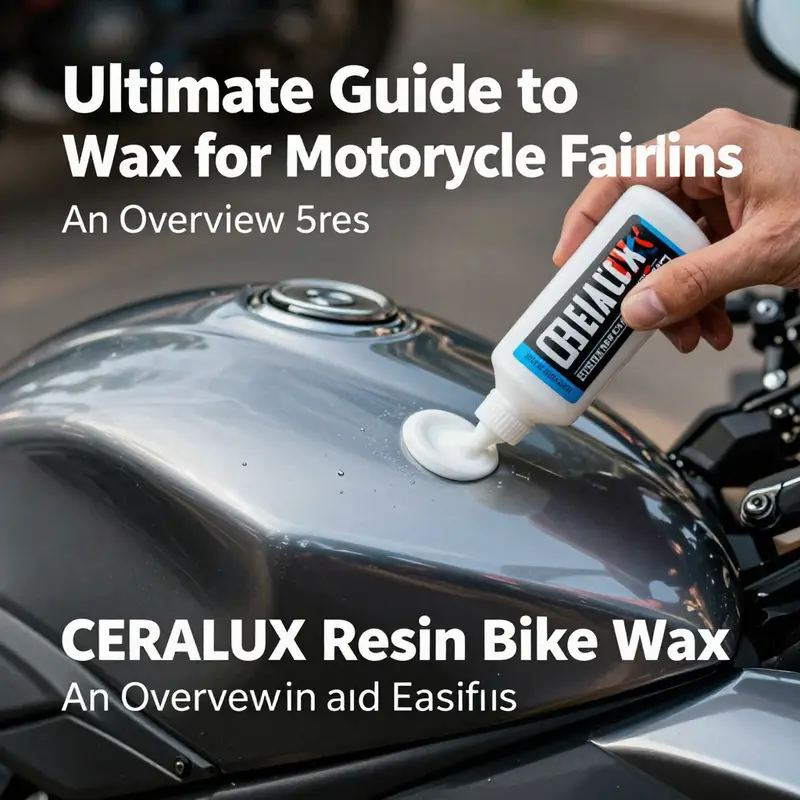

Maintaining the appearance and durability of motorcycle fairings is crucial for both aesthetic value and market competitiveness. Businesses in the motorcycle industry must prioritize effective maintenance solutions, and one of the best options available is the specialized CERALUX Resin Bike Wax Polish. This article explores its benefits, application techniques, and long-term maintenance strategies, providing business owners with essential insights into enhancing motorcycle fairing appeal and protection to attract customers and sustain their investments.

Gloss as Shield: Harnessing Resin-Based Wax Polishes to Protect Motorcycle Fairings

A motorcycle’s fairings—those sleek plastic or composite shells that crown the bike’s frame—are more than just styling. They are a first line of defense against wind, rain, grit, and the sun’s relentless UV. Over time, exposure to the elements can dull color, invite water spots, and invite micro-scratches that creep into the surface. That is where a resin-based wax polish designed for motorcycle fairings steps in as a quiet ally. It is not merely about immediate shine. It is about building a thin, durable shield that helps preserve the integrity of the plastics and maintain the bike’s showroom appearance through daily commutes, weekend rides, and occasional track days. The heart of this approach lies in the chemistry of resins: a non-abrasive, fast-drying film that bonds with the surface to form a protective layer while restoring color depth and clarity. The result is a finish that looks freshly waxed for longer and behaves like a water-repellent coat, shedding dirt and water with less effort during cleaning sessions. For riders who care as much about the look as the ride, this combination of gloss, protection, and ease makes a resin-based wax polish a practical cornerstone of regular maintenance.

To appreciate why such a product excels on fairings, it helps to consider the materials involved. ABS plastics and various composites used on modern motorcycles respond well to non-abrasive treatments that do not introduce swirl marks or micro-scratches. A resin-based formula delivers a resinous film that can flow into micro-molded textures on the surface, filling minor imperfections without harming underlying layers. When cured, the film resists dirt adhesion and remains flexible enough to withstand the flexing and vibration that come with riding. UV inhibitors embedded in the wax help slow down color fading and yellowing, which is especially important on fairings exposed to long hours of sunlight. As a result, the surface maintains sharper edges and more vibrant tones, contributing to improved visibility for the rider and a more premium look from every angle.

