For business owners focused on the motorcycle industry, understanding the components that enhance performance and aesthetics is vital. Among these, the fairings for the 2004 Honda CBR1000RR stand out, offering a blend of functionality and style. This article explores the significance of material choices, pricing dynamics, effective purchasing channels, and the voice of users, while also addressing emerging trends that could reshape the market landscape. Each chapter aims to equip you with critical insights, helping you make informed decisions in this competitive market.

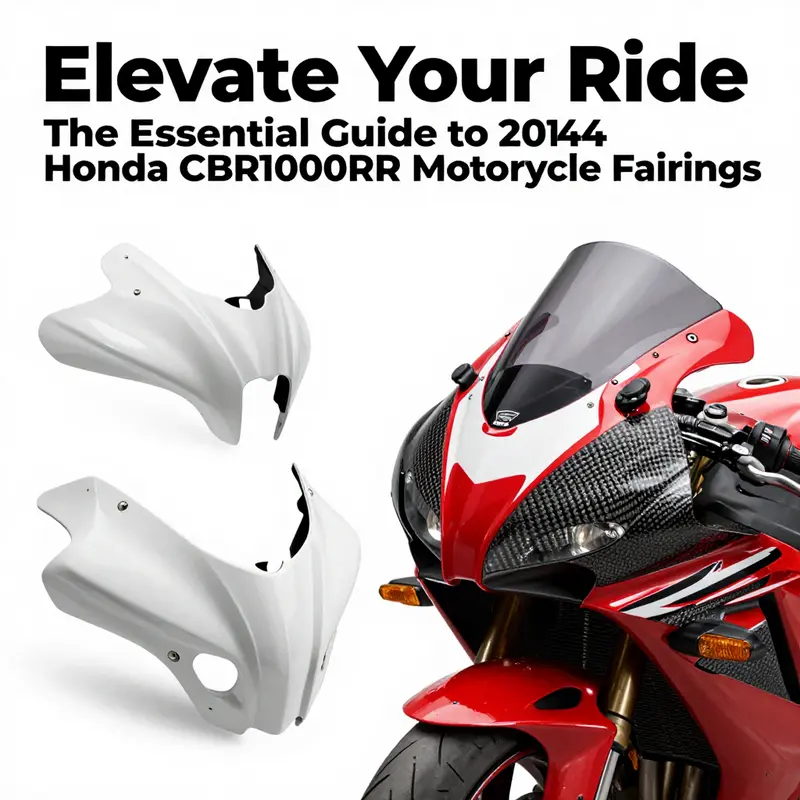

Materials and Configurations: The ABS Foundation and Carbon Fiber Edge of the 2004 Honda CBR1000RR Fairings

The fairings of the 2004 Honda CBR1000RR are more than mere shells; they are a built-in balance of protection, aerodynamics, and personal expression. In this chapter, material choice and panel configuration are treated not as afterthoughts but as core decisions that shape how the bike behaves, how it wears its appearance, and how owners manage ongoing costs. The story of these fairings starts with two broad families of material: ABS plastic and carbon fiber. Each represents a different philosophy of performance and practicality, and every choice reverberates through fitment, paintability, durability, and the rider’s experience at speed, in wind, and on the road.

ABS engineering plastic forms the backbone of most replacement fairings for this model, and it is the workhorse that makes sportbike customization accessible. Injection-molded ABS offers a compelling blend of strength, toughness, and resilience against weathering. It stands up well to minor impacts and road debris, and it holds its shape after repeated flexing. For riders who value reliable, repeatable fitment and a finish that can be color-mmatched and clear-coated with predictable results, ABS remains the practical default. Its repair story is simpler than carbon fiber’s: shallow scrapes can often be sanded and repainted, and the material responds well to the standard prep-and-paint process that shops perform regularly. The original or commonly used aftermarket ABS panels also tend to resist yellowing and surface crazing when exposed to sun and heat over time, which matters on a fairing that sits directly in the path of engine heat and sun exposure.

