Motorcycle front fairing kits are vital for both aesthetic improvements and functional enhancements of bikes. Serving as a key component in the motorcycle aftermarket, these kits not only improve aerodynamics but also significantly affect rider comfort and overall bike appeal. As a business owner, understanding the relevance and implications of fairing kits can enhance your product offerings and cater to a diverse clientele. Each chapter of this article dives into essential aspects, from their aesthetic importance and maintenance to popular models, economic impacts, and future trends in design and materials. By exploring these facets, you can better appreciate how front fairing kits can elevate your business in the motorcycle accessories market.

Where Aesthetics Meets Airflow: The Front Fairing Kit as a Crucible of Speed, Style, and Rider Comfort

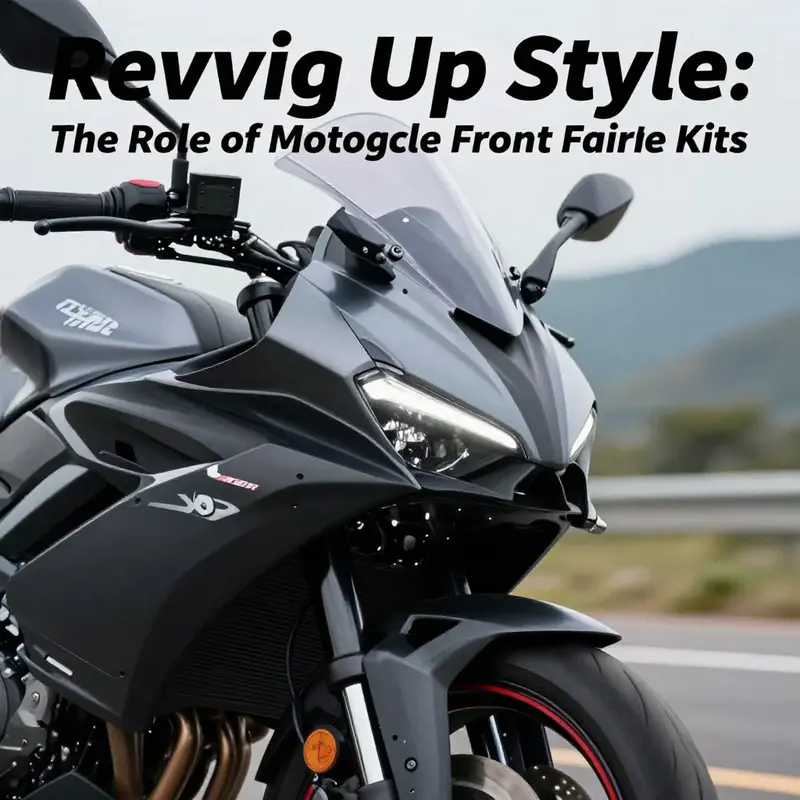

The front fairing of a motorcycle is more than a cosmetic mask. It is the first line of interaction between rider and environment, a carefully sculpted interface where form follows function. When a rider leans into a highway wind, the fairing becomes the mediator that channels air, reduces turbulence, and sets the tone for a ride that feels controlled rather than fought. A well-chosen front fairing kit does not merely dress up the bike; it tunes the bike’s behavior at speed, influences how wind interacts with rider and machine, and contributes to the perceived character of the machine. In this sense, the fairing is a kind of aerodynamic chassis skin—one that marries visual language with engineering intent to shape both performance and perception on the road. The quest for a kit that balances these aims begins with recognizing what the front end actually does in airflow terms. Air approaching the bike encounters sharp transitions where the wind is redirected around the headlight, the instrument cluster, and the leading edges of the frame and engine. If those transitions are abrupt, wind separates, creating drag and jitter that translate into buffeting at the rider’s helmet and fatigue over long hours in the saddle. A properly designed kit works as a streamlined conduit: it smooths the path of air, reduces wake behind the bike, and helps the chassis breathe more efficiently. The impact of that efficiency is not purely theoretical. Drag reduction can translate into better fuel economy, especially on long rides where the difference compounds with speed and elevation. High-speed stability can improve rider confidence, since the wind loads are more predictable and less prone to gust-driven wobble. All of this integrates with the bike’s existing geometry, weight distribution, and power delivery to create a motorcycle that behaves the way riders expect when they twist the throttle and lean into a corner. The front fairing kit performs its most conspicuous work by shaping the immediate air pocket in front of the rider. The height and curvature of the windshield play a decisive role in wind management. A taller windshield can deflect air upward and away from the riders’ line of sight, reducing helmet buffeting. But if it is too tall or poorly angled, it can introduce glare or create new vortices that unsettle the bike at speed. A skilled kit design accounts for these tradeoffs, delivering a balance where wind pressure is redirected away from sensitive areas without sacrificing visibility or imposing a cramped seating position. This is not merely a matter of surface styling; it is a question of how the bike’s nose integrates with the rider’s posture, helmet shape, and riding style. For riders who enjoy aggressive, sport-oriented positions, a front end that maintains clean airflow over the rider’s crown is a must. For those who prioritize all-day comfort and touring practicality, a fairing that suppresses headwinds around the chest and arms can noticeably extend riding hours before fatigue sets in. The chapter of aerodynamics that fairing kits write is not limited to air in front of the rider. The kit also interacts with the engine’s bay, the radiator profile, and the frame’s upper structure. The shape of the front pieces can influence how heat rises and dissipates, particularly in slow-speed maneuvers or urban traffic where aerodynamic cooling becomes more critical than outright top-end wind slicing. A well-honed kit does not obstruct cooling channels; rather, it harmonizes with them, maintaining efficient air pathways while still delivering a crisp, race-inspired look. Beyond the mechanical and the mathematical, there is an undeniable visual component that often defines a rider’s relationship to their machine. A front fairing kit can transform the bike’s entire silhouette, emphasizing lean lines, aggressive angles, and a factory-race aura that communicates purpose even when the bike is stationary. This transformation is not mere vanity; it signals intent and performance philosophy. When the eye catches the way light plays across the panel joints, or the continuity of lines from the windshield base to the nose and down into the upper fairings, the impression is of a machine that has been engineered with intent rather than mass-produced as a generic chassis. It is the visual embodiment of the aerodynamic goals that underlie the design. The choice of materials underpins both the performance and the aesthetics. ABS plastics, fiberglass composites, and carbon fiber each bring a distinct blend of weight, rigidity, and finish quality. ABS provides toughness and cost efficiency with solid colorability, making it a common choice for street riders who want durable