Adventure motorcycles demand a unique design that balances performance across varied terrains. Central to this performance is the fairing, which shields riders from wind, rain, and debris, while also enhancing aerodynamics and fuel efficiency. This article delves into the various types of adventure motorcycle fairings, focusing on full fairings, half fairings, and specialized rally-style fairings. Each chapter will reveal how these components contribute to a motorcycle’s overall functionality, durability, and rider experience.

Full Fairings: Sculpting Speed, Shelter, and Strength for Adventure Motorcycles

Full Fairings: Sculpting Speed, Shelter, and Strength for Adventure Motorcycles

Full fairings are more than cosmetic shells. On an adventure motorcycle they act as a performance tool, a weather shield, and a structural element that changes how the bike interacts with the rider, the air, and the terrain. When you study full fairings, you quickly see they are an integrated solution. They balance aerodynamic flow with rider comfort, protect mechanical systems from the elements, and create mounting real estate for the practical gear needed on long rides. This chapter examines how full fairings perform these roles, why their design matters for mixed on-road and off-road travel, and what tradeoffs riders should accept when choosing them.

A full fairing wraps the motorcycle from the upper cowl down to the lower belly pan. It often encloses the engine and extends rearward to blend into side panels. This continuous surface smooths airflow across the bike, reducing drag and stabilizing the chassis at speed. The result is fewer gusts hitting the rider, a calmer pressure field around the tank and legs, and better fuel efficiency on long highway stretches. For an adventure rider covering hundreds of miles in a day, those small gains add up to meaningful reductions in fatigue and fewer fuel stops.

Material selection is one of the first design decisions. High-impact ABS plastic and fiberglass composites dominate modern full fairings. ABS offers good impact resistance, flexibility, and ease of mass manufacture. Fiberglass can be stiffer and easier to repair in the field, but it can also crack under severe impact. Many manufacturers blend materials or add reinforcements in high-stress zones. The goal is to achieve a balance between toughness and weight. Excess weight forward or low on the frame can alter handling, so designers often use ribbing and hollow sections to retain strength while trimming mass.

Aerodynamics drives the visible form. Designers shape the fairing to guide airflow away from the rider while managing pressure zones around the engine and chassis. Integrated ducts channel air to the radiator and engine, preventing overheating without creating additional drag. Strategically placed vents break up low-pressure pockets beneath the bike, reducing lift and minimizing turbulence that can buffet the rider at high speeds. The fairing’s leading edge, windshield height, and curvature determine how the wind splits and reattaches. Small changes here affect the rider’s head and shoulder loads, and they influence overall stability during crosswinds.

Wind management is as much about rider ergonomics as it is about speed. A well-designed full fairing funnels air over the windshield and shoulders, creating a sheltered envelope for the torso. This lowers fatigue by reducing constant muscle tension and the need for a tucked posture. Riders can maintain a comfortable upright position for longer, preserving energy for off-road sections that require focus and balance. Some adventure fairings include adjustable wind deflectors or segmented screens. These allow on-the-fly tuning of airflow, trading bluffing protection for improved visibility or vice versa. For multi-day rides that mix highways and gravel tracks, that flexibility is invaluable.

Full fairings also play a central role in weather protection. Rain, dust, and cold hit a rider differently at 70 mph than at 30 mph. A continuous fairing creates an envelope that slows and diverts water and grit. It keeps critical components drier, which reduces the likelihood of water ingress into electrical connectors and sensors. The lowered exposure of engine internals also helps preserve finishes and seals when riding through mud and salt. For riders traveling through varied climates, this protection translates to fewer maintenance interventions and a lower risk of breakdown in remote areas.

Impact protection is another advantage. The outer shell absorbs and spreads forces from low-speed slides and impacts. When combined with crash bars and skid plates, a full fairing forms part of a layered defense system. Designers reinforce edges and mounting points to avoid panels breaking free and catching on obstacles during a tip-over. Modular designs that use sacrificial brackets or replaceable lower sections simplify repairs after an accident. Rather than replacing a large, expensive panel, riders can swap smaller sections and get back on the road quickly.

