Aftermarket motorcycle fairings have become a vital consideration for business owners in the motorcycle industry. These enhancements not only elevate the aesthetics of bikes but also provide crucial improvements in aerodynamics, protection, and, ultimately, rider performance. As the demand for sophisticated customization grows, understanding the latest advancements in aftermarket fairings becomes imperative. This comprehensive discussion will delve into the evolution of aftermarket fairings, material innovations, cost-benefit analyses, customization trends, and performance enhancements available today. Whether you are a retailer, manufacturer, or enthusiast, gaining insight into these facets will help shape your approach to the aftermarket fairing market.

Riding the Edge: Modern Aftermarket Fairings Redefine Performance, Protection, and Personal Style

Riding a motorcycle with aftermarket fairings is more than a cosmetic choice; it’s a deliberate engineering decision that speaks to how a rider interacts with wind, heat, and rider posture. In a landscape where engines are more efficient and chassis technology continues to evolve, fairings have become a canvas for optimizing performance while expressing personal style. Riders look for parts that can be installed with confidence, align with the bike’s lines, and deliver measurable benefits, whether that means cleaner flow over the rider and radiator, or a more aggressive stance that makes the machine feel like it belongs on a race track. This chapter follows the arc of what modern aftermarket fairings bring to the table: materials that balance stiffness and weight, design methods that embrace precision, and features that merge function with form in ways that both protect and propel the rider forward.

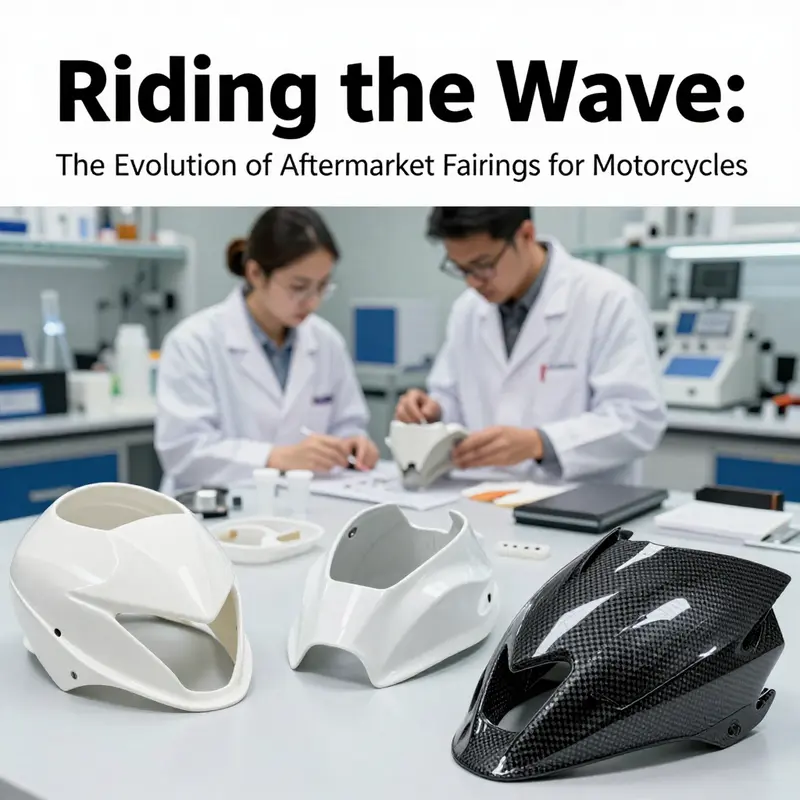

A central shift has been the material science behind these shells. Traditional OEM plastics set a baseline for durability and cost, but modern aftermarket options leverage advanced composites and engineered polymers to achieve strength without adding weight. Fiberglass-reinforced polymers and carbon fiber variants deliver a superior strength-to-weight ratio, which matters when every gram of mass is part of the bike’s inertia and every drag coefficient matters in the wind tunnel that is real-world riding. The result is not only better impact resistance in the event of a minor tip or gravel encounter but also a reduction in overall weight. A lighter shell can translate to crisper handling, more responsive steering, and modest gains in fuel efficiency as the bike experiences less rotational inertia during mid-corner transitions. Deeper, more complex geometries become feasible once the material can resist deformation at speed, which in turn supports more aggressive fairing profiles and integrated channels designed to guide airflow rather than simply block wind.

