Motorcycle enthusiasts have long sought ways to enhance performance, comfort, and protection on the road, and Windjammer fairings stand out as a solution that achieves all three. Specialized bodywork designed for motorcycles, Windjammer fairings offer optimal aerodynamics, significant weather protection, and rider comfort—elements crucial for those who value both style and function in their rides. This article will delve into the multifaceted advantages of Windjammer fairings, discussing their aerodynamic benefits, weather shielding capabilities, mounting compatibility, innovative designs by Craig Vetter, and current market trends. Through this exploration, business owners will gain a comprehensive understanding of how these fairings can elevate the motorcycle riding experience and cater to the needs of their customers.

null

null

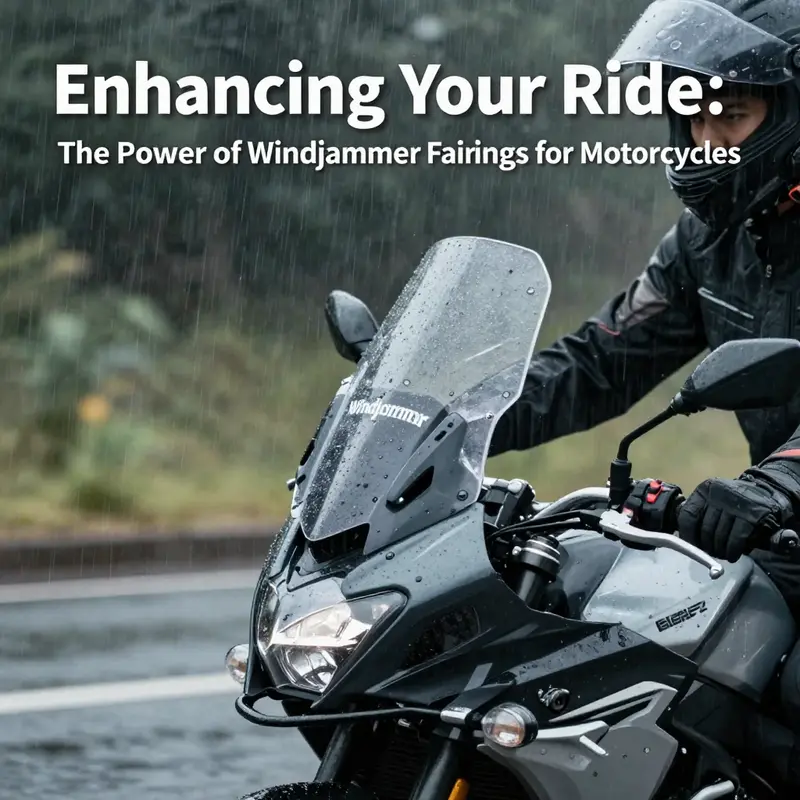

How Windjammer Fairings Block Wind, Rain, and Cold for Long Rides

Windjammer fairings transform the rider’s interaction with the elements by redirecting airflow and creating a protective envelope around the upper body. Instead of fighting gusts and spray, a rider behind a well-designed fairing experiences reduced buffeting, less direct rain, and a measurable drop in cold air exposure. This shift matters most on long tours and high-speed runs, where constant wind stress and weather exposure cause fatigue, chill, and reduced focus.

At the core of that protection is purposeful shape. Windjammer fairings use smooth, aerodynamic curves and extended lower edges to intercept and guide oncoming air around the rider. The fairing’s height and width are not decorative choices; they define the sheltered zone. Taller designs lift the wind column over the helmet and upper torso. Wider profiles wrap the shoulders and divert slanting rain that otherwise splatters the chest and arms. The result is a calmer pressure field in the rider’s space and less water driven into seams, vents, and clothing zippers.

Fitment is the practical side of weather defense. A fairing must seat cleanly against the bike’s frame and windshield hardware to avoid gaps that channel wind and water. Even small clearances can create turbulent showers aimed directly at the rider’s hands and lower torso. When evaluating fit, consider how the fairing mates with the motorcycle’s headlight area, handlebars, and instrument cluster. Proper integration keeps the airflow smooth and minimizes points where water collects and leaks into the cockpit area.

