Introduction

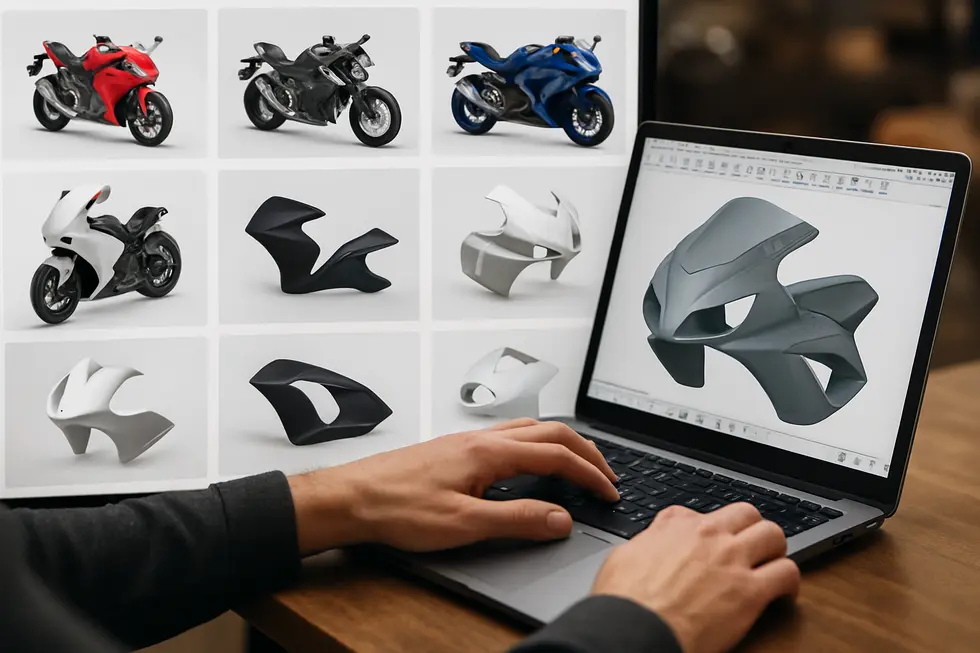

3D printed motorcycle fairings are reshaping the way business owners approach custom and replacement body panels. This innovative manufacturing method offers unprecedented flexibility in design, material choice, and production processes, enabling tailored solutions that meet unique customer demands and market trends. Exploring the design and material options, model acquisition and customization techniques, and the technical intricacies of printing, business owners can harness 3D printing to reduce costs, improve turnaround times, and increase product differentiation. Each of the following chapters deepens the understanding of these core aspects, providing a comprehensive roadmap to leveraging 3D printed fairings effectively.

Tables of Contents

Chapter 1: Design and Materials in 3d Printed Motorcycle Fairing

- Streamlining Performance: Aerodynamic Shaping and Material Synergy in 3D Printed Motorcycle Fairings

- Balancing Performance and Practicality: Material Choices for 3D Printed Motorcycle Fairings

- Enhancing Durability and Weather Resistance Through Material Choice and Design

- Innovative Strategies for Weight Reduction through Materials and Design in 3D Printed Motorcycle Fairings

- Harnessing Multi-Material 3D Printing for Durable, Lightweight, and Custom Motorcycle Fairings

Chapter 2: Acquisition and Customization of 3D Printed Motorcycle Fairing Models

- Navigating Online Marketplaces and Custom Design Tools for 3D Printed Motorcycle Fairings

- Mastering CAD Modifications for Tailored 3D Printed Motorcycle Fairings

- Mastering Material Choices and 3D Printing Techniques for Perfect Motorcycle Fairings

- Enhancing Fitment Precision: Leveraging 3D Scanning and Measurement for Perfect Motorcycle Fairings

- Harnessing Community Resources and Demonstrated Workflows for Custom 3D Printed Motorcycle Fairings

Chapter 3: Technical Processes and Printing Considerations for 3D Printed Motorcycle Fairing

- Selecting Durable and Performance-Optimized Materials for 3D Printed Motorcycle Fairings

- Harnessing Industrial-Grade Additive Manufacturing for Precision and Performance in 3D Printed Motorcycle Fairings

- Refining Form and Function: Essential Post-Processing Techniques for 3D Printed Motorcycle Fairings

- Integrating Aerodynamic Efficiency with Design Optimization in 3D Printed Motorcycle Fairings

- Ensuring Durability and Performance: Material Choices and Printing Techniques for 3D Printed Motorcycle Fairings

