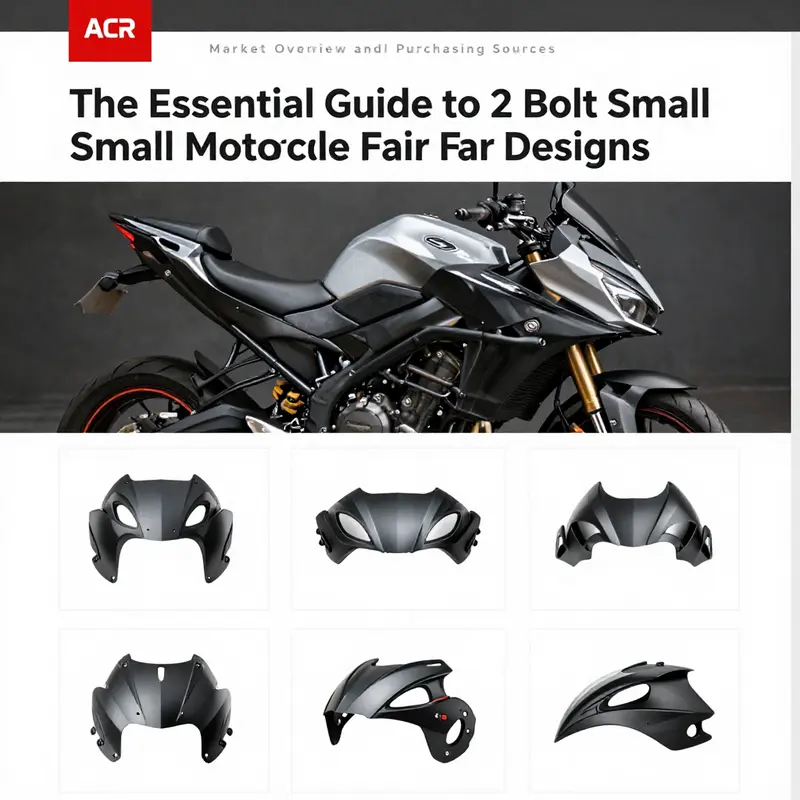

Understanding the nuances of 2 bolt small motorcycle fairings is crucial for business owners aiming to serve the motorcycle enthusiast community effectively. These fairings are not just aesthetic enhancements; they provide essential protection and performance benefits for various motorcycle models. This guide will explore the design intricacies of 2 bolt fairings, the materials that contribute to their durability, how to ensure compatibility with different motorcycle sizes, real-world applications of these fairings, and an overview of market trends along with purchasing options. Each chapter will equip you with the knowledge necessary to make informed decisions in this niche market.

null

null

Beyond the Bolt: How Materials Shape Durability in 2-Bolt Small Motorcycle Fairings

The 2-bolt small motorcycle fairing sits at a critical intersection of form and function. It must slice through the wind with minimal drag, shield the rider from road debris, and withstand weather and vibration—all while staying light enough to preserve the bike’s agility. In this compact category, the choice of materials and the durability of fasteners are not afterthoughts; they define how the fairing behaves under everyday riding and in the long arc of a season. A close look at the common material choices and the role of reliable fasteners reveals why these two bolts, paired with smart design, can carry more responsibility than their simple appearance suggests. The discussion that follows ties closely to practical realities: compatibility with small motorcycles, ease of replacement, and predictable performance across varied riding conditions.

A primary material for 2-bolt fairings is ABS plastic, a thermoplastic renowned for its impact resistance and balance of stiffness and flexibility. ABS acts like a shock absorber in miniature. When the bike encounters imperfect pavement, rough edges, or the occasional tip-in at the end of a lane, ABS flexes just enough to dampen vibrations without creating brittle cracks. It is also forgiving in manufacturing, allowing designers to mold aerodynamic contours that meet tight packaging constraints on small machines. The result is a fairing shell that holds its shape at speed and returns to its zero-load state after a bump, helping the overall ride feel smoother and more predictable.

