Aftermarket motorcycle fairings play a crucial role in optimizing the performance and aesthetic appeal of Honda motorcycles. For business owners in the motorcycle industry, understanding the nuances of fairing materials, aerodynamic designs, and maintenance accessibility is imperative. The following chapters delve into essential considerations, including material choices that enhance durability, the aerodynamic benefits of full fairings, the practicality of half fairings, and exciting customization options. By exploring each chapter, you’ll gain a comprehensive view of how aftermarket fairings can upgrade Honda bikes, ensuring they meet the diverse needs of riders while expanding your business offerings.

Material Truths for Honda Aftermarket Fairings: ABS, Fiberglass, and Carbon Fiber

Riding a Honda with aftermarket fairings requires understanding materials as much as chasing speed or style. The bodywork does more than look aggressive; it slices through air, shields the engine, and stands up to curb rash or gravel tossed from the highway. In this chapter we examine the three main materials dominating the aftermarket fairing scene: injection molded ABS, fiberglass, and carbon fiber, and how each influences performance, durability, and value for Honda riders. The goal is to illuminate material choices so riders can align them with riding style, maintenance habits, and budget. For those starting out, a practical starting point is the Honda fairings collection, which serves as a curated hub for exploring compatible panels and designs. Honda fairings collection.

When considering aftermarket fairings, the first decision often revolves around material. ABS, fiberglass, and carbon fiber each carry distinct fingerprints in terms of strength, weight, and how they respond to heat, impact, and weather. Injection molded ABS has become the industry standard for durability and fit due to its ability to produce consistent panels with tight tolerances. ABS is inherently tough; it resists impact well enough for daily riding and the occasional drop, and when molded through modern injection processes, the resulting panels align with OEM mounting points with predictable precision. The chemistry of ABS also accepts paint and clear coats reliably, a crucial factor since the visual outcome matters as much as the fit. A fairing made from injection molded ABS can take years of street miles, commuting in rain or shine, without sagging or warping in ways that can compromise airflow or panel fit.

The advantages of ABS extend beyond immediate resilience. Because it is relatively inexpensive to manufacture at scale, ABS panels offer an economical balance for riders who want the performance and protection of full or partial fairings without entering the luxury end of the market. For Honda riders who daily commute through variable weather, or who use their bikes for weekend track days but still need practical maintenance access, ABS can be a practical, long term choice. The ability to inject large, seamlessly connected panels also means fewer seams that catch dirt and moisture, which translates into easier cleaning and maintenance between rides. This practicality is especially valuable for riders who prefer to own the motorcycle for years and want the fairings to hold color and gloss with minimal fuss.

Yet no single material exists in a vacuum. Fiberglass and carbon fiber offer compelling alternatives, each trading some advantages for specific use cases. Fiberglass is lighter than ABS and can be molded into complex, aerodynamic shapes with relative ease. The lightness is helpful for riders chasing a performance edge, but fiberglass comes with a trade-off: it is more brittle and prone to cracking under sharp impact. That brittleness matters in everyday riding where gravel, curbs, or a low speed tumble can leave a panel compromised. For riders who value aesthetics and want clean lines, fiberglass can deliver an eye-catching look at a reduced price—but it is not always the best long-term hedge against the realities of street riding. When fiberglass panels crack, repairs can be more labor-intensive than replacing an ABS panel, especially if the original contours require careful re-shaping and color matching.

Carbon fiber, meanwhile, represents the high end of performance materials. The weight savings are meaningful, especially on bikes with limited power or where every gram matters for handling and acceleration. The strength-to-weight ratio of carbon fiber is exceptional, which makes it particularly appealing to track enthusiasts who want crisp, fast response and a distinct, premium aesthetic. But carbon fiber also commands a premium price that can stretch a project budget. Its durability under minor impacts is nuanced: carbon fiber resists bending well, yet surface damage or micro-cracks can occur with hard knocks, potentially affecting structural integrity or appearance before a rider notices. For most on-street riders, carbon fiber is a balance of performance and cost that tends to favor those who ride aggressively or race, and who are prepared to maintain a higher upfront and ongoing investment.

