The motorcycle aftermarket is a thriving sector, driven by a demand for customization and performance enhancement. Among the most popular upgrades are ABS injection aftermarket fairings, known for their cost-effectiveness and superior durability. With a material that combines resilience against environmental stressors and impacts, ABS fairings have become a preferred choice for riders looking to enhance both the aesthetics and functionality of their motorcycles. This article delves into the critical aspects of ABS injection aftermarket fairings, exploring their material properties, performance enhancements, installation and customization options, adherence to safety standards, and their economic impact on the market. Each chapter aims to equip business owners with insights necessary for navigating this lucrative segment of the motorcycle industry.

Beyond the Surface: ABS Injection-Molded Fairings and the True Edge of Motorcycle Aftermarket Performance

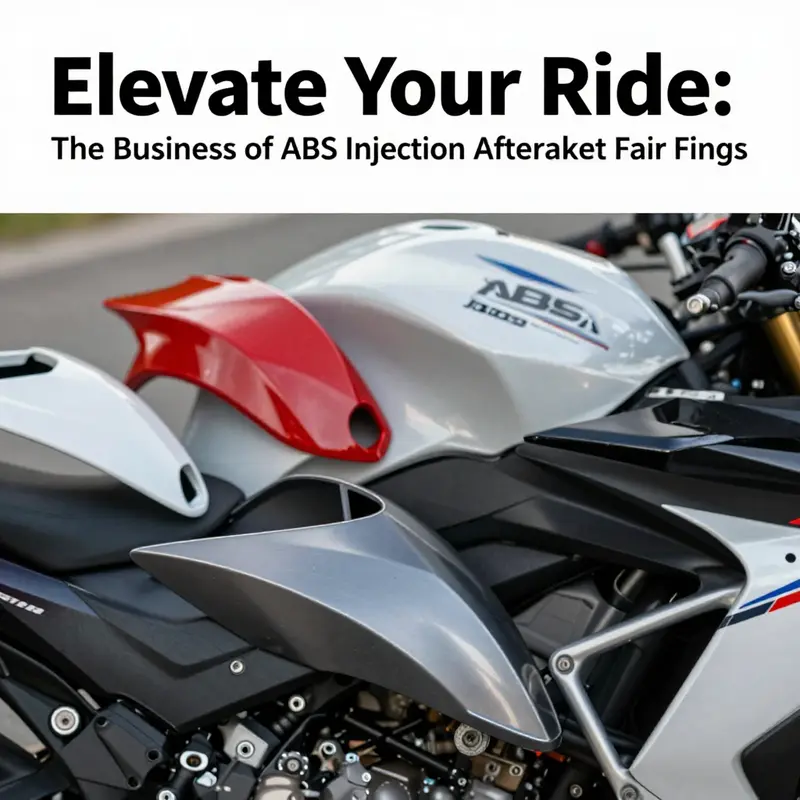

ABS, or Acrylonitrile Butadiene Styrene, has become a cornerstone in the aftermarket fairing market, not merely as a cheaper substitute but as a material that reshapes what riders expect from an upgrade. When ABS is processed through high-precision injection molding, the result is a set of panels that meet exacting tolerances, reproduce complex geometries, and present a surface finish that looks factory-new out of the box. This is not a cosmetic story alone; it is a narrative about how material choice, manufacturing discipline, and design intent converge to deliver aerodynamics, protection, and practicality in a single, cohesive package. For riders who want to refresh the look of a sport bike or to restore airflow dynamics to a machine that has seen a few seasons of highway miles, ABS injection-molded fairings offer a compelling balance of cost, durability, and performance that fiberglass and carbon fiber alternatives cannot always match at a similar price point. The process supports both OEM-styled and aftermarket-specific geometries, allowing for replacements that fit closely with the bike’s original silhouette while accommodating modern styling cues and added features that riders increasingly demand, such as integrated air inlets or housings for lighting elements.