Yet ABS is not the only option. In premium or custom outfits, polycarbonate may appear, valued for higher impact strength and greater resistance to shatter. Polycarbonate’s clarity and toughness can be advantageous in certain visual or structural applications, especially where larger, unbroken panels are desired or where the rider presses beyond typical city speeds. However, its cost and weight can be a limiting factor in the small-bike segment, where every gram matters and manufacturers often favor ABS as the default due to its excellent balance of price, processability, and performance. The choice between ABS and polycarbonate is thus a dialogue between riding style, exposure to edge impacts, heat from sunlight, and budget. The goal remains the same: maintain a clean silhouette, ensure a smooth surface for airflow, and keep the riding experience stable under real-world conditions.

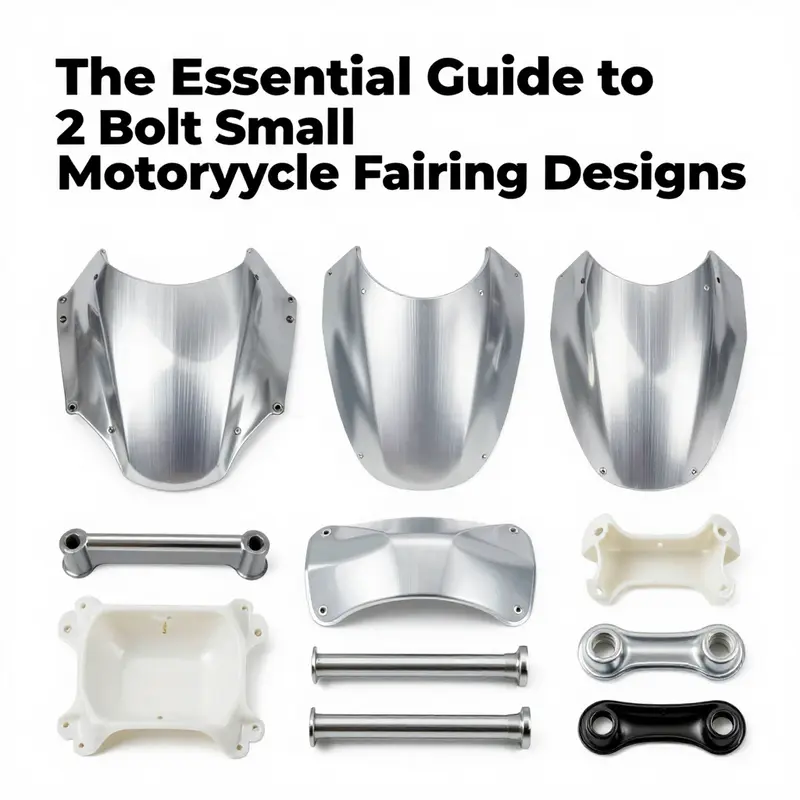

Beyond the shell, the fasteners and mounting hardware are equally decisive. The 2-bolt approach relies on robust, corrosion-resistant fasteners and well-engineered brackets that spread the clamping load without concentrating stress on a single point. Aluminum alloy bolts are a common choice for their light weight and favorable strength-to-weight ratio, while stainless steel screws offer superior corrosion resistance in wet climates and during year-round exposure to weather, UV, and temperature fluctuations. The studs, threaded holes, and accompanying brackets must resist loosening from vibration, which is especially important for smaller motorcycles that lean into corners and roll over imperfect roads at speed. When fasteners stay tight and the fairing remains securely mounted, the rider perceives fewer rattles, less air intrusion at high speeds, and more confidence that the panel will stay in place during lane changes or quick braking.

Durability, however, is never about a single material or a single bolt. It is the synergy of shell material, fastener quality, and mounting geometry. For ABS, UV stabilizers and proper molding margins reduce surface degradation over time, while edge radii and lattice reinforcements in high-stress zones help resist hairline cracks that can propagate from minor impacts. The mounting points must be designed to accommodate cyclic loads without yielding. In the absence of such design foresight, even a strong bolt can fail or loosen after repeated vibration cycles, leading to panel flutter or misalignment that undermines aerodynamics and safety.

An important practical consideration for riders and shops is compatibility. Small fairings come in many silhouettes and mounting patterns, so a kit that touts universal standards may still require verification against a specific model and fairing specification. This ensures that bolt lengths, thread pitches, and bracket positions align with the existing mounting bosses and grommets. A well-chosen kit offers multiple bolts and fasteners so the wearer can select combinations that fit their particular setup, ensuring even load distribution and secure clamping at each mounting point. This capability is especially valuable for riders who tinker, upgrade, or replace individual panels after a tip-in or a close pass with a branch on the road. In practice, checking the motorcycle model, fairing model, and installation method reduces the risk of mismatches that would otherwise become safety concerns or maintenance headaches.