Chapter 1: Design and Materials in 3d Printed Motorcycle Fairing

1. Streamlining Performance: Aerodynamic Shaping and Material Synergy in 3D Printed Motorcycle Fairings

Achieving optimal aerodynamic performance in 3D printed motorcycle fairings requires a meticulous balance between design and material selection. The fairing’s shape plays a pivotal role in minimizing drag and enhancing stability at high speeds. Smooth, flowing surface contours reduce air resistance by allowing airflow to glide over the bodywork seamlessly. Precise alignment of fairing panels is essential, not only to preserve aerodynamic efficiency but also to avoid unwanted vibrations that can destabilize the bike. Strategic integration of spoilers and air ducts manages airflow, directing it to optimize cooling while minimizing turbulence around the rider and chassis.

Materials such as carbon fiber-reinforced polymers and advanced thermoplastics contribute significantly to this design goal. These composites provide the necessary rigidity to maintain shaping integrity under aerodynamic loads, while their lightweight nature ensures the bike’s overall performance and handling remain uncompromised. The 3D printing process enables fabrication of complex, multi-piece fairing assemblies that can incorporate impact absorption zones and ventilation channels without adding weight. This modular approach also allows easier post-print assembly and maintenance.

The rider’s posture influences aerodynamic design decisions; sport bikes often favor forward-leaning positions to shrink the frontal area facing air resistance. Fairings must therefore complement not only the bike’s chassis geometry but also ergonomics, enhancing comfort without sacrificing aerodynamic gains. When aerodynamic shaping is paired with advanced, precisely printed materials, it translates into measurable improvements in speed, fuel efficiency, and rider stability, while elevating the motorcycle’s aesthetic appeal.

For deeper insights on integrating aerodynamic design with custom motorcycle fairings, explore this detailed resource from Summit Fairings: https://blog.summitfairings.com/explore-the-best-motorcycle-fairings-at-summit-fairings/

2. Balancing Performance and Practicality: Material Choices for 3D Printed Motorcycle Fairings

Selecting the right materials for 3D printed motorcycle fairings requires a careful balance between strength, weight, durability, and finish quality. Fairings must endure significant aerodynamic forces while protecting the bike’s internal components and maintaining a sleek appearance. Therefore, materials that combine mechanical robustness with lightweight properties are favored. Commonly used options include tough photopolymer resins, carbon fiber composites, and reinforced filaments, each chosen based on application-specific demands.

Tough resins designed for SLA and DLP printing provide excellent impact resistance and polishability, ideal for fairings that need a fine surface finish and reliable durability. These resins allow intricate details while maintaining the structural integrity required to withstand daily wear. On the other hand, carbon fiber composite filaments excel in creating lightweight, stiff parts, which are highly valued in performance and racing contexts. Such composites enhance the fairing’s stiffness without adding unnecessary bulk, thus improving handling and acceleration.

FDM printing processes often employ PETG or nylon filaments reinforced with carbon fiber, offering a high-strength, printable material that suits larger or more functional components. These composites balance printability with mechanical performance, making them suitable for structural parts that face vibration and minor impacts. Thermal stability is another critical factor, as fairings must resist deformation caused by engine heat and environmental exposure.

Post-processing techniques like sanding and polishing are essential to refine surface quality, reducing drag and enhancing aesthetics. By thoughtfully integrating material properties with design goals, 3D printed fairings can be both visually appealing and functionally robust, paving the way for more customized and optimized motorcycle bodywork.

For expanded insight into customizing and sourcing high-quality motorcycle fairings, explore this comprehensive guide on motorcycle fairings.

Additional technical details on resilient resin materials can be found through external resources detailing engineering-grade photopolymer options.

3. Enhancing Durability and Weather Resistance Through Material Choice and Design

Enhancing Durability and Weather Resistance Through Material Choice and Design

Durability and environmental resistance are critical factors in the design of 3D printed motorcycle fairings, directly influencing their longevity and performance on the road. The harsh conditions these parts face—including impacts, UV radiation, moisture, and chemical exposure—require careful selection of materials that withstand these challenges without compromising aesthetics or structural integrity. Among the best-suited plastics, ASA stands out for its exceptional UV resistance and weatherability, making it ideal for outdoor motorcycle components that need to maintain appearance after continuous sun exposure. ABS is favored for toughness and impact resistance, but it often demands additional UV stabilizers or protective coatings to extend its lifespan in sunlight.