panels that survive urban grinds and routine maintenance. Fiberglass offers a higher stiffness-to-weight ratio and can be molded into more aggressive shapes, reducing flex that could affect wing-like performance at speed. Carbon fiber, the lightest and most rigid option, delivers a premium look and the potential for real performance gains through lower unsprung weight. However, carbon fiber surfaces demand careful finishes and clear coats to resist UV exposure and maintain their luster. The finish, too, matters. Paint quality, laminate protection, and surface texture influence both the tactile feel and the perceived quality of the kit. A glossy, mirror-like finish might amplify the bike’s lines and highlight the sculpted forms, while a matte or satin texture can soften glare and emphasize a muscular, purposeful stance. The aesthetic layer must be durable as well, resisting stone chips and weathering while preserving the intended look over time. Alongside material choices, the mounting system and fitment quality determine how a kit performs in the real world. A kit that bolts up with precision to existing mounting points minimizes gaps, reduces rattles, and ensures consistent alignment with the headlight and windscreen. Poor fitment can negate aerodynamic advantages by creating micro-turbulence at critical junctions or by shifting under vibration, which not only harms performance but can irritate the rider over long distances. The practical dimension of upgrading or replacing a front fairing kit is the maintenance story. Even the most refined aerodynamic surface requires attention: re-fastening after a crash or a routine wipe-down, touch-up painting to cover chips, and periodic checks for cracks that could propagate under load. The decision between a full replacement kit, a half fairing, or a targeted single-panel approach hinges on several factors. A full replacement kit is the most transformative option, delivering a complete visual and aerodynamic overhaul and often restoring a showroom finish that accentuates the bike’s lines. It is favored by riders pursuing a cohesive, factory-like look or undertaking a complete restoration. A half fairing, by contrast, offers a balanced compromise: it preserves some lower body panels, which can reduce weight and simplify access to the engine and electrical components. This approach is common among sport-touring riders and urban commuters who want enhanced wind protection without the complexity of a full panel replacement. A single-panel replacement targets door handles of the bike’s aesthetic and structural integrity, providing a cost-effective fix for a damaged piece or a strategic upgrade for a sharper front end without altering the entire silhouette. For track enthusiasts and performance-oriented riders, race-inspired performance kits push the envelope on aerodynamics. These designs favor aggressive profiles, optimized airflow channels, and materials oriented toward stiffness and weight savings. They are typically finished with precision that mirrors the look of professional racing machinery, inviting admiration and signaling intent. The customization potential is vast, yet it is essential to maintain compatibility with the rider’s setup and use case. A kit should complement the bike’s instrument cluster, ensure the dashboard remains legible, and not obscure lighting elements. This is where integration with the windshield becomes crucial. Proper alignment of the fairing with the windshield influences wind deflection, glare, and the rider’s field of view. When done well, the combined system yields a calm airflow, a reduction in fatigue, and a front end that appears as if it were a single, sculpted unit rather than a collection of discrete parts. The broader value proposition of front fairing kits extends into resale value and long-term ownership satisfaction. Bikes that present a polished, integrated front end tend to attract interest from buyers who value both aesthetics and performance. A well-maintained kit, with consistent paint and proper sealing, can resist weathering, preserve color integrity, and prevent corrosion at fasteners and joints. In the end, the fairing is about more than looking good or shaving seconds off a lap time. It is about shaping a rider’s daily experience: the sense of control at high speed, the quiet confidence on a long highway stretch, and the pride of seeing a machine that looks as if it was designed for the rider’s exact ambitions. For riders who want to explore options in a structured way, a good starting point is to review collections that feature a range of styles and finishes, such as the Kawasaki fairings collection. This path encourages a thoughtful comparison of lines, materials, and mounting approaches, helping riders align their aesthetic desires with tangible aerodynamic benefits. The path from visual impact to measurable performance is not always linear, but it is guarded by a continuous dialogue between design and physics. The front umbrella of a bike’s bodywork shapes how the entire machine communicates with wind, rider, and road. A well-chosen kit translates the rider’s intent into a coherent mechanical statement: speed with composure, aggression balanced by comfort, and a look that remains readable and distinctive across miles and seasons. For those who crave additional technical perspective on how aerodynamic components work to improve speed and efficiency, an authoritative external resource offers a deeper dive into the science behind fairings and air management. External resource: https://www.motorcycle-riding.com/aerodynamics-fairings