The core appeal of ABS lies in its mechanical and thermal performance. ABS exhibits a remarkable balance of toughness and energy absorption. It can bend and deform under impact without shattering, a trait that translates to reduced risk of catastrophic failure when a rider encounters road debris or a minor collision. This energy-absorbing behavior is complemented by a toughness that resists microcracking and craze formation, ensuring the panels retain their integrity across years of exposure to road grit, vibration, and temperature cycling. In the real-world riding environment, ABS fairings encounter heat from the engine and exhaust areas, heat that can soften or warp other plastics. Here, heat-shield strategies—whether embedded within the material formulation or achieved through design choices in the panel layout—play a crucial role. These approaches minimize deformation near the hottest zones, maintaining both fitment and aerodynamic efficiency even on longer, hotter days.

Another pillar of ABS performance is its weathering resistance. Motorcycle fairings live outdoors and endure UV exposure, rain, and temperature swings that would challenge many polymers. High-quality ABS formulations used in injection molding resist such weathering when paired with UV stabilizers and color pigments designed for outdoor use. This combination helps preserve color stability, gloss, and surface integrity over time, reducing the risk of chalking or yellowing that can mar appearance and, more importantly, undermine the perceived value of a rider’s upgrade. In practice, these formulations are chosen to maintain a consistent look across a complete fairing set, which is essential for riders seeking visual coherence after color-matched repairs or replacements.

From a design perspective, the injection-molding process unlocks a level of precision that is difficult to achieve with hand-laid methods. Precision molds capture tight tolerances and replicate complex features with minimal post-processing. This capability is particularly valuable when fairings must interface cleanly with mounting hardware, riders’ electronics, and intake or cooling ducts. The result is a modular architecture where panels carry pre-drilled mounting points, which speeds installation and reduces the chance of misalignment during fitment. A modular approach also supports customization; riders can mix and match panels to refresh only portions of their bodywork while preserving the structural relationships that dictate airflow, engine cooling, and rider protection. For the rider who values both aesthetics and function, such integration matters as much as the raw panel strength.

In the flow of manufacturing, ABS injection molding stands out when comparing to other common materials. Fiberglass, while light and sturdy, demands skilled labor and longer curing times. It can also introduce inconsistencies in surface finish and shape, particularly on curved panels and complex contours. Carbon fiber, though exceptionally stiff and light, carries a premium price and presents repair challenges that may deter casual modification or frequent color changes. ABS injection molding, by contrast, yields a smooth, consistent finish with fewer post-processing steps, and it enables rapid production cycles for large-volume aftermarket programs. This combination of speed, consistency, and affordability explains why ABS-based kits have become a mainstay for riders who want a practical upgrade that can be installed quickly without sacrificing performance.