Design and construction methods have caught up with these material options. The combination of computer-aided design and precision manufacturing enables parts that fit a broader spectrum of bikes while maintaining tight tolerances. Three-dimensional modeling allows designers to simulate airflow and rider position, ensuring that the fairing’s curves work with the bike’s existing aerodynamics rather than fighting them. CNC machining and controlled lamination processes produce consistent skin thickness, predictable edge radii, and reliable mounting interfaces. The payoff is a kit that sits nearly as cleanly as a factory panel, with fewer gaps that can induce turbulence or heat pockets. This precision is not a luxury; it is essential for both performance and safety. If a fairing rents space around the dash or interferes with the fuel tank or radiator, it can create mechanical stress or overheating, undermining the very benefits it promises. By prioritizing exact fitment, manufacturers minimize installation complexity and maximize durability over the long run.

Beyond the shell itself, contemporary designs increasingly embrace functional features that extend their value beyond aesthetics. Built-in air ducts and optimized airflow channels are not cosmetic additions; they are strategic moves to reduce drag and improve engine cooling, particularly at higher speeds and in hot climates. The same airflow pathways that chase power gains also support the rider’s cooling needs, which can influence comfort during long rides and track sessions alike. Some designs even integrate with the bike’s cooling architecture to direct cooling air toward the radiator or oil cooler without creating excessive drag. Ergonomic considerations have also evolved. Custom seats, contoured bodywork, and carefully mapped rider postures link the cockpit experience with the fairing’s geometry. A well-executed kit can encourage a sportier, more aggressive posture that reduces wind fatigue while preserving control and comfort over extended periods. The look remains part of the equation, but the impression of speed becomes paralleled by tangible improvements in stability and confidence when leaned into a corner or entering fast straights.

As riders weigh options, compatibility becomes a decisive factor. The best-performing fairings live or die by their fit with a specific model and year. Subtle changes in frame geometry, mounting points, and alternate bodywork configurations across generations mean that not all kits are interchangeable. The careful buyer examines fitment charts, reads installation notes, and sometimes uses model-specific guides to confirm that the chosen panels align with the bike’s mounting brackets, tank cutouts, and belly pan interfaces. The risk of mismatched feed-throughs, misaligned gaps, or interfering components is real, and it undermines both aesthetics and function if it occurs. To navigate this, many buyers rely on resources that map compatible options to their exact bike make and year, ensuring that the fairing’s lines, attachments, and interlocks align with the chassis. For readers exploring model-specific options, the Honda fairings collection can serve as a dependable starting point to see how a given bike’s silhouette is addressed by aftermarket bodies. This emphasis on fit is not a barrier to entry but a guardrail that keeps riders from chasing performance at the expense of reliability.

The broader effect of these innovations is a market that values personalization as a route to practical performance. Riders who once accepted a stock look for a shell that is both protective and expressive. The improved resilience of modern aftermarket fairings, when sourced from reputable suppliers, means riders can invest with greater confidence that their panels will resist scuffs, crack under impact, or degrade under UV exposure in harsh climates. Coupled with advances in adhesives, sealing compounds, and lightweight mounting hardware, the overall system becomes a coherent package rather than a collection of replaceable shells. This coherence matters when adding other performance-focused elements, such as race-inspired bodywork, which speaks to aesthetics and aerodynamics alike while still remaining street-friendly. The lines between track-ready components and street-friendly enhancements blur as manufacturers continue to deliver designs that respect street legality and everyday usability while offering the same attention to curvature and integration that high-performance racing demands. The result is a fairing ecosystem that encourages experimentation—new shapes, new materials, new internal channels—without sacrificing the core safety and reliability riders expect.

Any discussion of aftermarket fairings should acknowledge the practical realities of purchasing and installation. Before committing to a kit, a rider will weigh the total cost of ownership, including preparation work, finishing, and potential repainting. While high-end composite kits tend to carry a premium, they can pay back that investment through reduced maintenance costs and longer service life compared with lower-cost alternatives. Durability matters not only in frontal impact but in the daily hazards of urban riding, where handling, parking mishaps, and road debris take a toll. Replacing a damaged fairing should be straightforward, and compatibility with standard mounting patterns helps ensure that future replacements remain manageable. The right kit should also align with other mods the rider intends to pursue, such as upgraded suspensions, braking systems, or heat-management solutions, so the fairing does not clash with the bike’s overall tuning. In practical terms, the choice often comes down to a balance among weight, price, and fit, with durability and aerodynamic effectiveness acting as the deciding factors when the rider rides hard or long on the road.

Finally, the market’s trajectory toward accessibility is a crucial part of the discussion. Advances in materials processing, tooling, and global supply chains have driven down costs while expanding quality options. This convergence makes sophisticated, race-inspired bodywork more approachable to a broader audience than ever before. Riders now may select from a spectrum that includes lighter-weight kits with integrated vents, ergonomically designed shapes, and color-matched finishes that reduce the need for post-purchase modifications. The chapter’s thread runs through the observer who looks at the bike and sees a silhouette tuned not just for speed but also for durability, comfort, and style. In a landscape where a well-executed aftermarket fairing can feel like a logical extension of the bike’s design, the rider gains a partner in the machine—one that improves shielding from wind, channels heat away from critical components, and frames the bike in a way that communicates the rider’s approach to performance. The result is a more confident ride, a more tailored machine, and a market ready to equip a growing legion of enthusiasts with options that respect both the sport’s heritage and its forward-looking ambitions.