The choice of material intersects closely with fitment and the overall riding plan. Honda models, known for their reliability and strong aftermarket ecosystem, require careful attention to mounting geometry and panel geometry. Full fairings, which enclose most of the chassis and engine, deliver superior aerodynamic efficiency and wind protection. They help maintain high-speed stability and minimize drag, a boon on long highway sections and track sessions alike. But full fairings come with higher price tags and potentially more complex maintenance access. Access to the engine for service or fixes can become more challenging because panels must be removed to reach key components. This is not a failure of design but a practical consideration riders should weigh when choosing a material and a fairing layout. A rider who values maintenance convenience may lean toward half fairings, which cover the upper portion of the bike—from the headlight to the handlebars—offering a compromise between wind deflection and engine accessibility. If a rider prioritizes a minimalist aesthetic and light weight, low fairings might be the choice to emphasize a clean, uncluttered front end. Each option has a material logic: the more extensive the enclosure, the more critical the panel’s rigidity and edge integrity become, and the material choice will color the maintenance experience and the long-term cost of ownership.

A central tenet across all Honda applications is paint quality and color match. The surface finish of ABS, fiberglass, and carbon fiber interacts with paint and clear coats in distinct ways. ABS, with its uniform resin matrix and compatibility with primer layers, tends to offer reliable paint adhesion and a smooth final gloss when the finishing process is well controlled. Fiberglass panels require careful surface preparation, including resin-rich priming and thorough sealing to prevent moisture ingress at the fibers’ exposed edges. Carbon fiber panels, particularly those with a clear-coated resin design, demand careful attention to pigment compatibility and resin content to avoid yellowing or hazing under UV exposure. In all cases, the painter’s prep work, the quality of the primer, and the climate during painting all contribute to a durable, showroom-like finish that can hold up to road grit and sun exposure. Paint quality is not merely cosmetic; it plays a practical role in weather resistance and color longevity, which is essential on motorcycles that live outdoors or in variable climates.

Beyond the raw material and paint, compatibility with the specific Honda model is a practical constraint that threads through every decision. The way a panel clips into place, how it aligns with the mounting points, and whether the surface curvature mirrors the factory design all influence the true value of a given offer. This is where the engineering work behind aftermarket fairings matters as much as the material. Injection-molded ABS kits, for instance, typically deliver very consistent fitment that remains reliable after repeated removal and reattachment during maintenance. For riders who plan to customize extensively—adding logos, graphics, or unique artwork—the injected ABS route offers design freedom while preserving structural integrity and alignment. For those who chase every gram of performance, carbon fiber offers a premium route with high stiffness and an aggressive aesthetic, though the installation process can be more exacting and the repair path less forgiving than ABS if an impact occurs. In all scenarios, it remains critical to verify that the chosen panels align with the bike’s subframes, fasteners, and radiator shrouds, while also anticipating potential minor fitment variances that sometimes surface with aftermarket components.

The material decision also interacts with the rider’s behavioral patterns. A daily rider who uses the bike for commuting in all weather may place a premium on the weather resistance and color durability of ABS. This material choice handles rain and sun with resilience, and the ability to repair or replace panels at a reasonable cost is a meaningful benefit. A weekend warrior who splits time between street riding and occasional track sessions might prefer a blend of weight savings and durability, a profile carbon fiber can sometimes satisfy—though at a higher cost and with a need for careful maintenance to keep the finish pristine. A track-focused rider who pushes the bike to the edge will appreciate the weight advantage and stiffness of carbon fiber or a well-implemented fiberglass setup in a carefully engineered configuration, provided the panels can sustain the heat and vibration of high-speed runs without compromising stability.

In practice, most riders end up choosing a hybrid approach: ABS for daily durability where cost-effectiveness matters, carbon fiber for selective panels where weight reduction and aesthetics are a priority, and fiberglass for certain midsections or decorative elements where the look matters but absolute impact resistance is less critical. This pragmatic mix respects the realities of road conditions, daily maintenance routines, and the rider’s financial plan while preserving the Honda’s inherent riding characteristics. It also reflects a broader truth about aftermarket fairings: the best choice is rarely a single universal winner. The optimal solution is a tailored package that aligns with the rider’s goals, the bike’s design language, and the environmental realities in which the bike lives.