On the other side of the spectrum sits carbon fiber, a material choice that leans toward minimizing weight and maximizing stiffness. The payoff is tangible: a lighter nose and upper bodywork can translate into crisper steering response and a perceived reduction in front-end mass. Carbon fiber’s strength-to-weight ratio is the primary appeal for riders chasing performance gains, especially those who want more aggressive aero shapes or a more compact, drag-reducing profile. Yet this advantage comes with caveats. Carbon fiber requires careful handling during fabrication and finishing, and it demands attention to resin systems and surface protection. When CF panels do crack or suffer deeper damage, repairs are more complex and costly, often requiring specialist services or panel replacement rather than simple patchwork fixes. Pre-preg or resin-infused variants can offer high strength, but they also come with higher price points and installation considerations. In short, carbon fiber is about weight and stiffness at the premium end of the spectrum.

The second axis of the discussion concerns the type or configuration of the fairings themselves. The 2004 model year was designed with a full fairing layout that wraps around the bike’s air intake and cockpit, with channels engineered to optimize airflow in high-speed scenarios. This full-coverage approach delivers a rider-friendly shield from wind and weather, reducing fatigue on long tracks or hours of highway cruising. It also creates a stable front-end atmosphere for the engine’s cooling demand and for the integration of lighting and instrumentation. When riders opt for partial or modified designs, the aerodynamic story shifts. A more aggressive, race-inspired contour might alter the boundary layer in ways that reduce drag at high speed but could elevate wind buffeting or noise at street speeds. Conversely, more open or ventilated designs can enhance cooling and heat dissipation but may expose the rider to gusts and wind pressure that alter the riding feel. The choice between full and selective coverage interacts with material selection: a CF shell might follow a thinner, stiffer design ethos, while ABS panels can be tuned with thicker sections or different layups to preserve stiffness without sacrificing impact tolerance.

All these material and configuration choices inevitably converge on a set of practical considerations that govern the buying decision. Paint adhesion is a recurring topic; ABS generally accepts standard automotive-grade primers and paints with familiar adhesion behavior and long-term color stability when clear coats are properly applied. Carbon fiber panels, especially in high-grade finishes, require attention to clear coating that resists UV degradation and micro-fracturing, lest the distinctive weave emerge through the finish. The finish quality is not merely cosmetic; it reflects the panel’s ability to resist stone chips and micro-climates where resin-rich CF faces might otherwise dull over time. Another critical factor is fitment. Even the most premium material cannot compensate for a sloppy mounting interface. Correct alignment of mounting points, gaps, and line continuity between adjacent panels matters as much as the panel’s material chemistry. The original engineering intent—how the fairings mate to the fuel tank, the lower cowl, and the radiator shrouds—guides the required precision. Poor fitment can exacerbate vibration, generate unusual wind noise, or create misalignment of fasteners that leads to stress cracking in high-load areas.

Cost dynamics also shape the material choice. ABS sets are notably more accessible, presenting a broad spectrum of prices that make it feasible for a rider on a budget to restore the bike’s bodywork without compromising most everyday riding expectations. The ABS option thus serves as a pragmatic baseline: it provides robust protection, predictable paintability, and reasonable replacement cycles. Carbon fiber, by contrast, commands a premium. The weight savings and the potential for sharper, more refined aerodynamics justify the extra expense for many enthusiasts, especially those who ride aggressively, track-day, or participate in events where weight and handling are decisive factors. In practice, a rider weighing the goals of performance against the realities of budget and maintenance will often use ABS for routine street use or early restoration, while CF panels find a home in cases where the owner seeks maximum lightweight performance and is prepared to invest in upkeep and specialist installation.

A small but meaningful part of the decision criteria is the purchasing channel and the expected after-sale support. The market offers a spectrum of sourcing options, each with its own reliability and fitment implications. The underlying message remains: prioritize vendors that offer clear fitment data, return policies, and the prospect of local support for installation challenges. The intrinsic variability of aftermarket panels means that even with a high-quality ABS set, a rider will benefit from a professional fitment check, panel alignment test, and, if needed, minor adjustments to the mounting points. The result is more predictable than price alone would suggest, and it preserves the rider’s confidence when the bike is exposed to the realities of road and track riding.