The practical value shows up most clearly in routine care. A proper maintenance routine begins with a clean slate: wash the bike with a mild, non-abrasive cleaner designed for plastics and finishes, then dry thoroughly. The aim is not to remove a heavy layer of grime with heavy scrubbing but to prepare a smooth surface that allows the wax to form an even film without trapped solids that could mar the gloss. Once the surface is dry, the wax polish can be applied in a thin, even layer. A small amount goes a long way, and the layer should be spread across the fairing with a soft applicator or microfiber pad using gentle, overlapping strokes. The goal is to lay down a uniform film rather than building up thick layers that can haze or become difficult to buff out. Allow the product to dry to a light haze in the recommended time, then buff with a clean microfiber cloth until the surface gleams.

In this approach, less is more. A thin coat that cures properly and is buffed to a high shine can deliver a smoother beading action and a more resilient finish than a heavy, sloppy application. The hydrophobic properties of the resin-based film are more effective when the film is uniform. When water drops encounter a well-applied layer, they bead and roll off more readily, carrying away surface dirt and reducing the risk of water spots that can etch at the surface over time. The film’s durability translates into longer intervals between re-waxing and less downtime spent on maintenance. The sense of accomplishment is tangible: the fairings look perpetually fresh, and the owner experiences less friction during routine cleaning, which encourages a more consistent care routine overall.

One of the compelling advantages of this kind of wax polish is its compatibility with a broad range of fairing finishes. Whether the surface is a glossy painted panel, a matte decorative section, or a textured plastic, resin-based formulas are designed to respect the underlying finish while imparting a unified gloss and protection. This is particularly valuable for riders who rotate through different bikes, or for those who own a show bike with multiple color schemes and decals. The polish tends to be non-abrasive enough to avoid micro-scratches during application, yet robust enough to resist removal by routine washing, rain exposure, or incidental dirt impact. In practice, it helps to view the polish as part of a care system rather than a single-step miracle. Used regularly, it creates a stable protective film, and over time the fairings begin to look consistently well-preserved, with fewer color inconsistencies and a more uniform reflection across the surface.

Beyond the mere gloss, there is a tactile truth: a well-maintained surface feels smoother to the touch, and the visuals reflect a more complete, cohesive silhouette of the bike. For riders who spend long hours on the road, the enhanced clarity of fairings can improve the perception of airflow and overall aerodynamics, even if only subtly. For show bike enthusiasts, the deeper color tone and high-gloss finish contribute to a more dramatic stage presence, capturing light in ways that highlight sculpted edges and the line of the bodywork. The subjective experience—feeling the smoothness under a gloved hand, seeing the reflections of street lamps in crisp, unbroken lines—becomes part of the riding ritual as much as the mechanical performance itself.

The routine can be woven into a broader care rhythm without disruption. After a bath or a wash, a quick inspection of the fairings reveals whether a touch-up is needed. In regions with harsh weather or frequent road spray, integrating this resin-based wax into a monthly or bi-monthly maintenance cycle can yield consistently better results than sporadic care. The key is to apply the treatment to clean, dry surfaces and to avoid applying it to areas where wax could trap water at seals or around decals. It is wise to test a small inconspicuous area if decals or special finishes are present, ensuring the wax does not alter the appearance or texture of those elements. This gentle precaution preserves the integrity of the decals and maintains the intended aesthetic across the entire fairing surface.

A broader look at maintenance philosophy helps illuminate why this approach is so trustworthy for riders who want longevity without sacrificing ease. The resin-based film acts as a sacrificial shield that takes the brunt of environmental challenges—sunlight, rain, dust—before they reach the underlying surface. In practical terms, that means fewer micro-scratches and less color fade to contend with when the bike comes out of the garage after a week or two of use. The film’s non-abrasive nature ensures that even during the buffing step, the risk of introducing new scratches is minimized, provided the user maintains a light touch and uses a clean cloth. The net effect is a more forgiving maintenance process: you can achieve a striking, showroom-like finish with a routine that respects the sensitive plastics that form today’s fairings.

The conversation about care for motorcycle fairings remains incomplete without acknowledging that care products live within an ecosystem. A resin-based wax polisher can be part of a coordinated system that includes a dedicated cleaner for visors and windshields, along with a follow-up polish that enhances longevity. This integrated approach helps ensure that the external surfaces stay clear and bright, while critical components like windshields, which demand streak-free clarity, receive complementary treatment without compromising safety or visibility. In practice, riders who use a complete resin-based care line often report higher satisfaction with the overall look and a calmer maintenance routine, since the products are designed to work in harmony and share compatible chemistry.