External resource: https://www.alibaba.com/showroom/aftermarket-motorcycle-race-bodywork.html

Shells of Speed: How Material Science Shapes Aftermarket Motorcycle Fairings

The shell around a motorcycle rider is more than a cloak of color and contour. It is a living interface between rider, machine, and the elements, where material science quietly governs how a fairing behaves at speed, in wind, and under impact. In the aftermarket world, fairings are not mere cosmetic replacements; they are engineered components whose choice of material informs durability, weight, aero efficiency, and price. The modern landscape favors a trio of core materials—ABS plastic, fiberglass, and carbon fiber composite—each bringing a distinct mix of rigidity, resilience, and cost. When a rider contemplates upgrading or replacing fairings, the decision hinges on a nuanced calculation: how the material interacts with the bike’s structural demands, how it performs across real-world riding conditions, and how it fits into the rider’s budget and maintenance expectations. As Derek Lin, a Motorcycle Composite Materials Engineer, notes, today’s best aftermarket fairings aren’t just cheaper—they’re often more resilient than stock, especially when sourced from reputable suppliers. This insight underscores a broader shift in which aftermarket solutions rival OEM parts not merely on aesthetics or price, but on functional longevity and consistency of performance.

ABS plastic has become the backbone of many ready-to-install aftermarket options, a nod to its time-tested balance of rigidity, lightness, and environmental tolerance. ABS holds up well to UV exposure, temperature swings, and road grime, which means it can endure everyday riding with less surface degradation than some alternatives. For riders who cover highway miles or commute through varying weather, the durability of ABS translates into fewer repairs, easier repainting, and predictable performance as temperatures shift. The material’s inherent stiffness helps maintain fairing geometry during moderate energy impacts, and its manufacturability makes large, smoothly contoured panels more affordable. The trade-off, of course, is weight. ABS is heavier than carbon fiber, and while it can be reinforced or glazed to improve impact resistance, the mass adds rotating and sprung weight factors a rider may care about on track days or spirited rides. Yet when the goal is a durable, affordable shell with wide compatibility and straightforward finishing, ABS remains a reliable choice. For riders who prize predictability and ease of maintenance, ABS aftermarket panels present a compelling value proposition that pairs well with mainstream sport bikes and cruising platforms alike.

Fiberglass occupies a middle ground between ABS and carbon fiber in both performance and price. It offers an elevated level of structural integrity relative to basic ABS, translating into panels that resist deformation under stress and can be customized with more aggressive shapes or additional reinforcements. This makes fiberglass fairings a favorite for riders who want a sturdy, robust alternative to stock while still avoiding the higher cost and complexity of carbon fiber. The weight difference between fiberglass and ABS is noticeable; fiberglass adds mass, which can influence handling and fuel efficiency in subtle but meaningful ways. Still, for riders who crave a combination of strength and customization—think reinforced mounting points, thicker sections around fasteners, or unique contouring for an aggressive aesthetic—fiberglass can be ideal. It responds well to resin systems and hand-lay processes that allow for tailored stiffness and impact resistance, while still remaining accessible to mid-range production runs and aftermarket shops. In practice, fiberglass panels often strike a balance: they are durable enough for track day bashing and casual riding alike, yet they retain a level of workability that suits custom paint jobs, graphics, and fitment adjustments common in the aftermarket ecosystem.

Carbon fiber stands at the apex of performance-oriented fairings, where the objective is to shave weight while unlocking stiffness that improves aero response and handling. The dimensionless strength-to-weight ratio of carbon fiber is compelling for riders who chase track performance, sharp turn-in, and high-speed stability. Carbon fiber composites excel in resisting flex under aerodynamic loads, which helps maintain precise contour alignment with the rest of the bike at speed, particularly in cornering or gusty crosswinds. The payoff is a dramatic reduction in weight and a potential uptick in fuel efficiency and responsiveness. The downside is cost and manufacturing complexity. Carbon fiber parts demand meticulous layups, controlled curing, and higher material costs, all of which push aftermarket pricing upward. For riders who ride aggressively on winding roads or tease sub-two-minute laps at a circuit, carbon fiber fairings deliver tangible performance dividends that justify the premium. Even so, the life cycle of carbon fiber—its susceptibility to UV-induced surface degradation if not properly coated, its vulnerability to sharp impacts that can cause delamination, and the need for skilled finishing—means riders should select trusted suppliers and ensure proper maintenance routines to preserve performance.