However, that comprehensive coverage has tradeoffs. Enclosing the engine complicates routine maintenance. Oil filter changes, clutch adjustments, and other service items may require panel removal. Designers address this problem by adding access panels and quick-release fasteners. Still, compared with a naked or lightly clothed bike, the extra steps extend service time. For riders who perform frequent field maintenance, this is a real consideration.

Weight and center of gravity shift are practical concerns. Full fairings add mass, usually concentrated on the front and sides of the chassis. If designers place heavy fairing elements poorly, they can affect steering feel and nimbleness at low speeds. To counter this, modern fairings are engineered to position material close to the frame and to use lightweight composites in outer sections. The result keeps the mass near the bike’s neutral axis, preserving cornering balance while still providing the strength and coverage riders need.

Stability at high speeds is a clear benefit. The fairing shapes the center of pressure so that aerodynamic forces align more closely with the bike’s center of mass. This reduces pitching and yawing tendencies. For long pulls on open highways, that means steadier cruise and less continual small steering corrections. Better stability also improves tire life and reduces rider strain during long solo runs. Where tours cross exposed terrain or loose surfaces that generate unpredictable wake, the fairing’s calming effect contributes to a safer ride.

Designers also account for crosswind sensitivity. A broad, tall fairing increases the lateral surface area that wind can push against. To mitigate this, many fairings taper toward the rear, allowing gusts to bleed off gradually. Integrated vents and cutouts can help equalize pressure on both sides, reducing the torque imparted by sudden crosswinds. Some adventure fairings pair with handlebar-mounted wind deflectors or auxiliary screens to fine-tune how gusts interact with the rider and controls.

A practical advantage of full fairings is the real estate they offer. Panels provide solid mounting points for lights, navigation units, and auxiliary switches. They hide wiring channels and protect connectors from the environment. For riders who equip bikes with auxiliary fuel tanks, heated grips, or multifunction lights, a full fairing simplifies clean wiring runs and hides hardware in a tidy way. This integration keeps cockpit clutter to a minimum and reduces the chance of snagged cables during rough riding.

Modularity is critical in adventure applications. Many modern full fairings adopt a modular approach. Upper sections can be removed for off-road use without exposing the mechanicals fully. Detachable lower bowls protect the engine during gravel runs and can be swapped if damaged. Mounting bosses for racks and luggage can be reinforced independently of the main shell. This modularity keeps repair costs lower after a crash and allows riders to adapt the bike to the ride ahead, whether that ride is a continent-spanning tour or a technical desert stage.

Repairability influences material and joint choices. Fastening systems that use captive nuts, slotted mounts, and replaceable tabs make field repairs easier. When a sacrificial tab breaks, it is far cheaper to replace than to remanufacture a full cowl. Fiberglass sections can be patched with resin and cloth in remote regions, while thermoplastic panels often benefit from heat welding to restore integrity. Riders planning remote adventures should consider fairings with simple, serviceable construction.

Finishes and surface treatments also matter. Matte coatings hide surface scuffs better than glossy paint. Clear coats resist ultraviolet degradation. Textured lower panels can be more forgiving where rock chips are common. Designers often leave high-impact areas unpainted or fitted with protective film. For riders crossing varied terrain, those small design choices delay the cosmetic decline of a fairing and keep the bike presentable while preserving resale value.

Fitment is a practical issue often overlooked until installation. Modern bikes use precision-molded panels with tight tolerances. Aftermarket full fairings vary in accuracy, which affects gaps, rattle, and aerodynamic performance. Poorly fitting panels can generate extra noise, trap water, or create flow separation that undermines stability. When choosing a fairing, inspect mounting points and alignment features. A well-designed kit should align easily without forcing hardware or creating stress concentrations.

Lighting and visibility are part of the system, not an afterthought. Full fairings commonly incorporate mounts and housings for main and auxiliary lamps. A clean, integrated headlight assembly improves beam aim and keeps wiring protected. Adventure riders often run additional lights for fog or off-road illumination; a full fairing with reinforced lamp bosses makes those upgrades simpler and neater. Concealed wiring pathways reduce the risk of damage from branches, rocks, or luggage straps.

Thermal management is another critical function. A full fairing traps air in pockets around the engine and exhaust. Without proper vents, heat build-up can reduce performance and rider comfort. Designers include ducts that feed cool air to radiators and expel warm air through chimney vents. These features help maintain stable engine temperatures under load and keep the rider’s legs from baking when the bike idles in hot climates.

