Understanding the types of plastics used in motorcycle fairings is critical for business owners seeking to enhance product quality and customer satisfaction. Motorcycle fairings primarily utilize materials like ABS plastic and its blends, known for their durability and manufacturing efficiency. This article delves into the various plastics, manufacturing processes, performance characteristics, and future innovations, providing a comprehensive guide for decision-makers in the motorcycle industry.

Shaped by Choice: The Material Story Behind Motorcycle Fairings, From ABS to Carbon Fiber

Motorcycle fairings do more than contour a bike’s silhouette; they are the first line of defense for the rider, the shield against wind, debris, and a spectrum of weather, and a carefully chosen set of materials that must marry form with function. The material story behind these plastic shells is a narrative of balance. Designers and manufacturers weigh toughness against weight, cost against processability, and esthetics against longevity. At the heart of this balance lie a small but critical trio of plastics: ABS, PC/ABS blends, and, in select racing or premium applications, carbon fiber composites. Each material brings a distinct set of properties to the fairing, and each is chosen with an eye toward how the bike will be used, maintained, and even crashed. The result is a versatile family of panels that can be mass-produced with consistent quality, yet tailored to the demands of street bikes, sport machines, and race machines alike.

A close look at ABS reveals why it has become the mainstream choice for fairings across many manufacturers. Acrylonitrile butadiene styrene is prized for its well-rounded performance: good strength, solid impact resistance, and a processing window that suits high-volume production. For manufacturers, the injection-molding process—where molten plastic is injected into a mold to form complex shapes—offers speed, repeatability, and tight tolerances. ABS parts emerge with smooth surfaces and predictable shrinkage, which translates into reliable tool paths for painters and clear coats. These attributes are not merely technicalities; they map directly to how riders experience the bike. A fairing carved from ABS can be shaped with sharp lines and aerodynamic profiles, then finished in a glossy or matte veneer that resists the elements while preserving color fidelity. The material’s impact resistance is especially valuable in the event of a low-speed collision or a runway-like gust that might nudge a bike off line.

But no single plastic can claim perfection for every scenario. ABS is strong and surprisingly tough, yet it has its limits. Its thermal performance is adequate for standard riding conditions, but sustained high engine temperatures or fast, sustained high-speed airflow can push the material toward softer edges and long-term creep. Prolonged exposure to UV light can accelerate surface degradation and color fading, a factor that riders often notice after years of sun exposure. To mitigate these risks, manufacturers frequently add UV stabilizers and surface finishes, and in many cases, standard ABS is reinforced with protective coatings. This approach keeps the outer shell looking fresh while maintaining the core mechanical attributes that make ABS so economical and manufacturable.