Mounting systems influence both protection and long-term reliability. Rigid, well-engineered mounts hold the fairing steady, preventing chatter and misalignment that worsen noise and reduce sealing effectiveness. Quick-release or bolt-on solutions each have trade-offs: the former offers convenience but must lock without play; the latter provides permanence but makes removal less flexible. A mount that allows small adjustments helps align the fairing with different windshield heights or accessories while maintaining tight seams. Sealed mounting points and vibration-damping bushings extend the weatherproofing by preventing loosening over miles of riding.

Material choice and construction details are equally important. Molded composites and layered fiberglass achieve smooth surfaces that shed water and resist fatigue. A quality finish prevents micro-fissures where moisture can enter and degrade mounting bushings or corrode fasteners. Look for fairings with reinforced edges and flush-mounted hardware to channel water away from joints. Internal drainage channels or lip seals at the lower edges can take spray away from the rider and the bike’s electrical components. These details are subtle until neglected, then they become the source of persistent leaks and corrosion.

Wind noise and rider comfort are linked to weather protection. A fairing that deflects wind but creates noisy turbulence around the helmet can defeat the comfort gains from reduced wetness. Conversely, a design that reduces wind around the head and neck improves thermal comfort by lowering wind chill without amplifying noise. The balance comes from the fairing’s curvature and the windshield’s rake and lip. Combining a taller fairing with a properly profiled windshield minimizes the direct blast to the helmet while maintaining a quiet zone where the rider breathes and hears. That quiet zone reduces fatigue and keeps the rider alert on long, wet rides.

Thermal management is a lesser-discussed but vital aspect of weather protection. By creating a sheltered cavity, a fairing limits the layer of cold air which makes contact with the torso and arms. That microclimate allows the rider’s clothing to perform more effectively. Heated grips and clothing become more efficient because warm air is retained longer inside the sheltered zone. In colder weather, the fairing’s ability to block wind provides a larger benefit than increasing insulation alone. On humid or drizzly days, the fairing keeps the rider drier and delays saturation of outer layers, preserving body heat and comfort for longer stretches.

Visibility and weather protection interact. A fairing’s windshield must shed rain and minimize optical distortion. Properly contoured windshields lift raindrops away from the rider’s line of sight and reduce streaking that forces constant helmet visor wiping. Windjammer-style fairings that accept larger windscreen profiles allow for better deflection of spray and serve as platforms for add-on deflectors or tall screens. When the windshield and fairing work together, the rider can keep a clear visual field with less need to change head position or use intermittent visor wiping, both of which improve safety during adverse weather.

There are trade-offs: larger fairings add windage in crosswinds and increase the surface area that catches side-blasts. Good design mitigates this by shaping the fairing to channel cross-currents smoothly along the bike’s silhouette. Well-designed units redirect sideways gusts around the rider and toward the bike’s chassis, reducing the leverage and steering disturbance. Riders should consider how a fairing behaves in gusty conditions for their typical routes. Coastal roads, mountain passes, and open plains each present different crosswind patterns that influence the ideal fairing profile.

Supplementary options can enhance weatherproofing without replacing a primary fairing. Clip-on deflectors, add-on lower panels, and sealed pockets for wiring reduce points where water can intrude. While universal accessories can help, purpose-built fairings that match the motorcycle’s geometry provide the most consistent coverage. Accessories should be evaluated for how they alter airflow; poorly placed add-ons can create turbulence that undermines the main fairing’s function. For riders using supplemental pieces, incremental testing at varied speeds is the best way to find a configuration that retains weather protection across conditions.

Maintenance and inspection preserve protective performance. Regular checks of mounting hardware, seal integrity, and surface condition keep water out and prevent mounting loosening that degrades comfort. Clean finishes repel water and make it easier to spot hairline cracks or stress points. After long rides in rain or through gravel, check the fairing’s underside for lodged debris that can trap water and accelerate corrosion. Timely replacement of worn bushings and fasteners keeps the fairing aligned and effective.