Choosing the right full fairing for adventure riding comes down to priorities. If long-range comfort and fuel efficiency are vital, prioritize aerodynamic shape and a tall, adjustable windshield. If you ride aggressively off-road, look for modular designs with replaceable lower bowls and reinforced mounting. If you perform your own maintenance often, seek access panels and fasteners designed for quick removal. The ideal fairing will match the expected terrain and the rider’s tolerance for complexity.

Finally, consider how a full fairing integrates with protective accessories. Attachments such as crash bars, skid plates, and luggage racks must interact safely with the fairing’s mounting system. A strong chassis-mounted rack that doesn’t rely on fairing tabs will survive impacts better than a rack bolted to bodywork. Similarly, crash bars should be sized and positioned to prevent the fairing from being trapped beneath the bike during a tip-over.

A thoughtfully engineered full fairing transforms an adventure motorcycle. It streamlines airflow, shelters the rider, and shields vital systems from harm. It creates a tidy platform for navigation, lighting, and luggage, while increasing comfort on long highway miles. At the same time, riders must accept tradeoffs: modest weight increases, slightly more complex maintenance, and a need for careful fitment. For many adventure riders, the benefits in reduced fatigue, better fuel economy, and improved durability outweigh these costs. The result is a bike that feels composed at speed, protected on rough tracks, and more capable across the varied landscapes that define adventure riding.

For a deeper primer on full fairings and their practical roles, see this practical guide. (https://www.alibaba.com/product-detail/What-Is-a-Full-Fairing-Bike-A-Practical-Guide_1600542389652.html)

For fairings and replacement panels compatible with popular adventure and sport models, explore a broad collection of OEM-style parts here: Honda fairings collection

Half Fairings for Adventure Bikes: The Balanced Approach to Protection, Weight, and Access

Half fairings sit at the intersection of practicality and performance for many adventure riders. They cover the upper motorcycle area—headlight, instruments, handlebars, and the top of the engine—without fully enclosing the frame. This selective coverage changes how the bike behaves on highways, forest roads, and gravel tracks. A half fairing smooths airflow across the rider and controls. It reduces buffeting and fatigue on long stretches of pavement. At the same time, it preserves mechanical access and reduces repair costs compared with a full enclosure. For riders who split time between tarmac and trails, this middle ground can be the most useful choice.

A half fairing’s shaping matters as much as its coverage. Designers sculpt the upper panels to deflect wind around the rider’s chest and helmet. The goal is not to achieve the ultimate aerodynamic coefficient. Rather, it is to reduce the peak gusts and turbulent zones that fatigue riders on long days. The rider experiences calmer airflow, yet feels more connected to the environment than with an extensive shell. That connection helps when negotiating variable road surfaces. You can hear the engine and sense traction changes more readily. That heightened feedback matters off-road, where subtle inputs keep the bike upright over rough ground.

Weight is a defining advantage of half fairings. By leaving the lower engine and frame exposed, a half fairing trims mass from plastic panels and mounting hardware. Less mass improves handling, especially at low speeds and over technical surfaces. A lighter front area reduces inertia in quick direction changes. It also minimizes the leverage of impacts during drop scenarios. Those who prefer nimble steering and rapid recoveries often favor the lighter approach. Reduced weight can also ease suspension tuning, because there is less rotational mass to control. For long expeditions where every kilogram counts, that saving compounds over time.

Maintenance and access are important trade-offs that often determine a rider’s choice. Half fairings open up the engine bay and exhaust headers, making routine checks quicker. Oil top-ups, air filter inspections, and small repairs avoid the removal of large bodywork panels. That practicality translates to less downtime on trips far from service centers. Adventure riders who value field repairs and modular swaps can benefit from easier access. Even when using protective skid plates and guards, a half fairing keeps the core systems reachable without tools for panel removal.

Durability considerations guide material selection for half fairings. Impact-resistant ABS plastic is common because it balances toughness, weight, and cost. Thermoplastic composites and reinforced polymers offer better resistance to cracking under stress while remaining flexible enough to bend and return to shape. Some riders prefer panels that flex rather than shatter when struck by debris or during a fall. That behavior helps prevent sharp edges and reduces the risk of tearing mounting points. Reinforced mounting brackets and bushings absorb energy too, preserving alignment and preventing stress concentrations that lead to failure.