A coherent approach to durability also considers environmental exposure. Weatherproof features—sealed interfaces, corrosion-resistant coatings, and protective surfaces—are essential. Aluminum bolts resist corrosion yet should be treated or cleaned to prevent galvanic reactions with uncoated steel parts nearby. Stainless steel screws are reliable in rain and UV exposure, guarding against loosening and rust that can compromise the panel’s integrity and rider safety. The combination of weather resistance and mechanical resilience gives a fairing the staying power needed for daily commuting or longer tours, where the same piece may encounter sun, rain, road salt, and temperature swings. In that light, the durability of a 2-bolt fairing hinges on more than the material choice; it rests on a systems approach that integrates shell, fasteners, brackets, and the way the assembly maintains its clamping force under vibration.

For enthusiasts who want to visualize these principles in action, exploring how different silhouettes manage load and airflow can be enlightening. The contours of a well-designed small fairing are not merely about aesthetics; they reflect a balance between crash-worthiness, drag reduction, and the practicalities of field maintenance. In a tight form factor, even the slightest misalignment can create a gap that spoils the flow of air and invites chatter at speed. The 2-bolt configuration, when implemented with reliable materials and precise machining, can offer a predictable, repeatable clamping solution that preserves both appearance and function after minor encounters with road debris. This is where the choice of materials and fasteners ceases to be theoretical and becomes an everyday reliability metric riders use when they decide whether a replacement panel is worth the investment.

From a rider’s perspective, the conversation often circles back to replacement feasibility. A kit that includes multiple bolts and compatible brackets, designed for common mounting patterns, makes field service straightforward. In practice, mechanics and hobbyists appreciate how easy it is to replace a single damaged bolt or an entire fastener set without resorting to bespoke hardware. The small motorcycle fairing, with its two-bolt anchor points, becomes a model for how thoughtful hardware design can reduce downtime and preserve the ride’s integrity. The result is a chassis that maintains smooth airflow, a panel that remains securely attached, and a rider who can focus on control rather than maintenance intricacies.

For readers who want to connect these material insights with broader choices, a note on contour fitment can be helpful. While the specifics of a model may vary, observing the shared patterns across different producers can illuminate common mounting philosophies and standardization trends in the small-bike sector. A practical cue is to compare how shells respond to heat exposure and how fasteners hold up after a season of riding. If a panel shows dulling of its surface or the bolts begin to loosen after a few rides, those signs point back to material quality and fastening design. In that sense, the 2-bolt fairing becomes more than a cosmetic shell; it is a compact example of how engineering choices in materials and hardware translate into real-world durability.

To further explore how this topic translates into practical choices for riders curious about fitment and contour differences, consider looking at the Yamaha fairings collection for reference on common mounting patterns and silhouette design. This contextual comparison helps frame what a small fairing needs to deliver in terms of shape, mounting points, and ease of maintenance. For broader reading on how to select fairings for durability and compatibility, a comprehensive guide on motorcycle fairings is available online, which discusses materials, construction, and installation considerations in a more general sense. This broader perspective can help riders evaluate whether a given 2-bolt kit is aligned with their riding goals and mechanical expectations.

External resource for deeper reading: Motorcycle Fairings Guide. https://www.carinterior.com/motorcycle-fairings-guide-how-to-choose-one/

Internal resource reference: For practical examples of compatible silhouettes and mounting layouts, explore the Yamaha fairings collection. https://www.summitfairings.com/collections/yamaha-fairings

Threads, Fit, and Flow: Sizing and Compatibility for 2-Bolt Small Motorcycle Fairings

The small two-bolt fairing is a study in balance between lightness, strength, and aerodynamics. This chapter explains how bolt size, material, and installation practices influence durability, ease of service, and panel alignment under wind and vibration.

Most common diameters in two-bolt fairings are M5 and M6. In practice, lighter mounting points may use M5, while heavier points frequently use M6. A universal bolt kit can be convenient, but compatibility depends on exact length, thread pitch, and head style for each mounting boss. Always verify the specific location, spacer use, and panel geometry before swapping parts.