For riders who want a tangible reference to the arrangement and availability of panels designed for this model family, a dedicated aftermarket collection offers a coherent starting point. You can explore a catalog that curates the Hondaa CBR1000RR fairings for the 2004-2005 range, which aligns with the shape and mounting scheme of the bike discussed here. See the collection here: Honda CBR1000RR fairings 2004-2005.

The conversation about materials and configurations would be incomplete without acknowledging the broader context of the data that informs these choices. The 2004-2005 ABS fairing variants are documented in widely accessible listings that emphasize material content, fit, and the practicality of installation. The material designation—high-quality ABS plastic imported for durability and print clarity—sits at the core of many replacement sets. While carbon fiber remains the aspirational path for weight reduction and aerodynamic finesse, ABS continues to be the workhorse that makes restoration and customization widely feasible for riders at all levels. This duality—ABS for accessibility and CF for performance—frames the decision landscape for owners who want to maintain the bike’s original spirit while embracing personal performance and aesthetics.

In sum, the material and type decisions surrounding the 2004 CBR1000RR fairings are not abstract. They directly affect how the bike feels under the rider, how reliably it protects vital components, and how a rider can recover and refresh the look as the years accumulate. ABS provides a robust, paint-friendly, cost-conscious path that keeps the bike road-ready and visually coherent. Carbon fiber offers a performance-oriented option that can translate into meaningful handling advantages when used with skill and care. The full-fairing design of this era serves as a platform for these materials to express themselves, balancing protection with airflow, weight with rigidity, and durability with the hope of a future restoration that remains faithful to the bike’s original intent. For owners, the key is to weigh the goals—daily usability, track potential, and long-term maintenance—against the realities of cost and compatibility. When in doubt, prioritize fit, finish, and a plan for support that keeps the fairings performing across seasons and miles. The result is a bike that not only looks the part but carries the rider with a confidence born from a well-considered choice in materials and configuration.

External resource: https://www.ebay.com/itm/186179433819

Weight, Wallet, and Width: Price Ranges and Purchase Paths for the 2004 Honda CBR1000RR Fairings

When a rider steps back from the showroom and imagines the silhouette of the 2004 Honda CBR1000RR, the fairings come into sharp relief. They are not merely cosmetic; they shape how quickly the bike cuts through air, how stable it feels at speed, and how inviting it is to the eye. For a first-time or budget-conscious rebuild, understanding the price landscape and the routes to acquiring fairings becomes as important as the choice of color. This chapter threads together material options, price bands, and the ways riders actually obtain fairings for a legacy machine like the 2004 CBR1000RR, while keeping a practical eye on fit, finish, and long-term value.