Complementing these materials, PETG offers a balance of durability, flexibility, and chemical resistance, which contributes to handling minor abrasions or exposure to fuels and oils. Nylon adds abrasion resistance and mechanical strength, but like ABS, it benefits from additives or finishes to enhance UV stability. Beyond raw material properties, the design approach plays an essential role: smooth surface finishes limit water ingress and debris buildup, which preserves the fairing’s physical condition and aerodynamic efficiency. Precise dimensional control ensures a snug fit to the motorcycle frame, reducing vibration-related stresses that can lead to cracking.

Strategically using supports such as HIPS during printing allows complex geometries—like detailed headlight fairings—to be achieved cleanly with minimal post-processing. Moreover, integrating composite reinforcements like carbon fiber-infused filaments significantly boosts impact resistance and UV protection while keeping weight down, delivering a premium quality often found in aftermarket parts. This multi-material approach helps tailor mechanical properties across the fairing, addressing areas with higher stress or environmental exposure.

Optimizing durability is ultimately a combined effort of material science and thoughtful design. Prioritizing UV-resistant plastics, using coatings where necessary, refining surface finish, and employing composite reinforcements create fairings capable of enduring the demanding outdoor conditions motorcycles face. Such design strategies, paired with emerging 3D printing techniques, open possibilities for producing robust, visually striking fairings customized for both function and style.

For deeper insights into these advanced material combinations and printing processes, a recent review of multi-material enterprise 3D printing provides valuable information on achieving high durability through innovative techniques. Additionally, exploring premium motorcycle fairing options can offer inspiration on how quality materials and designs elevate practical durability while enhancing aesthetic appeal.

4. Innovative Strategies for Weight Reduction through Materials and Design in 3D Printed Motorcycle Fairings

Achieving significant weight reduction in 3D printed motorcycle fairings hinges on the strategic interplay of material selection and advanced design optimization. Lightweight, high-strength materials like carbon fiber reinforced composites have revolutionized fairing construction by offering exceptional strength-to-weight ratios, far surpassing traditional metals such as steel or aluminum. These composites retain the necessary durability and impact resistance while dramatically lowering the mass of the components. In parallel, advanced polymers and polymer-carbon fiber blends tailored for 3D printing provide versatile options, delivering mechanical robustness with reduced weight, and enabling the production of complex, customized shapes that conform precisely to motorcycle specifications.

Design innovation plays an equally vital role in optimizing fairness weight. Techniques like topology optimization leverage computer-aided stress analysis to remove non-essential material from low-load regions, producing lean yet structurally sound geometries. Incorporating internal lattice or honeycomb structures further reduces material consumption without sacrificing rigidity, capitalizing on 3D printing’s capacity to fabricate intricate internal patterns unattainable by traditional methods. Beyond structural considerations, aerodynamic shaping refines the fairing’s contours to minimize drag, which enhances performance and indirectly supports lightweight design by reducing the need for overly robust constructions designed to counteract airflow issues.

The synergistic use of these materials and design methodologies produces fairings that are not only lightweight but also tailored for specific motorcycle models and riding conditions. The precision afforded by 3D printing ensures consistent wall thickness control and internal architecture customization, empowering creators to push the boundaries of conventional manufacturing constraints. This fusion of material science and design ingenuity underscores the transformative potential of 3D printed motorcycle fairings, making them a compelling choice for riders seeking performance and personalization.

For more insight into examples of carbon fiber applications in motorcycle parts demonstrating these principles, visit the detailed Kawasaki Carbon Fiber Parts Main Index. In addition, explore the range of designs and customization possibilities by browsing the Summit Fairings blog, which showcases a variety of affordable and innovative fairing solutions.

5. Harnessing Multi-Material 3D Printing for Durable, Lightweight, and Custom Motorcycle Fairings

Advanced multi-material 3D printing revolutionizes motorcycle fairing fabrication by blending diverse materials to meet exacting performance and aesthetic demands. By combining materials such as carbon fiber composites, ABS plastics, and bio-based resins in a single print, manufacturers can achieve lightweight structures that do not sacrifice strength or durability. This capability enables tailored solutions, optimizing impact resistance, heat dissipation, and finish quality to suit specific models like the ZX6R.

One key innovation is material blending, which pairs recycled polymers or plastic waste-enhanced HDPE with carbon fiber reinforcements. This approach not only strengthens the fairing but also aligns with sustainability goals by reducing environmental impact. Such blends can maintain OEM standards for fit and function while introducing robustness suitable for daily riding stresses.