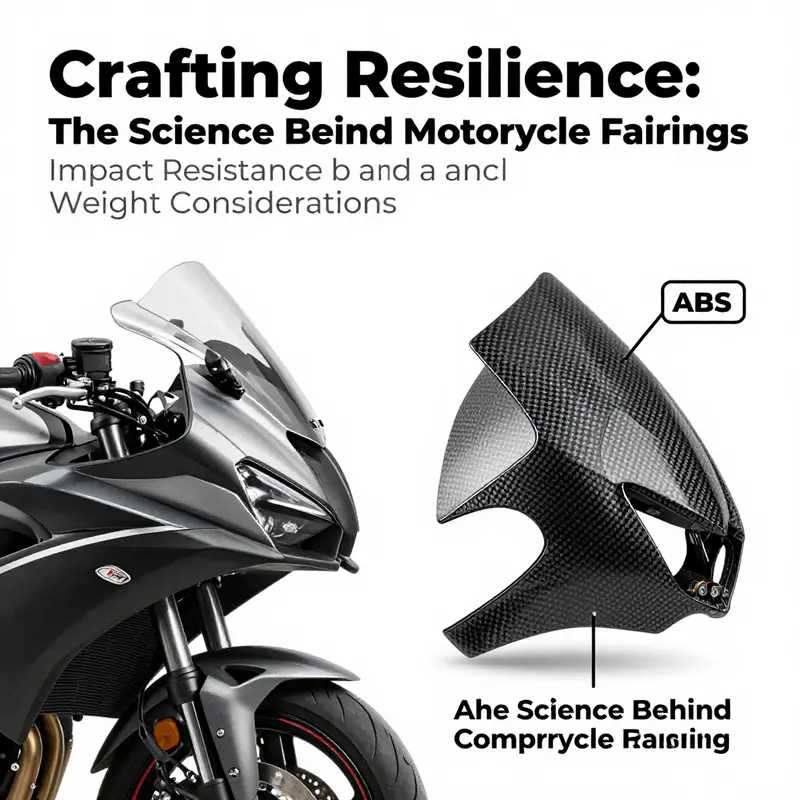

Where ABS shines in daily use, PC/ABS blends extend the envelope of durability. Polycarbonate brings stiffness and heat resistance to the table, and when it is blended with ABS, the resulting material inherits a tougher, more thermally robust character. The blend is especially appealing in high-performance or racing contexts where brief bursts of engine heat, aerodynamic heating, and more aggressive riding dynamics can test a fairing’s endurance. PC/ABS adds toughness under impact while preserving the ease of processing that makes ABS so attractive for mass production. In practice, PC/ABS can absorb more energy during a crash without cracking in small, localized zones, which matters when a rider’s survival and comfort hinge on the fairing maintaining integrity during and after a slide or impact. It also handles temperature excursions better, reducing the risk of warping or delamination as the bike’s body elements heat up under the sun or during long straights with high ambient air flow.

The PC/ABS advantage does not come without trade-offs. The blend typically costs more than standard ABS, and its higher thermal and mechanical performance can complicate processing details. Some molding temperatures are higher, and the material’s viscosity behavior requires careful mold design to avoid issues like shear-induced degradation or incomplete filling in complex geometries. Yet for riders who demand a higher degree of heat resistance and structural assurance, PC/ABS represents a pragmatic upgrade that preserves color stability and surface finish, even under strenuous riding conditions. In the realm of accessories and performance parts, PC/ABS has become a preferred option for tail sections, fenders, and other exterior panels that must withstand both the wind-blast of high-speed aerodynamics and the incidental impacts that occur in busy environments.

Beyond these two mainstream options lies the realm of carbon fiber composites. Carbon fiber offers a different set of principles: remarkable stiffness-to-weight ratio, exceptional fatigue resistance, and outstanding thermal stability. When carbon fiber is used for fairings, it is typically realized as a composite: layers of carbon fiber embedded in a resin matrix. This structure delivers a level of rigidity that can help maintain precise aerodynamic contours under load and over time. Carbon fiber’s lightweight nature translates to performance dividends—massive reductions in unsprung weight and a lower overall bike weight, which in turn influences handling, acceleration, and braking behavior. Yet carbon fiber is not a universal replacement for ABS or PC/ABS. The cost of raw materials, specialized manufacturing equipment, and the artisanal level of control required to lay up and cure carbon fiber components push fairing costs into a premium tier. For most street deployments, the durability and economy of thermoplastics win out; for top-tier racing and some limited-edition models, carbon fiber’s advantages justify the investment. In those high-performance contexts, carbon fiber’s surface finish may also require different aesthetic treatment, as the natural appearance of the weave and its potential subtleties can be accentuated with clear coatings designed to preserve depth and resonance under racing lights and camera scrutiny.

The decision to use ABS, PC/ABS, or carbon fiber is less about a single property and more about an engineering compromise stretched across the entire motorcycle system. Fairings do not operate in isolation; they interact with subframes, mounting hardware, gaskets, and the engine’s heat management plan. They must resist wind-driven moisture, absorb some of the mechanical energy of impacts, and endure sudden temperature swings as riders shift between shady canyons and sunlit straights. The surface finish—gloss, matte, metallic—must stay vivid across years of washing, waxing, and accidental abrasion, which means the base resin’s color stability and the quality of the protective coatings matter as much as the base polymer’s intrinsic properties. In practical terms, the standard ABS panel is a tried-and-true choice when cost, manufacturability, and surface quality are the priority. It provides a solid canvas for aerodynamics, branding, and color—an essential triad in a market that prizes both performance and presentation.

The PC/ABS option sits between ABS and carbon fiber in the spectrum of properties. It offers improved impact resistance over plain ABS and a higher heat tolerance that guards against deformation under the sun or behind the fairing’s own generated heat. This makes it a natural fit for sports bikes that push the envelope in speed and continuous engine operation, where a slightly larger buffer against thermal effects can preserve the panel’s geometry over time. The blend also tends to retain a good surface finish, which is crucial for the bike’s visual identity. Riders who demand longevity in high-temperature environments—such as prolonged highway riding in hot climates or long races with intense engine activity—often benefit from PC/ABS’s extended service envelope.