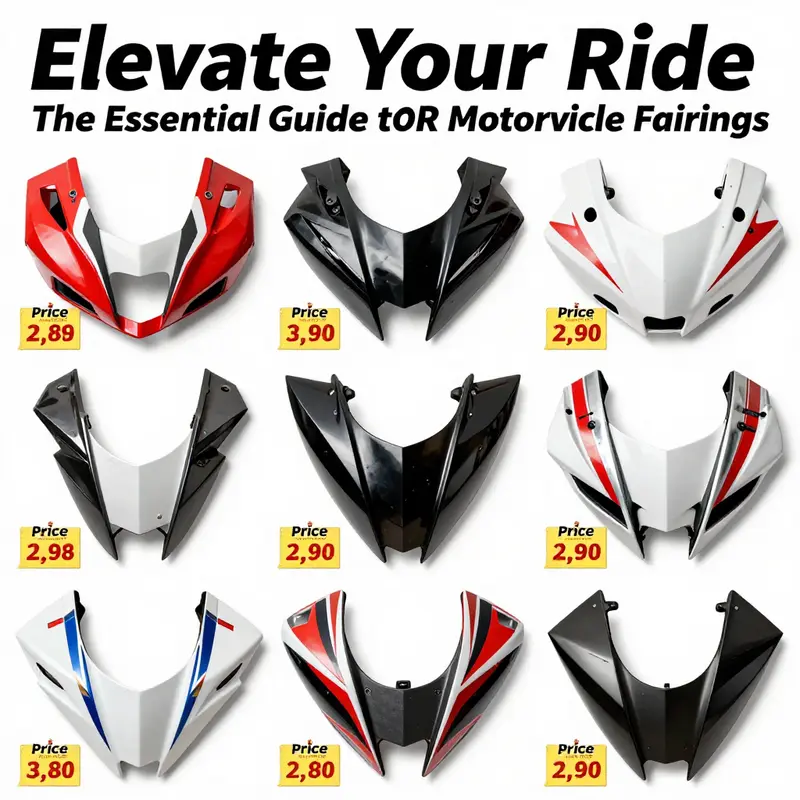

A common starting point for replacement fairings on this model is an injection-molded plastic kit. Engineered from ABS, these panels arrive as a durable, impact-resistant shell that can withstand the bumps of daily riding and occasional cornering mishaps. The appeal is obvious: the material is cost-effective to manufacture, relatively forgiving in repair, and available from a broad array of suppliers. In real-world terms, this translates to price bands that sit at the friendlier end of the spectrum. Typical complete sets in this category fall into a wide range—from roughly twenty-five to fifty dollars for unpainted or basic variants, with even lower entry points for certain stock-style replacements. It is not unusual to encounter standalone sections or simplified kits priced in the mid-twenties. For riders who want a clean, factory-like look without stretching the budget, these injection-molded options are a sensible baseline. They offer good protection and a straightforward mounting process, which matters greatly when work windows are tight and downtime is costly.

Beyond the basics, the market presents a premium path that promises weight savings, greater stiffness, and a sharper aero profile: carbon fiber fairings. Here the physics meets philosophy. Carbon fiber can shave off valuable grams, particularly across large panels like the belly and side covers, and it tends to deliver a more rigid, studio-perfect surface for those who care about resonance and handling in high-speed scenarios. The flip side is the price—this is a premium route. Price anchors for a full carbon fiber kit can begin in the vicinity of a few hundred dollars and climb quickly, depending on the grade of the carbon, the method of fabrication, and whether the kit is a complete set or a partial replacement. In one common market snapshot, a complete carbon kit starts well above three hundred dollars, often hovering near the four-figure mark when the top-end, pre-impregnated construction and finish are included. The difference between a high-volume, injection-molded core and a race-oriented carbon assembly is not merely cosmetic; it translates into weight, stiffness, and the confidence a rider feels when the shoulder of the throttle opens wide. Pre-preg or hand-laid carbon fiber, typical of more bespoke or performance-focused vendors, tends to push the price into the several hundreds of dollars range, and can crest into the five-figure realm only in limited editions or extensively customized configurations. Even so, for riders who view the bike as a performance instrument rather than a hobby, carbon fiber presents a compelling case for selective upgrades, especially on corners and down the long back straight where every gram saved matters.

In addition to these two broad camps, there are customizable or painted options that exist on the spectrum between economy and exclusivity. Some vendors offer painted finishes or unique graphic treatments that can transform a stock-looking shell into a distinctive statement on two wheels. The price for these more stylized sets varies, often shaped by the extent of customization, the complexity of the graphics, and whether the finish is applied as part of a complete kit or as a surface treatment on top of a basic shell. Such packages can place the total near the higher end of injection-molded offerings or at the lower end of carbon fiber assemblies, depending on the artistry and materials involved. Consumers should anticipate not only the sticker price but the potential for additional costs in prep and paint, especially when color-matching to an existing bike or achieving a particular livery requires careful shading and clear coats that hold up against UV exposure and abrasion.