Customization possibilities expand dramatically through multi-material printing. Complex color gradients, split-color schemes, and finishes ranging from matte to glossy allow riders to express individual style without the limitations of traditional manufacturing. UV-resistant polymers embedded within these prints protect the vibrant colors and surfaces, addressing long-term outdoor exposure challenges.

Functionality also improves as embedded features like integrated heat shields and honeycomb core structures enhance thermal management and structural rigidity. These designs reduce weight and boost performance without requiring additional assembly, enabling rapid prototyping and low-volume production runs. This agility supports enthusiasts who seek bespoke modifications often restricted by factory constraints.

Ultimately, leveraging engineered polymers with advanced composites in multi-material 3D printing unlocks a new era of fairing design that balances form, function, and environmental responsibility. For enthusiasts pursuing durable and personalized fairings, these innovations present compelling advantages over traditional manufacturing. To explore a wide variety of customizable 3D printed fairing models and accessories, the motorcycle community can find extensive resources at Summit Fairings’ selection of motorcycle fairings.

For detailed insights into advanced carbon fiber composites applicable in automotive and motorcycle bodywork, Hexcel’s HRH-302 materials provide an industry benchmark: https://www.hexcel.com/.

Chapter 2: Acquisition and Customization of 3D Printed Motorcycle Fairing Models

1. Navigating Online Marketplaces and Custom Design Tools for 3D Printed Motorcycle Fairings

The process of acquiring 3D printed motorcycle fairing models begins with exploring dedicated online marketplaces that offer a wide range of STL files tailored to specific motorcycle models and years. Platforms hosting these digital assets provide both free and premium designs, often created with printability and fitment in mind. For riders seeking designs compatible with models such as sportbikes or cruisers, these resources present a convenient starting point. Once a suitable file is obtained, the opportunity for customization becomes a critical advantage of 3D printing technology. Utilizing CAD and 3D modeling software, enthusiasts and professionals alike can adjust scale, refine contours, or alter mounting points to ensure perfect integration with their motorcycle. The use of advanced design tools allows for modifications that improve aerodynamics and aesthetics, while also considering the mechanical demands of real-world use.

Beyond the design phase, selecting materials that complement the print and provide durability is key. After printing, finishing techniques may incorporate composite materials such as carbon fiber reinforcements to enhance strength without significantly increasing weight. This approach bridges digital customization with advanced material science, creating fairings that balance form and function. Online tutorials and guides further empower users by offering detailed insights into scaling strategies and customization methodologies, ensuring that the final product is not only visually appealing but also structurally sound.

This seamless connection between digital marketplaces, comprehensive customization tools, and cutting-edge materials fosters an accessible yet sophisticated avenue to obtain and tailor motorcycle fairings. For riders eager to refine their bike’s silhouette or replace damaged panels, this pathway enables rapid acquisition combined with precise, personalized adaptation.

For more insights into customization and fairing choices, explore comprehensive motorcycle fairing resources.

Reference for advanced composite materials: Hexcel carbon fiber composites.

2. Mastering CAD Modifications for Tailored 3D Printed Motorcycle Fairings

The process of acquiring and customizing 3D printed motorcycle fairings begins with sourcing accurate digital models. Enthusiasts and professionals often turn to online repositories that offer a wide array of STL and CAD files tailored for motorcycle customization. These databases include not only fairings but also complementary components such as engines and frames, providing a holistic approach to 3D printed motorcycle modifications. After obtaining a base design, CAD software like Fusion 360 or SolidWorks becomes essential to refine and adapt these models to specific motorcycle frameworks and rider preferences.

Customization frequently involves resizing fairings to match different chassis dimensions and ergonomic requirements. Designers enhance mounting interfaces by adding or altering brackets and holes, ensuring a secure and precise fit. Aerodynamics can be improved by sculpting vents, channels, or other airflow-optimizing features directly into the digital model. Complex geometries are often segmented into printable parts to overcome printer build volume limitations, with digital assemblies carefully planned for a seamless fit after printing.

Advanced users may leverage Finite Element Analysis (FEA) within their CAD environments to simulate stress and optimize the fairing’s structural integrity. This approach helps in balancing weight reduction and durability, preventing material overuse without compromising protection. Once the design is finalized, it is exported as an STL file and prepared for 3D printing, where material choices such as ABS or carbon fiber composites significantly influence the part’s toughness and finish quality.

Post-processing techniques like sanding and coating follow printing, delivering the desired aesthetic and surface smoothness while enhancing environmental resistance. This tailored CAD-driven workflow empowers creators to produce highly customized, aerodynamic, and structurally optimized motorcycle fairings, pushing beyond the constraints of conventional manufacturing methods.

