decision framework should also account for how a particular fairing integrates with the bike’s aerodynamics, how it contributes to rider comfort over long distances, and how readily it can be serviced when maintenance periods arrive. In other words, the fairing should be viewed as an active component of the riding experience—one that influences endurance, weather resistance, and the sense of control a rider feels when traversing miles of highway or backcountry lanes. When material selection and standard adherence align with a rider’s goals, the outcome is not only a more pleasant ride but a more reliable platform that can stand up to the rigors of daily use and occasional touring expeditions.

To explore a curated catalog of fairings and related panels that illustrate the practical variety discussed here, readers can consult the broader collections that organize components by fitment and styling. This catalog approach helps bridge the gap between theory and hands-on customization, supporting riders as they assess compatibility, weight implications, and finish options. Fairings catalog provides a representative cross-section of how designers and engineers translate the principles of material selection and safety standards into tangible, installable parts that honor the cruiser ethos while embracing modern manufacturing realities. This resource emphasizes the idea that a fairing is not merely a cover but a carefully engineered interface between rider, machine, and environment.

On a broader regulatory horizon, the National Highway Traffic Safety Administration and related agencies provide ongoing guidance and updates about safety requirements for motorcycle components, including fairings. While individual standards evolve with new research and testing methods, the core expectation remains constant: protect the rider without compromising control or visibility. For those seeking formal reference and the most current compliance criteria, official safety documentation is available through the agency’s website. This external resource offers deep insight into the rationale behind windscreen and fairing attachment standards, the testing methodologies used to validate performance, and the legislative framework that sustains consistent quality across manufacturers and aftermarket suppliers.

In sum, materials and standards for cruiser fairings are inseparably linked to the riding experience. The choice of ABS, fiberglass, or carbon fiber shapes the fairing’s behavior in the wind, its resilience against the elements, and the ease with which it can be integrated into a bike’s overall architecture. Standards, in turn, provide the guardrails that ensure those choices translate into safety, reliability, and predictable performance under a wide range of conditions. When designers and riders work within this integrated framework, fairings become more than protective shells; they become a critical ally in comfort, style, and long-distance capability. The result is a cruiser that carries its character across miles with steadiness and grace, where the visible line of the fairing mirrors the quiet confidence of the ride itself.

Shaping the Wind: Custom Fairings and the Revival of Metric Cruiser Aesthetics

The road is a long, silent partner to the rider, and as metal hardens into motion, the fairing becomes more than a shield. It is a conversation between wind, heat, and chrome, a way to tune the machine’s personality to the rider’s pace. In the market for metric cruisers, fairings are moving beyond mere protection. They are becoming integral parts of a carefully crafted riding experience, blending retro charm with modern efficiency. The latest shifts reveal a sector where customization is no longer a niche but a dominant impetus. Riders seek not just shelter from the elements but a means to express individuality, to sculpt aerodynamics around the bike’s classic silhouette, and to align performance with comfort across long highway miles. The outcome is a marketplace that rewards both form and function, where the line between aesthetic appeal and practical gain grows increasingly thin and increasingly important.

The most visible trend is customization itself, a response to riders who want their machines to tell a personal story rather than echo a factory line. Among cruiser enthusiasts, the Batwing style has become synonymous with a bold, expansive front end that announces presence on the road. This preference is not merely about size or drama; it reflects a desire for better wind management at speed, a smoother ride at cruising velocities, and a broader canvas upon which owners can apply color, texture, and detailing. Even when a rider does not choose the most elaborate design, the option to adjust line, contour, and shading offers a meaningful upgrade from stock aesthetics. The market rewards these choices with a growing variety of shapes and finishes, all engineered to integrate with the bike’s timeless vibe rather than overwhelm it.