From Fitment to Finish: Mastering Front Fairing Installation and Care

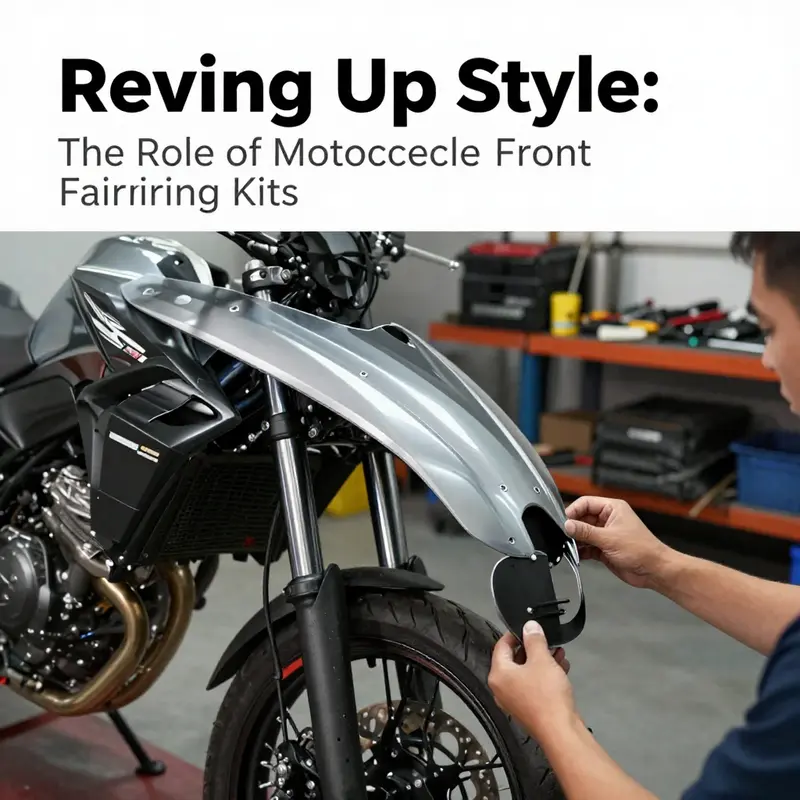

Installing a motorcycle front fairing kit is a task that tests patience as much as it tests skill. These panels do more than change the bike silhouette; they shape how the machine cuts through air, how the rider experiences wind and noise, and how the cockpit stays centered at speed. The process rewards deliberate planning, a calm pace, and the right set of tools. For riders pursuing a balanced mix of protection, aerodynamics, and personalization, the front fairing becomes a craft project that must respect the bike frame geometry, balance, and the rhythm of vibration and heat that accompanies high speed riding. The journey from bare frame to a finished shell is not a one step swap but a carefully choreographed sequence where every piece must align with the next, and every fastener must earn its torque value. The result is not merely looks; it is a coherent aerodynamic envelope that works with the bike rather than against it, a shield that also respects access to the engine, the instruments, and the rider line of sight in all weather. The Installation Journey A practical installation begins with a thorough cleansing of the frame and mounting surfaces. Dirt, grease, or lingering adhesive can sabotage alignment and leave stubborn gaps that throw a bike’s aerodynamics off balance. This initial step is more than cosmetic; it is preventive medicine for a smooth fit. As the fairing pieces are laid out, a careful rider will verify that every panel belongs to the same system and that the fasteners for each attachment point match the manufacturer’s plan. Modern front fairings, built for performance applications, typically rely on a constellation of fasteners—bolts, screws, and clips—each selected for a specific joint and each prescribed with a torque value. Ignoring these details invites a range of outcomes, from flutter and wobble at speed to stress cracking on a panel when the engine heat and vibration are at their peak. Alignment is the decisive moment. Panels must meet along clean lines, with even gaps and a curvature that mirrors the frame’s geometry. When misalignment exceeds a fraction of a millimeter, the air no longer flows evenly across the surface, and the rider feels the drag, buffeting, and noise that accompany a less-than-crisp finish. The goal is not a perfect seam but a functional seamlessness that you barely notice while riding. To achieve this, some builders temporarily clamp components in place or use painter’s tape to test fitment before final tightening. The approach is practical and patient, because rushing through the process rarely yields long-term reliability. A design note that helps many installers ease through fitment concerns is the structural logic of modern fairings. A 2026 patent disclosure describes a front fairing cover with robust, symmetrical lugs and L-shaped plates at the opening end. Those features carry bolt holes and mounting pins arranged to attach directly to upper and lower connecting plates without the need for additional supports. In real-world terms, that translates into a crisper, more predictable assembly. The design intention is to reduce the number of intermediary adapters and minimize play that can develop under heat, vibration, and highway speeds. While not every kit will echo this exact geometry, the principle remains: a well-thought mounting system makes alignment more forgiving and the finished product more rigid. For riders, that means less tuning after the bolts first snap into place and less chance that a gust of wind or a pothole will shift the panels out of line. The installation steps themselves are straightforward in concept but exacting in practice. Start by removing or loosening the stock panels only as far as needed to expose the mounting points without disturbing every clip and seal at once. Take photographs or