Manufacturing choices extend beyond the raw material. The tooling, curing processes, and surface finishing dictate not only how the panel looks but how it behaves under real-world conditions. ABS parts are frequently produced using injection-molding processes that yield consistent geometry and a factory-ready finish, slimming the path from purchase to install. Fiberglass panels often rely on hand layups or high-volume spray techniques, enabling robust builds with controllable resin content. Carbon fiber components demand more elaborate resin transfer molding or prepreg approaches, where resin content, fiber orientation, and cure cycles determine stiffness and surface finish. Each route influences the final weight, rigidity, and impact resistance of the finished part. The material science behind aftermarket fairings thus becomes a practical guide to choosing how you want your bike to meet the road’s demands: a lighter, more aggressive carbon option for the track, a sturdy fiberglass shell for rugged riding, or a balanced ABS alternative for daily commutes and weekend rides.

Another layer of consideration is the evolution of materials toward sustainability and responsible manufacturing. The industry is increasingly exploring recycled plastics and bio-composites that can reduce environmental footprints without sacrificing core performance metrics. This trend aligns with broader environmental goals while preserving the mechanical properties riders rely on. In addition, ongoing innovations in composite engineering continue to squeeze more performance out of lighter materials, broadening the range of motorcycles and riding styles that can benefit from aftermarket fairings.

A practical thread running through all of this is compatibility and fitment. Regardless of the material, aftermarket fairings must align with mounting points, through-holes, and cowl geometry of the target model. In practice, riders are advised to verify fitment with their specific make and model before purchase, and reputable suppliers typically publish fitment notes and recommended hardware to ease installation. A reliable shell that fails to align with brackets or fuel-tiller access can negate the benefits of superior materials, producing rattles, air gaps, or degraded aerodynamics. The modern marketplace, with its broad range of designs and finishes, continues to reward those who consider the physics of wind, plus the practicalities of serviceability, repairability, and paint compatibility. The interplay between form and function is most evident in the way a fairing not only reshapes the bike’s silhouette but also interacts with the rider’s field of view, seat height, and riding posture. A well-chosen aftermarket shell contributes to a smoother ride by reducing turbulence around the rider’s torso and head, while also providing a protective shield that can absorb and redistribute energy in a minor crash, potentially reducing bodywork repair costs over time.

For riders who want to explore options within a trusted brand ecosystem, the Honda fairings collection offers a curated starting point for understanding how different forms and panels can integrate with a given model range. A careful comparison across ABS, fiberglass, and carbon fiber designs reveals how each material responds to impact and temperature, how it accepts paint and decals, and how its surface finish holds up to road debris and UV exposure. The choice becomes a reflection of riding goals: everyday reliability, weekend canyon carving, or competitive track work. In practice, the decision often comes down to a balance of weight, stiffness, and cost, with the rider’s budget and maintenance willingness acting as the tiebreaker. Even with this variety, one constant remains clear: the latest aftermarket fairings are not mere reinforcements of the stock look. They embody an engineering philosophy that treats the bike as a system where aerodynamics, weight distribution, and rider ergonomics coalesce into a better riding experience. A well-chosen fairing can offer not only improved wind protection and aesthetic appeal but also measurable gains in handling and efficiency, all while keeping an eye on durability and serviceability.

The broader takeaway is that material science is not just the backstage worker of aftermarket upgrades. It is the instrument that tunes performance in the real world. ABS delivers reliable, economical, everyday resilience. Fiberglass offers customizable robustness for the rider who wants a stronger shell without reaching for the carbon price tag. Carbon fiber promises exceptional lightness and stiffness for those who chase track performance, aided by advanced manufacturing methods. Emerging eco-friendly materials promise to keep pace with the demand for lighter, stronger, and more sustainable parts. As a rider contemplates a fairing upgrade, the decision is less about chasing the latest trend and more about aligning the material’s properties with riding style, maintenance discipline, and long-term ownership costs. The end result is a fairing that not only enhances the bike’s look but improves its performance envelope—an aerodynamic partner that respects the rider’s intent and the machine’s engineering heritage.