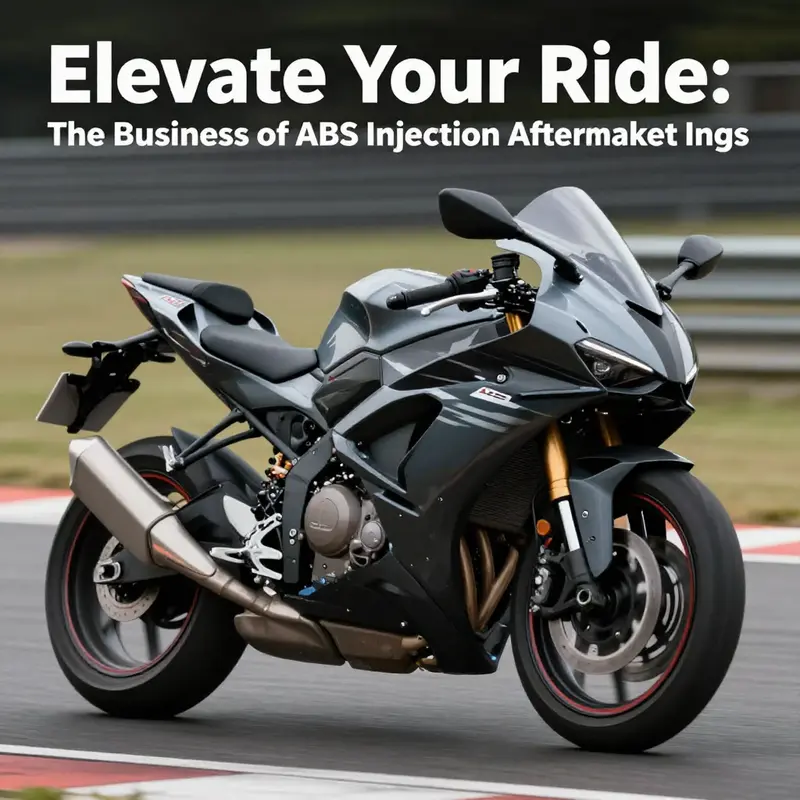

The material’s compatibility with modern design objectives is equally important. Today’s ABS fairings are engineered with aerodynamics in mind. Subtle shaping details—such as refined curvature around the chin, smoother transitions at the shoulder lines, and carefully sculpted air channels—help reduce drag and improve the bike’s overall airflow. When paired with optimized internal features, such as air vents and integrated housing for LEDs or instrument clusters, ABS panels can contribute to a ride that feels more stable at speed and more predictable in crosswinds. Riders who ride aggressively on twisty roads or who push sport-touring machines into spirited miles often benefit from the quiet efficiency gained by streamlined fairings, and ABS makes it feasible to implement these shapes without ballooning costs or introducing structural risk.

A practical advantage of ABS injection-molded fairings is repairability. If a panel sustains moderate damage, it can often be repaired with specialized adhesives and filler compounds designed for plastics, or, depending on the damage, replaced at a fraction of the cost of carbon-fiber or composite alternatives. This repair-friendly aspect supports a pragmatic ownership experience; riders can extend the life of their investment without engaging in costly custom rebuilds. Moreover, because ABS is a standardized material, the supply chain for replacement parts tends to be broad and accessible, which translates into shorter downtime and easier maintenance. The predictability of material behavior—how ABS responds to impact, temperature, and repair methods—helps technicians and enthusiasts alike feel confident that a fix will endure the next ride, whether it’s a daily commute or a weekend sprint to a mountain pass.

Beyond raw performance, ABS injection-molded fairings address practical concerns that matter to riders who value value and safety. The panels’ rigidity and surface integrity reduce the risk of panel flutter at high speeds, a factor that contributes to stable aero behavior and a smoother ride. The surface quality also matters from a safety standpoint; a consistent finish helps maintain the rider’s visibility profile, which is especially important for day-to-day riding in urban environments where glare and reflections can affect perception. Compliance with road-legal standards is another consideration, and reputable manufacturers design ABS kits to meet broadly applicable safety and durability benchmarks. The combination of rigorous fitment, tested crash tolerance, and predictable repairability makes ABS a sensible choice for riders who are balancing cost with risk management.

In terms of fit and compatibility, injection-molded ABS panels are often designed around original geometry yet capable of accommodating a range of aftermarket connectors, accessory mounts, and service panels. This alignment supports straightforward installation on a diverse set of sport and sport-touring platforms. Designers also take color fidelity into account, aiming for consistent pigment dispersion that matches the bike’s existing colorway or offers a ready-to-polt finish that can be tailored by the end user. The end result is a set of panels that feels “right” when bolted to the frame, preserving both the machine’s silhouette and its aerodynamic profile. To explore a practical example of this approach, see the Fairings catalog for a sense of how a modular ABS kit can reproduce classic lines while adding new, integrated features.

For readers who want a quick reference to a catalog that illustrates these principles in action, there is a concise, widely circulated resource that maps similar fitment ideas and modular possibilities. Fairings collection can serve as a basis for understanding how a typical ABS-based kit aligns with original geometry and how pre-drilled mounting points simplify installation and customization. This kind of reference is useful not as a product pitch, but as a demonstration of the engineering logic behind modern ABS fairings: the tension between preserving airflow efficiency, protecting critical components, and offering riders the chance to express personality through color and styling—without compromising safety or reliability.