Choosing a fairing for weather protection means balancing coverage, fit, mounting quality, and material durability. A properly matched fairing reduces direct wind, sheds rain from the rider’s line of sight, and creates a sheltered microclimate that lessens wind chill. Combined with careful mounting and maintenance, the benefits are endurance, reduced fatigue, and a more focused ride in poor weather. For riders seeking compatibility across different motorcycle families, exploring specialized fairings collections can reveal options tailored to specific bike geometries; for example, a targeted selection of Yamaha fairings provides models that fit sport and touring platforms without sacrificing protection.

For a manufacturer example of how integrated wind deflectors and fairing design improve rider protection, refer to this resource: https://www.harley-davidson.com/europe/en/vehicle-parts/accessories/fairings/batwing-fairing-5-in-wind-deflector.html

Anchored Aerodynamics: How Mounting Systems and Model-Specific Fit Shape Windjammer Performance

The essence of windjammer fairings is not only their curve or their surface finish, but how they enter the bike’s architecture. When a rider pushes into a headwind on a long road, the fairing’s job is to guide air smoothly around the rider and toward the radiator and wheel. That outcome depends as much on how the fairing attaches as on its own shape. The mounting system is the unseen backbone that translates aerodynamic theory into real-world stability, quietness, and comfort. Without a robust, purpose-built attachment, even the most elegant fairing can become a source of flutter, misalignment, or wind noise at speed. This is why the relationship between the fairing and the frame matters as much as the fairing’s outer silhouette itself. The design philosophy behind windjammer fairings begins with a frame-mounted approach. By connecting to the bike’s frame rather than relying solely on handlebars or sliders, these fairings gain a centralized, rigid anchor point. The frame acts as a stiff spine, resisting the bending forces generated by gusts and by the rider’s motions at highway speeds. The aerodynamic intent—curved deflection of air and a stable slipstream—depends on that spine staying true. When the mounting is well chosen and correctly aligned, the fairing can maintain its optimal angle across a range of speeds and postures. If not, the fairing tends to tilt, flutter, or separate from the airflow at the moment when the rider needs it most. The result is not just a louder cockpit, but a degradation of the very performance the fairing is meant to deliver: reduced wind protection, altered steering feel, and inconsistent buffeting. The subtlety here is that mounting is not a one-size-fits-all decision. There are different chassis geometries, steering head angles, and fork axles to consider, and each of these can influence how a frame-mounted fairing behaves. A fairing designed to hug a particular bike’s silhouette might require precise fore-aft alignment, exact vertical placement, and careful trimming of the lower edge to avoid rubbing against the upper radiator guard or the wheel’s travel path. Even small shifts in attachment points can ripple through the aerodynamics, changing the fairing’s effectiveness and the rider’s sense of comfort. The compatibility conversation that follows mounting is equally important. Not every frame will accommodate every fairing design, even if the basic mounting philosophy is the same. The critical variables are typically model-specific: frame width at the headstock, mounting point spacing, downtube diameter, and the presence of any interfering hardware such as instrument clusters, ignition coils, or battery boxes. In many cases, a fairing is engineered to fit a particular model’s year range, because frame geometry can change as manufacturers revise chassis components. In practice, this means riders must verify that a given fairing kit was designed for their exact make, model, and year. The risk of a mismatch goes beyond cosmetic misalignment. If the fairing’s mounting points do not align with the frame’s hard points, installation can become a compromise. Bolts might need adapters, gaps could appear between the fairing and the fork crown, and the upper edge might clash with the headlight or dash assembly. In worst-case scenarios, misfit can create stress on the mounting hardware, leading to loosening over time or even failure under high-speed gusts. The practical path through this complexity starts with careful reference to fitment guides and official specifications. Reputable manufacturers and trusted retailers usually publish year-by-year charts that map applicable models to compatible fairing designs. The moment a rider discovers a discrepancy—such as a slightly different bolt pattern, different spacing between mounting points, or a frame feature that blocks a docking bracket—the prudent move is to pause and reassess. Compatibility is not merely about whether a fairing can be physically attached; it is about whether it will perform as intended under the bike’s specific geometry and rider posture. A fairing that fits but sits at a suboptimal angle or with imperfect seal against the tank or windscreen can function as a wind trap, channeling air in unwanted directions or creating gaps through which weather and noise penetrate. That is why guidance from the manufacturer or a trusted aftermarket source matters. They