Among the broad family of fairings, half fairings have earned a prominent place. They offer a pragmatic compromise: more protection than nothing, yet lighter and easier to manage than full enclosures. For metric cruisers—machines celebrated for their relaxed riding stance and open, air-friendly lines—half fairings preserve the essential openness of the cockpit while guiding airflow to reduce windblast on the face and chest. Riders who travel long distances at highway speeds often report noticeably less fatigue when wind is deflected upward and away, even if the bike’s core character remains visually unaltered. The balance between protection and visibility is not just a practical calculation; it is a stylistic choice that keeps the bike’s classic lines intact while still hinting at modern aerodynamic thinking. This balance is particularly appealing to enthusiasts who value the cruiser’s heritage and want a more comfortable, more controllable ride when the sun climbs and the road stretches toward the horizon.

Material choices sit at the heart of this evolution. The mainstream standard is reinforced ABS or fiberglass, a combination celebrated for durability, impact resistance, and cost efficiency. These materials behave well in varied climates—resisting moisture, heat, and UV exposure—while remaining relatively simple to repair or replace during maintenance. This combination of resilience and affordability empowers riders to invest in a high-utility accessory without sacrificing reliability. For those who crave lighter weight and a premium edge, carbon fiber options exist, though they remain a smaller share of the market due to cost. The shift toward durable, cost-conscious composites reflects a broader consumer expectation: aftermarket parts should improve performance or comfort without imposing prohibitive price points. The balance between material quality and accessibility now defines many aftermarket offerings, helping the market grow in a sustainable way.

Compatibility is the practical engine behind the trend toward a more customizable fairing ecosystem. Riders are increasingly urged to verify fitment with their specific make and model to ensure that the design aligns with mounting points, tank area contours, and the rider’s seating position. When a fairing fits cleanly, the wind management is consistent, maintenance access remains straightforward, and the overall look stays cohesive with the bike’s proportions. This emphasis on fitment compatibility helps explain why some designs resonate more strongly with the cruiser community. It is also a reminder that the aftermarket environment benefits from clear, accurate compatibility charts and transparent product descriptions. The result is a marketplace where the consumer can shop with confidence, knowing that a given fairing will not create awkward gaps or interference with essential controls.

The aesthetic-versus-functionality tension that has defined many gear categories for years is becoming more nuanced in this space. In warmer climates, where airflow is a daily concern, designers are optimizing aerodynamics to channel air efficiently around the rider without stealing the bike’s character. The modern look often blends aggressive lines with classic curves, a combination that signals both speed and tradition. Even where the visual language remains rooted in retro cues, refined curves and smoother transitions deliver performance gains that riders can feel: reduced drag at highway speeds, steadier air pressure across the chest, and a calmer cockpit environment that helps the rider stay focused on the road. The best designs read as a natural extension of the bike rather than a bolt-on addition, and this is precisely what fuels their growing appeal among metric cruiser owners.

Riders who plan upgrades frequently weigh affordability against quality and longevity. The market’s response has been a widening array of options that meet or exceed OEM durability at a more accessible price. The availability of affordable fairings that still meet high standards of resilience and weather resistance allows a broader cohort of riders to pursue meaningful upgrades. The increased competition in this space has pushed manufacturers to innovate without inflating price, driving improvements in fit, finish, and ease of installation. A well-made ABS fairing can endure road salt, rain, and sun for years, while a carefully engineered fiberglass option can deliver a precise fit with minimal modification. For riders who view their bike as a long-term companion, these choices offer an attractive balance between upfront cost and lifetime value.

As the conversation around installation and compatibility evolves, the importance of straightforward, plug-and-play solutions becomes more pronounced. The modern aftermarket sector is increasingly populated with designs that reduce the need for professional installation, offering clearer mounting points, standardized hardware kits, and straightforward instructions. This simplicity expands accessibility, enabling riders to perform upgrades in a home garage with basic tools and some patience. The shift toward standardized mounting interfaces—paired with robust customer support and responsive supplier networks—supports a smoother, faster path from purchase to riding. It also helps builders and shop owners present a more reliable value proposition to customers who want customization without sacrificing reliability or service ease.