For more insights into expertly curated fairing options and customization inspiration, explore this resource on motorcycle fairings.

External source: https://www.yeggi.com/q/motorcycle+engine+stl/

3. Mastering Material Choices and 3D Printing Techniques for Perfect Motorcycle Fairings

Acquiring and customizing 3D printed motorcycle fairings begins with selecting or creating accurate digital models tailored to your bike’s specifications. These models can be sourced from online marketplaces offering both free and premium templates or expertly sculpted from photographs and sketches for a personalized fit. Once the digital design is prepared, the critical decision of material and printing technology comes into focus, as these choices directly impact the fairing’s durability, weight, aesthetic, and performance.

Materials commonly used include ABS, prized for its toughness and impact resistance, ideal for fairings expected to endure physical stress. PETG offers a balance of strength and flexibility, providing good resistance to environmental factors while maintaining ease of printing. Nylon brings even greater toughness and flexibility, suited for parts requiring resilience in demanding conditions. Resin-based materials, utilized in SLA or DLP printing, allow for high-detail surfaces with exceptional finish quality but usually lack the mechanical strength of thermoplastics, reserving them for decorative or smaller trim components.

The selection of 3D printing technology shapes the final quality and functionality of the fairing. Fused Deposition Modeling (FDM) is favored for larger parts, enabling the use of robust thermoplastics like ABS and PETG. While cost-effective, it often requires detailed post-processing to smooth layer lines. SLA and DLP printing deliver superior detail and smoothness with photopolymer resins, excellent for intricate sections but less suited for structural elements due to brittleness. Selective Laser Sintering (SLS) uses powdered materials to build complex, strong parts with no need for support structures, making it an excellent option for durable, lightweight fairings with complex geometries.

To guarantee precision fit and functionality, meticulous scaling and digital fitting checks are imperative before printing. Post-processing, including sanding, painting, and sealing, further enhances durability and aesthetics, allowing for artistic customization alongside functional design. This approach highlights the transformative potential of 3D printing: from readily accessible customizable models to advanced material and technology choices, enabling riders to craft fairings that perfectly merge style, protection, and performance.

For those interested in exploring detailed techniques and model options, several guides provide comprehensive insights into the nuances of 3D printing for motorcycles. One such resource offers valuable tips on optimizing print settings and materials for motorcycle-specific parts: 3D printing technology overview and tips. Additionally, for inspiration and practical examples, downloadable kits demonstrate how these principles manifest in real-world applications.

Explore further expert insights and a broad selection of motorcycle fairings at Summit Fairings blog.

4. Enhancing Fitment Precision: Leveraging 3D Scanning and Measurement for Perfect Motorcycle Fairings

Enhancing Fitment Precision: Leveraging 3D Scanning and Measurement for Perfect Motorcycle Fairings

Achieving impeccable fitment for 3D printed motorcycle fairings demands a seamless integration of advanced 3D scanning and meticulous measurement techniques. Beginning with precise 3D scanning, devices capture the intricate surface geometry and exact dimensions of existing motorcycle components. This digital replication ensures that every contour and edge is faithfully recorded, offering an accurate basis for creating customized or replacement fairings that fit perfectly without misalignment.

Once the digital scan is obtained, the data is imported into CAD software where further customization occurs. Here, modifications can be made to enhance aesthetics, improve aerodynamics, or accommodate rider preferences, all while maintaining strict dimensional accuracy. Careful attention during this phase ensures that any alterations do not compromise the essential fit with the motorcycle’s frame and mounting points.

To validate the integrity of the design, dimensional measurements of the digital model are systematically compared against physical parts, allowing designers to identify and correct potential discrepancies. Adjustments also factor in printer-specific behaviors such as material shrinkage or dimensional tolerance variations. This iterative process of scanning, modeling, and measuring fosters progressive refinements that eliminate common fitment issues like gaps or misalignments.

Material selection and printing parameters play a pivotal role in complementing fit accuracy. Durable and weather-resistant materials such as ABS and ASA are often selected to endure operational stresses while maintaining dimensional stability. Additionally, parameters like wall thickness and infill density are optimized to ensure the final printed fairing withstands real-world conditions without deformation.

This comprehensive workflow ensures that each 3D printed motorcycle fairing not only matches the rider’s style and performance demands but also installs flawlessly. Enthusiasts and professionals alike benefit from this precise approach, demonstrated by successful applications such as tailored headlight brackets that prove fitment accuracy across varied motorcycle models.