For riders who want to continue the exploration, a practical move is to consider which panels are most at risk in their usual environment and choose material accordingly. If you live where winters are hard and road salt is a factor, you might lean toward ABS for its impact resistance and easier repair pathways. If your focus is weight reduction for track days or spirited weekend rides, carbon fiber can offer the look and performance improvements you’re seeking, so long as you’re prepared for the premium price and potential maintenance overhead. If your priorities center on cost-effective customization with a balance of weight and strength, fiberglass can serve as a transitional material that offers aesthetics without a prohibitive price tag. In every case, the goal remains clear: to protect the bike’s core architecture—engine, radiator, and chassis—while preserving access for maintenance and ensuring that the fairings integrate cleanly with Honda’s engineering philosophy.

As you map these considerations, keep in mind that the decision rarely lives in isolation. Paint quality, compatibility with your model, and the intended riding context all feed into the final assessment. Material selection will influence how easy it is to paint a design you love, how long you can expect the finish to endure under UV exposure, and how accessible routine service will remain once the panels are installed. The practical takeaway is straightforward: for most riders seeking a balanced, long-term solution, injection molded ABS remains the baseline choice due to its durability, cost-effectiveness, and reliable fit. Carbon fiber and fiberglass present attractive alternatives for riders with specific goals—weight savings or aesthetic emphasis—yet they bring trade-offs that deserve careful consideration before purchase.

To deepen practical understanding and see how different material choices map onto model-specific fit and color options, readers may consult broader resources on fairing selection and installation practices. For further context, external insights into aftermarket fairings offer a broader framework for evaluating the materials in play and how they affect performance and durability over time. How to Choose Aftermarket Motorcycle Fairings: A Practical Guide.

In sum, material choice matters for Honda aftermarket fairings as much as the aesthetic design does. The panels you select will shape wind protection, stability at speed, and the ease with which you can service the bike in the long run. ABS provides reliable, everyday value with predictable results; fiberglass offers a lighter, cost-conscious aesthetic option with some caveats; and carbon fiber delivers peak performance and a premium look for riders ready to invest. With careful consideration of your riding style, climate, and maintenance habits, you can assemble a fairing package that respects the bike’s original engineering while delivering the performance and personality you want on the road or track.

How Full Aftermarket Fairings Transform Honda Performance and Comfort

How full aftermarket fairings transform Honda performance and comfort

Full aftermarket fairings reshape how a Honda motorcycle interacts with the air around it. They create a continuous surface that guides airflow smoothly from the windscreen back along the tank and tail. This smoother profile reduces drag and lowers turbulent zones that buffet the rider. The result is better fuel economy, a steadier ride at speed, and reduced fatigue on long runs. For riders who spend hours on highways or who push their machines near top speed, those differences are noticeable and measurable.

Beyond raw numbers, full fairings change the feel of the bike. A faired Honda presents less frontal area to oncoming air. Less frontal area means engines work with less resistance to hold a given speed. That reduces throttle corrections and engine strain. Riders report that, with full fairings, cruising at highway speeds feels easier. The cockpit becomes calmer, with lower wind noise and fewer sudden gusts across the torso and helmet. That quieter environment also makes signaling and auditory awareness easier, which can translate into safer, less stressful rides.

Aerodynamics affect more than straight-line speed. Full fairings stabilize the entire chassis by smoothing pressure gradients around the bike. Reduced pressure differences minimize lift at high speed and help keep the front wheel planted. This improved stability aids corner entry and mid-corner confidence, since aerodynamic disturbances that might unsettle the chassis are diminished. On models that were designed with sporting intent, aftermarket fairings that mirror OEM geometry preserve the intended aerodynamic balance while often trimming incremental drag.