For riders who like to tailor their setups to specific fairings, the choice of a resin-based polish should consider the surface material and the level of gloss desired. Some fairings feature a very high-gloss paint that benefits from a meticulous, ultra-thin film and a careful buff to maintain that mirror-like finish. Others incorporate a matte or satin accent, where a too-heavy application can occasionally erase the intended texture. In these cases, the application method becomes as significant as the product itself: gentle pad pressure, even coverage, and avoiding circular, heavier motions near accents or edges can preserve the intended look while still delivering the protective benefits. The user’s technique, more than the product’s inherent potency, often shapes the final effect. This is why a resin-based approach—paired with mindful application and routine care—tends to yield the most reliable, long-term results across a spectrum of fairing designs.

As with any maintenance decision, a practical, tested approach wins over an idealized, one-size-fits-all solution. The resin-based wax polish for motorcycle fairings is designed to be user-friendly and forgiving, but great results come from consistency. A rider who commits to a lightweight, even layer every few rides will likely enjoy a surface that stays bright, repels water, and resists dirt buildup longer than a neglected surface. The simplicity of the process—wash, dry, apply thin coat, buff—becomes a reliable ritual rather than a chore, turning maintenance into a natural part of riding culture rather than a burdensome task. The resulting finish is not merely cosmetic. It is a practical, protective layer that helps preserve the fairings’ structural integrity and aesthetic appeal, contributing to the bike’s value and the rider’s confidence on the road.

For those who are curious about expanding their care system, it is worth exploring how a resin-based polish fits with the broader ecosystem of surface care. While the wax polish focuses on a durable, gloss-boosting film, complementary products in the same family can address other exterior elements, from windshields to body panels, with consistent chemistry and performance. This synergy can reduce the guesswork involved in selecting products and help ensure that the surface remains harmonized in both appearance and protection. The end result is a more coherent, dependable maintenance routine that suits riders who demand both style and practicality from their machines.

If you are mapping out your maintenance plan and want to explore related options for fairings, consider browsing the Honda fairings collection to understand how OEM designs influence finish care and compatibility. Honda fairings collection This link provides context on the kinds of finishes that commonly appear on popular models and how a resin-based care approach can be tailored to those surfaces. While this chapter stays focused on the wax polish concept, the broader point remains: compatibility with the specific fairing material and finish type is a meaningful predictor of long-term results, and a thoughtful, surface-aware routine will yield the best blend of protection and appearance.

In closing, the case for resin-based wax polishes on motorcycle fairings rests on a simple idea: create a thin, resilient, and aesthetically pleasing shield that honors the material beneath. The film-based protection helps resist dirt and water, reduces the frequency of polishing, and preserves color vibrancy in the sun-drenched and weather-challenged environments where riders spend most of their time. The practical steps—clean, dry, thin coat, gentle buff—are straightforward, but the payoff is substantial: a fairing that looks almost new after a long ride and a care routine that fits naturally into the rhythms of motorcycling. For riders who want to extend the life of their fairings without sacrificing shine, a resin-based wax polish designed for motorcycle fairings offers a reliable, convenient path forward.

External resource: https://www.resinbike.com/collections/resinbike-cera-lux

Guardians of the Glow: The Protective Power of Wax on Motorcycle Fairings

The fairing of a motorcycle is more than a styling feature; it is a working shell that meets the road first and the rider last. When you roll out, the fairing faces sun, rain, insect spray, road grime, and the occasional stone that skips from a tire. In that daily grind, a thoughtfully chosen wax—specifically one formulated for fairings—acts not merely as a cosmetic glaze but as a functional shield. It creates a durable, hydrophobic layer that helps keep the surface clearer for longer, reduces maintenance friction, and slows the creeping effects of the elements on plastic and composite materials. The idea is simple in theory: you prepare a clean, dry surface, apply a thin, even coat, and wipe away the residue to leave a smooth, bead-ready finish. But the practical impact runs deeper. A well-applied wax film forms a barrier that resists water and contaminants, making the next wash quicker and less aggressive, and it can preserve the color and structural integrity of the fairing over years of exposure. The beauty of this approach lies in its balance between protection and practicality. It is not a replacement for proper cleaning or careful riding; it is a complement that works in the background, quietly reducing wear without demanding constant attention from the rider.