As the market continues to mature, the conversation around aftermarket ABS fairings increasingly centers on how material choices intersect with design intent and user needs. ABS injection molding successfully bridges that gap by providing a platform that is robust enough for daily riding, flexible enough to accommodate stylistic edits, and economical enough to make upgrades accessible to a broad range of riders. The material’s resilience under UV exposure, its energy-absorbing characteristics, and its compatibility with advanced surface finishes together create a compelling value proposition: a set of panels that can protect the engine, shield the rider from the wind, and deliver a fresh look that resonates with the bike’s performance character. This alignment of durability, aesthetics, and practicality makes ABS injection-molded fairings more than a component upgrade; they are a strategic choice for riders who demand enduring value from their motorcycle’s bodywork.

External Resource: https://www.bikeandride.com.au/aftermarket-fairings-guide/

The Aerodynamic Edge: Performance, Durability, and Precision with ABS-Injected Aftermarket Fairings

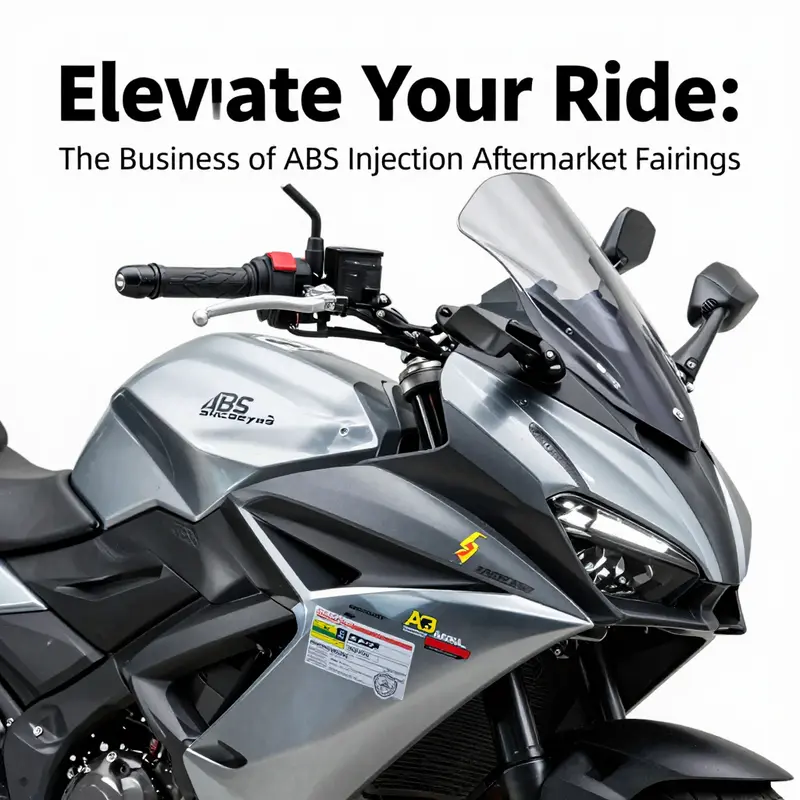

Riders who chase both speed and reliability increasingly turn to ABS injection molded aftermarket fairings as a practical convergence of materials science, aerodynamics, and accessible customization. The appeal rests not only on looks or price, but on a balanced package that strengthens how a bike slices through air, how its skin handles road abuse, and how that skin integrates with the frame and engine without becoming a maintenance headache. When you blend high-grade ABS with the precision of injection molding, you get a panel system that is lightweight, tough, and surprisingly forgiving of the realities of street riding—from sunlit summer miles to late-season rain and grit. ABS, in this context, behaves like a steady partner: resilient against impact, resistant to UV fade and weathering, and stable across a wide temperature range. Unlike cheaper plastics that can creep under load or deform with heat, quality ABS maintains its geometry, which is essential for the fairings to do their primary job—manage airflow and protect critical components while preserving rider comfort and confidence at speed. This is not mere cosmetic upgrading. It is a material choice that quietly amplifies a bike’s performance envelope without demanding a heavier investment or invasive fabrication work.