Material choice plays a central role in how effectively a full fairing performs. Injection-molded ABS is common because it balances strength, flexibility, and weight. ABS holds shape under load and returns from minor impacts without fracturing. That resilience keeps the sealing lines tight around the headlight, screen, and tank, which matters for predictable airflow. Composite resins or fiberglass can be lighter or stiffer in specific builds, but they may require more care in shaping and fitting. For riders who value long-term dimensional stability and straightforward repairs, high-impact ABS is usually the most practical option.

Fit and finish affect aerodynamic outcomes as much as raw shape. Gaps, misaligned mounts, and rough edges generate unwanted turbulence and add drag. Aftermarket kits that follow the original geometry allow for cleaner integration with the frame, forks, and lights. Properly fitted fairings maintain continuous flow lines and minimize vortices that slow the bike. That makes fitment a top priority when choosing a kit: the best material and design will underperform if installation leaves seams and steps where air can separate.

Weight distribution is another subtle but important factor. A full fairing adds mass around the front and midsection, and that shifts the bike’s moment of inertia slightly. When designers keep fairing weight low, this change is negligible. Lightweight constructions and careful reinforcement maintain steering feel and agility. Conversely, heavy, poorly designed panels can dull response and amplify crosswind sensitivity. For this reason, riders who install full kits often choose panels optimized for both stiffness and minimal weight, preserving the balance engineered into the chassis.

Wind protection is a practical benefit that directly affects comfort and endurance. Full fairings channel airflow over and around the rider, reducing chest pressure and preventing helmet buffeting. On long-distance runs, this translates to lower fatigue and steadier concentration. Reduced windblast also improves cold-weather tolerance and decreases exposure to rain and road spray. Riders who commute or tour benefit from the fairing’s ability to keep instruments and controls clearer, reducing the need for bulky gear and making long trips more enjoyable.

Fuel efficiency gains are a natural extension of reduced drag. When a faired motorcycle slices through the air more cleanly, it requires less power to maintain speed. Small percentage improvements in aerodynamic efficiency can mean noticeable mileage gains at highway velocities. For many riders, that means fewer stops and a less stressed engine during sustained high-speed travel. The net effect is practical: better range from the same fuel tank and a quieter, more efficient highway experience.

Aesthetics and personalization should not be dismissed as mere vanity. Fairings offer a large canvas for color schemes, graphics, and protective coatings. Riders can match a kit to their bike’s OEM lines or choose a unique look without sacrificing aerodynamic gains. Paint quality and surface finish matter for airflow. A smooth, well-painted surface creates less skin friction and helps maintain laminar flow at critical points. High-quality finishes also resist chips and UV degradation, which preserves both appearance and performance over time.

Maintenance access is a trade-off when choosing full fairings. They enclose more of the chassis and engine than half or low fairings, making routine checks slightly more involved. Thoughtful design accounts for this by using removable panels or quick-release fasteners. Kits that mimic OEM mounting points provide access panels in logical places, allowing oil checks, filter changes, and other tasks with minimal disassembly. Riders who frequently work on their bikes should evaluate ease of access when selecting a kit, balancing aerodynamic gains against workshop convenience.

Compatibility with the specific Honda model is non-negotiable for predictable performance. Fairings tailored to precise model years and configurations ensure that vents, headlight apertures, and mounting points line up. Correct alignment keeps flow lines intact and avoids localized turbulence. Off-the-shelf universal panels can look appealing and fit loosely, but they rarely reproduce the aerodynamic benefits of model-specific kits. Investing in a kit designed for your motorcycle’s frame and fork geometry produces the most consistent and reliable improvements.

Durability under real-world conditions is another practical concern. Road debris, stones, and weather expose fairings to repeated stress. High-impact ABS and reinforced composite blends absorb hits while resisting cracks. Reinforced mounting tabs and strategic bracing help spread impact forces and reduce the risk of catastrophic failure. This resilience matters on long rides where repair options are limited, and it keeps the bike looking and performing well for years.