For those chasing maximal lightweight performance, carbon fiber’s appeal is undeniable. Its use in fairings is typically reserved for high-end, performance-focused models or specialized race machines. The weight savings and stiffness can contribute to more precise steering response and reduced rotational inertia, which matter when aerodynamics and rider control are under scrutiny. However, carbon fiber is more complex to process. It requires precise layups, controlled curing cycles, and protective measures to prevent fracture under edge loading. Its appearance, while striking, can also be more sensitive to surface imperfections if not properly finished. In some cases, manufacturers combine carbon fiber with thermoplastic skins or use carbon-fiber-reinforced plastics (CFRP) to create load-bearing shells that retain impact resistance while exploiting carbon’s strength-to-weight advantage.

From a manufacturing perspective, the choice of material influences how fairings are designed and assembled. ABS parts are well suited to standard injection molding, and the process is forgiving when it comes to intricate surface details. Paint shops can apply and seal coatings with high repeatability, enabling consistent color and gloss across thousands of units. When PC/ABS is specified, the molding window remains broad but requires careful attention to thermal history to avoid warping or micro-cracking in sharp corners and radii. For carbon fiber, the production line becomes a hybrid of materials science and craft. The layup sequence, resin system, and curing regime must be tightly controlled. Even the choice of a protective clear coat becomes a strategic decision: whether to emphasize the weave’s aesthetic or to create a seamless surface that reads like a single material. The result is a spectrum of production philosophies that reflect each brand’s philosophy of durability, performance, and rider experience.

Surface appearance is another arena where these materials diverge. ABS, thanks to its compatibility with a wide range of finishes, can be coated to achieve anything from a deep gloss to a contemporary matte. The surface can hold decals, metallic flecks, or gradient fades with minimal risk of distortion after curing. PC/ABS maintains color stability under UV exposure better than plain ABS in many cases, which translates to longer-lasting color integrity for bikes that spend more time sunny than shaded. Carbon fiber, by contrast, offers a distinctive optical character because of the weave. Some riders and designers love that the exposed weave adds a tactile, high-tech aesthetic, while others prefer a uniform paint layer over a CFRP shell. In either case, finishing carbon fiber fairings requires compatible sealants, clear coats, and sometimes additional surface preparation to prevent micro-cracking at the edges where the resin system meets the reinforcing fibers.

Durability in the field harkens back to how fairings absorb energy. ABS can deform yet absorb energy in a way that protects the inner components during minor impacts. It can be repaired in many cases with conventional automotive repair methods, and scratches can often be sanded and repainted, allowing an owner to restore the panel’s appearance without a full replacement. PC/ABS strengthens that energy absorption profile and reduces the likelihood of micro-cracking in the sure-to-happen stone chip or low-speed tumble. The response to environmental extremes—hot sun, rain-soaked roads, cold wind—stays favorable, provided the resin chemistry is properly stabilized and the panel is not subjected to cycles of extreme heat and rapid cooling that could provoke thermal fatigue. Carbon fiber panels behave differently in the face of damage. While the damage may be more challenging to repair—requiring specialized procedures—the weight savings and stiffness can preserve aerodynamic integrity even when a portion of the weave is compromised. In practice, this means a rider’s risk calculus changes with material choice: ABS or PC/ABS for broad accessibility and repairability, carbon fiber for specialized performance where weight and stiffness deliver tangible benefits.

Sustainability and lifecycle considerations are not afterthoughts. Thermoplastics like ABS are, in the broad sense, recyclable, especially when collected from production streams and processed into new parts. PC/ABS blends introduce additional recyclability questions because of the mixed resin system, but advances in plastics recycling have made it increasingly feasible to reclaim and reprocess high-value materials. Carbon fiber, with its composite nature, presents a different challenge. Recyclability tends to be more complex and less economical in many factory settings, prompting designers to consider long service life, repairability, and end-of-life strategies that minimize waste. In the end, the material choice reflects not just mechanical requirements but also environmental goals, manufacturing footprints, and the broader sustainability program of the motorcycle’s brand and network of suppliers.

Among these considerations, the final selection mechanism often reduces to a layered assessment: how hard the bike will ride, where it will live, how heavy it can afford to be, and how the total cost of ownership stacks up over the bike’s expected life. ABS provides broad usability with straightforward manufacturing. PC/ABS adds a cushion of resilience for hotter or more demanding environments. Carbon fiber delivers peak performance in the most demanding contexts, with a cost structure that matches the premium outcomes it secures. The art of choosing a material for a motorcycle fairing is thus not a single decree but a series of calibrated decisions. In daily use, the aim remains constant: preserve rider safety, protect essential components, and maintain the motorcycle’s visual identity across miles of pavement and time.