The performance dividend from ABS injection fairings begins at the skin level, where the material’s inherent toughness translates into predictable behavior on track and street alike. The injection molding process yields parts with consistent wall thickness and dimensional stability, which reduces the risk of bending or cracking when the bike takes a jolt from a pothole or a high-speed gust. From a rider’s perspective, that stability matters. A fairing that holds its shape under stress keeps surrounding air aligned with intended pathways, which in turn preserves the aerodynamics engineers’ intent: smooth, laminar airflow that minimizes drag and prevents turbulent wake. The result is a ride that feels more composed, with fewer gust-induced wiggles at higher speeds and during rapid lane changes. This is particularly important when a rider leans into an aero-sensitive section of highway or a twisty back road where micro-adjustments in posture interact with the bike’s skin to influence stability. When the panels stay true to form, the overall balance of front-end lift and rear-end downforce remains more predictable, reducing the need for compensatory steering input and allowing the rider to concentrate on line choice and throttle discipline.

Aerodynamic optimization remains a core selling point for ABS fairings because these components are designed as a system rather than as standalone shells. The shapes are crafted to channel air efficiently around the bike’s frame, engine, and exhaust, with attention paid to how each panel meets the next. In practice, this translates to measurable gains: a reduction in parasitic drag that can buoy top-end speed and contribute to more favorable fuel economy during sustained, sport-oriented riding. The exact drag reduction varies with model geometry, but the principle holds. A well-fitted ABS fairing kit can trim drag by a noticeable margin compared with older stock skins, because the new shapes are intentionally streamlined and tuned to the bike’s geometry. With a close and precise fit, airflow remains attached to the surface longer, which reduces boundary layer separation and the onset of turbulent wake that can raise drag and instability at speed. For riders who aspire to faster, more controlled riding, that means a more confident ride when the needle climbs toward the red line or when a wind chop tries to push the bike offline in a gusty stretch of road.

A key advantage of ABS injection molded panels is their ability to be tailored for a specific model’s silhouette without sacrificing structural visibility or panel-to-panel mating. The precision fit is not merely about cosmetics; it’s about ensuring that all fasteners, mounting points, and seams align so the aerodynamic performance is not compromised by gaps or misalignment. When mounting points are pre-drilled and engineered into the parts, installation becomes straightforward and repeatable, reducing the temptation to improvise with ad hoc fixes that might loosen under vibration. This is particularly important given that aftermarket kits aim to deliver road legality, crash protection, and consistent performance across a broad spectrum of riding conditions. The best kits achieve a balance between easy, tool-light installation and robust connection that resists loosening from routine vibration and high-speed impacts.

The modular design approach behind many ABS fairing kits also invites customization without sacrificing safety. Panels can be swapped or swapped partially to alter aesthetics or airflow without rewiring the bike or compromising the integrity of the structure. This modularity is a functional advantage in the real world: riders can upgrade the look or tune the airflow characteristics for a season of riding, then revert or recalibrate for the next set of conditions. In this way, ABS fairings function as a form of lightweight, aerodynamic chassis enhancement rather than as mere cosmetic wraps. And because respected manufacturers align their products with road-legal standards, riders can rely on consistent performance and safety compliance across different jurisdictions. The certification and testing that often accompany these kits provide reassurance that the parts were designed not just to look right but to behave right when the bike is pressed hard or confronted with a rough surface, rain, or debris.

From a value perspective, ABS injection molded aftermarket fairings strike a balance between cost, durability, and performance that is compelling for many riders. The upfront cost can be far more affordable than a full OEM replacement, yet the long-term benefits—improved aerodynamics, better protection of the engine and undercarriage, and less fragility under impact—translate into real-world dividends in both performance and operating costs. As a practical matter, riders can expect to see longer service intervals for protective components and a lower likelihood of micro-damage accumulating over a season, given the material’s resilience to UV light and weather exposure. While the exact economics depend on the kit, model, and level of finish, the value proposition remains consistently strong for riders who operate in variable climates and on routes that demand both speed and endurance.