provide not only the correct parts list but also the correct mounting sequence, torque specifications, and sometimes different hardware sets for tall versus short windshields. The mechanical details—mounting bolts, spacers, grommets, and docking hardware—are more than hardware; they are the levers that tune the fairing’s interaction with air and rider. The choice between a bolt-on frame kit and a quick-release variant is not purely convenience. A bolt-on system tends to offer greater resistance to vibration and wind-induced movement, which matters at highway speeds. Quick-release options can be advantageous for seasonal storage or frequent model changes, but they demand robust latch mechanisms and precise tolerances to avoid wobble. The material selection also enters the compatibility dialogue. ABS plastic, fiberglass, and composite blends each bring different characteristics to the mounting conversation. ABS may offer friendly impact resistance and easier repair after a tip or scrape, and it often tolerates a bit more heat exposure from the radiator or engine compartment. Fiberglass or composite assemblies can provide a lighter weight and a more seamless finish, but they can be less forgiving when the frame vibrates. The rider’s purpose further shapes the mounting and compatibility calculus. A touring rider prioritizes stability and weather protection; sport-oriented riders may seek a fairing that partners with aggressive body positioning and tighter cockpit aerodynamics. In both cases, the mount must tolerate posture changes as the rider shifts weight or stands on the pegs for a corner exit. The conversation around fitment also naturally touches the windscreen system. Some kits are designed to couple with specific docking hardware or windshield heights. Compatibility here matters because the windscreen not only defines the rider’s line of sight but also interacts with the airflow around the fairing. The wrong combination can produce turbulence, which travels up the rider’s torso and into the helmet. It is thus wise to check the intended configuration against the rider’s height, riding style, and preferred shelter from the weather. For riders who value practical access to options, the market often provides a spectrum of docking solutions and mounting kits. These are designed to accommodate tall or short windshields, different clearance requirements, and even variations in the fairing’s internal bracing. That flexibility is part of why windjammer systems have persisted as a compelling choice for many decades: they can be tuned to a specific bike, a specific rider, and a specific climate. The maintenance chair of this discussion—fitment and mounting—also opens a door to the more tactile, tangible aspects of the installation. The alignment process involves more than just getting bolts tight. It requires steering the fairing into a position where the rider’s line of sight remains clear, air flows cleanly around the torso, and the lower edge threads a seamless path just above the front tire’s travel arc. In practice, this means checking the clearance around the fork crown and ensuring there is no binding as the front wheel engages compression or rebound in the suspension. A successful installation yields not only better aerodynamics but also a quieter cockpit, diminished wind noise at speed, and less perceived buffeting. It also leaves room for future upgrades or changes. The market’s existing ecosystem includes a wealth of fitment guides and community knowledge that can aid a careful buyer in selecting the right combination of fairing, frame mounting system, and windshield hardware. A practical path to navigate this landscape starts with one reliable step: verify the exact model-year fitment with the manufacturer’s specifications or a trusted retailer before purchase. For riders exploring compatible options, a direct reference to the broader world of compatible products can offer a wider sense of what works and why. A good starting point is to browse the available Honda-focused fairing collections, which provide an accessible sense of how different mounting arrangements and model-specific adaptions are deployed in real builds and restorations. See the Honda fairings collection for a sense of the variety and the practical realities of fitment in the market. Honda fairings collection. The story of mounting and compatibility is not about chasing a single ultimate design but about understanding how the bike’s skeleton and the rider’s posture cooperate with the outer shell. When this triad of frame, fairing, and dock hardware aligns, the windjammer becomes more than a stylish add-on; it becomes a predictable, integral part of the motorcycle’s aerodynamics. The result is a ride that feels calmer, steadier, and more capable across a broad speed range and weather spectrum. As with any sophisticated piece of engineering, the work lies in ensuring that the parts talk to each other as intended. This means diligence in reading fitment specifications, patience during installation, and a willingness to revisit a mounting plan if early rides reveal misalignment or unexpected noise. The payoff is a fairing that delivers on its promise: reduced drag, improved rider protection from the elements, and a quiet, confident ride that makes long-distance journeys more enjoyable rather than punishing. External resource: https://www.vetterfairings.com/products/vetter-windjammer-fairing-1979-honda-cb750k