A primary benefit of wax on fairings is UV protection. Plastic and composite fairings can fade, chalk, or develop micro-cracks when exposed to prolonged sunlight. The sun’s rays carry energy that can degrade pigments and weaken polymers over time, especially on bikes left to bake under open skies. High-quality waxes can include UV blockers that help preserve color depth and the mechanical resilience of the surface. Even as you admire that glossy finish, you can take reassurance in knowing that a portion of the sun’s assault is being mitigated by a protective film rather than directly striking the material. The effect is not a miracle cure, but it is a real, cumulative defense. When the fairing enjoys this extra shield, the color remains truer, the plastic stays more flexible, and the finish resists the dulling that often follows long exposure to sun and heat. The story here is about longevity as much as it is about appearance, and that harmony is what makes efficient waxing an essential part of fairing care.

Beyond UV protection, the wax serves as a shield against minor scratches and routine contaminants. The road is a harsh tutor, offering up tiny abrasions from grit and sap, bird droppings, and weather-driven pollutants like acid rain. The slick, dense film a resin-based or similarly formulated wax creates reduces the surface energy of the fairing, making it harder for particles to cling and harder still for acids and solvents to etch into the top layer. When you wash the bike after a ride, the dirt comes away more cleanly because it had a harder time sticking in the first place. In practical terms, that means fewer swirl marks, less microabrasions, and a finish that looks bright and uniform far longer than it would without a protective layer. This is not just about vanity; it is about reducing the cumulative stress on the surface, which translates to less aggressive polishing down the road and a better chance of maintaining the integrity of decals and color throughout the bike’s life.

The aesthetic payoff—depth, gloss, and that inviting wet look—often accompanies the protective benefits. Some wax formulas are designed to boost the apparent depth of the underlying color, helping the fairing look polished and new even after months of use. This depth comes from how the wax sits on the surface, filling in micro-irregularities and smoothing reflections so light bounces in a way that reads as richer and more even. The practical side is that a fairing with enhanced gloss is easier to clean because the smooth surface resists dirt adhesion more effectively. The minute film acts like a second skin, not a hard coat of glass, preserving the tactile feel of the finish and maintaining the bike’s presence on the road. The dual outcome—improved protection and enhanced appearance—makes wax a logical, if sometimes understated, part of routine maintenance for riders who care about both form and function.

In the flow of everyday care, time and effort matter. For riders who value quick turnaround between rides, a pH-neutral spray wax with UV protection offers a convenient option. It can be sprayed on after a ride, wiped gently, and dried to a water-beading finish within minutes. The ability to refresh the protective layer rapidly means you can keep the fairings looking presentable in the field, even during travel or long tours where a detailed waxing session is impractical. For enthusiasts who want the longest possible interval between applications, a high-grade paste wax provides deeper penetration and longer-lasting protection. Paste formulations tend to deliver a more durable film, resisting wash-offs and environmental challenges for several weeks to months, depending on climate and riding conditions. In both cases, the key is to tailor the approach to the riding regime and the environment, recognizing that wax is not a one-size-fits-all solution but a dynamic component of ongoing protection.

A practical, human-centered way to think about wax for fairings is to view the process as part of a routine that respects the materials and the rider. Fairings, whether plastic or composite, carry layers of protective finishes themselves. A well-chosen wax respects those layers, providing a new top coat rather than aggressively abrading or altering the surface. This is important because aggressive polishes or cleaners can erode clear coats or delicate finishes over time, especially on older or previously treated surfaces. The wax’s role is to complement and preserve, not to correct damage or remove history. Before applying any product, the surface should be clean and dry. Any sign of moisture on the surface during application can trap moisture beneath the film and compromise the finish, so a thorough dry-off is essential. The rider’s habit should be to avoid applying wax over any stubborn contaminants. If bird droppings or tree sap have etched into the surface, it’s better to remove them first with a gentle cleaner specified for fairings than to cover them with wax and seal the issue underneath a glossy finish. And yes, while the wax can aid in repelling water, it does not substitute for regular cleaning, especially after riding in salty, muddy, or highly polluted conditions. A clean baseline ensures the film can adhere evenly and perform as expected for the life of the wax layer.