For readers who want to explore practical implications and see how materials translate into real-world parts, this deeper dive into the catalog of fairing options can offer a tactile sense of the choices at hand. fairings catalog provides a concrete sense of how panels are shaped, finished, and positioned as part of a broader design language. While the catalog itself is a repository of parts, the materials behind those parts reveal the logic engineers use when balancing strength, weight, and aesthetics. The same logic is at work across brands and models, as manufacturers seek to deliver fairings that endure the road, protect the rider, and remain visually compelling for years.

In sum, the typical motorcycle fairing falls into a family of thermoplastics characterized by ABS and PC/ABS as the workhorse materials, with carbon fiber reserved for the upper end of performance. This material triad reflects a broader engineering philosophy: use a material that aligns with the bike’s mission, from everyday commuting to track-level performance, and ensure that the resulting shell contributes positively to aerodynamics, protection, and longevity. As technology and recycling methodologies evolve, the line between these materials may blur further, with new blends and composites offering improved combinations of impact resistance, heat tolerance, and weight. But the central truth remains clear: the plastics chosen for motorcycle fairings are not incidental. They are the visible and functional embodiment of a careful engineering conversation about safety, speed, and style.

External reference for further reading on plastics in motorcycle fairings can be found here: https://www.engineeringtoolbox.com/plastics-motorcycle-fairings-d_1952.html.

null

null

Material Truths Under the Skin: How Plastic Types Shape Performance, Safety, and Style in Motorcycle Fairings