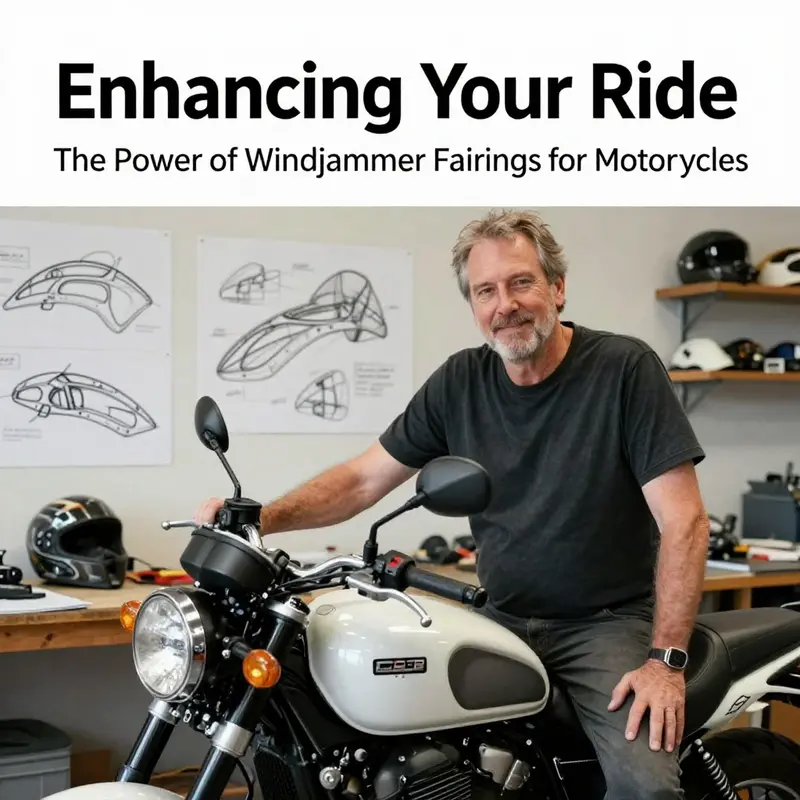

Riding the Horizon: Craig Vetter’s Windjammer Innovations and the Aerodynamic Revolution in Motorcycle Design

Craig Vetter’s innovations in motorcycle wind protection and aerodynamics began with a bold step in 1971 when the Windjammer appeared as a fully integrated fairing. It wasn’t merely a piece of plastic over a bike; it was a complete rethinking of how a rider experiences a long journey. The fairing extended forward, wrapping the headlight and instrument cluster, blending form and function in a way that reduced buffeting and made wind noise manageable while keeping the cockpit dry. The effect on rider comfort was immediate and tangible: shoulders relaxed, arms comfortable, and fatigue delayed. For many riders, the Windjammer opened a new possibility—travel farther with less effort and more weather protection.

Sales exploded; roughly a hundred thousand units found homes within a few years, a sales signal that aerodynamics and integrated design could move the market. The success did more than fill a niche; it pushed manufacturers to rethink chassis and styling to accommodate a new category of motorcycle designed around rider protection and long-range efficiency. In its wake, the cruiser archetype—long-legged, boulevard-styled machines with ample wind protection—emerged as a dominant design language in the industry. The Windjammer set a benchmark for fitment, as fairings had to align with frame geometry, steering rake, and dashboard layout without compromising ground clearance or handling. The result was a new standard that united comfort with capability, inviting riders to push farther and faster with more control over the ride.