Aerodynamic performance does not stop at the shape of the fairing. Windshield height, rake, and curve influence how the airflow behaves across various rider sizes and stances. A short windscreen with a steep angle will protect the visor but may send turbulent air downwards. Taller, properly curved screens can create a smoother bubble, lowering fatigue for taller riders and pillions. Adjustable screens offer another layer of versatility. When the road turns rough, lowering the screen reduces crosswind leverage. On fast open roads, raising it improves protection and stability. These small adjustments give half fairings surprising flexibility.

Integration with accessories is another point where half fairings shine. Their exposed upper section often has room for mounting solutions for GPS units, auxiliary lights, and compact wind deflectors. Fabricators and kit makers commonly include integrated mounting tabs or reinforced areas for bolt-on accessories. This modularity helps riders tailor the setup for specific trips. For instance, adding extra lighting for night passages or a compact fairing-mounted instrument pod for navigation does not require a complete redesign. The fairing acts as a work surface, granting utility without the bulk of a full enclosure.

Crash and repair economics favor the partial approach in many scenarios. When a fall damages a half fairing, the typical repair is limited to replacing the upper panel and perhaps a few mounts. Full fairings can hide larger damage and carry higher replacement costs. Since half fairings expose more of the mechanicals, it is easier to assess and remediate functional damage after a mishap. Riders who frequently ride rough roads appreciate the lower cost of ownership that comes from smaller, simpler body panels. This economic resilience matters on extended journeys where parts availability is uncertain.

Comfort extends beyond wind protection to include thermal management and vibration control. Half fairings allow more heat to radiate from the engine, which can be an advantage in cooler climates. The exposed lower engine provides passive cooling that helps prevent heat soak at low speeds. Conversely, on hot days, the rider may feel more warmth compared with a fully enclosed fairing. Designers can mitigate this by routing airflow and adding venting. Vibration damping mounts reduce buzz transmitted through the handlebars and plastic, improving comfort without heavy insulation.

The riding environment shapes the decision more than abstract comparisons. For mixed-surface loops that include highway runs and off-pavement stretches, half fairings are often the pragmatic choice. They give the rider fast-road capability without committing to the mass penalty of full trunks. For primarily highway-based touring with occasional dirt detours, some riders will prefer a larger fairing. Conversely, those who expect sustained technical off-road riding usually trade aerodynamic neatness for the most durable, minimalist protection possible. Thus, the half fairing slots neatly into a continuum of choices, offering hybrid benefits to hybrid riders.

When considering modifications, compatibility is paramount. A fairing must match the bike’s geometry and mounting points closely. Poorly matched panels can alter steering feel and cast unpredictable loads on forks. Proper fitment also preserves cooling pathways for the radiator and exhaust. Upgrades should target materials and bracket design first. Choose panels that use reinforced attachment areas and vibration-isolating bushings. That approach maintains alignment through rough terrain and reduces the chance of fastener fatigue. For many riders, choosing a kit designed for their chassis yields the best real-world results.

Wind buffeting and rider posture are practical outcomes of fairing design. A well-shaped half fairing reduces helmet shake at highway speeds. It also smooths airflow over the shoulders, which lowers neck strain. However, buffeting can occur if the screen is mismatched to rider height or posture. Testing different screen heights and angles often produces immediate improvements. Small add-ons like ear deflectors and hand guards further tune airflow. Together, these adjustments create a more controllable aerodynamic envelope for the rider without the need for full enclosure.

Installation and serviceability intersect. Half fairings typically fasten with fewer bolts than full sets. That simplicity makes field removal quicker. It also helps when trail repairs are needed. Keeping a small panel removal kit inside the luggage can reduce roadside work to a few minutes. Maintenance friendliness is not just about speed. It is about the ability to perform checks and minor repairs without a full workshop. This capability increases self-sufficiency on long routes and contributes to peace of mind in remote areas.