When considering installation, blending professional fitment with rider preferences yields optimal results. A careful installation aligns panels, seals edges, and tunes the fairing’s relation to mirrors and screen angle. Small adjustments to windscreen height or tilt change how air is directed over the helmet and chest. Riders with different statures should experiment to find the best setup. A well-installed fairing should feel like a natural extension of the bike, not an add-on.

Track-focused riders will appreciate that full fairings can lower lap times by improving high-speed stability and reducing drag. Streamlined panels reduce aerodynamic lift under braking and through fast corners. They also protect vital components from heat and debris during aggressive use. However, track use demands stronger fasteners and sometimes alternative screen profiles for optimal downforce and cooling. Choosing materials and mounting systems rated for track stresses is essential to avoid failures under extreme conditions.

Urban commuters and touring riders will value comfort and weather protection more than marginal top-speed gains. For them, the biggest benefit of a full fairing is a calmer ride and better protection from the elements. Fairings reduce spray and wind-chill and make urban riding less tiring. That daily comfort adds up, making the bike easier and more pleasant to live with.

Ultimately, installation of a full aftermarket fairing on a Honda is a decision that balances aerodynamics, comfort, maintenance, and appearance. When a kit is well matched to the model, crafted from resilient materials, and installed with care, the advantages are clear. You get improved fuel efficiency at speed, reduced rider fatigue, and a more composed, confident machine. Whether the priority is long-distance comfort, steady highway cruising, or track stability, the right full fairing can transform the motorcycle’s performance and personality.

For riders who want to explore model-specific options, consult dedicated Honda fairings collections to find kits designed for exact model years and fitments: https://www.summitfairings.com/collections/honda-fairings

For a technical breakdown of how fairings affect drag and fuel usage, see this external resource: https://www.motorcycle.com/how-does-a-faired-motorcycle-improve-aerodynamics-and-fuel-efficiency/

Halfway to the Aerodynamic Edge: Accessibility, Performance, and Honda Half Fairings

A half fairing on a Honda blends accessibility, comfort, and performance into a practical package. It shields the upper front end and windscreen while leaving the engine and lower chassis accessible for routine maintenance, reducing service downtime and keeping ownership approachable. This balance makes half fairings appealing to riders who commute, ride weekends, or enjoy sportier styling without committing to full bodywork. Aerodynamically, the kit offers a measurable gain over naked bikes by smoothing air over the shoulders and chest, which can reduce rider fatigue on long rides and at highway speeds, while preserving the nimbleness Honda riders expect from a well-sorted chassis. Material choices, typically injection molded ABS, provide a robust, light platform that accepts paint and graphics well and holds up to weather and road grime. Compatibility hinges on model-specific mounting points and cockpit geometry, so buyers should verify fit with their Honda model and ensure access panels align with the headlight and instrument cluster. The popularity of half fairings with Honda is driven by cost and customization potential: a lighter, more affordable upgrade that still offers a distinct, sport-inspired silhouette and the ability to personalize colorways and logos. For riders curious about options, a dedicated Honda fairings collection can guide fitment and finish, while broader aftermarket overviews help compare how half fairings perform against other configurations on the road and track.

Tailored Looks and Performance: Design and Customization for Honda Aftermarket Fairings