Price is only one side of the ledger when evaluating acquisition methods. The channels through which riders obtain fairings for a 2004 CBR1000RR shape the total cost in practice as much as the sticker price on the box. Large global marketplaces offer a dizzying array of options that span the entire spectrum—from budget ABS to advanced carbon fiber. The upside is the breadth of choice and the occasional opportunity to catch promotions or bundles. The downside can be longer shipping times, variability in quality control, and the headaches that come with ensuring a fitment that aligns with the bike’s specific frame geometry and mounting hardware. Because these fairings are designed to fit a certain vintage of the CBR1000RR, narrowing the selection to items explicitly advertised as compatible with 2004-2005 models helps prevent compatibility surprises at install time. For riders who prize speed and convenience, such marketplaces can deliver a rapid path to a working restoration, especially if the seller offers clear return policies and detailed fitment notes.

Dedicated motorcycle parts retailers present a different kind of value proposition. They tend to emphasize fitment accuracy and customer support, sometimes offering pre-ride consultations to verify mounting points and hardware compatibility. For a bike of this vintage, aligning with a retailer that specializes in Honda sport bikes, and specifically in the CBR lineage, can reduce the risk of misfitment and the often frustrating process of trial and error during installation. These sources may be more conservative with pricing but compensate with confidence in the product’s geometry and in post-purchase assistance, should any alignments or paint-matching concerns arise after the kit arrives. When moving down the chain from mass-market sellers to boutique providers, it is reasonable to anticipate more complete kits, potentially including mounting hardware, grommets, and sometimes even pre-drilled holes that align with the bike’s original fastener grid. This level of completeness matters for a model like the 2004 CBR1000RR, where the sequence of steps from unboxing to riding is marked by precise science: removing old panels, cleaning mounting points, and securing the new shell with a little care so as not to warp the fairing edges in the first tightening pass.

A practical note to keep in mind is the condition of the panels upon arrival. Unpainted injection-molded shells can be a good base for a custom colorwork, but they require patience and proper surface preparation to achieve a showroom finish. If you plan to spray match, budget for sandpaper grits, primer, base coats, and a clear coat that resists UV wear. The alternative—ordering a factory-finish, already-painted set—reduces those prep efforts but often comes at a premium, sometimes accompanied by longer lead times. For riders who want to minimize repaint tasks, evaluating the finish quality and expected color tolerance from the seller becomes critical to avoid a mismatch that undermines the entire restoration effort. The recommended approach is to seek complete kits where the paint-ready surfaces align with the expected color maps for the model year in question, and where the seller offers clear photos or swatches that demonstrate the finish under natural light.

If you are anchoring your decision in value rather than pure performance, the comparison often centers on the total cost of ownership. A basic ABS kit, while affordable, may require more frequent touchups and may not deliver the same rigid feel during aggressive track sessions. A carbon fiber option, although costly upfront, can yield lower mass and stiffer panels, which translates to crisper steering responses at speed. For a rider who uses the bike as a daily rider with occasional weekend laps, a well-selected ABS kit with a durable clear coat can be the most sensible blend of practicality and style. For the enthusiast seeking the highest possible performance envelope, a carbon fiber kit, perhaps sourced from a European or specialty producer, becomes a long-term investment that aligns with the bike’s legacy as a performance-oriented platform.

In practical terms, a good starting point for exploring options is to look at a curated Honda-focused fairings lineup that groups options by model family and generation. A centralized collection that covers the 2004-2005 CBR1000RR can help the buyer compare fitment notes, finish options, and price bands without wading through unrelated models. For readers who want a quick jump into the broader ecosystem, a direct route to a dedicated Honda fairings collection offers a structured overview of the options available for this specific bike family. Honda fairings collection provides a gateway to vetted choices and helps align expectations with actual product offerings, rather than relying on generic search results that may include incompatible panels or older, ill-fitting designs. This kind of targeted browsing is particularly valuable when the goal is to restore the bike to a ride-ready condition with panels that align with the original mounting geometry and the rider’s aesthetic goals.