External resources can help round out these considerations. For a broader guide to choosing aftermarket fairings, see the external resource: https://www.motorcycle.com/motorcycle-fairings-guide/

Between Budget and Brilliance: How Cost Shapes Quality in Aftermarket Motorcycle Fairings

Riders seek more than just a new look when they install aftermarket fairings on their motorcycles. The right fairing upgrade promises a blend of aesthetics, improved aerodynamics, and added protection. Yet beneath the surface of slick curves and glossy finishes lies a practical question that every keeper of a bike must answer: how much should I spend, and what quality should I expect for that price? The answer is rarely simple, because the cost of aftermarket fairings is driven by a matrix of variables that interact with each rider’s goals, climate, and riding style. On one end sits the OEM standard, engineered for guaranteed fit and factory finish, often with exacting tolerances and branded warranties. On the other end lies a vibrant aftermarket ecosystem that offers a spectrum of materials, finishes, and fabrication methods. The task for the rider is to translate priorities into a price-to-performance equation that holds up over time, under stress, and in changing weather conditions. In practice, this means looking beyond the sticker price and evaluating how material choices, design intent, and support features translate into real-world benefits on the road or track. A fairing is more than a shell; it is a critical interface between rider, bike, and environment, shaping airflow, rider comfort, and the bike’s handling at speed. The chapter that follows explores this balance in depth, grounded in the mechanics of cost and the tangible advantages of quality design and materials, and it frames the decision as a value proposition rather than a single price tag.

Cost factors begin with the most obvious distinction: OEM versus aftermarket pricing. Original Equipment Manufacturer fairings can carry substantial per-section costs, often ranging from three hundred to over a thousand dollars depending on the bike model, the level of engineering, and the guarantee of precise fitment. Those numbers reflect not only the raw material and manufacturing cost but also the brand’s assurance of compatibility with the bike’s mounting points, the built-in aerodynamics that the manufacturer researched, and a level of long-term support. In contrast, aftermarket options frequently deliver meaningful savings, with reductions that can reach or exceed half of the OEM price for similar coverage and protection. This is not a universal rule, of course. Some aftermarket lines command premium pricing because they target specialized performance goals or offer factory-like finishes and simpler replacement cycles. Still, for riders who want a balance of aesthetics and protection without breaking the bank, the aftermarket segment presents a compelling value proposition. The key is to understand where that savings comes from and what compromises, if any, accompany it.

Material quality is the most visible axis along which cost translates into performance. The price difference often signals differences in the raw materials and the processing methods used to shape them. Lower-cost aftermarket fairings may rely on standard plastics or simpler composites that perform adequately in casual scenarios but could be more susceptible to impact damage, UV degradation, and surface wear over time. These materials may show earlier signs of chalking, fading, or micro-cracking after exposure to sun and rain, particularly if the finish is not UV-stabilized or if the surface is not properly treated for weather resistance. In contrast, higher-quality aftermarket fairings typically employ more advanced materials such as ABS, polycarbonate, or carbon fiber reinforced composites. ABS and polycarbonate offer a robust combination of impact resistance and flexibility, helping panels resist cracking when they encounter debris or a minor tip-over. Carbon fiber reinforced composites push weight savings further while enhancing stiffness and wind response, though at a premium price. Each material brings its own advantages: better durability and UV resistance, a more factory-like appearance, and a surface that can hold color and gloss longer with less maintenance. The payoff is a more confident ride in varied weather, and less friction between the rider and the bike when trimming speed or changing lines on the course.

Beyond the base materials, the quality of a fairing often manifests in practical features that influence long-term value. Installation guides that are clear and model-specific minimize the risk of misalignment, which can cause rubbing or added wind noise. A well-designed aftermarket fairing uses a shape that respects the bike’s original aerodynamic flow while offering the flexibility of customization. Some premium aftermarket lines come with detailed fitting templates, adjustable mounting points, and hardware designed to withstand repeated assembly and disassembly during maintenance or color changes. Warranties are another strong indicator of confidence from the maker. A longer warranty communicates reliability and a willingness to stand behind the product in the event of manufacturing defects. For riders who want reassurance, these assurances can translate into lower long-term costs by reducing the likelihood of early failures or unexpected replacements.

Cost and quality also intersect with the broader performance goals of the rider. A fairing is not just a cosmetic upgrade; it can change how a motorcycle handles at speed. Aerodynamic efficiency depends on the precision of the panel gaps, the alignment of profiles, and the smoothness of the surface. High-quality aftermarket fairings tend to maintain tighter tolerances and a cleaner surface finish, which can translate into reduced drag and more stable steering characteristics during high-speed riding. This impact on performance extends to fuel efficiency as well. Even marginal improvements in aerodynamics can yield measurable gains over long rides or on the track, where every watt of resistance matters. The tradeoff is that such gains often accompany a higher upfront cost, especially when the fitment is model-specific and the installation requires a meticulous approach. Riders who ride aggressively or race-spec environments may find the higher initial expense a prudent investment for long-term stability and speed management. Those who ride casually and prioritize cosmetic enhancement or light protection may prefer mid-tier options that deliver a balanced mix of looks, protection, and reasonable durability without a premium price.