One of the most important elements in choosing an ABS kit is model-specific fit. Precision fitment around contour lines, engine covers, radiator shrouds, and chassis triangulation points ensures not only aerodynamic efficacy but also the safety and reliability riders demand. When a kit is engineered to align with the bike’s original geometry, the result is a seamless integration where the panels work with the frame’s stiffness characteristics rather than fighting against them. The end user experience is one of confidence: no rattling, no hotspots from heat buildup, and no unnecessary flex that can lead to more drag or fatigue in long rides. In practice, this means that a rider can install a kit relatively quickly, verify all mounting points, and then ride with the sense that the bike’s underlying structural integrity remains intact and the ride quality is preserved. The modular and pre-drilled nature of many ABS kits also means riders can customize their setup safely, swapping pieces or refining color and finish without sacrificing core alignment. This combination of precise fit, durable materials, and thoughtful engineering is what makes ABS injection molded aftermarket fairings more than an accessory; they become a performance-focused upgrade that respects the motorcycle’s original intent while extending its capabilities.

For readers seeking a wider sense of what is possible in this space, it helps to view ABS fairings as part of a broader ecosystem of aftermarket enhancement that emphasizes reliability and measurable performance gains. The options available cover a spectrum of popular sportbike platforms, offering different finishes—from unpainted to factory-like color and gloss—so riders can achieve a look that matches their performance goals and riding style. The price ranges, while variable, generally reflect the balance of durability and aerodynamic benefit: affordable enough to be a tempting upgrade for a rider on a budget, yet robust enough to perform under track-ready or highway-speed conditions. The result is a practical, scalable approach to upgrading an old or worn fairing set or moving a bike toward a more aggressive aero profile without resorting to a full OEM replacement. In short, ABS injection molded aftermarket fairings deliver a cohesive package—strength, shape, and certainty—that helps a motorcycle carve through air with greater efficiency and with a confidence that only comes from knowing the skin is built to endure.

For readers who want to explore the breadth of options or see how these concepts translate into real-world availability, a convenient starting point is online catalogs that organize fairing kits by model family and rider preference. Within these collections, you’ll find the broadest ranges of fit and finish, along with detailed specifications that explain the materials and construction methods used. As part of a broader ecosystem, these kits are positioned to complement other performance upgrades, such as improved intake or exhaust strategies, by ensuring that the bike’s silhouette remains a net positive contributor to aerodynamics rather than a drag-inducing obstacle. The synergy between materials science, design optimization, and practical installation highlights why ABS injection molded aftermarket fairings have become a mainstay for riders who value progress that’s measurable in both speed and everyday usability.

Internal link reference: For a broad view of compatible bodywork categories, see the Honda fairings collection. Honda fairings

External resource: The following external listing provides a concrete example of ABS injection molded fairing kits and their stated performance attributes, including durability and airflow considerations. External resource: https://www.alibaba.com/product-detail/ABS-Injection-Molding-Yellow-Fairing-Kit_1600348477245.html

ABS Injection: Precision Fit and Personal Flair for Aftermarket Fairings

ABS injection molded aftermarket fairings offer a balance of durability and lightness. ABS resists weathering, UV exposure, and road debris, helping maintain the finish after miles on sun, rain, and spray. When engineered properly, these panels also contribute to aerodynamic efficiency and a cohesive look that honors the bike’s original design.