Ultimately, the choice among ABS, carbon fiber, or painted plastic comes down to a blend of budget, intended use, and the patience to manage installation. The 2004 CBR1000RR’s fairings are a gateway to transforming the bike’s presence, performance, and protective envelope. As with any restoration or modification project, the informed buyer weighs upfront costs against long-term benefits and considers how the final outcome will be used: daily commuting, weekend canyon carving, or a track-day machine. The market’s breadth means there is no single correct path; rather, there is a spectrum of options, each with its own fitment realities, finish quality, and post-purchase support. By anchoring decisions to clear expectations about weight, rigidity, and the needs of the rider, a rider can navigate the price range and acquisition channels with greater confidence—and end up with fairings that truly complement the 2004 CBR1000RR’s enduring appeal.

External resource: For a broader view of current market options and price landscapes, see this external catalog of motorcycle fairing options: External resource.

null

null

Rider Voices, Real-world Tests: Feedback-Driven Evolution of the 2004 CBR1000RR Fairings

Rider feedback is not a footnote in the story of fairings; it is the compass that keeps design honest, relevant, and progressively better. For the 2004 CBR1000RR, the fairings did not merely cloak an engine and frame; they framed the rider’s experience, translating airflow, vibration, and aesthetic taste into measurable cues that engineers and manufacturers could understand. In a segment of motorcycling where a few millimeters of clearance or a slight change in contour can alter stability at triple-digit speeds, the value of real-world input becomes evident. The journey from concept to production is not linear. It proceeds through cycles of testing, feedback, adjustment, and retesting, with the rider’s perspective serving as the most immediate and honest test bench. When a rider opens a package and fits a set of replacement panels, the initial impression matters as much as the long road test that follows. If the parts arrive with a tight tolerance or, conversely, with a mismatch that requires a workaround, the user’s first-hand reaction becomes a data point that can prompt a quick fix or a broader design rethink. In a market where aftermarket options proliferate, the benchmark for quality is not only fit, finish, and weight, but also how readily a product adapts to voices from the street and the track alike.

Product validation begins the moment a customer unpacks a new fairing kit. The process described in the knowledge base—test the product on arrival and provide feedback, with a promise of responsive support—frames a culture of accountability. It is not enough to design something that looks aggressive or promises aerodynamic gains; the product must prove itself in the messy, diverse conditions of real riding. Riders ride in rain and sun, at city speeds and on the open highway, over imperfect roads and on smooth tarmac. They mount the pieces, adjust mounting points, and encounter variances in fit that no CAD model could fully predict. Feedback channels then convert those impressions into concrete guidance for the next production cycle. A report may highlight a minor alignment issue with a mounting tab or call out a rattling at sustained highway speed. Each observation becomes an input for manufacturing engineers, who translate it into revised tolerances, revised fixtures, or reinforced structures. In this sense, the user becomes a co-designer, whose practical insights help transform a good concept into a robust, widely adoptable product.

This collaborative approach is particularly important for a model like the 2004 CBR1000RR, where the fairings are meant to balance bold styling with precise aerodynamics. Riders often measure performance not just by top speed but by how the bodywork behaves as speed fluctuates, how it responds to crosswinds, and how it dampens or amplifies wind noise. If feedback repeatedly surfaces concerns about high-speed rumble, buffeting, or loose panels, the manufacturer can respond with targeted refinements. The process may involve re-engineering fasteners, adding bracing at critical junctions, or selecting a slightly different resin or composite layup to improve stiffness without adding weight. Even seemingly minor decisions—like tightening the curvature of a shoulder line or adjusting the wind-deflector angle—can change the perceived stability in how air interacts with the bike at tempo-rich speeds. The rider’s voice, in this scenario, is both a validator of current strength and a beacon for future innovation.

The themes of continuous improvement and innovation, in turn, illuminate how feedback shapes not just the current generation of fairings but the market’s broader expectations. In a environment where the supply of ABS injection-molded options, carbon fiber variants, and premium finishes competes for attention, user feedback creates a practical filter. It helps manufacturers decide where to invest in higher-cost materials, such as carbon fiber, and where a well-executed ABS solution delivers satisfying value. The insights from riders who want lighter weight for acceleration and handling, or who demand more robust impact resistance for casual track days, feed directly into a portfolio strategy. When a rider notices that a certain line reduces weight by a few hundred grams while preserving rigidity, that data point can steer material selection in subsequent runs. Conversely, if feedback highlights edge chipping or color-mate inconsistencies after exposure to sun and rain, it triggers considerations of paint compatibility, protective coatings, or surface treatment techniques. The dynamic between rider input and manufacturing capability is a living dialogue, and the 2004 model’s fairings demonstrate how this exchange translates into tangible improvements across iterations.