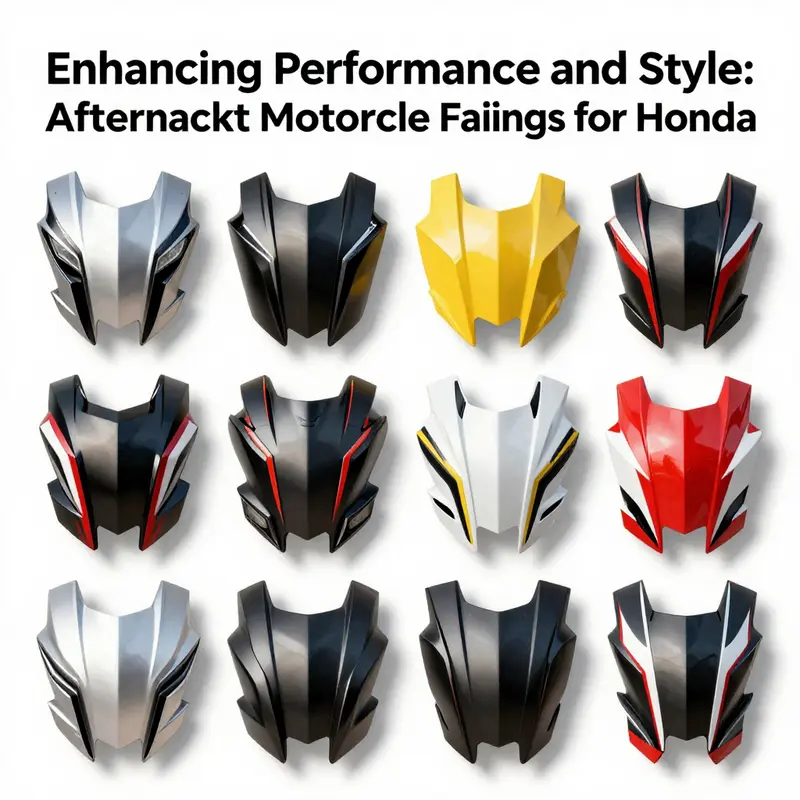

Design and customization shape both appearance and function for Honda aftermarket fairings. Riders choose fairings to express style and to tune performance. The process begins with a clear idea of priorities. Are you chasing aerodynamic gains on the highway, a race-inspired look for the track, or a distinctive custom build for the street? The answer guides choices in silhouette, material, finish, and fit.

A strong design starts with the fairing type. Full kits wrap the bike, delivering the most aerodynamic benefit and the most visual transformation. Half kits preserve some mechanical access while improving wind protection and retaining a classic appearance. Low fairings keep things minimal and lean, improving front-end aesthetics without altering the bike’s core lines. Each form carries implications for weight, cooling, and maintenance. When you pick a style, imagine how it changes everyday tasks like oil checks and brake bleeding. Good design anticipates these needs.

Material consistency underpins reliable customization. Among plastics, injection-molded ABS is the best compromise between durability, weight, and affordability. It returns predictable dimensions after molding. That dimensional stability matters when panels must align around Honda’s subframe and tank. ABS resists impact and holds fasteners securely. Alternatives such as hand-laid fiberglass or low-cost polypropylene may initially seem attractive. Fiberglass can crack on impact and warp over time. Polypropylene can be flexible and hard to finish nicely. For a look that lasts and a fit that stays true, insist on injection-molded ABS.

Paint and surface preparation are the next decisive layer. A high-quality paint process includes multi-stage priming, base coating, and a clearcoat with UV inhibitors. The primer stage seals the ABS and prevents solvent issues later. A skilled base coat brings depth and consistent color. The clearcoat protects the art and adds gloss or matte uniformity. UV protection prevents fading and chalking. Also look for proper curing protocols; insufficient cure time leads to soft finishes and premature chipping. A fairing that is well painted does more than look good. It shields the substrate from road grime, salt, and sun.

Customization extends beyond color. Many manufacturers offer modular elements that let you mix and match components. Swap windshields, change side panels, or fit a different front spoiler without replacing the whole kit. Modular systems reduce cost and increase creative freedom. They also lower the barrier for future upgrades. If you plan to evolve your bike gradually, choose a kit with compatible add-ons and standardized mounting points. That saves time and keeps the bike coherent as you change its personality.

Graphic options range from simple two-tone layouts to complex race replications. Matte finishes and satin sheens are popular for a modern aesthetic. Chrome accents and metallic flakes draw attention but need precise sealing to avoid flaking. For custom artwork, vinyl wraps can be a practical choice. They protect the paint and are reversible. High-end bespoke services can translate a sketch into a fitted kit. Those services involve more upfront cost but guarantee a unique result and a paint schedule matched to the fairing material.