Choosing a half fairing often comes down to balancing four variables: protection, weight, access, and modularity. Riders who prioritize quick maintenance and lightweight agility often find the half fairing ideal. Those who favor maximum weather protection and the quietest high-speed ride may still prefer larger enclosures. Yet for many adventure riders who deliberately pursue versatility, half fairings represent a thoughtful compromise. They shield the essential upper area from wind and debris, while keeping the engine accessible and the bike responsive on varied terrain. This pragmatic balance makes the half fairing an enduring option for mixed-surface touring and fast exploration.

For riders exploring fairing options, viewing available collections specific to their chassis helps. One relevant resource is the Honda fairings collection, which shows how different kits fit and function on common platform types. https://www.summitfairings.com/collections/honda-fairings

Further reading on the trade-offs between full and partial fairings offers useful data and design context. The following article provides a clear comparison of performance and style considerations: https://www.motorcycle.com/riding-gear/full-vs-half-fairing-guide/

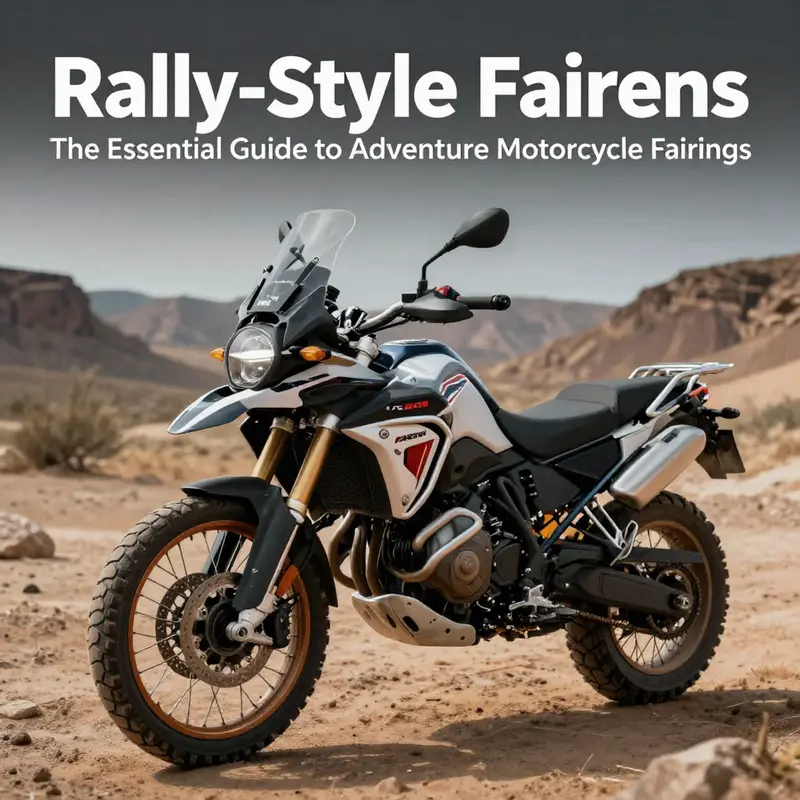

Rally-Style Fairings: Customization in Adventure Motorcycle Fairings

Rally-style fairings are more than a design clause on an adventure machine; they are a philosophy written in carbon, fiberglass, and resin. They embody a balance between protection, performance, and personality, a triad that becomes most evident when riders push beyond paved roads into landscapes that demand both a stout backbone and a flexible silhouette. In this world, the fairing is not merely a shell that reduces wind drag; it is a modular platform that shapes the rider’s experience across long highway hauls and gnarly backcountry tracks. The rally style is defined by purpose-built geometry: higher sweep angles, integrated wind deflection near the rider’s torso, and deliberate gaps or vents that manage heat and air pressure as conditions change, all designed to keep momentum and composure intact when fatigue threatens accuracy or comfort. It is a design conversation that favors clarity over ornament, where every contour serves a function and every attachment point invites a practical choice about how the bike will live on the trail and on the highway.

To understand why rally-style fairings invite such a hands-on relationship with customization, one must consider the demands of adventure riding in a holistic sense. Riders venture into wind and weather with equipment that must endure impact, spray, and mud without breaking the rhythm of the journey. The fairing becomes a shield that channels wind away from the rider’s chest and shoulders, reducing fatigue and allowing the eyes to stay focused on the horizon rather than bracing against gusts. It also serves as a protective cradle for delicate components that otherwise become vulnerable to debris or sudden off-road strikes. But the protective barrier cannot be at odds with accessibility. The rally approach embraces modularity: it anticipates that the bodywork will be repurposed, repaired, and reconfigured as the rider’s route evolves—from long-distance touring to split-second need for additional lights, navigation hardware, or luggage anchors. In this sense, customization is not a vanity project. It is a pragmatic response to the bike’s duty cycle and the rider’s evolving mission.