Determining the right fit requires a mindful evaluation of long-term value. The best approach blends practical testing with honest expectations. How will the fairing perform under stress, in rainy weather, or across a long highway stint where UV exposure is a constant? Will the surface finish hold color and gloss after repeated cleaning with common motorcycle care products? How easily can the fairing be repainted or repaired if damage occurs? These questions help separate short-lived trends from genuine durability. For some riders, the advantage of a higher-quality fairing is not only how it lasts but how it preserves the bike’s overall integrity. A well-fitted, durable fairing helps maintain consistent rider positioning and reduces turbulence around the head and shoulders, which contributes to a calmer ride on long stretches and during wet weather. It also reduces potential rattles or vibration that can emerge when gaps and seams loosen with time. In other words, investing in quality can preserve comfort and control over the life of the bike, even if the initial price is higher.

The decision framework also benefits from model specificity and fit compatibility. Because motorcycles vary in mounting points, headlight shapes, and fairing-to-fuel-tuel interfaces, the aftermarket market has responded with model-tailored lines and universal systems that require careful alignment. A patient buyer will verify fitment with their exact make and model before purchase and will seek guidance from installation instructions or dealer support when available. This diligence helps avoid misfit issues that can compromise aerodynamics and protection. If a rider wants a broader selection within a specific brand ecosystem, exploring a dedicated collection that lists compatible models can simplify the process. For example, riders exploring a particular niche for model-specific fairings can consult a dedicated collection that focuses on that brand. This approach narrows the field to options with proven fit, reducing the risk of purchase mistakes and returns. If you are seeking model-specific options for a certain brand, you can explore the Kawasaki fairings collection to find compatible designs and to understand how aftermarket lines align with factory geometry.

Different riders will weigh these factors differently. Budget-conscious riders may prioritize aesthetics and basic protective capability, accepting a mid-tier level of material durability and a straightforward installation process. They gain value mainly through price-conscious selections that still respect the basic needs for weather protection and impact resistance. For riders who demand high-speed stability, aerodynamics, and long-term reliability, investing in a reputable brand with proven materials and robust warranties can be worth the premium. The long-term savings in reduced maintenance, fewer paint touch-ups, and better fatigue resistance can outweigh the initial cost difference. In this view, the cost premium is a rational bet on predictable performance, not merely a color and finish choice.

To close the loop between cost and quality, it helps to consider how ongoing innovations influence value. Material science continues to push the bounds of what aftermarket fairings can do, enabling lighter weight without sacrificing strength and enhancing impact resistance with smarter resin systems and multi-layer finishes. Advanced manufacturing methods, from precision molding to digital fitment guides, contribute to a more reliable first install and easier future maintenance. These improvements collectively widen the affordable spectrum of high-quality options, making it more feasible for riders to select fairings that perform at or near OEM levels while keeping upfront expenditures reasonable. The result is a mature aftermarket landscape where cost does not have to equal compromise, and where riders can tailor their choice to personal riding style and risk tolerance.

In the end, choosing a fairing is a balance between value and aspiration. For some, the priority is a look that turns heads while delivering solid protection and dependable fit. For others, every gram of weight saved and every tenth of a second shaved from a lap time matters, and the premium price is a rational investment. The crossroads is not simply a question of dollars spent but of long-run performance, maintenance ease, and the confidence that comes with a project that blends craft with purpose. For readers who want a practical starting point on how to compare options, a helpful step is to examine the materials, the warranty, and the installation support offered by the manufacturer. In particular, confirming compatibility with the exact bike model before purchase remains essential to ensuring that the investment translates into real benefits on the road and the track. For readers aiming to dig deeper into model-specific varieties, the Kawasaki fairings collection represents a focused example of how aftermarket lines align with factory geometry and performance expectations. Kawasaki fairings.

For a broader understanding of how fairings influence overall performance, including their impact on speed, stability, and rider comfort, see an external overview of fairing types and properties. This resource provides context beyond specific brands and models and helps connect the practical choices of cost and material with tangible ride quality: https://www.motorcycleperformancetoday.com/motorcycle-fairings-types-properties-performance