This feedback loop also plays a crucial role in refining the user experience beyond performance metrics. Aesthetic preferences—color options, decal styles, and the ability to customize visuals—often surface in rider feedback and can steer product lines toward more versatile or expressive offerings. The market’s appetite for personalization is tempered by practical constraints; yet when feedback consistently points toward a preferred finish or a desire for easier color-matching with aftermarket components, designers can respond with more standardized palettes or modular finishing options. The rider’s sense of identity on the bike matters, and the fairings’ appearance is a key part of that identity. The feedback-driven approach helps ensure that the exterior not only protects the bike but also communicates the rider’s character without compromising the engineering beneath.

Trust and loyalty grow from this two-way dialogue. When a rider’s concerns are heard and addressed through tangible changes, the relationship between consumer and manufacturer deepens. The knowledge base emphasizes the importance of feedback as a mechanism for quick problem solving and long-term quality assurance. This responsiveness signals to the community that the brand values hands-on experience and appreciates the practical realities of ownership. In turn, riders become ambassadors for the product line, sharing credible anecdotes about fit, durability, and ease of installation that carry weight with prospective buyers. This social proof is particularly compelling in a market where replacement parts can dramatically reshape the bike’s behavior and personality. The ability to deliver reliable assistance, as suggested by the guidance to contact support with any issues, reinforces a commitment to continuity. It reassures buyers that the relationship does not end at purchase but extends into ongoing maintenance and customization.

From a buyer’s perspective, the implications of this feedback-centric model are concrete. When evaluating replacement fairings for a model like the 2004 variant, the decision often hinges on fit accuracy, ease of installation, and how the panel geometry interacts with the original chassis and other components. The material choice—whether ABS, with its balanced cost and durability, or carbon fiber, with its lightness and stiffness—becomes a trade-off that is constantly rebalanced by user input. The real-world data collected from riders who install and ride with these panels helps the market calibrate expectations: how much weight is saved, how much stiffness is gained, how much drag reduction is plausible, and what the true maintenance implications are after thousands of miles. This is not purely an engineering exercise; it is a conversation that molds the community’s standards for what constitutes a high-quality replacement fairing.

An integrated view of the process shows how these elements coalesce. The initial design provides a baseline for fit and performance, but it is the rider’s hands-on experience that tests dimples, alignment, and aerodynamics in the open world. The subsequent iterations—driven by user feedback—refine mounting hardware, adjust panel radii, and improve finish durability. The market, in turn, reacts to these refinements with a willingness to invest in higher-end materials or to explore new manufacturing methods when feedback indicates clearer value. The result is a more resilient, responsive, and expressive set of options for enthusiasts who want their bikes to look as good as they perform. This is the essence of feedback-driven design in the context of 2004-era fairings: a collaborative path where rider experience informs engineering choices, and where each improvement is validated by the next round of real-world testing.

To ground these observations in a broader reference, readers can consult contemporary evaluations of the bike that highlight how the chassis, power delivery, and suspension interplay with the new plastic bodywork. External reference: https://www.motorcycle.com/2004-honda-cbr1000rr-review/ will offer complementary perspectives on how the 2004 bike was received and how its fairings contributed to the overall experience at the time. In parallel, for those exploring different aftermarket pathways, the internal link to the Honda CBR1000RR fairings 2004-2005 collection provides a concrete example of how the market translates rider feedback into tangible product families. You can explore the collection here: Honda CBR1000RR fairings 2004-2005 collection.