create a simple reference map of where each fastener belongs. This catalog of the bike’s original state serves as a guide through reinstalling the panels in the correct order and orientation later. With the frame clean, the new fairing pieces can be positioned for a dry run, allowing you to verify that the top edge aligns with the headstock, that the sides tuck neatly along the fuel tank and frame rails, and that the bottom edges mirror each other on both sides. At this stage a careful check of the instrument cluster, headlight, and the windscreen mounting also helps prevent conflicts later in the process. When the dry fit looks right, the final stage is to torque each fastener to spec values. The torque is not a universal target; different attachment points demand different tightening forces. The goal is to secure the panel firmly without over-stressing the plastic or bending a metal mounting plate. Attention to detail in the early steps pays dividends when the bike is finally tested in a wind tunnel of one — your driveway or a quiet street. The panels should sit flush, with consistent edge gaps and no binding around the headlight assembly or instrument housing. Any stiffness in closing panels or subtle binding during installation is a sign to recheck alignment and adjust clamps or shims. For riders who want to push the envelope, sport or race-style fairings offer a wide canvas for color, logos, and artwork. The upside is a highly personalized look that matches the rider’s intent and riding style; the downside is a greater need for precise, sometimes intricate assembly and, in some cases, professional-grade fitting techniques that ensure the design intent remains intact at speed. It is a balance between creativity and engineering discipline, and the best projects acknowledge the limits of DIY with the confidence to seek specialized assistance when needed. The installation is only half the story. Maintenance is the other half, and it is less dramatic but equally important for longevity and performance. The fairing kit, once mounted, becomes a living part of the motorcycle’s breathing system. It is constantly subjected to heat from the engine, air pressure from forward motion, and the vibrations that come with road irregularities. Regular checks help catch issues before they become expensive or dangerous. A simple inspection schedule includes a visual scan for cracks or crazing in the plastic, a test for looseness around fasteners, and a quick assessment of panel gaps. If a panel is slightly loose after a long ride, a re-torque within the manufacturer’s specification can restore the tight, even contact that was present after installation. After impacts or months of riding, the mounting points deserve particular attention. Over time, vibration and thermal expansion can loosen the quincunx hole or round holes described in the design notes. A routine inspection can preempt rattles and misalignment. Cleanliness remains essential. The recommended cleaning approach is a gentle wash with mild soap and water. Harsh chemical cleaners, abrasive scrubbing, or high-pressure water streams can degrade paint and sealants, compromise fit, and remove protective coatings. A soft cloth followed by a light dry wipe helps preserve color and gloss without introducing micro-scratches that would worsen over time. For panels with painted or clear-coated finishes, a dedicated plastic-safe cleaner can help keep the surface clear of sap, bird droppings, and road grime that otherwise dulls the finish. The maintenance narrative is simple but powerful: a small, consistent routine of inspection and careful cleaning keeps the fairing kit looking sharp and functioning as intended across seasons and miles. Choosing the right kit and the right approach to installation and care also hinges on compatibility and materials. Front fairing kits come in an array of substrates, from durable ABS plastics to fiberglass and