Thread pitch matters as much as diameter. Even within M5 and M6 families, pitches can vary to suit particular manufacturing tolerances. If you cannot access documentation, measure pitch with a thread gauge and confirm engagement depth. The bolt length must be chosen so the fastener engages a nut or captive insert while avoiding interference with moving parts or channels for airflow.

Material choices influence weight and corrosion resistance. Aluminum bolts paired with ABS spacers are common in lightweight fairing kits, offering a favorable stiffness-to-weight ratio and easier mounting. Protect against corrosion by choosing compatible coatings or anodized finishes.

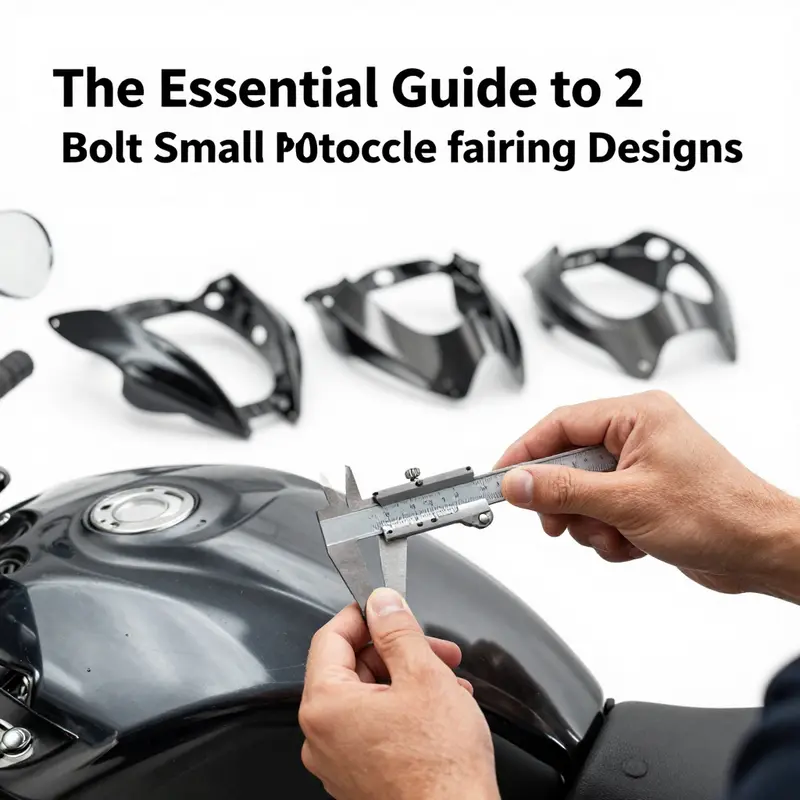

Approach to replacement or upgrade starts with model verification, followed by careful measurement and torque planning. Confirm the model and fairing variant, inspect existing bosses, measure hole diameters and spacing, and check spacers. If manual torque specs are unavailable, use a gradual tightening sequence for two-bolt panels: tighten each bolt to a consistent spec and repeat until the panel sits evenly.

Model-aware resources help ensure correct fit. Look for model-tuned pages that catalog fairing shapes, mounting bosses, and hardware by generation. For example, model-specific pages for popular bikes guide bolt choices and alignment. A direct path to model-tuned resources is the Honda CBR250R fairings collection.

External references can provide a practical benchmark. A retailer’s listing can confirm common diameters, pitches, and lengths across multi-model kits. For instance, see the following resource: https://www.amazon.co.uk/dp/B0BQZVJ9XW

Overall, the goal is to preserve safety, aerodynamics, and the rider’s confidence by selecting fasteners that fit the mounting bosses, spacers, and fairing geometry, and by applying proper torque with even loading across the two bolts.