In sum, the role of user evaluations and feedback in shaping the 2004 CBR1000RR fairings is emblematic of a broader engineering truth: practical input from riders is the most immediate and actionable measure of a product’s success. It anchors design decisions to lived experience, fuels ongoing innovation, and builds trust between makers and users. When the rider’s voice is heard and acted upon, the fairings evolve from cosmetic shells into functional partners that enhance the bike’s dynamic character. The dialogue between rider and manufacturer thus remains essential—continuously guiding improvements, confirming value, and ensuring that the 2004 model’s fairings remain relevant in a changing market and a diverse community of riders.

旧时代外壳在现代市场中的再解读:2024潮流对经典整流罩的影响与适配

在讨论摩托车改装的整流罩时,2024年的市场趋势并非直接改变老款件的定价或设计,而是改变了改装路径的认知。对于较早型号的整流罩,可能的影响包括材料选择、可获取性、以及对外观与空气动力学平衡的再评估。研究显示没有专门针对“2024年市场趋势”对特定老款的权威分析,但从材料、渠道、设计语言的变化中,我们可以推断出潜在机会。

在材料层面,ABS注塑件因成本低、易于大规模供应而仍占据主导地位;碳纤维以重量减轻和刚性提升带来潜在的空气动力学优势,但高昂价格成为制约因素。2024年的趋势强调在同一套件中实现“轻量化+耐用性”的综合解决方案,碳纤维或基于预浸料的定制件正逐步成为长期投资,即便成本高于ABS。

可获取性与渠道方面,全球化贸易让旧款整流罩有了更多维度的选择,但低成本渠道往往伴随匹配精度、表面处理和配套件的波动。因此,优先选择本地有售后服务的渠道,必要时通过现场比对确认尺寸与缝隙。对预算敏感的改装者,可通过提升ABS件的表面处理和涂层稳定性来提高性价比;对追求重量与强度的车友,碳纤维方案的综合收益将逐步显现。

模型匹配与安装风险也需要新认知。现代整流罩的设计语言强调边缘形状、进气口布局与曲面连续性,较旧车型的替换件常需在保持原几何轮廓的前提下进行二次加工。因此,购前应核对尺寸数据、涂层说明及兼容性,必要时进行实物比对或现场试装,以减少表面龟裂、涂层脱落等问题。

美学与维护方面,2024年的趋势鼓励定制化表达与可持续性并重。ABS件易于再喷涂和修补,成本低且色差风险较小;碳纤维件在涂层保护方面需要更精细工艺以避免微裂与光泽退化,确保长期外观与性能的稳定性。

购买与施工的核心仍是尺寸匹配。市场的替换件大致分为“尽量接近原尺寸/轮廓”的替代品和“近似通用型”的件套,后者可能需要裁切或打磨。任何追求省时省力的做法都可能带来缝隙渗水、涂层脱落等风险,因此应提前做现场测量,优先选择提供清晰尺寸数据与兼容性说明的渠道。

价格与售后也是决策关键。ABS件的成本更易被接受,碳纤维件的价格区间较大,需权衡长期维护成本与性能收益。另一个现实是保修条款和退换政策,具备本地化服务网络的供应商能在安装阶段提供即时解决方案,降低二次加工风险。

行动指南:在预算允许的范围内,优先选用高质量ABS件以确保尺寸与涂层稳定性;若追求重量与空气动力学提升,可以结合预算逐步引入碳纤维件,并做好完整的安装与表面处理计划。无论选择哪种方案,确保材料、配件、涂层、安装工具与技术支持处于同一水平线,是避免后续问题的关键。若需要参考具体系列,可以浏览相关整流罩系列页面,例如2004-2005整流罩系列页面(链接见文末)。https://www.summitfairings.com/collections/honda-cbr1000rr-fairings-2004-2005

Final thoughts

The market for the 2004 Honda CBR1000RR motorcycle fairings continues to evolve, influenced by customer preferences, material advancements, and pricing strategies. Business owners need to stay updated on these dynamics to cater effectively to their customers. By understanding the significance of material choice, navigating the diverse pricing landscape, selecting reliable purchasing channels, valuing user feedback, and anticipating market trends, businesses can position themselves to thrive in this competitive niche. Ultimately, the right fairings not only enhance bike performance but also attract customers looking for quality and style.