carbon fiber composites. Each material has its own profile of lightness, stiffness, impact resistance, and repairability. An aerodynamic shell built from a lightweight material can offer speed advantages, while a tougher composite may resist impact better in urban riding. Color and finish choices matter too not just for aesthetics but for UV resistance and weathering performance. When evaluating a kit, riders should consider model compatibility, the ease of obtaining replacement mounting hardware, and the availability of color-matching options to ensure the final appearance remains cohesive with the rest of the bike sheet metal and paintwork. In practice, this means reading the installation manual closely, verifying that the kit is designed for the specific frame geometry and steering rack, and recognizing that a modicum of compromise may be necessary when chasing perfect fit on an older model or a nonstandard chassis. The connection between install and long-term value is more than fashion. A well-fitted front fairing contributes to resale value by signaling responsible ownership and a thoughtful upgrade path. The investment in a solid fit can translate into lower maintenance costs over time, fewer air leaks, and less wind noise that might otherwise force riders to adopt uncomfortable riding positions. The appeal of a clean, integrated look is not only about style; it is about functionality, efficiency, and a riding experience that remains engaging rather than fatiguing. For riders who like to personalize their machines but still want a dependable, well-engineered interface between rider, machine, and environment, a front fairing kit offers a compelling combination of form and function. If you are exploring a broader range of fitment options or seeking a connected purchasing path, you can browse the Yamaha fairings collection for options compatible with a wide variety of bikes. This collection provides a starting point for understanding different design languages, mounting schemes, and finish choices that a rider can reference when planning a swap or upgrade. It can also serve as a practical reference point for what makes a clean, durable installation and a high-fidelity finish possible across different model lines. For readers who want to dig deeper into design trends that shape modern front fairings, recent industry discussions highlight how symmetry, mounting efficiency, and integrated wind protection influence both performance and rider comfort at speed. A practitioner’s guide to these features emphasizes the role of a well-engineered mounting geometry, the value of direct attachment points that minimize the need for extra supports, and the importance of minimizing air resistance without compromising access to the cockpit. In practice, the right combination of geometry and materials can yield a panel that feels almost invisible in motion, yet offers tangible gains in stability, noise reduction, and ride quality. Detailed design notes in contemporary fairing kits often reflect a balance between proven aerodynamic principles and the flexibility demanded by a diverse riding community. As you plan your next upgrade keep in mind that the installation manual provided by the kit’s manufacturer remains the most reliable source of guidance. The manual outlines the exact order of assembly, the recommended torque values for every fastener, and the sequence that prevents rework. Whether upgrading for enhanced protection, better aerodynamics, or a personal expression, the union of thoughtful installation and ongoing maintenance ensures the front fairing kit remains safe, functional, and visually compelling throughout its service life. External resources offer broader context on design trends and performance considerations that can inform your choices and help you evaluate different approaches to fitment and care. External resource: https://www.yamahamotorcycles.com/r3-fairing-kit-overview