Another important consideration is the surface area and its contact with other bike components. When applying a wax to a fairing, care should be taken to preserve grip and safety in touchpoints. While fairings do not normally contact a rider’s hands while riding at speed, some edges and decals might be near foot pegs or levers. It is wise to avoid leaving any wax residue on brake components, tires, handgrips, or footpegs, as residual film can modify grip or interfere with braking performance in a very small but real way under certain temperatures and conditions. The best practice is to apply to clean, dry surfaces and wipe thoroughly, ensuring there is no excess film at interfaces where it could cause grip issues. This careful approach preserves safety while still delivering the surface protection that wax provides.

There is value in recognizing how wax interacts with different fairing materials and finishes. Some surfaces are more prone to micro-abrasions, especially if they have been repaired, repainted, or modified with aftermarket parts. In such cases, testing a small, inconspicuous area first helps confirm the product’s compatibility with that specific finish. The goal is uniform protection without altering color, texture, or decal clarity. When done right, the wax can help maintain even coloration across panels, minimizing the visual disparities that show up after seasons of sun and weather. For riders who maintain a commitment to originality or resale value, this consistency matters as much as the shine itself.

If you look at a broader sense of motorcycle maintenance, the wax serves as a complement to a broader care philosophy. Washing frequency, choice of cleansers, drying methods, and storage habits all influence how well a wax layer performs over time. A thorough wash that uses a gentle shampoo designed for sensitive finishes, followed by a careful dry with a microfiber towel, provides a ready canvas for wax. In turn, the wax film reduces surface energy and helps resist the sticking of road grime, making subsequent cleanings less intense and more forgiving. The cycle—wash, dry, wax—becomes not a chore but a quick ritual that protects the fairings as you ride, store, and travel. The continuity of care matters as much as the care itself, because wax is most effective when part of an ongoing discipline rather than a sporadic, one-off treatment.

What does this mean for riders who are curating a garage of fairings from different eras and manufacturers? The principle remains: choose a resin-based or similar modern coating that is designed for plastics and composites, apply it to a clean, dry surface, and maintain the discipline of regular reapplication according to climate and riding style. The performance advantage is not about chasing the latest glossy finish alone; it is about creating sustainable protection that preserves color, reduces staining, and minimizes the wear that long-term exposure would otherwise impose. In practical terms, that means a fairing that stays bright through the spring sun and the summer downpours, that beads water off rather than letting it linger, and that remains comfortable to clean and inspect without requiring aggressive scrubbing. The reward is not merely a cleaner surface; it is a more resilient one that holds up under the curious realities of road use and weather, panel by panel, ride by ride.

For riders looking to connect the idea of protective care with a community of like-minded enthusiasts, there is value in exploring the broader ecosystem of fairing care and aftermarket options. Within the world of Honda fairings and other brands, the surface care conversation often overlaps with what riders expect from aftermarket parts and replacements. Internal resources and communities that discuss fairings—such as those cataloging and organizing Honda fairings collections—can provide practical alignment on compatible finishes, application nuances, and material sensitivities. For example, riders exploring Honda fairings can reference and consult dedicated collections that help identify compatible panels and mounting considerations, which in turn informs decisions about surface protection that won’t conflict with fitment or aesthetics. See the Honda fairings collection at Summit Fairings for more on how fairing choices intersect with surface care and appearance. Honda fairings at Summit Fairings.

As you weigh the protective benefits of wax for motorcycle fairings, it’s helpful to anchor your expectations in a practical understanding of material science and field conditions. A resin-based wax designed for fairings offers a balanced combination of hydrophobicity, UV resistance, and self-cleaning properties that translate into real-world advantages. The water beading that beads away helps to minimize water staining and helps prevent tiny droplets from settling into micro-scratches. This reduces the likelihood of chemical etching from environmental contaminants and makes subsequent maintenance sessions less onerous. While the glossy finish is a tangible reward, the true reward is the smoother experience of owning a bike that looks good with less effort and retains its value with time. The next ride feels just a bit better when you know the surface beneath your gloves is protected by a layer that was applied with care and consideration for its long-term performance. It is, in short, a small but meaningful investment in the bike’s exterior health—and in the rider’s time and enjoyment on the road.

For those who want to place this practice within a broader maintenance strategy, it is reasonable to treat waxing as an operational detail that supports broader goals: fewer abrasive encounters on the surface, easier cleaning, and longer intervals between more intensive detailing sessions. This approach respects the fairing material and the rider’s schedule alike. It also aligns with best practices drawn from technical guides and field experience, which emphasize surface cleanliness, compatible products, and precise, restrained application. When done thoughtfully, waxing becomes a sustainable habit rather than a one-time effort; it becomes a recurring moment of care that preserves the beauty and resilience of the bike’s most visible exterior shell. In that sense, the wax isn’t simply a product; it is a small act of stewardship—protective, practical, and quietly effective.