The outer skin of a motorcycle—the fairing—does more than just shield the rider from wind and rain. It defines the bike’s silhouette, channelizes airflow, and bears the brunt of debris and weather at speed. Yet the material that forms this shell is rarely noticed by most riders until a scuff, a crack, or a color mismatch catches the eye. Material choice is a hidden engineering conversation, balancing strength, weight, cost, and manufacturability while also shaping aesthetics and long-term reliability. In the world of motorcycle fairings, plastic is not a single, monolithic entity. It is a family of polymers, each with a fingerprint of properties that can tilt performance toward protection, speed, or style. The dominant workhorse in many production motorcycles is ABS—acrylonitrile butadiene styrene. ABS stands out for its toughness, impact resistance, and ease of manufacture. It is especially well-suited to injection molding, a process that can rapidly create complex, curved fairings with consistent wall thickness and smooth surfaces. The material’s inherent ductility allows fairings to deform rather than shatter when subjected to accidental impacts or road hazards. For riders, that translates into fewer punctures or fractures during a run over rough highways or a minor tip-over in a parking lot. For manufacturers, ABS reduces scrap, shortens cycle times, and keeps unit costs in check. The trade-off, of course, is that ABS is not an unstoppable shield. Under prolonged heat, UV exposure, and the occasional high-speed impact, ABS can yellow, craze, or lose its gloss. The polymer’s stability hinges on additives, surface coatings, and the exact processing window used in molding. These decisions ripple through a bike’s lifecycle: serviceability, repainting after collisions, and resale value after years of exposure to sun and weather. The next layer of sophistication enters the scene with PC/ABS blends—polycarbonate and ABS combined to produce a material with higher impact resistance and better heat tolerance. In high-performance or premium motorcycles, PC/ABS strikes a balance between the rugged toughness of ABS and the temperature resilience of polycarbonate. The blend improves resistance to thermal softening in hot engine bays, reduces the risk of crazing from repeated sun exposure, and helps maintain a glossy, smooth finish under demanding riding conditions. It is not a magic wand, however. PC/ABS typically carries a higher cost than pure ABS and can require more careful control of processing temperatures to prevent delamination or warping in extreme heat. Yet for riders who push their machines to the limit on sunny coastal highways or track days, PC/ABS offers a measurable cushion against heat-related distortions and the microcracking that can accompany repeated thermal cycling. For the rarefied tier of sportbikes and track-focused machines, carbon fiber composites enter the conversation. Carbon fiber brings an extraordinary stiffness-to-weight ratio and exceptional fatigue resistance, but at a price. Carbon fiber fairings are often lighter than their ABS or PC/ABS counterparts, and they can be molded or laid up to produce near-seamless, aero-efficient shells. In practice, many riders encounter carbon fiber in a hybridized form: outer cosmetic panels or selected structural sections laminated with thicker carbon fiber layers, paired with a core of thermoplastic or polymer composite to keep costs in check. This approach delivers high-speed stability and improved rider protection without the proportional expense of a full carbon construct. The result is a tiered material strategy: ordinary-market motorcycles lean on ABS for durability and cost efficiency, premium machines lean on PC/ABS for improved heat tolerance and sustainment of finish, and top-tier machines borrow carbon fiber where performance gains justify the investment. An additional layer of nuance comes from the role of windshields and transparent facets on many fairings. In those applications, polycarbonate offers superior impact resistance and toughness, often with scratch-resistant coatings that resist fingernail marks and environmental abrasion. Acrylic (PMMA) can deliver crystal-clear clarity but tends to crack under sharp impact and may yellow with age. PVC, less common for high-end transparency, can be used in certain environmental sealing roles or interior linings. This spectrum of materials underscores a more general truth: the fairing is a composite in the broadest sense, combining different polymers to meet the diverse demands of speed, weather, and rider protection. The manufacturing processes themselves reflect these demands. ABS and PC/ABS are ideally suited to injection molding, a mass-production workhorse that can reproduce fine features—air channels for cooling, integrated mounting bosses, and smooth radii—while maintaining uniform wall thickness. The ability to inject- mold complex geometries contributes to consistent part quality, reduced post-processing, and the capacity to incorporate color and texture within the mold. Paint application on ABS-based parts is well established. Primers and base coats adhere reliably, and clear coats can embed a high-gloss finish that resists UV degradation when properly formulated. The paint layer is not merely cosmetic. It adds a protective barrier against moisture, minor abrasion, and chemical exposure from road salts and cleaning agents, extending the life of the outer shell. In high-end configurations, a protective coating on PC/ABS or polycarbonate components may further reduce surface scratching and maintain optical clarity for longer periods. The interplay between material choice and environmental exposure is a practical concern for riders who live in regions with strong sun, high humidity, or corrosive road conditions. ABS on its own can be sensitive to UV light, gradually losing its impact strength and color saturation if left unprotected. UV stabilizers, antioxidants, and surface coatings are common remedies, but they introduce additional cost and mass. PC/ABS can mitigate some of these UV-related issues due to the inherent stability of polycarbonate, but again, coatings and maintenance play a role. When fairings are built for racing or other extreme use, manufacturers may incorporate carbon fiber in strategic locations to reduce weight where it matters most—often at the leading edges, under panels, or in areas that bear the most aerodynamic load. The engineering logic is straightforward: a lighter fairing surface reduces inertia and can improve throttle response and cornering stability, especially in high-speed straight lines and during rapid directional changes. Yet carbon fiber comes with its own set of constraints. It requires specialized layup processes, skilled fabrication, and careful quality control. The result is a panel that can be exquisitely light and