The aerodynamics of rally-style fairings are finely tuned to yield a stable cockpit at speed while maintaining enough openness to prevent the kind of pressure buildup that can hamper breathing and focus on longer stretches of tarmac. A well-conceived rally fairing guides air past the engine and radiator zones, reduces buffeting on the rider’s helmet, and shapes the flow to help the machine cut through headwinds with less drag. At highway speed, even a small improvement in aerodynamic efficiency can translate into measurable gains in fuel economy and fatigue reduction. This is not mere cosmetics; it is the calculus of efficiency made tangible in real-world riding. The fairing’s silhouette—its widest points, its side panels, the height and curvature of the windscreen, and the angle of the lower deflectors—works in concert with the rider’s position to establish a seamless interaction between the bike and the air around it. When a rider leans forward, the fairing’s geometry should still manage wind pressure without forcing an abrupt change in posture or requiring constant micro-adjustments to remain balanced.

Customization thrives in this ecosystem because adventure riders are not monolithic in their needs. Some seek maximum weather protection for wet, cold climates, prioritizing weather shields that extend to the shoulders and upper arms, with integrated deflectors that minimize rain intrusion. Others chase a lighter, more agile balance, favoring pared-down fairings that invite quicker steering responses and easier engine service access. Still others want modularity that accommodates a growing array of electronics: auxiliary lights for night navigation, dash-mounted GPS or rugged tablets, and mounting points that can accept additional luggage systems without forcing a reconfiguration of panels or brackets. The rally style, in its essence, supports this spectrum through a design language that embraces adaptable interfaces, fasteners that tolerate field adjustments, and fairing sections that can be swapped or augmented with relative ease. It is no accident that the rally aesthetic has grown into a language of its own—a language that speaks to the rider’s desire for self-expression without surrendering function.

From a practical standpoint, the process of customization often unfolds along a few broad paths. There is the DIY route, where riders sculpt fairing pieces from composites, test-fit them with scale models, and refine the form through a cycle of mounting, riding, and adjusting. This approach rewards a patient mindset and a willingness to learn. The steps are not theatrical; they are iterative. A common thread in successful DIY efforts is the disciplined attention given to the mounting points. Rally-style fairings rely on robust, evenly distributed attachment strategies so that impacts don’t translate into torque that could loosen bolts or crack panels. The rider learns to balance the weight of added components with the need for quick access to critical service points. The goal is to avoid a situation where the rider must disassemble large swathes of bodywork to reach an air filter or a spark plug. When done thoughtfully, DIY customization yields fairings that are lighter, stronger, and better aligned with the rider’s proportions, posture, and preferred riding stance.

Another route is the semi-custom or modular kit path. In this approach, riders select a core fairing arrangement designed to fit a family of motorcycles, then augment it with additional pieces or extensions to tailor protection, aesthetics, and utility. Frame extensions, additional shrouds, light-integrated panels, or mounting rails ready-made for navigation devices are common examples of this path. The modular strategy recognizes that adventure bikes are meant to be versatile tools, and a single footprint on a fairing can be adapted to a variety of missions. It also helps manage costs: you can begin with a core, upgrade selectively, and preserve the bike’s core geometry so as not to compromise handling. In this sense, customization is not a one-off event but a continuum—a cycle of evaluation, modification, and re-evaluation that mirrors the rider’s evolving ambitions and terrain preferences.

For riders who want to pursue a path of high-performance customization, the resources extend beyond hardware. There is a cultivated body of knowledge around material selection, fabrication techniques, and finish work that supports more ambitious projects. Carbon fiber, fiberglass, and advanced resins offer varying degrees of strength-to-weight performance, impact resistance, and ease of repair. A fresh fairing project often begins with a clear set of priorities: durability against trail debris, ease of maintenance access, and the ability to seal out wind and rain while still permitting service access when needed. The collector’s mindset—curating a bike that mirrors a rider’s mood and mission—plays a central role here. The tacit understanding is that the rally fairing is as much a canvas for personal expression as it is a functional aerostructure. Riders often mix textures and finishes to evoke the rugged, outdoorsy spirit of their journeys: a matte carbon weave, a gloss overlay to highlight lines, or a rugged, hand-painted motif that echoes the landscapes they ride through. This convergence of craft and travel is where the practice resides as much as the product.