External reference: for a broader, research-backed discussion of fairing materials and protective coatings in the Honda context, consider this technical guide: A Technical Guide to Fairing Motorcycle For Honda.

Shining Shield: Mastering Wax Application on Motorcycle Fairings

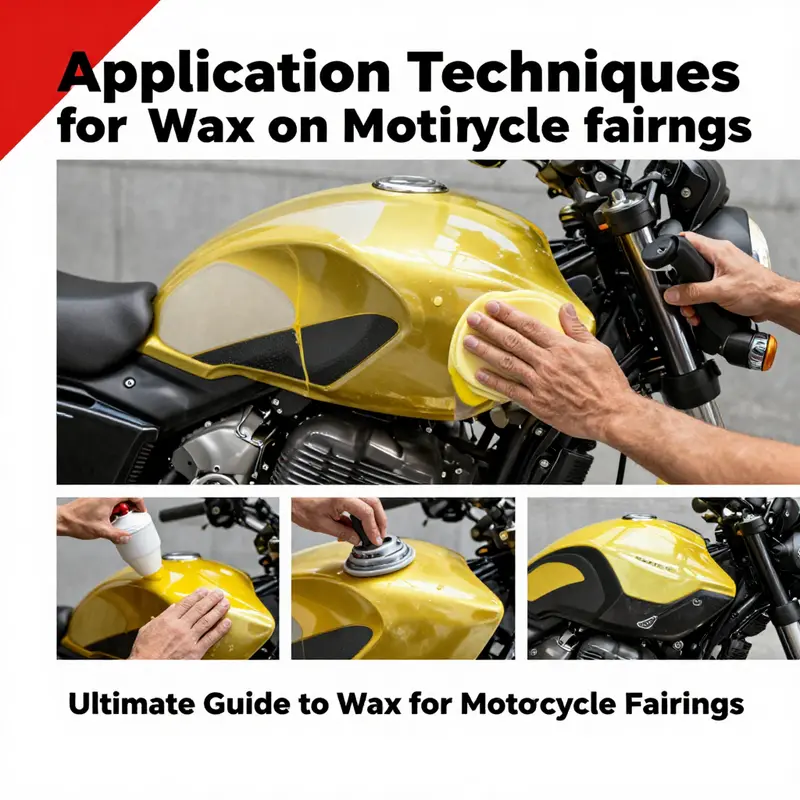

The gloss of a motorcycle fairing does more than catch the eye; it signals a layer of care that protects the plastic shell from the daily assault of road grime, weather, and UV exposure. When we talk about wax for motorcycle fairings, the conversation moves beyond aesthetics and into a practical ritual of maintenance. The fairings themselves, most often crafted from ABS plastic or fiberglass, carry a unique susceptibility to contaminants and micro-scratches. A well-chosen wax creates a protective shield that not only beads water and repels dirt but also reinforces the color and depth of the paint or finish beneath. The right wax becomes a thin, durable film that wears gracefully, letting the bike look freshly waxed even after a few weeks of exposure to sun, rain, and the occasional bug smear. In practice, the science of waxing a fairing blends material knowledge with patient technique, yielding a result that is as functional as it is visually striking. And because plastics are the most common material in modern fairings, understanding how wax interacts with those surfaces is essential. A dedicated resin-based wax polish designed for bike fairings, when chosen for the correct formulation, can deliver long-lasting protection, exceptional hydrophobic performance, and an easy maintenance cycle that suits a rider’s schedule. Such products are designed to form a protective layer without introducing abrasives that could wear down the surface or dull decals and textures over time. The goal is not to outshine the fairing’s original finish with an aggressive shine, but to preserve it—keeping color vibrant, edges crisp, and the surface smooth to the touch. The real advantage shows up in real-world riding: water beads and slides off instead of clinging, salt and road grime rinse away more readily, and the surface resists minor chemical spills from fuels and sprays. It is this combination of protection and ease that makes the waxing ritual worthwhile, especially for riders who spend long hours on the road or in harsh climates. The practice also serves as a maintenance touchpoint that connects the rider with the bike’s overall care routine, a small but meaningful act that communicates respect for the machine as a living piece of equipment rather than a simple metal shell. Yet the value of waxing does not lie in dramatic, one-off interventions. It rests in a disciplined, repeatable process that can be learned, refined, and integrated into a rider’s regular cleaning cycle. The best outcomes come from a sequence of careful steps, where cleanliness, surface readiness, and product compatibility align to produce a finish that looks deeper and lasts longer. The science behind wax for fairings emphasizes a few core principles. First, the surface must be clean and free of contaminants; otherwise, particles trapped under the wax can create micro-swirls and uneven reflections. Second, the surface must be dry; even a thin film of moisture can compromise adhesion and promote streaking. Third, the wax must be formulated for plastics and painted surfaces, with no abrasive components that could scratch or haze the finish. These are not arbitrary guidelines but practical guardrails that protect the delicate plastics and the complex curves of a fairing. The application itself is less a race and more a choreography. The rider or caretaker starts with a thorough cleaning using a pH-neutral motorcycle shampoo and a microfiber towel. A pH-neutral formula cleans effectively without stripping wax-friendly oils or leaving behind cleansing residues that could interfere with adhesion. Dirt, oils, and waxy residues are all enemies of a clean, consistent wax layer; they trap under the film or create small pits where water and dirt can collect. Once the fairing is clean, it must be completely dry before anything else touches the surface. Water droplets on the surface break the wax’s uniform contact with the plastic, reducing the hydrophobic effect and forcing the wax to work harder to achieve the same seal. Patience here pays off in the long run, giving the wax a clean slate to adhere to and enabling a more even, bead-like finish once buffing begins. The choice of wax is a step that rewards knowledge of materials. A high-quality, non-abrasive wax, specifically designed for plastics and painted