exceptionally strong but far less forgiving in terms of repair speed, color matching, and overall cost. For most riders, the fairing’s life-cycle realities—repairs after a mishap, repainting after a scrape, and replacement after long-term wear—drive material selection as much as performance performance. ABS can be relatively easy to repair with standard plastic welding techniques or patching materials. PC/ABS, with its additional polycarbonate content, can require more careful heat management during repair, but it still offers repairable resilience. Carbon fiber panels, while offering superior stiffness, often demand a more specialized repair approach, with a higher risk of finishing inconsistencies if the layup is damaged. An everyday consideration for riders is the weight difference between materials. A lighter fairing translates into a small but meaningful improvement in handling, throttle response, and fuel efficiency, especially on longer rides where every ounce matters. Weight savings in high-performance builds can enable crisper steering and more precise air management, contributing to better overall ride quality at speed. The subtle but real performance difference emerges most clearly in aero-vehicle dynamics. The fairing’s shape works in concert with the material’s stiffness, flexibility, and ductility. A slightly more flexible ABS panel can absorb minor impacts without transferring forces to the rider or to the motorcycle’s frame. A stiffer PC/ABS panel helps maintain a smooth surface at high speeds, preserving laminar flow and reducing turbulent wake that could otherwise increase drag. Carbon fiber, being extremely stiff, helps maintain a precise shape under load, which matters when wind loads grow with speed or when a rider adopts aggressive riding angles. The aesthetic dimensions of material choice cannot be ignored. The colorfastness of ABS provides designers a broad palette and predictable repainting workflows. Plastics can be pigmented through the entire mass of the part or applied as surface coatings, offering a spectrum of finishes from high-gloss gleam to matte textures. The surface texture can also influence perceived temperature—dark, glossy finishes absorb more solar heat than lighter, matte ones. These choices ripple into rider comfort at rest and in motion, where even a small temperature differential across a fairing’s surface can affect perceived heat near the torso and arms. The conversation about materials also touches on lifecycle and sustainability. ABS and PC/ABS are more readily recyclable in many regional programs than carbon fiber composites, which pose recycling and reclamation challenges due to mixed materials and resin matrices. This is not merely an environmental concern; it influences production planning, disposal costs, and the long-term economics of a model’s design. In a sense, the material choice reflects a philosophy of balance: everyday reliability with responsive performance for mass-market motorcycles, or weight savings and stiffness for limited-edition or racing-oriented builds. The dialogue among ABS, PC/ABS, and carbon fiber is not about a single “best” plastic. It is about a careful alignment of properties to intended use, climate, maintenance regime, and the rider’s expectations for durability, serviceability, and aesthetics. For the reader curious about how these material decisions translate into real-world options, a broader view of the market reveals a spectrum of fairings tailored to different riding cultures and budgets. Model variety stems from the materials chosen for the shell and, importantly, for the transparent components that complete the aerodynamics package. In this light, the fairing becomes a case study in material science where chemistry, manufacturing, mechanical engineering, and design language converge. It is a reminder that the illusion of sameness—an identically shaped panel—hides a hidden calculus of performance metrics and lifecycle costs. For readers who want to explore how these material choices appear across different models and brands, the Honda fairings collection offers a useful snapshot of the range of design decisions in contemporary motorcycles. Honda fairings collection demonstrates how the same fundamental polymer families can be spun into very different outcomes, depending on the demands of the bike, the expectations of its riders, and the technical constraints of production. Ultimately, material choice is not a single lever you pull to improve a bike. It is a multi-dimensional conversation about how a fairing deflects wind, resists impact, preserves rider comfort, and ages gracefully under sun and rain. When a rider tilts the helmet toward the wind and sets the throttle, the fairing’s material is at work—absorbing shocks, maintaining alignment, and keeping the surface finish intact long after the first track day. The chapter’s objective is not to pick a winner in a vacuum but to illuminate how the selection of ABS, PC/ABS, or carbon fiber as the foundational shell informs nearly every downstream outcome. From processing ease to repair cycles, from paint compatibility to long-term color stability, from weight to aero stability, the material under the skin is a silent partner in every ride. For those who want to dive deeper into the science of transparency and impact, the windshields on many motorcycles provide a parallel case study. Modern shields made from polycarbonate typically outshine acrylic in impact resistance and maintain optical clarity under abrasion and environmental exposure. Coatings further extend life, reducing scratch marks and keeping visibility high even after years of highway duty. This layered understanding—how core polymers interact with coatings, additives, and processes—helps explain why fairing design remains an active field of material science, engineering, and art. The practical implication for riders is straightforward: when shopping for a new bike or a replacement panel, consider how the manufacturer’s material choice aligns with your riding style, climate, and service plan. If you ride in hot climates or participate in frequent track days, PC/ABS may offer the best blend of heat tolerance and durability. If budget and serviceability are paramount, ABS provides a weaponized combination of toughness and manufacturability. If ultimate weight reduction and stiffness are the guiding stars, carbon fiber variants—though pricier—can deliver a noticeable ride feel in the right chassis. In all cases, the story is the same: the fairing’s material is a handshake between design intent and physical reality. It is the quiet force that makes a rider feel fast, safe, and aesthetically satisfied every time the wind hits the face and the machine responds with predictable, confident balance. External resource: https://www.cycleworld.com/article/motorcycle-windshield-materials-performance