Vetter followed with Windjammer II and Windjammer III, versions that refined edges, tuned the airflow, and addressed practical realities of mounting and serviceability. Each iteration sharpened the balance between drag reduction and weather sealing. The fairings grew sleeker, with smoother profiles and better transitions where the fairing met the handlebars, instrument pod, and tank area. More attention was paid to windshield curvature, which influenced how air separated from the surface and where turbulence began. The goal remained consistent: reduce wind pressure on the chest and helmet, minimize buffeting, and widen the rider’s stance in the saddle without constraining the knees or the hips. In practice, this meant a more confident riding posture at sustained highway speeds and a more predictable slipstream, two factors that significantly improved comfort on long rides. The improvements also helped breathing and stamina, especially when winds shifted or gusted across open terrain.

Material choices—primarily molded fiberglass and later composite blends—made these fairings sturdy yet lighter than earlier structures. The practical benefits were substantial: modular repair, easier customization, and a durable finish that could weather road salt, rain, and sun. The shape itself became part of the motorcycle’s identity, a smoothing of the silhouette that invited then-contemporary styling cues while still prioritizing rider protection. The windjammer concept, in other words, had shifted from an accessory into a defining element of the bike’s engineering envelope. The later models, including a variant known as the ST, showcased how a single fairing family could adapt to touring needs while still preserving the look that collectors and riders came to trust as part of a mature, purposeful machine. These materials and shapes demonstrated more than durability; they embodied a philosophy that the rider’s experience could be elevated without sacrificing the machine’s core performance traits.

Even as the classic fairing lineage matured, Vetter’s curiosity pushed him toward cross-disciplinary ideas. The Defiant Torpedo project—a hybrid concept that blended scooter and motorcycle elements—illustrated a continuing belief that comfort, power, and handling could be reimagined through form. Built around a Harley-Davidson Sportster engine and a custom frame, the Defiant showed that a well-designed fairing could extend beyond conventional boundaries without surrendering performance. It was a reminder that aerodynamics is not just about speeds; it is about shaping the rider’s experience, from clutch hand to ankle, through the interplay of wind, weight, and response. The Defiant’s bold experimentation underscored a larger truth: aerodynamic thinking should be applied across the spectrum of motorcycle design, from practical touring machines to unconventional platforms that challenge conventional wisdom.

For anyone seriously considering a Windjammer or similar integrated fairing today, several criteria remain essential. Aerodynamic efficiency, matching fitment to the specific bike, and reliable weather protection are the pillars. Riders must confirm compatibility with their model’s frame and the windshield docking hardware. The mounting method—whether bolt-on, adhesive, or a hybrid system—affects maintenance, vibration, and how easily the fairing can be swapped or replaced. Noise is another factor; at higher speeds, a fairing can become a source of wind chatter if the profile generates turbulent flow around the helmet. This is where careful evaluation of the boundary layer and the shape of the leading edges matters, as small changes in curvature can shift the acoustic landscape inside the helmet. Beyond the technical, there is a tactile dimension: a properly tuned fairing changes the whole relationship between rider and road, making long distances feel shorter and trips more deliberate and enjoyable.

The story of windjammer-inspired fairings is also a story about the evolving ecosystem of aftermarket parts and customization. Replacement mounting kits for various windshield heights and models exist, enabling riders to tailor the setup to winter weather or summer sport riding. Some conversions require a more substantial frame alignment, while others rely on quick-release hardware that makes adjustments practical on a two-wheel road trip. Importantly, the choice goes beyond aesthetics; it touches ergonomics and safety. A well-integrated fairing keeps the rider protected from rain and wind pressure, distributes the wind load more evenly across the torso, and reduces fatigue that could dull reaction time on a long day in the saddle. The broader implication is clear: as aerodynamics becomes a baseline expectation, the emphasis shifts from purely fast machines to thoughtfully engineered systems that support the rider throughout the journey.

Today’s riders also explore a broad spectrum of aftermarket lines that emphasize fitment and customization across a wide range of models. For example, explore the Yamaha fairings catalog, which illustrates how contemporary designs approach airflow management while aligning with frame geometry and docking systems. This lineage—rooted in Vetter’s early discoveries but evolving with modern materials and manufacturing—demonstrates that aerodynamic thinking remains central to rider comfort and control. The continuity from that initial breakthrough to today’s modular, customizable systems shows that the wind is not merely something to endure; it is a parameter to engineer around, tuned to the rider’s posture, the bike’s balance, and the road’s temperament.