surfaces, provides the right balance of slickness and protection. Waxes intended for metal or clear coats can contain abrasives or chemical formulations that may risk micro-scratches or clouding on plastic finishes. The precise chemistry matters: a resin-based film that bonds to the plastic without heavy fillers, a formula that yields a hydrophobic surface, and inhibitors for UV light to slow color fading. The essence of this choice is not in a single superstar outcome but in the consistency of protection across months and across weather. The application method follows a simple, repeatable pattern. One uses a soft foam applicator pad or a microfiber cloth to apply the wax in small, circular motions over a section roughly 1 square foot at a time. Working in manageable segments helps ensure the product does not dry too quickly and become difficult to buff. A light, even layer is the target; thick coatings are more prone to streaking and longer haze times. The wax needs to haze—usually within five to ten minutes, depending on ambient temperature and humidity—before it can be buffed away. Waiting too long can make buffing harder, while buffing too early can leave behind a residue that requires extra effort to remove. Buffing should be done with a clean, soft microfiber cloth using gentle pressure in a cross-hatch of motions to lift the last trace of wax and to reveal the glossy finish underneath. The goal is not a high-gloss mirror in a single pass, but a balanced, durable luster that remains attractive after weeks of exposure. The texture of the plastic—whether smooth or slightly textured, painted or decals present—can influence how the wax finishes. On a smooth ABS surface, the film can sit evenly and the reflections appear crisp, while over textured areas the wax may highlight some micro-variations in the surface. In either case, a light hand and a steady rhythm help maintain consistency across the entire fairing. The maintenance cycle itself sets the rhythm of care. For most riders, reapplying wax every four to six weeks is ideal for keeping the hydrophobic layer fresh and the finish vibrant. In harsher climates, with frequent rain, road salt, or aggressive UV exposure, waxing more often can help preserve the color and depth of the paint. An additional benefit of regular waxing is its protective barrier against light chemical exposure and minor abrasions from dirt and debris kicked up at speed. The surface’s resistance to such elements translates into easier cleaning and a more forgiving finish when the fairing inevitably encounters the road. A well-executed wax routine also reflects a mindful approach to decals and graphics. If decals or painted graphics are part of the fairing, it is essential to apply wax carefully around edges that might lift or peel. In some cases, applying wax in the same motion pattern used during installation, following the contours of the fairing, can minimize the risk of disturbing graphics. Ridges, vents, and intakes on fairings can trap moisture or wax if attention isn’t paid. The diligent practitioner will take extra care around these features, perhaps using a smaller applicator for tight curves or a brush-like applicator to reach behind vents. The best wax experiences are those that blend with the bike’s overall care routine. Cleaning, drying, waxing, and buffing can be framed as a single, cohesive ritual rather than separate tasks. This coherence reduces the chance of missteps and makes the process more enjoyable, especially on days when you are polishing after a long ride and want the bike to feel newly cared for when you park it in the garage. The materials, the steps, and the discipline of technique come together to produce results that are not merely superficial. A properly waxed fairing resists dulling from UV light, a common cause of color fade on pale or bright finishes. It sheds water with a predictable beading action, reducing the likelihood of water spots that can compromise the appearance over time. It also forms a protective barrier that absorbs small impacts and reduces the roughening effects of road debris. While the wax does not repair deep scratches, it can help prevent new micro-swirls by providing a forgiving, protective layer that eases future cleaning. This is especially valuable for riders who wash their bikes in cold conditions or in areas with hard water, where mineral deposits can be a nuisance. The human element matters just as much as the chemistry. The best waxers are those who bring patience, attention to surface conditions, and a rhythm to their process. The difference between a fairing that shines for