For insights into cutting-edge 3D scanning applications and detailed customization examples, refer to the Creality 3D scanner demonstration. Additionally, explore a broad range of compatible motorcycle fairing models and customization ideas at Summit Fairings Blog.

5. Harnessing Community Resources and Demonstrated Workflows for Custom 3D Printed Motorcycle Fairings

The journey of acquiring and customizing 3D printed motorcycle fairings often begins within vibrant online communities where designers and enthusiasts exchange models. Popular platforms such as CGTrader host a wealth of downloadable fairing designs in formats like STL and OBJ, providing users with ready-made templates tailored for various motorcycle models. This accessibility empowers hobbyists to either print directly or embark on personalizing these models through CAD software, adapting dimensions, shapes, and stylistic elements to achieve a precise fit and distinctive aesthetic.

Customization is a critical stage where creativity meets function. Users commonly modify designs by resizing fairings to accommodate specific frames or enhance aerodynamic profiles. Adding unique graphics or structural features through modeling tools further refines the fairings, which balances visual appeal with mechanical requirements. For those seeking to replicate or improve existing parts, 3D scanning technology is an invaluable asset. Devices like handheld scanners capture intricate details of original components, enabling accurate digital reproduction and enabling further tailored adjustments before printing.

The printing process itself is a carefully choreographed sequence that community members often share through platforms like TikTok, illustrating the entire workflow from slicing digital files to final fabrication. These demonstrations highlight parameter settings for different printers—ranging from FDM to resin systems—and emphasize how to optimize layer thickness, infill, and support structures to ensure durability and dimensional accuracy. For larger fairings, users frequently print segmented parts before assembly, overcoming printer volume constraints.

This collaborative ecosystem nurtures an open exchange of ideas, enabling enthusiasts to learn, adapt designs, and perfect their outputs with guidance from shared experiences. Leveraging these community-driven resources and documented workflows, riders can create personalized, functional fairings that blend innovation with practical performance. To explore further about sourcing motorcycle parts, visit Discover Affordable Motorcycle Fairings at Summit Fairings.

More detailed insights into downloadable and customizable designs for motorcycle components can be found at sites like CGTrader, where a diverse array of free and premium models are available for immediate use or bespoke adaptation.

Chapter 3: Technical Processes and Printing Considerations for 3D Printed Motorcycle Fairing

1. Selecting Durable and Performance-Optimized Materials for 3D Printed Motorcycle Fairings

The success of producing high-quality 3D printed motorcycle fairings hinges significantly on choosing the right materials that seamlessly balance strength, durability, and environmental resistance. Among popular thermoplastics, ASA (Acrylonitrile Styrene Acrylate) stands out due to its exceptional UV resistance and ability to withstand weather exposure, ensuring the fairing maintains its structural integrity and appearance over time when exposed to sunlight and rain. This makes ASA a preferred option for outdoor motorcycle use, where consistent exposure to elements is unavoidable.

PETG (Polyethylene Terephthalate Glycol) also emerges as a viable choice, boasting good impact and chemical resistance. When combined with carbon fiber reinforcement, PETG filaments gain remarkable stiffness and strength while remaining lightweight — a crucial factor for maintaining motorcycle agility and performance. Carbon fiber-infused composites elevate these properties further, enabling the production of rigid yet lightweight fairings that do not compromise on mechanical robustness.

Printing these advanced materials necessitates equipment capable of sustained high temperatures. Such conditions improve layer adhesion and prevent common issues like warping or delamination, particularly important when working with ASA or carbon fiber filaments. Since motorcycle fairings often have complex curved geometries for aerodynamic efficiency, careful attention to slicing, layer orientation, and the strategic use of supports helps preserve dimensional accuracy and structural reliability.

Post-processing plays a vital role in refining the surface finish, contributing not only to aesthetic appeal but also to aerodynamic performance. Techniques like sanding, priming, and painting smooth out printed layers, resulting in a sleek, durable exterior ready for real-world conditions. Moreover, ASA’s lower thermal expansion reduces warping compared to ABS, making it more user-friendly for outdoor applications.

For readers looking to explore further, valuable resources on material properties and printing strategies can be found in detailed guides such as Carbon fiber parts production and curing.

Ultimately, selecting ASA and PETG composites with carbon fiber reinforcement offers the best combination of durability, weather resistance, and lightweight performance essential for reliable 3D printed motorcycle fairings.