In the realm of practical guidance, the availability of information and the accessibility of tools shape what is feasible for most riders. A widely referenced guide to carbon fiber rally fairings outlines the philosophy of shaping and finishing that a DIY builder can pursue with careful planning. While the specifics of any single project may vary, the core principles—accurate replication of the intended silhouette, clean mold-making or plug-up, and a disciplined approach to surface finishing—translate across projects and models. The narrative here is not about chasing a perfect replication of a design but about achieving a reliable, well-finished fairing that compliments the bike’s geometry and the rider’s needs. The journey is as much about learning to navigate constraints—like the need for adequate ventilation around the engine bay, or ensuring that the added fairing does not obscure the rider’s view or the instrument panel—as it is about chasing a certain aesthetic.

The practical reality is that many riders lean toward options that balance cost, weight, and durability. A full, heavy fairing can deliver unmatched weather protection and aero efficiency at speed but can be more demanding to repair or replace after a crash or off-road impact. Conversely, a lighter, modular setup can be easier to maintain and customize in the field but may require compromises on wind protection at higher speeds or in adverse weather. The rally style embraces this spectrum by openly offering choices: full coverage for long-haul comfort, selective fairing extensions for added weather sealing, or minimal packages that foreground the rider’s stance and the bike’s mechanical accessibility. The design objective is to create a coherent system where each element—the windscreen, side panels, radiators shrouds, and lower deflectors—works in tandem with the rider’s posture and the bike’s center of gravity. When this harmony is achieved, the rider can lean into the throttle with confidence, knowing the air is being managed, the heat is being ventilated, and the bike’s silhouette communicates an intentional readiness for exploration.

Aesthetics, often underestimated in its influence on performance, plays a subtle but real role in the customization dialogue. The rally style invites riders to craft a visual story that resonates with the journey they envision. The choice of surface finish—matte versus gloss, carbon fiber tone, or a bold, weathered look—can affect perceived weight, wind comfort, and even the rider’s sense of connection to the machine. Decals, color accents, and subtle branding are not mere afterthoughts; they are part of a disciplined design language that communicates and reinforces the rider’s intent. The key is to keep the balance intact: the visual cues should harmonize with the bike’s geometry, avoid creating visual clutter that distracts the rider, and support the practical needs of navigation, lighting, and luggage mounting. In this sense, customization becomes a practice in disciplined restraint as much as creative expression, ensuring that every aesthetic choice reinforces the performance logic of the rally configuration rather than compromising it.

The ecosystem surrounding rally-style fairings also highlights the importance of compatibility and future-proofing. A modern rally setup thrives on components that offer secure mounts, reliable fasteners, and redundancy measures where necessary, particularly in off-road contexts where vibrations, impacts, and sudden changes in temperature can stress fixtures and seals. Riders who plan for the long term think about serviceability: how easily can a panel be removed for windshield replacement, how robust are the mounting points after repeated flex and torque, and how well does the design accommodate future upgrades in lighting or instrument displays? These considerations influence not only the quick-fix repairs but the long-term maintenance plan. They shape the rider’s confidence when faced with a wet, rocky pass or a remote stretch where a quick patch might be the difference between continuing the journey and turning back. The rally approach, with its emphasis on modularity and thoughtful integration, acknowledges that a bike is a living, evolving companion and that its armor should adapt without becoming a barrier to ongoing exploration.