Two-Bolt Small Fairings: Lightweight Aerodynamics, Easy Customization, and Everyday Protection

Two-bolt small fairings occupy a pragmatic middle ground in the world of motorcycle bodywork. They are not meant to cloak an entire bike in wind-deflection, nor are they merely decorative add-ons. Instead, they offer a deliberate balance: enough steering alignment to improve rider comfort at speed, enough protection to shield critical components from road spray and debris, and enough modularity to suit a wide range of riding styles. The underlying philosophy is simple and practical. The fairing pieces themselves are purpose-built for small motorcycles and for models where every gram of weight matters. They rely on a compact mounting pattern that uses two secure points, making installation straightforward and, crucially, removable when access is needed for maintenance or quick weather-driven changes. In the material world, these small fairings often blend durable aluminum with resilient ABS plastics. Aluminum provides stiffness and a crisp edge to the piece, helping it resist flex under load and maintain a clean silhouette at higher speeds. ABS, with its impact resistance and weather resilience, protects the finishing layers from scuffs and minor abrasions. The combination is not about luxury materials but about predictable performance over time. A well-designed bolt kit, crafted from these materials, adds to the kit’s reliability by ensuring the fasteners stay secure without galling or corrosion. Users highlight that the reliability of a two-bolt setup hinges on accurate matching of the motorcycle model and the specific fairing pattern; a precise fit translates into easier installation and longer intervals between checks. This is not a one-size-fits-all story, but a careful alignment of parts, pattern, and purpose that makes the small fairing a versatile upgrade rather than a risky mod. For riders assembling or replacing components, the emphasis rests on verification: confirm the model, confirm the fairing’s mounting coordinates, and confirm that the bolt length and thread pitch match the factory standards. When these factors align, the installation becomes nearly intuitive, with the two bolts slotting into pre-engineered anchors and the fairing settling against the fork crown or headlight assembly with a neat, controlled fit. When a rider starts from this point, the fairing’s presence’ significance becomes more than cosmetic. It shapes the ride experience by guiding wind away from the rider’s chest and helmet at urban and highway speeds, reducing fatigue on longer commutes and easing buffeting on windy days. While the smallest fairings cannot compete with full fairing packages in terms of complete wind shelter, they can noticeably improve comfort during everyday riding, especially for riders who value agility and quick, clean lines over a wall of protection. The impact on aerodynamics, though measured, is real: a smoother nose profile reduces drag and helps maintain stable steering inputs as speed increases, which in turn supports better control in city traffic and on backroads alike. The practical effect is a bike that feels more composed during a daily shuffle through traffic and a little more confident on those weekend daytime rides when weather shifts unexpectedly. Aesthetics should not be neglected either. The two-bolt approach lends itself to modular styling and easy color-matching. Riders can swap finishes to reflect seasonal palettes or to coordinate with custom paint schemes without committing to an entire fairing system. The modular mindset invites experimentation without significant financial risk, encouraging owners to explore different visual identities or to tailor the bike’s silhouette to changing riding priorities. This is where the broader ecosystem around small fairings comes into view: the availability of compatible mounting hardware, spacers, and clips that fit a spectrum of headlight housings and instrument clusters. While some kits emphasize universal compatibility, there is value in verifying compatibility with the specific model’s headlight mount and the fairing’s inner geometry to avoid clashes with the brake lines or steering components. For riders curious about how this translates into real-world options, practical references exist that catalog a broad range of fairing shapes designed for common sport and commuter bikes. A quick look at the broader ecosystem highlights how two-bolt configurations integrate with both OEM-inspired and aftermarket styling approaches, enabling a clean installation that preserves service access and reduces downtime.

The minimalist installation profile of two-bolt small fairings often translates into tangible benefits on the scale of maintenance and upkeep. Because the mounting points are few and deliberate, removing and reattaching the fairing for routine checks—such as adjusting headlight alignment, inspecting wiring behind the cluster, or cleaning the radiator vicinity—takes a fraction of the time required for larger, more complex fairing systems. This is not simply a convenience; it reduces the temptation to bypass maintenance tasks, which, over time, can compromise performance or safety. In the same breath, the lightweight nature of these components tends to preserve the bike’s overall handling characteristics. A weight penalty is thus minimized, which matters for smaller displacement machines where every gram can influence nimbleness and fuel efficiency. Riders who emphasize a balanced blend of sportiness and practicality often find that two-bolt fairings deliver a palpable enhancement without overburdening the chassis. The cost perspective aligns with this philosophy as well: while no aftermarket bolt kit is free, the smaller scope of a two-bolt solution typically makes it more affordable than full fairing replacements. The economic sensibility becomes part of the appeal for riders who want measurable gains—comfort, improved aerodynamics, better component protection—without a high investment. In this light, the small fairing is less a luxury feature and more a sensible, performance-conscious upgrade that respects the bike’s original character and intent. It invites a broader audience—from the daily commuter who seeks a gentler wind, to the weekend warrior who wants a sharper silhouette and easier customization, to the curious builder who wants to swap looks with speed that remains predictable and manageable. The overarching idea is that the two-bolt system opens a space for experimentation without demanding a wholesale commitment to a full fairing suite; it makes aerodynamic improvement approachable and maintainable over time. And it connects with a lineage of aftermarket support designed to accommodate this precise kind of fit without forcing riders into rigid, model-specific pathways.