Fitment is where design meets reality. Even the most striking fairing will disappoint if mount points misalign or clearances are tight. Fitment guides and templates are essential. Check the supplier’s documentation against your exact Honda model and year. Minor model differences, such as fork diameter, headlight configuration, or subframe shape, can change fit dramatically. Where possible, inspect mock-up photos or installation videos for your same model. Panels that tuck cleanly behind the tank and around the headlight create an integrated look. Poorly fitting panels hang or gap and degrade both aesthetics and aerodynamic function.

Fasteners and mounting hardware deserve attention. Stainless-steel hardware resists rust in wet conditions. Well-placed backing plates prevent stress cracking at screw points. Rubber grommets isolate vibration and reduce squeaks. Some kits include quick-release fasteners for easier removal at the track. Consider which fasteners you will access frequently. Choose hardware that balances security with convenience so panels stay tight under load but can be removed without fuss.

Aerodynamics is subtle but real. Aesthetic lines can either improve or harm airflow. Smooth transitions guide air without creating turbulence. Sharp troughs or abrupt edges can trap debris and amplify buffeting. If you prioritize performance, prioritize fairing lines that follow the bike’s natural flow. Small spoilers and winglets can tune front-end feel. However, modifications that significantly alter pressure zones may require suspension or steering adjustments. A well-designed fairing complements the chassis without demanding major setup changes.

Practical customization also considers serviceability. Riders who perform their own maintenance should prioritize panels that allow easy access to key components. Removable mid-sections, hinged panels, and quick-release systems make routine tasks less time-consuming. If you commute regularly or plan long trips, access to the oil filter and battery without removing half the bike is essential. Design that honors maintenance routines will save time and reduce the temptation to skip inspections.

Finish options affect long-term ownership. High-gloss layers show swirls and scratches more readily than matte finishes. Matte surfaces require special cleaning products to avoid shine spots. Clear protective films can preserve high-traffic areas like the tank edge and lower belly sections. Ceramic coatings increase scratch resistance and make cleaning easier. Decide whether your bike will be a garage queen or a daily rider, and choose finishes accordingly.

Customization also covers ergonomics. Windshield height and profile change rider comfort. Taller screens reduce fatigue on long rides. Lower screens favor an aggressive tuck and reduce frontal area for high-speed runs. Side panel shapes influence knee contact and rider position. Small adjustments to fairing geometry can make big differences in rider comfort and control. When customizing, test windshield and panel variations before committing to permanent changes.

Color matching and badge placement can transform a kit from just another aftermarket shell into a signature bike. Use color swatches under natural light to ensure hue and finish match. When incorporating decals, place them where they accent lines and avoid cluttering already busy areas. Badges and logos should be balanced and proportionate. Visual hierarchy matters; viewers should understand the bike’s focal points at a glance.

Installation planning is part of the design process. Custom paint and art should wait until fit and alignment are final. Test-fit panels unpainted to ensure gaps and mounting points are correct. Make minor trimming adjustments while the plastic is raw. Once the fit is right, send panels for final finishing. This sequence avoids costly repainting or rework.

Budgeting for customization requires realism. Base kits offer rapid transformation at low cost. Higher tiers add better paint, improved fitment, and bespoke options. Balance cost against how long you plan to keep the bike and how integral the fairings are to its identity. Spending more on a high-quality, well-fitted kit yields better resale value and fewer headaches during installation.

Finally, documentation and support matter. Look for suppliers that provide fitment guides, hardware lists, and clear returns policies. Access to spare panels and replacement parts makes future repairs simpler. Good documentation shortens project timelines and reduces frustration.

If you want to browse a broad set of compatible designs and fitment options, consult a dedicated Honda fairings collection tailored to multiple model years and styles. For factory-inspired accessories and performance-tested options developed with racing input, see official performance resources: https://www.hrc-honda.com/.

Final thoughts

When selecting aftermarket motorcycle fairings for Honda, business owners must weigh material durability, aerodynamic functionality, and accessibility. By understanding the unique benefits of full, half, and low fairings, businesses can better cater to the diverse preferences of riders, combining performance with aesthetic appeal. Moreover, offering customization options will attract enthusiasts seeking personalized touches. This comprehensive approach not only enhances the rider’s experience but also positions your business as a leader in the aftermarket accessories market.