Craig Vetter’s influence persists in the way designers ask how to shield a rider from wind without burying the machine’s character. His work invites designers to balance function with form, to anticipate real-world riding conditions, and to remember that aerodynamics serves the rider, not merely the machine. The Windjammer line and its successors sparked a shift in how motorcyclists value weather protection, long-range comfort, and the aesthetic that accompanies a journey. Looking forward, the challenge remains to apply those same principles to new powerplants, new materials, and new riding cultures while preserving the human-centered focus that began with that first, confident glide into the wind. As the industry continues to explore lighter composites, active aerodynamics, and modular comfort systems, the core idea remains unchanged: the rider’s experience is enhanced when wind is managed with intention, not endurance alone. This understanding keeps the horizon broad, inviting riders to pursue longer, more comfortable adventures without compromising the machine’s soul.

External reference: https://www.thedailybeast.com/craig-vetter-the-man-who-changed-motorcycles-with-a-fairing

Where to Find Windjammer-Style Fairings: Market Signals, Availability, and Buying Paths

The market for windjammer-style fairings sits at an intersection of enduring rider needs and broader shifts in the motorcycle aftermarket. Riders still want long-ride comfort, weather protection, and improved aerodynamics. At the same time, online marketplaces, changing supply chains, and material innovation are reshaping how those fairings reach buyers. This chapter traces the market cues you should watch when hunting for a windjammer-style fairing, how availability is changing, and practical ways to find parts that fit your motorcycle.

Demand and the broader aftermarket backdrop

Demand for motorcycle accessories has grown steadily across mature markets. Enthusiast communities in North America and Europe continue to invest in upgrades that enhance comfort and touring capability. That creates clear opportunity for windjammer-style fairings, which offer both functional benefits and a distinctive aesthetic. Growth in accessory categories—clutch kits, wheels, and other items—signals healthy aftermarket activity. When the overall market expands, specialized components like full fairings often follow: more sellers enter the space, used parts circulate faster, and sellers list rarer items with greater frequency.

Two trends amplify availability. First, a cultural attachment to riding in many Western countries supports healthy aftermarket demand. Riders who tour or commute are likelier to seek enhanced wind protection. Second, the shift to online retail channels increases cross-border availability. Sellers in different regions list parts on large platforms, and social commerce can surface rare or vintage fairings quickly. The result is a larger, more geographically diverse pool of sellers than a decade ago.

Supply-side shifts and material innovation

The supply side is also evolving. Composite materials and improved molding techniques reduce production costs for complex fairing shapes. That makes it viable for small manufacturers and custom shops to produce windjammer-style fairings in limited runs. At the same time, the rise of electric motorcycles encourages innovation in accessory design; streamlined bodywork often complements electric platforms, and that design attention filters into the broader accessory market.

These material and production improvements matter for buyers because they increase the variety of available shapes, mounting options, and finish quality. Smaller shops can now produce fairings that mimic the fit and finish once exclusive to larger manufacturers, and aftermarket producers often offer fit kits for multiple motorcycle frames. If you prioritize a lightweight shell or a particular finish, newer suppliers are more likely to meet those preferences.

Where the fairings turn up: channels to watch

Online marketplaces remain the primary discovery channel. Large e-commerce platforms draw international sellers who list both new and used fairings. These listings can include everything from freshly molded touring shells to reconditioned used units. Social platforms and short-form video channels are increasingly significant discovery sources. Many shops now rely on social video to demonstrate mounting systems and ride tests, and those clips often lead directly to sales.

Local classifieds and community groups remain crucial for used parts. When someone removes a fairing to change the look of their bike, the fairing often appears in local listings before it reaches broader marketplaces. If you prefer to inspect parts in person, scanning regional ads and joining owner groups focused on touring setups increases your chances of finding a well-preserved, correctly matched fairing.