For readers hungry for deeper exploration into compatible designs across popular models, the Summit Fairings catalog offers a practical reference point. The Yamaha collection, for instance, provides a focused range of fairings that illustrate how small, two-point mounts can be harmonized with contemporary naked and sport-touring platforms. This internal reference helps frame expectations about fit and aesthetics while underscoring the importance of model-specific verification. For learners who want to see how the two-bolt approach translates into a tailored experience on the road, the sequence of installing a small fairing naturally leads to a cleaner, more confident ride. It is a reminder that the best outcomes come from careful selection, precise measurement, and a willingness to adapt visuals and protection to the rider’s needs rather than to a one-size-fits-all blueprint.

External resource: https://www.kinglionmotorcycles.com

Tiny Panels, Broad Potential: Market Dynamics and Purchasing Paths for 2-Bolt Small Motorcycle Fairing Kits

Two-bolt small motorcycle fairing kits sit at a curious intersection of form and function. They are not about full-body aerodynamics or extreme race-grade protection; instead, they cater to riders who want a lighter, more customizable aesthetic without sacrificing rider accessibility or street practicality. The core appeal lies in modularity: compact fairings that attach with just two points, yet still deliver a clean, directional profile. In this niche, the materials and construction matter as much as the mounting method. A kit that combines lightweight aluminum with durable ABS components can offer a practical balance—strength where it’s needed, flexibility where it helps. For the everyday rider, that means easier maintenance, simpler part replacement, and the confidence that a quick bolt-on change won’t derail the schedule of a weekend ride. The market is driven by people who view their bike as a canvas—an instrument for personal expression as much as a vehicle for transport—and the two-bolt approach matches that mindset with minimal commitment and maximum modular potential.

From the design perspective, the trend toward quarter fairings and small panel units reflects a longing for sport-touring aesthetics without the bulk. These compact pieces are engineered to mount near the headlight or along the upper fork area, where even small changes in geometry can alter the lines of the machine. The two-bolt principle is not just a matter of fewer fasteners; it communicates a philosophy of straightforward, repeatable installation. For riders who experiment with different looks—swapping panels to refresh color schemes, textures, or air intake profiles—the two-bolt system acts like a plug-and-play interface. This simplicity has a practical value too: it reduces the risk of misalignment during maintenance and enables quick panel swaps after a routine service or an incidental crash that doesn’t require a full factory rebuild. A kit that respects this philosophy will emphasize consistent bolt spacing, standardized thread sizes, and corrosion-resistant materials that tolerate the rigors of daily riding.

Choosing compatible hardware is a surprisingly common stumbling block. Even when the mounting pattern is clearly two bolts, the surrounding geometry—the curvature of the panel, the thickness at the attachment points, and the way the panel interacts with nearby components like mirrors, gauges, and turns signals—determines whether a kit will fit on a specific model. Practitioners in this space frequently advise riders to verify the motorcycle model and the exact fairing specifications before committing. In practice, this means checking the mounting holes, the panel curvature, and the join lines where the piece would overlap with the headset or handlebars. When a kit is advertised as universal or semi-universal, it’s essential to confirm whether the two-bolt setup is truly compatible with the bike’s frame tolerances and whether the kit includes adapters or shims if the original hardware won’t align perfectly. Materials play a decisive role here too. Aluminum provides a light, stiff backbone that reduces overall weight, while ABS sections offer impact resistance and a forgiving surface for quick color matches or decals. The best kits blend these materials into a cohesive unit, so the installation feels integrated rather than cobbled together with mismatched parts.