Front Fairing Kits in Context: How Brand-Driven Design Shapes Aerodynamics, Fit, and the Riding Experience

The front of a motorcycle is more than a shield from wind; it is a carefully shaped airfoil, a fascia that blends identity with engineering. When a rider considers a front fairing kit, she is not merely choosing a cosmetic upgrade. She is selecting a package that will influence airflow, rider comfort, engine protection, and even the way the bike behaves at the edge of its performance envelope. The chapter that follows is less a catalog of options and more a narrative about how different design philosophies from various brands and model families translate into a harmonized riding experience. It is about the balance between form and function, and how a front fairing kit can be the catalyst that transforms a motorcycle’s personality without compromising its core geometry.

To begin, it helps to recognize the spectrum of front fairing kits available. Some riders want a complete transformation, and a full replacement kit offers a showroom-quality finish by replacing the entire front end, including the fairing around the headlight, the instrument cluster surround, and sometimes the windshield. Others seek a more targeted revamp, opting for a half fairing kit that covers the upper portion of the bike for a sportier silhouette and improved wind protection while leaving access to the lower engine and components relatively straightforward. There are also single panel replacements for precision repairs or upgrades when only the most exposed piece is damaged or outdated. Finally, race-inspired performance kits focus on aerodynamic refinement and weight reduction, typically using lightweight composite materials designed to shave seconds from a lap time and to project a professional racing aesthetic.

The appeal of these options is not universal. It shifts with a rider’s intent: daily commuting, long-distance sport touring, or high-speed track days all call for different emphases on wind protection, maintenance access, and removable panels. Aero performance is a top priority for riders who push toward high speeds or who ride in gusty or open-road conditions. Comfort becomes a deciding factor when wind buffeting translates into fatigue over miles or hours, and the integrated windshield on most front fairings is a direct response to that need. At the same time, many riders view the fairing as a canvas for personal expression, a chance to imbue the motorcycle with a sharper line, a more aggressive stance, or a factory-race look that communicates intent even when the bike is parked.

From a design perspective, the association between a front fairing kit and a specific brand or model is rooted in geometry. The fairing must contour to the bike’s frame, twin headlight arrangement, and the path of the wind around the forks and radiator. The mounting points, the curves around the tank, and the way the panels intersect with the instrument cluster are all constraints that determine fitment. A well-matched kit respects the bike’s underlying line, preserving the existing steering geometry, rake, and weight distribution. When a kit is poorly matched, it can introduce misalignment, increased drag, or unwanted flutter at speed. The best kits, by contrast, feel almost like an extension of the machine—an integrated solution rather than an afterthought tacked onto a frame.