Beyond Traditional Plastics: How Advanced Materials Redefine Motorcycle Fairings

Motorcycle fairings are no longer a simple shield against wind and debris; they are a front line where material science, design, and engineering converge to influence handling, efficiency, and rider safety. The evolution from basic thermoplastics to a toolkit of advanced materials reflects a broader shift in how manufacturers think about weight, stiffness, heat tolerance, and the survivability of riders in demanding conditions. At the core of this shift remains a material conversation that starts with the well-worn workhorse of the industry and moves outward toward composites, elastomeric innovations, and intelligent system integration. The result is a more tuned, more resilient, and more adaptable fairing system that can be shaped not only to cut drag but to accommodate sensors, lighting, and absorbing mechanisms that dampen the ride itself. ABS, Acrylonitrile Butadiene Styrene, has long served as the backbone of mass-market fairings. It offers a compelling mix of toughness, impact resistance, and processability. Injection molding makes ABS cost-effective at scale, and its ability to hold paint and finish produces a glossy, showroom-ready surface that appeals to enthusiasts seeking a pristine look straight from the showroom floor. ABS’s heat resistance, while adequate for everyday riding, becomes a more nuanced factor in high-performance or extended-heat environments where engine bay radiance or radiant sun exposure can stress surface coatings and underlying substrates. This is where PC/ABS blends begin to appear as a natural evolution. PC/ABS blends combine the resilience and processability of ABS with the higher heat tolerance and clarity of polycarbonate. The result is a material that can withstand longer exposure to heat and UV light without compromising surface integrity or color stability. For riders who push into spirited riding or long sessions on hot tracks, PC/ABS blends offer a margin of safety in the form of less surface deformation and more durable paint finishes. The blend also supports more demanding aesthetics, enabling deeper hues and more consistent gloss under varying lighting conditions. Yet, even PC/ABS has its trade-offs. While it improves resilience, the raw material cost is higher, and the molding process can demand tighter controls to maintain dimensional stability across different bodywork sections. For high-performance or premium models, the conversation often shifts toward composites. Carbon fiber, in particular, has entered the discourse as a material that can dramatically reduce weight while boosting torsional stiffness and impact resistance. The allure is understandable: lighter fairings translate to improved acceleration, handling, and fuel efficiency, while stiffer panels resist aerodynamic flutter at high speeds. Carbon fiber can also enable more sculpted geometries, allowing designers to craft aerodynamically optimized shapes with fewer compromises. The higher cost and more complex manufacturing—often involving prepregs, autoclave curing, or hand-linished layups—mean carbon fiber remains a niche choice for top-tier or racing-oriented models. It is not a universal substitute for thermoplastics, but rather a parallel path that expands the toolkit available to engineers and designers. The present chapter’s most striking pivot comes from real-world innovation in carbon fiber approaches that blur the line between consumer fairings and performance aerospace. Reports from a Guangzhou-based initiative, the Low-Altitude Sky Team, suggest self-developed carbon fiber materials are being employed to cut weight further while increasing payload capacity. This combination—lighter weight with higher effective carrying capacity—speaks to a broader optimization strategy: fairings that help the bike shed weight where it matters and still support additional equipment or rider protection. In practice, that translates to improved maneuverability and response across a wider range of speeds and riding scenarios, from tight urban confines to sweeping high-speed runs. The potential ripple effects extend beyond raw performance: better aerodynamics, reduced engine load, and lower overall fuel consumption, all of which contribute to lower emissions and better efficiency over the life of the motorcycle. Alongside the hard structural materials, elastomeric and damping technologies are reshaping the way fairings interact with the rest of the machine. Cellasto®—a high-compressibility elastomeric solution—offers resilience against oils and other fluids while maintaining durability under repeated loads. In fairing assemblies, these smart elastomeric blocks can serve as vibration-damping buffers or as part of sensitive mounting schemes. The practical effect is a quieter, smoother ride with less transmitted vibration to the rider and the chassis. In a sport or off-road context, where rough surfaces and abrupt throttle inputs are the norm, damping elements embedded within or adjacent to the fairing can dramatically improve ride quality and component longevity. The net result is not simply a more comfortable ride; it is a more reliable system that retains its cosmetic integrity and structural performance after repeated exposure to heat, oil, and physical shocks. Design is not an afterthought but a core driver of material selection. The fairing must be aerodynamic, protective, and aesthetically compelling, all while accommodating lighting, sensors, and airflow management. The design language in recent years has embraced dynamic aesthetics and functional integration. Award-winning concepts from major design events reveal a trend toward forms that breathe with the bike’s performance envelope—think of taillight systems that respond to braking with dramatic illumination and shapes that seem to harness air as a design element rather than merely redirect it. Such features demonstrate that modern fairings can be both expressive and functional, a philosophy that pushes materials science to deliver surfaces that are not only glossy but intelligent. In this context, carbon fiber and advanced elastomeric dampers become not just parts of the visible shell but integral players in a holistic system that couples lighting, aero, and chassis dynamics. For riders who want to see tangible examples of current offerings, a look at the broader market is informative. In particular, the Honda fairings collection provides a window into how OEMs implement fit, finish, and compatibility across multiple models and generations. It is instructive to consider how these fairings balance protection, weight, and serviceability while preserving a uniform appearance across model lines. For readers who want to explore options more directly, a practical path is to examine a few representative lines and compare finish quality, fitment accuracy, and paint stability under stress testing. See