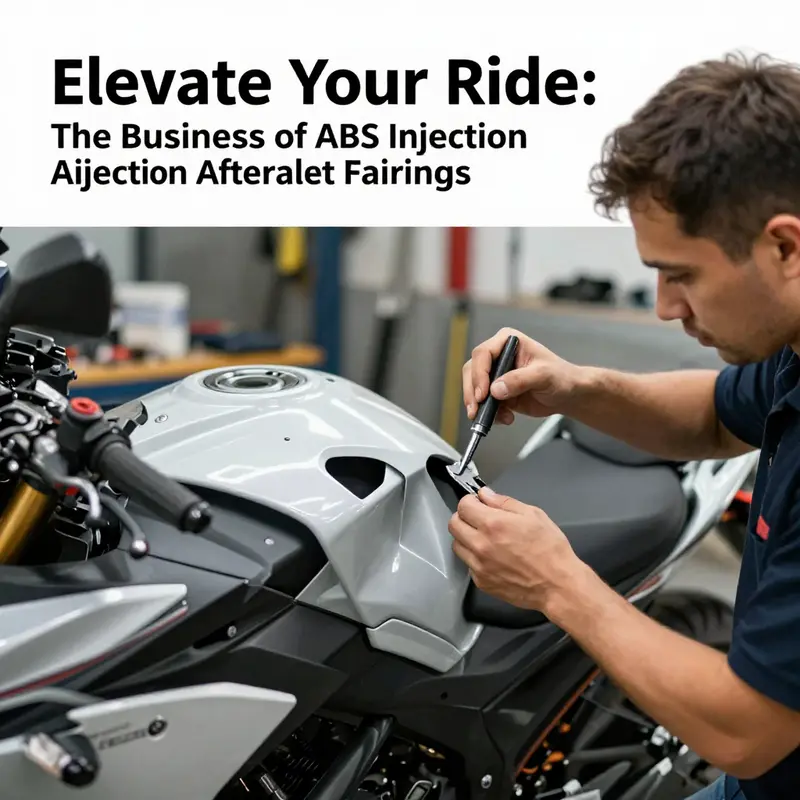

Model specific fit is the cornerstone of a reliable installation. Kits should align with the bike’s brackets, mounting points, and cutouts for lights and vents. Even with model specific kits, a careful dry fit is essential to verify clearances around the steering head, radiator shrouds, and frame rails before any fasteners are torqued.

The mounting sequence often follows a middle out approach, starting with the centerline then working toward the sides. Pre-drilled holes guide the assembly order, helping to achieve even gaps and a clean silhouette while reducing wind noise and potential chafing.

In addition to fit, customization is a core benefit. Unpainted panels provide a canvas for color, decals, and textures. ABS holds paint and clear coats with good adhesion and UV resistance, allowing gloss or matte finishes that suit the rider’s style.

Aerodynamic refinements can be explored through venting and reshaped contours to align with riding goals and reduce drag. Safety and compliance: choose kits that meet standards and include documentation of tolerances.

Finally, consider the bike’s ecosystem: panels interact with the radiator, airbox, and under seat heat management. A thoughtful installation preserves the intended airflow while enabling personal expression.

An informed buyer often looks to model specific lines and reputable manufacturers to ensure consistent fitment and predictable results.

Meeting the Mark: Safety Standards, Testing, and Compliance for ABS Injection Aftermarket Motorcycle Fairings

Safety compliance is not optional when it comes to aftermarket ABS injection fairings. Riders choose these fairings for cost, durability, and looks. Yet the practical value lies in their ability to protect the bike and rider while remaining road-legal. This chapter explains the regulatory landscape, the engineering choices that enable compliance, and the practical checks a buyer should perform before fitting a replacement fairing.

Regulatory frameworks vary by region, but their goals align: preserve rider safety and vehicle stability. In the United States, federal and state agencies set standards for parts that affect crashworthiness and visibility. In Europe, United Nations Economic Commission for Europe (ECE) regulations guide the design of motorcycle equipment. These frameworks do not spell out every detail of aftermarket bodywork. Instead, they require that parts do not compromise safety-critical systems. For injection-molded ABS fairings, achieving compliance means meeting tests for impact behavior, mounting integrity, and thermal stability.

Material choice is the first and most visible compliance factor. Acrylonitrile Butadiene Styrene (ABS) shows a balance of stiffness and toughness. It absorbs energy without shattering. It tolerates temperature swings seen in daily riding. It resists UV-related degradation when properly compounded. These intrinsic properties make ABS a sensible base for fairings meant to perform under stress. But not all ABS is equal. Quality control in resin formulation, additives for UV resistance, and processing parameters during injection molding shift material performance. Manufacturers aiming for compliance source high-grade ABS and document their material specifications. That documentation supports both testing and traceability.

Testing is where theory becomes proof. Reputable aftermarket fairings undergo mechanical impact tests. These measure how the part behaves when struck or when it flexes under load. A compliant fairing should flex predictably and return energy in a way that avoids sudden fragmentation. Tests also validate mounting points. A secure, precision fit prevents fairing movement that could affect steering or airflow. Manufacturers will test attachment hardware and use reinforced inserts in stress zones. When reinforced correctly, the fairing helps channel impact forces away from critical frame elements.