Material choice is central to that integration. ABS plastics remain a common baseline for front fairings, offering a strong balance between impact resistance and ease of molding. For riders chasing a stiffer, lighter, or more premium appearance, fiberglass and carbon fiber composites provide higher stiffness-to-weight ratios and a distinct aesthetic that many describe as race-ready. The choice among these materials influences not only the weight a rider carries but also the way the panels respond to temperature changes, sun exposure, and road debris. A lighter option can enhance performance by reducing unsprung weight, but it may require more careful handling during installation to ensure that the panels maintain their shape under load. Heavier, more rugged variants may resist road rash better in a crash or after a gravel-filled commute, but they contribute to a different feeling of heft at higher speeds.

The finish options are equally telling. A contemporary kit can arrive in raw or primer finishes, inviting the builder to paint-match to factory tones or to craft a bold, contrasting look. The primer or unfinished state can be a functional choice for track-day riders who want to shield the panels from scuffs during rapid color changes or testing sessions. It also enables a color-obsessed rider to stage custom paint work that mirrors the bike’s overall palette or creates a new, personal identity. In all cases, color and finish must be considered in tandem with the bike’s existing lines; a mismatched color or an out-of-scale graphic can ruin the perception of flow that the kit is supposed to establish.

Fitment and installation are the practical heart of the decision. Some riders prefer a straightforward swap that minimizes downtime, opting for a kit engineered for quick mounting with standardized fasteners. Others may embrace a more involved process that includes alternative mounting points or reshaped internal bracing to accommodate accessories such as headlights, mirrors, or aftermarket instrument clusters. The installation experience reflects the rider’s skill set and the availability of workshop resources. The sense of accomplishment that comes with achieving a precise, gap-free fit can be as rewarding as the resulting performance gains. Because every model has its own contouring and limitations, the onboarding experience—how easily a kit aligns with the existing components—becomes almost as important as aero performance itself.

Riding stance and protection also shape a kit’s perceived value. A kit designed with a focus on aerodynamics tends to emphasize a clean silhouette that minimizes drag, thereby contributing to improved air flow and a smoother ride at speed. A kit aimed at rider comfort prioritizes wind deflection and a shield that reduces buffeting on the helmet, which can make a long day in the saddle less fatiguing. A more robust fairing that guards the engine and electrical bits from road debris can be a practical choice for riders who traverse rougher surfaces or weather-drenched routes. All these goals can be achieved without sacrificing the line that makes a bike instantly identifiable on the road; this is what many riders mean when they say a front fairing kit integrates identity with engineering.

Another dimension is maintenance accessibility. A full replacement kit may sacrifice some ease of service in the name of a flawless aesthetic, particularly around the headlight and instrument cluster where access to bulbs or sensors may be more constrained. Half-fairing designs often strike a practical balance, keeping the upper engine and wiring accessible while preserving the streamlined look. The single-panel approach can be a practical compromise when a single piece has suffered damage but the rest of the fairing remains pristine. On the race side, performance-oriented kits typically aim for compact shapes that reduce weight and drag but require careful, sometimes specialized, maintenance procedures and faster-part availability. In all cases, a rider should plan for patchwork repairs, color matching, and potential repainting if the kit is painted to a specific shade—factors that can affect ownership cost over time.

As clients look across the market, the brands and model families that historically attract attention share a pattern: riders gravitate toward kits that echo the bike’s original language while offering enhancements in aerodynamics and protection. A modern sport platform often benefits from a lightweight, minimal front assembly that emphasizes air separation control and rider visibility. A sport-touring or adventure-oriented machine may favor a half fairing that buffers the rider from wind at highway speeds while preserving access to pannier mounting and frame geometry. For track-focused builds, weight reduction, clean lines, and a racer’s stance tend to dominate the decision pathway, with emphasis on materials and shaping that deliver the best possible handling at high velocity. Across these preferences, the underlying logic remains consistent: the kit must respect the bike’s identity, improve the rider’s physical experience, and stay reliable through aggressive riding conditions.