Fitment and mounting realities

Availability is only part of the equation; fitment is the other. Windjammer-style fairings are not universally bolt-on. Compatibility depends on windshield docking hardware, headlight and fork geometry, and handlebar clearance. Many sellers specify compatible models, but careful measurement is essential. Look for listings that include mounting kits or specify the type of windshield bracket required.

Some fairings are sold as kits with adjustable mounting options. Others are one-off shells that require custom brackets. If a listing lacks mounting hardware, factor in the cost of custom fabrication. In many cases, local shops that specialize in bodywork will provide bracket fabrication and alignment services, which is often a worthwhile investment when the fairing itself is rare or priced attractively.

Price signals and the used market

Because windjammer-style fairings serve touring riders, many used units change hands as owners update or restore their bikes. Price dispersion is wide: low-cost, cosmetically rough shells appear frequently, while finished, painted, or rare-profile fairings command higher prices. Auctions and classifieds sometimes reveal quick bargains, but shipping and repair costs can erase savings. For larger fairings, pickup-only listings are common precisely because transporting a full shell safely is expensive.

Watch for signs that justify a higher price: a complete mounting kit, intact windshield hardware, high-quality fiberglass or composite construction, and a clean finish that requires minimal repair. Conversely, a bargain-priced shell may still be a smart buy if a local body shop can repair or refinish it economically.

How to evaluate listings and sellers

When browsing, prioritize listings with clear photos of both exterior surfaces and mounting points. Ask sellers about any cracks around bolt holes, previous repairs, and whether the fairing was fitted to the specific motorcycle model you own. If mounting hardware is included, verify whether it uses a quick-release style or a permanent bolt-on system. These details determine install time and whether the fairing will interfere with routine maintenance.

For new or reproduced fairings, review seller return policies and warranty terms. Sellers that provide fitment diagrams or install guides reduce installation risk. For used parts, buyer protection policies on marketplaces are important; they can provide recourse if the part is significantly misrepresented.

Regional variations and rarity

Availability varies by region. In areas with strong touring cultures, you’ll find more new and used windjammer-style fairings on the market. In regions where short-distance commuting or sport riding is more common, these fairings are rarer and often priced higher. If a desired profile seems absent locally, cross-border purchases are feasible but factor in shipping, duties, and the risk of damage during transit.

Specialty shops and small fabricators increasingly list limited runs online. If you want a specific contour or finish, following niche builders on social channels is an effective strategy. These makers often produce runs tied to demand signals they gather from followers, which means joining mailing lists or groups can give you advance notice of upcoming releases.

Practical buying pathway

Start by surveying online marketplaces and regional listings. Narrow options to those that include clear images of mounting points. Confirm whether the seller includes a mounting kit and whether the fairing was mounted on a bike with similar handlebar and windshield geometry. If a listing is distant, request additional photos and ask about return options. Consider local pickup for used shells to inspect them before committing.

If you prefer new or reproduced shells, look for sellers that provide fitment guides and return policies. For custom fabrication, connect with local body shops that can fabricate brackets and finish the part. Finally, weigh total cost: price, shipping, mounting hardware, and finishing work all contribute to the final investment.

The market for windjammer-style fairings reflects larger aftermarket dynamics: steady demand, expanding online supply, and greater access to small-scale production. By focusing on fitment, inspecting mounting points, and choosing the right purchasing channel, you can navigate availability and find a fairing that suits your riding style and bike geometry.

External resource: https://www.ebay.com/

Internal link: For a broader sense of fairing types and fitments, see the Honda fairings collection: https://www.summitfairings.com/collections/honda-fairings

Final thoughts

Incorporating Windjammer fairings into the motorcycle riding experience is a proven way for business owners to offer products that enhance performance, comfort, and protection for their customers. As the market for these fairings continues to grow, understanding their aerodynamic benefits, weather protection capabilities, compatibility options, and the innovative history provided by designers like Craig Vetter becomes essential. Offering Windjammer fairings not only meets the demands of modern motorcyclists but also positions business owners as trusted providers of quality motorcycle gear. This, in turn, can lead to increased customer satisfaction and loyalty—key components in the competitive motorcycle market.