the Honda fairings collection for context and tangible reference points in the ongoing material conversation. Beyond the raw materials and the hardware, the industry story is increasingly about intelligent, adaptable systems. The market for motorcycle accessories, including tailboxes and similar components, has grown to hundreds of millions globally, driven by consumer demand for utility, personalization, and technological integration. Market analyses project continued expansion in the accessory segment, with tailboxes alone approaching hundreds of millions in value and a steady CAGR that signals strong consumer appetite for modular, integrated solutions. In this environment, fairings are not mere shells; they are platforms that can host sensors for air flow, temperature, or vibration, integrate micro-motors for dynamic shaping, and support data wiring for connectivity and telemetry. The vision is a fairing system that can be tailored to rider preferences—weight, finish, aerodynamics, and even the feel of the ride—through modular components and smart materials whose properties can be tuned by design. The design and material story would be incomplete without acknowledging the sustainability dimension. Plastics, by their nature, pose questions about recyclability and end-of-life handling. ABS and PC/ABS blends can be recycled in certain streams, but the downstream processes must be robust and well-managed to preserve material integrity and minimize waste. Carbon fiber, while offering performance advantages, raises questions about recycling and scrap handling that industry players are actively addressing through process innovations and closed-loop initiatives. The push toward lighter, more efficient fairings aligns well with broader sustainability goals, as lower vehicle weight reduces energy demand over the motorcycle’s operating life. Yet the pursuit of lighter, stronger, and more integrated materials must be balanced with environmental considerations, end-of-life strategies, and the economic realities of advanced composites manufacturing. In addition to material choice, manufacturing approaches themselves are evolving. The ability to combine plastics and composites within a single fairing structure—sometimes through hybrid layups or through overmolded interfaces—offers opportunities for optimizing stiffness where it matters most and allowing soft, compliant edges to absorb impact energy. This kind of hybridization supports more complex geometries, improved fitment, and more resilient assembly under vibration and temperature cycles. It also opens the door to functional integration where sensors, fasteners, and damping elements are seamlessly embedded during production, rather than added as post-assembly features. The future is less about choosing one material and more about orchestrating a material system where each component contributes to a larger performance envelope. The implications for riders extend beyond the track. Aerodynamic efficiency, precise handling, and NVH reduction translate to real-world benefits such as reduced rider fatigue over long distances and better control in adverse conditions. Lightweight, stiff, and well-damped fairings can contribute to more predictable handling when lean angles increase or when wind gusts buffet the bike at highway speeds. The integration of advanced elastomeric dampers and smart materials helps to maintain a refined riding feel even as overall weight trends downward. In this sense, the material story becomes a riders’ performance story, with engineering choices translating into measurable improvements in comfort and safety. As the fairing ecosystem evolves, the future will likely feature a blended materials strategy that marries thermoplastics, composites, and smart damping. This approach balances the cost and manufacturability advantages of ABS with the lightness and stiffness of carbon fiber and the resilience of elastomeric dampers. It also accommodates design ambitions that favor expressive, technologically integrated forms. For designers, the challenge is not simply to reduce weight but to maintain or improve impact resistance, surface finish, and durability across a rider’s lifetime, while enabling future upgrades through modular or embedded systems. For engineers, the challenge is to ensure that these material systems play well with vibration, acoustic behavior, and heat management—an area where the interface between materials science and mechanical design becomes as critical as the chemistry itself. Looking ahead, the convergence of new materials and new design methodologies may enable even more dramatic breakthroughs. The idea of adaptive aerodynamics—structures that respond to speed, wind, and rider posture—could become feasible as sensors, actuators, and materials interact in real time. Lightweight, high-strength fairings could host embedded sensors that monitor temperature, strain, and airflow, feeding data to adaptive control systems that optimize cooling and drag reduction on the fly. The modular component concept—where fairings, tail sections, and canards can be swapped or reconfigured for different riding styles—could bring customization to an entirely new level, turning each bike into a bespoke platform aligned to individual performance goals. For readers seeking a broader frame of reference on current trends and innovations in motorcycle fairing technology, a survey of design awards and critical design commentary offers a useful compass. The Red Dot Design Award, for example, highlights how form and function converge in modern motorcycle design, drawing attention to how material choices support not only aesthetics but also ergonomic and aerodynamic goals. This kind of recognition points to a broader industry consensus: fairings are vehicles for experimentation, where materials science, mechanical engineering, and design philosophy come together to push what a two-wheeled body can do. The future of fairings will likely be shaped as much by these cultural and perceptual shifts as by any single material breakthrough. For a deeper dive into design philosophy and award-winning concepts, the Red Dot Design Award resource provides a useful touchstone for understanding how contemporary motorcycles translate material capability into usable, attractive form. External resource: Red Dot Design Award for motorcycles

Final thoughts

A comprehensive understanding of the types of plastics used in motorcycle fairings, such as ABS and PC/ABS, highlights their importance in durability, weight reduction, and manufacturing efficiency. As technology and material science evolve, staying informed about innovations in motorcycle fairings will be crucial for business owners looking to remain competitive. By leveraging quality materials and advanced manufacturing processes, businesses can enhance their product offerings and satisfy customer demands for performance and aesthetics.