To bring the ideas together in a practical sense, consider how a given kit interacts with color, finish, and the chosen model’s lines. A kit that follows the silhouette of the bike’s original front end will feel cohesive even when the rider is pushing toward the redline. In some cases, enthusiasts opt for a kit that accents the bike’s most distinctive features—perhaps the headlight assembly or the sculpted tank juncture—while preserving the instrument cluster’s legibility and the rider’s line of sight. This attention to alignment matters more than sheer complexity; a well-aligned kit tends to require less time re-adjusting mounting points and less effort chasing gaps that sing when the bike is in motion.

An important caveat is the marketplace reality: not every kit is a perfect drop-in for every model. Fitment data is often model-specific, and a kit designed for one frame geometry may not line up perfectly with another. This is where the conversation about brands and models becomes practical rather than theoretical. Riders who intend to upgrade their front end should invest time in verifying fitment notes, understanding the panel count, and assessing whether the kit includes or requires aftermarket components beyond the panels themselves. It is also prudent to consider warranty implications and the availability of replacement parts should a panel incur damage during a spirited ride or a careless moment in the paddock.

For readers who want to explore the practical side of the topic further, a curated collection that groups fairing options by compatibility can serve as a helpful starting point. The mid-to-lower weight class often sees a broader range of compatible, modular designs that can be mixed and matched with relative ease, making it easier for riders to experiment with different looks and aero setups without committing to a complete front-end overhaul. In these cases, a half fairing or a quarter-panel option can deliver a distinctive, race-inspired look while still preserving the practicalities of regular service and maintenance. The result is a bike that not only looks the part but also feels more confident at speed, with a smoother ride, reduced wind noise, and a more purposeful silhouette that communicates intent even when the bike is stationary.

Riders who want to delve deeper into availability and model-specific options can consult dedicated collections that categorize front fairing options by the frame and year. These resources help ensure that the chosen kit aligns with the bike’s mounting points and aesthetic language, simplifying installation and reducing the chance of fitment surprises. The exploration of these options is not merely about finding something that looks fast; it is about aligning a kit’s aero profile with the bike’s geometry so that the whole ensemble behaves like a single, coherent system on the road or the track. The story of a front fairing kit, then, is a story of alignment—alignment between air, rider, and machine—and the most compelling outcomes arise when this alignment feels almost inevitable once the panels are in place.

For readers who want to review practical pathways to finding compatible kits and to visualize how different front-end options alter the bike’s presence, consider exploring a curated online collection that groups options by make and model era. The product pages offer not only fitment notes but also color and finish choices, which are essential to achieving a seamless appearance. This approach helps riders who crave both performance gains and personal expression to settle on a configuration that feels right to them and their machine. An accessible way to begin is to explore a collection focused on a particular family, then widen the search to related models that share design cues and mounting strategies. The experience becomes less about chasing a specific part and more about understanding how a well-chosen kit can harmonize with a bike’s silhouette, rider posture, and intended riding context.

As a closing reflection, the practice of selecting a front fairing kit is a doorway into a broader conversation about modification, identity, and performance. It invites riders to think about how air moves around a machine, how a rider’s posture interacts with wind and noise, and how materials respond to heat, impact, and time. It is a practical exercise in planning, budgeting, and patience, balanced by the thrill of seeing a bike transform before one’s eyes. The right kit does more than cover a front end; it redefines the way a rider experiences speed, shelter, and connection to the road. When a kit is chosen with attention to fit, finish, and function, the result is not merely a more impressive visage. It is a nuanced instrument that enhances the entire riding experience.

Internal link reference for further exploration: Honda fairings collection

External resource for additional reading on aerodynamic principles behind fairing design: https://www.nasa.gov/aeronautics

null

null

null

null

Final thoughts

In summary, motorcycle front fairing kits play a pivotal role in enhancing both the aesthetic appeal and performance of motorcycles. For business owners, comprehending this significance can be a game changer in product offerings, leading to potential market growth and consumer satisfaction. As trends continue to evolve in design and materials, staying abreast of these developments will be critical for success in the competitive landscape of motorcycle accessories. By investing in quality fairing kits, you not only improve your inventory but also elevate the riding experience for customers, fostering brand loyalty and driving sales in the long run.