In parallel with the hardware conversation, there is a rich landscape of knowledge and community practice that underpins successful rally-style customization. Riders share experiences about mounting strategies, windscreen choices, and compatibility with navigation and lighting accessories. This communal knowledge—gleaned from long trips, wet nights, and windy mountain passes—forms a practical curriculum that helps newcomers evaluate what to prioritize in their own builds. It also provides a benchmark for reliability and resilience: if a setup endures a particular route’s harsh conditions, it stands as a credible baseline for others to emulate or modify with confidence. The culture around rally-style fairings is one of shared learning and iterative improvement. It respects tradition—the endurance-race ethic that values durability and repeatable performance—while inviting experimentation in ways that align with the rider’s personal map of adventures. And for those who want to push the boundaries further, the path is inviting: start with a solid core, augment with modular pieces as needed, and keep the line of sight and service access clear, so every mile of the next journey remains an opportunity for discovery rather than a test of endurance against equipment failures.

As this practice matures, it begins to shape a broader narrative about rider–machine partnership. The rally fairing is not only a protective shell; it is a platform for adaptation—a stage where the rider can choreograph inputs, control responses, and tailor the machine to the unique tempo of each expedition. The discipline of customization—choosing where to invest time and resources, how to document changes, and how to evaluate the impact of each modification—reflects a conscientious approach to riding that respects both the machine’s integrity and the terrain’s demands. It also invites a forward-looking curiosity: how might advances in materials science, rapid prototyping, and modular hardware further empower riders to reconfigure their machines with greater ease, lower weight, and stronger protection? In this sense, rally-style fairings become a moving target of improvement, encouraging riders to test new configurations while honoring the core principles that make this lineage possible: protection without compromising access, aerodynamics without sacrificing maneuverability, and aesthetics that reinforce purpose rather than obscure it.

For readers who want to explore the practical thread of customization further, a glance at the broader community resources and examples can illuminate the path. The practicalities of shaping, finishing, and mounting—especially for carbon or composite fairings—are well supported by a wide array of guides and shared templates that encourage careful planning, precise measurement, and patient assembly. While the journey will inevitably require trade-offs—weight saved here, protection gained there—the overarching objective remains clear: to fashion a fairing system that is reliable, adaptable, and aligned with the rider’s ambitions. The result is a motorcycle that speaks with a coherent voice across terrain types, one that is ready for a long highway stretch and equally prepared for the demands of a remote dirt track. The transition from factory silhouette to customized rally form is more than an upgrade; it is a recommitment to the core promise of adventure riding—that with the right balance of protection, performance, and personal expression, the road less traveled becomes less about risk and more about discovery. The road ahead, much like the trail beneath the tires, rewards the thoughtful rider who treats fairing customization as a continuous, deliberate practice rather than a one-off project.

For those who want a tangible starting point in this ongoing exploration, the Honda fairings collection demonstrates how a core platform can be extended, reinforced, and personalized while maintaining a coherent fit across a family of models. The collection illustrates, in a clear and practical way, how essential it is to align the fairing geometry with the motorcycle’s frame, core mechanicals, and rider geometry. It also highlights the importance of considering wind deflection, mounting simplicity, and maintenance access when planning an upgrade. The path from concept to on-road reality is navigated most effectively by anchoring decisions to functional priorities first and then layering in the expressive elements that reflect the rider’s adventures. This approach—prioritizing performance and durability while allowing room for personal style—preserves the machine’s integrity and ensures that what began as a protective shell evolves into a trusted partner on every mile ahead. When the day’s ride ends and the road again fades into the distance, the rally-style fairing remains a visible testament to a rider’s deliberate choice to blend resilience with individuality, a reminder that the journey itself is the craft and the machine both a canvas and a companion.

Internal link: For readers curious about practical examples and a curated selection, explore the Honda fairings collection. Honda fairings collection says much about how core compatibility, easy maintenance, and modular expansion can harmonize in a single platform without losing the essence of the rally philosophy.

External resource: A detailed, technique-focused project offers a hands-on viewpoint on carbon fiber rally fairing construction, including mold shaping and finishing. https://www.instructables.com/CARBON-FIBER-MOTORCYCLE-RALLY-FAIRING-5-STEPS/

Final thoughts

Adventure motorcycle fairings are indispensable components that significantly influence the overall riding experience. Full fairings enhance protection during long rides, while half fairings offer agility and easy maintenance. Rally-style fairings ensure ruggedness and adaptability for diverse adventures. Understanding these options helps motorcycle owners make informed decisions, optimizing both their machine’s performance and their riding comfort. Investing in the right fairing solution can transform an ordinary ride into an extraordinary journey.