Shaping Speed: Modular, High-Performance Aftermarket Fairings

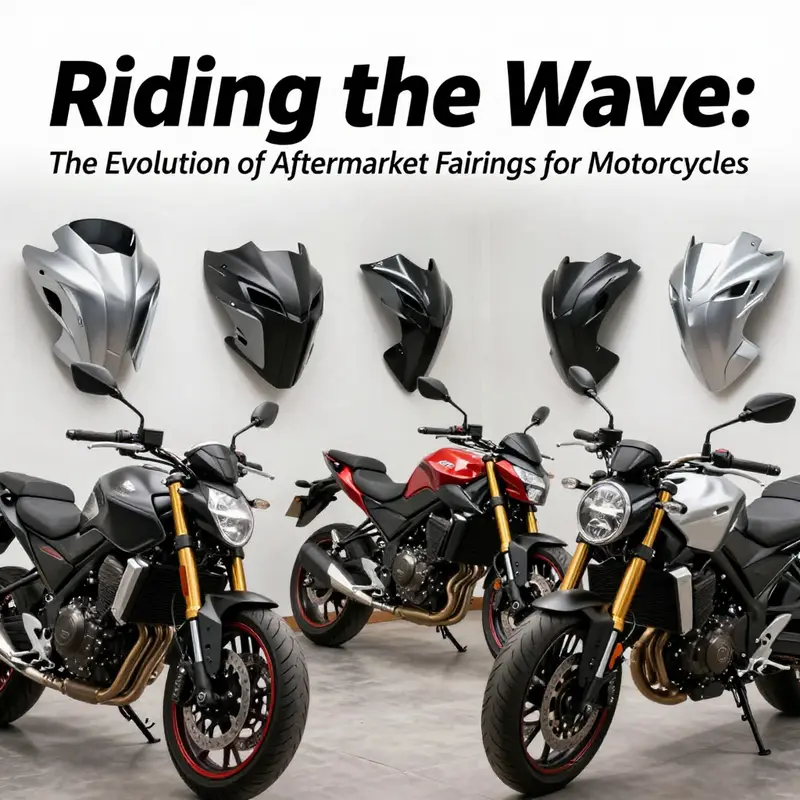

The world of aftermarket motorcycle fairings has evolved from simple cosmetic upgrades to integrated systems that balance aesthetics, aerodynamics, and rider comfort. Riders now expect modularity that lets them swap windshields, side panels, and front-end components in minutes, turning customization into an ongoing process rather than a single kit purchase.

Material choices remain central. ABS plastic remains common for its cost and repairability, while carbon fiber offers exceptional strength and weight savings. Fiberglass provides a middle ground of stiffness and affordability, enabling designers to tune stiffness and dent resistance across panels.

Advances in manufacturing enable new finishes and personalization. Matte and gloss surfaces, laser etched graphics, and direct-to-substrate printing support distinctive looks that endure. Additive processes allow small functional features such as air dams and vent inserts to be customized quickly.

Function as well as form drives the trend toward smarter fairings. Integrated vents, adjustable spoilers, and optimized air dams help direct cooling air and reduce buffeting without compromising stability at speed. These features translate to smoother rides and better handling for riders chasing track days or long highway stints.

Practical considerations matter. Model-agnostic, brand-neutral design focus on fit, durability, and airflow helps protect value over time. Prospective buyers should verify mounting points, suspension clearance, and overall compatibility with their make and model before purchasing.

Viewed as a platform for ongoing expression, aftermarket fairings are becoming a living component of a bike. The modular mindset, advanced materials, refined finishes, and a growing set of add-on components point to a future where customization can evolve with riding goals and conditions.

Air, Weight and Heat: How Aftermarket Fairings Deliver Measurable Performance Gains

Design, materials and fit: the mechanics of performance

Aftermarket fairings are more than cosmetic upgrades; they are targeted interventions in the bike’s interaction with air, weight and heat. When a fairing is engineered and fitted correctly, it reshapes the airflow around the motorcycle and rider. That reshaping reduces drag, smooths pressure gradients, and controls turbulence. The immediate effects are higher attainable speeds, steadier handling at velocity, and reduced fuel consumption on sustained rides.

Aerodynamics is the primary performance lever. A streamlined silhouette trims the frontal area and smooths the path air must travel. Less turbulent wake behind the bike means the engine wastes less power pushing air aside. On highways or tracks, riders will notice the throttle requires less input to maintain the same speed. This translates directly into two measurable improvements: boosted top speed and improved fuel economy. Even modest drag reductions can produce perceptible gains at speed, because aerodynamic forces grow with the square of velocity.

Stability follows naturally when airflow is consistent. Turbulent pockets and sudden pressure changes translate into twitchy steering and unsettled chassis behavior. A well-contoured fairing channels air cleanly around the forks, tank and rider, reducing oscillations that occur at higher speeds. That smoother flow reduces rider fatigue and fatigue-driven mistakes. It also fosters predictable feedback through the handlebars and footpegs. Riders pushing a bike near its limits—whether on a canyon road or a racetrack—value this predictability. It lets them concentrate on line and throttle rather than compensating for random buffet.