a week and one that continues to glow for months is often a matter of deliberate, repeatable steps and the selection of a product designed for plastics rather than generic finishes. For riders who want to connect this care to a broader ecosystem of accessories and bodywork, exploring a broader range of parts and fitment—such as the Honda fairings available from specialized suppliers—can provide context for the kinds of plastics used and how a given care routine interacts with different surface textures and color layers. For a practical link to such options and to compare surfaces across different models, you can explore the Honda fairings collection. Honda fairings collection This reference helps readers visualize how various fairing geometries respond to polishing and waxing in real-world scenarios, reinforcing that the underlying material and finish guide the care choices rather than a one-size-fits-all approach. Returning to the routine, it is worth noting that not every rider will find the same formula perfect for their climate, their riding style, or their fairing color. Some finishes may call for a slightly more slick, polymer-rich wax, while others benefit from a film with higher UV inhibitors and a longer dwell time before buffing. The key is to adapt within the safe boundaries of plastics care and maintain a steady protective layer. This adaptability does not mean compromising on fundamentals. The clean surface before application, the dry surface, the sector-by-sector method, the natural drying time, and the careful buffing—all remain constant. A disciplined approach yields a dependable, repeatable result that helps protect the fairing’s original lines and keeps those lines looking as sharp as the bike’s performance. As you advance in your wax routine, you may find personal preferences for applicator type, cloth texture, and even the duration of the haze period. These preferences should still honor the core guidelines: non-abrasive formulations, plastics-friendly chemistry, and thorough buffing to a smooth, glassy finish. The ride from a newly waxed fairing to a surface that continues to gleam through the season is a journey of small decisions—choices about cleaning products, drying methods, and the timing of each waxing session. The end result is a surface that is easier to maintain during road trips, more resistant to water marks after a sudden shower, and more forgiving when the bike sits in a damp garage overnight. For the enthusiastic rider who cares for every detail, waxing is more than maintenance; it is a craft that honors the very material that shapes the silhouette of the bike. It is a practice that brings out the best in the fairing’s color, texture, and shape, while also extending the life of the surface against environmental elements. In flowing terms, the process links care to performance and appearance to longevity. The chapter you’ve engaged with is about competence—about understanding how plastics behave under a film coat, how to prepare the surface, and how to execute a method that respects both the material and the ride. It is about recognizing that wax is not merely a surface treatment but a stewardship act, one that ensures your motorcycle remains not only fast but resilient and well-presented on the roads ahead. For more context on how these practices translate across different chassis designs and surface finishes, readers may browse related content that highlights the diversity of plastic fairings used in contemporary bikes and the tailored care routines that accompany them. The careful, consistent approach to waxing that this chapter outlines aligns with the broader ethos of motorcycle maintenance: attention to detail, respect for materials, and a commitment to consistent, repeatable care that supports performance and appearance in equal measure. External resources can offer practical demonstrations and professional insights that complement this discussion, such as tutorials that walk through the waxing process step by step. External resource: https://www.motorcycle.com/motorcycle-maintenance/how-to-wax-a-motorcycle-fairing/

null

null

Final thoughts

Utilizing CERALUX Resin Bike Wax Polish provides motorcycle businesses the opportunity to significantly enhance the aesthetic appeal and longevity of fairings. By understanding its protective benefits, mastering application techniques, and committing to regular maintenance, business owners can ensure their bikes stand out in the marketplace while protecting their customers’ investments. Adopting these practices is vital for retaining customer satisfaction and driving repeat business.