[External reference: Carbon fiber parts production and curing]

2. Harnessing Industrial-Grade Additive Manufacturing for Precision and Performance in 3D Printed Motorcycle Fairings

The use of industrial-grade 3D printing technologies revolutionizes the production of motorcycle fairings by enabling precision, strength, and rapid development cycles that meet the high demands of performance-oriented riders. Unlike consumer-level printers, industrial additive manufacturing employs large-format systems capable of processing advanced materials such as carbon fiber-reinforced polymers and high-grade metals like titanium. These materials deliver an exceptional balance of lightweight construction, mechanical rigidity, and thermal resistance—key factors in motorcycle applications where aerodynamic efficiency and durability under heat stress are critical.

A core advantage of industrial printing lies in its micron-level accuracy, which ensures that aerodynamic fairings fit precisely and perform optimally. Small dimensional deviations can alter airflow and handling, so manufacturers rely on the exact repeatability these machines provide. Additionally, the ability to produce complex geometries with integrated functional features, such as embedded cooling channels or structural reinforcements, offers design freedoms that traditional fabrication cannot easily achieve. This capability leads to fairings with optimized aerodynamic profiles and improved rider protection.

Scalability is another hallmark of industrial 3D printing, as large-format metal printers can fabricate multiple parts or sizable components without sacrificing quality. This scalability supports both rapid prototyping and final-part production, compressing development timelines while controlling costs. For example, race teams can iterate quickly on fairing designs, refining shapes and materials before the final version hits the track.

These advanced technologies have been adopted beyond racing contexts, benefiting electric motorcycles and street bikes by providing lightweight, customizable bodywork solutions. Industrial-grade additive manufacturing bridges materials science and precision hardware, meeting stringent performance, durability, and thermal management standards essential for modern motorcycle fairings.

For further technical insights on these applications in motorcycle racing, see this detailed overview: https://news.imotorbike.com/en/2025/08/how-robozes-3d-printing-tech-is-powering-yamahas-motogp-pursuit/

Explore more on tailored motorcycle bodywork solutions at Summit Fairings’ expert blog.

3. Refining Form and Function: Essential Post-Processing Techniques for 3D Printed Motorcycle Fairings

Post-processing is a vital step in transforming raw 3D printed motorcycle fairings into polished, functional components ready for real-world use. After printing, surfaces often exhibit visible layer lines and minor imperfections inherent to common methods like Fused Deposition Modeling (FDM). Addressing these issues begins with progressive sanding, employing finer grit sandpapers to achieve a smooth, uniform texture. This process not only enhances the visual appeal but also prepares the surface for subsequent coatings.

To further perfect the finish, filling gaps and small voids with automotive putty ensures seamless coverage and structural consistency. This step is crucial for eliminating defects that could compromise the final paint job or aerodynamic efficiency. Once the surface uniformity is attained, applying a high-quality primer suited for plastics fortifies adhesion and smoothness. Following priming, durable automotive-grade paints are used to match custom color schemes, giving the fairing a professional and vibrant look.

Protective clear coatings add an essential layer of UV resistance and durability, preserving both appearance and mechanical resilience against environmental wear. For materials like ABS or nylon blends, annealing or heat treatment may be employed to enhance strength and thermal stability, raising performance under riding conditions.

Printing considerations remain tightly linked to post-processing outcomes. Selecting materials such as ABS or carbon fiber-infused filaments ensures the fairing withstands impact and heat. Strategic print orientation minimizes the need for supports on visible areas, reducing post-print cleanup and maximizing strength along stress lines. Precision in CAD modeling and 3D scanning, paired with controlled printing parameters like infill density and layer adhesion, lays the groundwork for a fairing that meets exact fitment and functional demands.

By integrating meticulous post-processing with thoughtful printing strategies, riders and fabricators achieve 3D printed motorcycle fairings that deliver on aesthetics, durability, and performance. For detailed insights into sourcing and selecting aftermarket fairings, exploring affordable motorcycle fairings options can offer practical inspiration.

For comprehensive guidelines and case studies on processing and material choices, refer to expert communities and technical resources focused on motorcycle customization and 3D printing workflows.

4. Integrating Aerodynamic Efficiency with Design Optimization in 3D Printed Motorcycle Fairings

Optimizing the design of 3D printed motorcycle fairings demands a meticulous balance between aerodynamic performance and manufacturing feasibility. Central to this process is shaping the fairing to minimize drag and enhance airflow, thereby increasing high-speed stability and shielding critical components from impact and environmental wear. Aerodynamic enhancement often involves the strategic incorporation of features such as integrated winglets that improve downforce while smoothly directing airflow around the motorcycle. Advanced simulation techniques, particularly Computational Fluid Dynamics (CFD), enable designers to iteratively refine fairing contours, ensuring a harmonious blend of reduced aerodynamic resistance, adequate cooling, and rider comfort.