Cooling is an often-overlooked performance benefit. Many modern fairing designs incorporate ducts and vents that manage the flow of cooling air to critical components. Properly placed inlets feed fresh air to radiators and brake ducts, while outlets evacuate hot air efficiently. This targeted channeling helps maintain optimal engine temperatures during prolonged hard use. It also preserves brake performance by preventing excessive heat build-up in the calipers and discs. The end result is more consistent power delivery and braking feel over the course of a long ride or an intense session.

Material choice underpins these aerodynamic and cooling advantages. High-grade ABS blends strength with flexibility, resisting impacts while remaining cost effective. ABS is a common choice for riders seeking reliable performance without excessive expense. Carbon fiber, by contrast, offers superior stiffness and a best-in-class strength-to-weight ratio. For racers or those chasing every handling edge, swapping heavier panels for lighter, stiffer carbon reduces unsprung mass and lowers inertia during directional changes. That change sharpens turn-in and makes the bike more responsive at the limit. However, carbon’s cost and brittle failure modes require careful consideration.

Precision fit matters as much as material. Even the best aerodynamic profile fails if gaps, misaligned mounts or rough edges create turbulence. A tight fit keeps the fairing aligned with factory mounting points and the frame’s contour. It prevents panels from vibrating loose and stops air from being forced into unintended cavities. Manufacturers that provide fitment charts and installation instructions reduce the chance of poor integration. Riders should verify compatibility before purchasing and expect some trimming or reinforcement during installation. When fit and finish are right, the fairing becomes a seamless part of the motorcycle’s aerodynamic package.

There are trade-offs to balance. Full-coverage racing fairings maximize aerodynamic efficiency and cooling control, but they can complicate daily riding tasks like maintenance and visual inspection. Minimal or sport-touring fairings improve wind protection and comfort with less sacrifice in accessibility. Weight savings from lightweight materials improve acceleration and nimbleness, but extremely light panels may transmit more vibration to the rider. The correct choice depends on intended use: commuting, long-distance touring, weekend track days or competition.

Integration with rider ergonomics is critical. A fairing’s profile should complement the rider’s posture to reduce drag. When the rider and fairing form a cohesive aerodynamic unit, the combined frontal area shrinks significantly. That means less buffeting at speed, easier tuck positions, and improved energy efficiency for the rider. For those who spend many hours on the saddle, fairings that reduce wind blast around the torso and shoulders dramatically improve comfort. Comfort in turn allows a rider to sustain higher average speeds without exhausting themselves.

Real-world testing validates theory. Effective upgrades will show measurable differences on both instruments and the road. Objective tests include recorded top-speed runs, consistent fuel-economy logging over identical routes, and thermographic checks to confirm better heat evacuation. Subjective feedback—reduced rider fatigue, crisper steering, and steadier high-speed posture—also confirms improvement. When possible, test modifications incrementally. Fit a single fairing piece first, then evaluate. This approach isolates variables and helps pinpoint which components yield the best returns for cost and effort.

Installation quality influences longevity and safety. Correct mounting hardware and reinforcements prevent flex-induced cracking. Fairings that are too loose amplify vibration and may fail under stress. Conversely, over-tightening can warp panels and distort airflow. Using the original mounting points whenever possible preserves chassis geometry and avoids unintended load paths. For riders who prefer plug-and-play solutions, reputable sellers who provide clear guides and vehicle-specific kits reduce installation errors and deliver consistent results. If you need model-specific options, check the Honda fairings collection for compatible configurations.

Finally, manage expectations. Aftermarket fairings are powerful tools, not miracle workers. They amplify strengths where the bike already has potential and mitigate some weaknesses. Gains depend on the quality of design, material selection, and the precision of the fit. For riders focused on track performance, a combination of light panels and ducted cooling yields the largest marginal benefits. For long-distance riders, wind protection and comfort-oriented shapes produce the greatest real-world advantage. In every case, measure before and after, respect fitment guidelines, and prioritize parts from suppliers who publish fitment data and installation instructions.

For a practical, step-by-step approach to selecting high-performance aftermarket fairings and understanding technical specifications, the industry guide linked below offers hands-on advice and testing criteria:

https://www.motorcycleparts.com/guides/aftermarket-fairings-guide

Final thoughts

As the motorcycle aftermarket market continues to evolve, aftermarket fairings stand out as a vital component for those seeking improvements in both style and performance. The advancements in materials science, coupled with the trends in customization and performance enhancements, underscore the potential for business opportunities in this sector. For retailers and manufacturers, focusing on high-quality, durable, and customizable fairing options could facilitate not just sales but also customer satisfaction and brand loyalty. By remaining informed and adaptable to new technologies and market preferences, businesses can thrive in the dynamic landscape of aftermarket motorcycle fairings.