Alongside practicality, there is a clear appetite for modularity. A growing number of designs aspire to be adaptable, allowing riders to swap wings, fairing shells, or windshields to suit different riding conditions or moods. In concept, modular fairings embody sport-touring sensibilities, where riders seek versatility across a spectrum of journeys—from comfortable long-haul cruises to weekend canyon rides. The practical promise is simple: a rider can tailor protection, airflow, and even storage potential to daily conditions, without committing to a single rigid configuration. The industry is paying attention to these modular concepts and exploring ways to make them more intuitive, reliable, and affordable. The result is a future in which a single fairing frame may host multiple shell options, each aligned to a particular riding scenario.

For riders who crave deeper customization, the market is increasingly open to color, texture, and finish options that let the bike breathe a personal hue into metal and plastic. The aesthetic language of fairings now rivals traditional chrome and paint in its influence on perceived value. A carefully chosen finish can emphasize the bike’s lines, deepen the visual depth of the bike, and mirror other elements of the rider’s gear. When a rider selects a finish that harmonizes with their bodywork, the result is a coherent, intentional look that enhances the overall presence on the road. The design conversation has moved beyond mere protection and toward a complete, personalized visual statement that respects the cruiser’s heritage while inviting contemporary polish.

The human element remains central. The preference for half fairings often reflects a desire to retain a clear view of the road, a tactile sense of the bike’s mechanics, and an accessible engine bay for maintenance. Yet even when performance is the goal, the rider’s sense of identity and pride in the machine persists as a core influence. This is not merely about chasing the latest trend; it is about choosing a configuration that feels like an extension of the rider’s daily experience. The most successful designs acknowledge this interplay and deliver a product that respects the bike’s proportions, preserves accessibility, and enhances comfort without erasing the bike’s soul. In this sense, the market’s direction is less about replacing tradition and more about enriching it with thoughtful engineering and user-centered thinking.

From a supply-chain perspective, the market is learning to balance volume with customization. High on-time delivery rates, low reorder incidences, and rapid response times are now widely cited as essential indicators of a supplier’s reliability. These metrics underpin consumer trust and help aftermarket providers sustain a steady stream of compatible, high-quality parts. The ability to meet demand promptly ensures that riders who invest in a fairing upgrade are not left waiting or dealing with restocking delays. It also supports a broader ecosystem of retailers, garages, and custom shops that depend on dependable inventory flow. The result is a healthier, more resilient market that can respond to evolving rider preferences without sacrificing quality or service levels.

In the end, the fairing market for metric cruisers reflects a broader truth about modern motorcycling: riders want to feel connected to their machines, their routes, and their communities. They demand gear that respects tradition while inviting experimentation. They want protection that does not disguise the character of the bike, and comfort that makes long rides feel shorter. They want products that are easy to install, durable in harsh conditions, and affordable enough to justify upgrading. And they want a marketplace that can deliver on these expectations with clarity and speed. That is the heartbeat of the current trend, a signal that customization, practical engineering, and stylistic harmony will continue to drive fairings for metric cruisers well into the next era. For riders curious about contemporary options and a concrete sense of how to integrate such pieces with a cruiser’s existing silhouette, a look into the Yamaha fairings collection offers a good starting point, illustrating how a modern line can complement a classic ride while maintaining compatibility and accessibility.

As the chapter of wind and chrome continues to unfold, the community of riders, builders, and suppliers will likely push toward even more thoughtful, modular solutions. The conversation will be shaped by climate, geography, and usage patterns, but the core appeal remains clear: a fairing that respects the machine’s heritage, enhances rider comfort, and offers a canvas for personal expression. In that sense, the market trends discussed here are less about passing fads and more about the ongoing, collaborative effort to balance aesthetics with performance. The road invites this balance, and the fairings that emerge from it will carry forward the cruiser’s legacy with renewed vigor.

External reference: https://www.bikeexif.com/aftermarket-motorcycle-fairing-guide/

Final thoughts

Motorcycle fairings for metric cruisers represent an essential combination of style and functionality, offering heightened comfort and protection while enhancing the bike’s aesthetics. Understanding the different types of fairings, their benefits, and the materials used in their construction helps business owners make informed choices that align with current market trends and consumer preferences. As the motorcycle accessories market continues to evolve, those who stay updated will position themselves favorably to meet the rising demand for quality and stylish motorcycle enhancements.