The digital design workflow begins with precise 3D modeling, enabling accurate scaling and custom fitting to specific motorcycle frames. This step is vital to accommodate both the mechanical and aesthetic requirements inherent in motorcycle fairings. Rapid prototyping through 3D printing facilitates essential testing phases where form, fit, and aerodynamic characteristics can be evaluated and optimized without costly tooling or materials wastage. Given the inherent limitations of printing technology, such as build volume and material properties, designs often integrate internal structures like lattices or honeycombs. These structures help retain rigidity while minimizing weight, a key advantage in performance-oriented applications.

Material choices strongly influence final performance and printability. Carbon fiber-reinforced composites, produced via continuous fiber 3D printing, provide superior strength-to-weight ratios and surface finish quality critical for aerodynamic smoothness. Print orientation and layer adhesion are carefully planned to maximize mechanical strength and ensure cohesive surfaces that reduce air turbulence. Post-processing steps, including sanding and resin coatings, further refine surface texture to enhance aerodynamic flow and improve UV and weather resistance. Ensuring dimensional accuracy through digital fitting guarantees seamless integration with mounting mechanisms and the overall motorcycle architecture.

This synthesis of aerodynamic principles, digital design, and printing considerations unlocks the potential for highly customized, lightweight fairings optimized for performance. For an in-depth look at aerodynamic simulation methodologies applied to motorcycle fairings, visit Computational Foam Dynamics and Design Optimization. To explore a range of customizable fairing options enhanced by continuous innovation in digital fabrication, consider reviewing resources at Explore the Best Motorcycle Fairings at Summit Fairings.

5. Ensuring Durability and Performance: Material Choices and Printing Techniques for 3D Printed Motorcycle Fairings

Durability and functional performance are critical when producing 3D printed motorcycle fairings, where the demands of real-world conditions strongly influence technical decisions. Selecting the right material is foundational; engineering plastics such as polycarbonate (PC) and advanced tough resins provide impact resistance and longevity suitable for protective motorcycle panels. These materials balance hardness with flexibility, reducing the likelihood of cracking under stress from vibrations, minor impacts, and aerodynamic loads. Composite filaments infused with carbon fiber often enhance strength without significantly adding weight, key for maintaining a motorcycle’s agility.

Printing parameters also play a pivotal role. Optimizing print orientation ensures that load-bearing directions align with the strongest axis of the printed layers, maximizing structural integrity. Complex fairings necessitate careful layer placement and support strategies, especially when overhangs and intricate shapes are involved. Multi-material printing opens avenues to combine rigid protective components with flexible mounts or seals, delivering both durability and functional adaptability.

Post-processing treatments further augment performance by enhancing surface finish and environmental resistance. Techniques like polishing or UV-protective coatings improve wear resistance and protect the fairing from sunlight degradation, ensuring a longer service life. Efficient post-processing strengthens the fairing’s resilience against moisture and abrasion—common environmental hazards for motorcycles.

Together, these choices in materials, printing orientation, and finishing steps form a comprehensive approach crucial for achieving fairings that not only look custom but offer performance comparable to traditional aftermarket parts. This integration of material science and printing techniques illustrates how additive manufacturing is advancing functional motorcycle components.

For deeper insights into technical processes, related resources offer guidance on optimizing printing workflows for motorcycle parts. More on this can be found at Summit Fairings’ technical blog.

External research underscores the importance of balancing toughness and weight, recommending tough resin variants and polycarbonate plastics to meet durability requirements while maintaining lightness for performance [5].

Final thoughts

3D printed motorcycle fairings open expansive opportunities for business owners striving to lead in customization, efficiency, and innovation. Understanding the critical relationship between design and materials empowers the creation of functional and visually arresting fairings matched to diverse consumer needs. Accessing and tailoring digital models from established marketplaces multiplies options while reducing development overhead, enabling agile product flows. Navigating technical printing challenges with informed strategies ensures durability and quality, vital for customer satisfaction and brand trust. Taken as a whole, mastering these aspects positions businesses to capitalize on the unmatched flexibility and creative potential of 3D printing technology, fostering growth and distinction within the competitive motorcycle fairing market.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.