The purchasing landscape for these two-bolt fairing kits is surprisingly accessible, yet it rewards a careful buyer’s eye. The market includes large, general retailers that carry universal mounting kits and a wide assortment of bolts and screws specifically labeled for fairing installations. The advantage of these universal sets is breadth: riders can assemble a bolt kit from a broad pool of fasteners, ensuring enough variety to match different mounting holes, thread types, and lengths. However, breadth can also mean inconsistency in finish, corrosion resistance, and head design. A 177-piece collection, for example, provides the raw material for many installations, but the onus remains on the buyer to sort out compatibility with their particular fairings and model. The second lane is auction and resale platforms, where replacement body bolt kits in standard sizes can be found. The advantage here is value and availability; the downside is variability in quality and packaging, which may lead to missing pieces or mismatched thread sizes. The third lane is direct-to-market channels and supplier platforms that emphasize OEM-level parts and certified materials. These listings often advertise lightweight aluminum construction and corrosion resistance, along with claims of crash-tested viability. For the careful buyer, the key is to balance price with confidence in the source and a warranty or return policy that can mitigate the risk of buying off-brand hardware.

In practice, riders can leverage these options by framing a simple checklist before purchase. Start with model and fairing type: confirm the exact mounting pattern and whether the kit is designed for two bolts in a given location. Next, verify the material mix and the finish: aluminum components should resist galling and corrosion, while ABS portions should tolerate UV exposure and minor impacts without cracking. Then, confirm compatibility with nearby components, including headlight units, turn signals, and handlebars, because clearance is a common obstacle that can turn a seemingly perfect kit into a misfit nightmare after the first test fit. Finally, scrutinize the supplier’s reliability: look for clear specifications, return policies, and, if possible, reviews or photo documentation from other riders who have used the kit on similar models. This disciplined approach turns a niche product into a reliable upgrade rather than a gamble.

For riders who want a guided glimpse into options, a curated online catalog can be a practical first stop. A dedicated fairings collection that aggregates two-bolt compatible components offers a window into the range of shapes, finishes, and mounting philosophies in play. By exploring such a catalog, a buyer can visually assess how the two-bolt pieces contribute to the bike’s silhouette and how the lines of the panel interact with the bike’s original geometry. This is where the promise of modularity meets the discipline of fit: you can recognize the potential of a two-bolt kit to transform the bike’s stance without committing to a full fairing overhaul. A thoughtful catalog visit also sets expectations for weight balance, center of gravity implications, and the practicalities of maintenance access created by the panel arrangement. When you combine this catalog insight with the practical buyer’s checklist, you’re well positioned to move from concept to installation with confidence.

The purchasing journey is also about knowing where to look for reliable, up-to-date options. The market’s diversity—from universal bolt kits at mass retailers to OEM-level offerings on supplier marketplaces—results in a spectrum of prices and assurances. For the curious rider, a practical option is to explore a broad catalog of fairings that can be filtered by mounting style while also noting which entries explicitly advertise a two-bolt system. This approach keeps the focus on two essential factors: ease of installation and predictable performance. Whether you are a café racer preparing a weekend project or a commuter rider seeking a styling refresh with modest aerodynamic gains, the two-bolt fairing kit is a compelling proposition when matched to careful sourcing and a clear plan for fit and finish. The market reward is not merely improved looks or reduced wind buffeting; it’s a faster, more repeatable upgrade path that respects the bike’s core geometry and the rider’s time.

For riders ready to browse a targeted starting point, consider checking a curated Honda fairings collection to gauge the aesthetic range and hardware compatibility that two-bolt systems can offer. This internal resource provides a practical reference as you plan your upgrade path and compare panel profiles, mounting strategies, and material finishes. As with any bike modification, the journey from idea to ride is navigated most smoothly when the rider begins with clear compatibility checks, a realistic budget, and an understanding that the two-bolt approach is as much about ease of maintenance as it is about style. The result is a bike that feels lighter, quicker to service, and more expressive on every ride—whether it’s a morning commute or a weekend twist-your-wrist session.

External resource: https://www.alibaba.com/product-detail/Honda-CBR900RR-1994-1995-motorcycle-fairing-kit_1600583552122.html

Final thoughts

The journey through the landscape of 2 bolt small motorcycle fairings reveals the significant role they play in enhancing both the functionality and aesthetics of motorcycles. For business owners, understanding the intricacies of design, materials, and compatibility not only empowers your offerings but also positions you to meet the needs of a diverse customer base. As you navigate purchasing decisions and market trends, remember that the right fairing can make all the difference in a rider’s experience. Equip yourself with knowledge to make sound decisions in this specialized domain.