Thermal testing matters as well. Components mounted near engines experience heat cycles. A compliant ABS fairing must resist creep and distortion across expected temperature ranges. Heat tolerance testing simulates prolonged exposure to engine heat and sunlight. Photostability or UV testing subjects samples to accelerated sunlight to predict long-term color retention and surface embrittlement. Passing these tests ensures the fairing will remain functional, not brittle, over a typical service life.

Aerodynamics may seem cosmetic, but it has safety implications. Fairings that are aerodynamically unstable can create buffeting or lift at speed. Manufacturers that pursue compliance measure drag and lift in wind tunnels or through computational fluid dynamics. A fairing with poor aerodynamic integration can affect handling and tire load distribution. For that reason, fitment precision is assessed alongside aerodynamic behavior. Precision fit reduces turbulence and maintains stable airflow over the chassis and rider, positively affecting high-speed control.

Certification marks and documentation are your proof of testing. When a product carries a regional mark—such as an approval label or a manufacturer’s declaration of conformity—it indicates that the product has passed required checks or that the supplier accepts responsibility for compliance. Savvy buyers ask for data sheets, test certificates, and material traceability records. These documents should show the resin grade, the test methods used, and the results for impact, thermal, and UV tests. A supplier who cannot produce such documentation should raise a red flag.

Beyond test certificates, installation instructions are part of safe use. A well-documented kit includes detailed mounting diagrams and torque specifications for fasteners. It explains any required reinforcement steps and gives guidance on compatible hardware. Improper installation can nullify compliance advantages. For instance, using incorrect fasteners can concentrate loads and create fracture points. A precision-fit fairing designed for direct bolt-on installation reduces the chance of user error. Some kits include pre-drilled mounting points and factory-aligned fixtures to simplify the process.

Traceability connects a product back to its manufacturing process. Good manufacturers label batches and keep production records. This practice allows recalls or targeted quality checks if a defect emerges. Traceability also ties the finished part to the specific ABS formulation used during molding. When compliance disputes arise, traceable production data speeds resolution and protects riders and sellers.

While documentation and testing establish a baseline, real-world durability completes the picture. Many compliant fairings are subjected to road testing that includes highway runs, exposure to varied climates, and track sessions. These tests expose the fairing to mechanical fatigue, vibration, and sustained aerodynamic loads. Data gathered in these tests validates laboratory results and helps refine reinforcement patterns around headlights, bellies, and side mounts. A fairing that performs well in both lab and field tests is more likely to preserve safety margins over time.

Legal considerations should drive purchasing choices. Regulations often prohibit parts that alter safety-critical systems or reduce the effectiveness of lighting, signals, or mirrors. Buyers should confirm that the fairing preserves these systems’ function and access. If a kit changes a lighting angle, it may fail inspection in some jurisdictions. Ensuring compatibility with your bike’s safety systems helps avoid costly legal complications and keeps the bike safe to ride.

When assessing suppliers, prioritize transparency and third-party verification. Reputable suppliers publish test summaries and provide easy access to compliance documentation. They also respond to technical inquiries about fitment and materials. When a supplier touts high-quality ABS and claims durability, ask for the underlying test data. Independent third-party labs offer the most credible verification. Certifications backed by recognized labs carry greater weight than unsupported statements on a product page.

Maintenance and repairability also relate to compliance. ABS fairings that can be repaired with standard adhesives or heat-based welding maintain functional safety after minor incidents. Manufacturers that design parts with replaceable subpanels reduce the need to replace entire assemblies after a small impact. This modular approach helps preserve structural integrity and can be a sign of thoughtful engineering focused on long-term safety.

Finally, the buyer’s role is active. Verify certification marks and request test reports. Inspect the part for consistent wall thickness and clean moldings. Check that mounting points are reinforced and that hardware is included. Follow installation instructions precisely. After fitting, perform a road test at moderate speed to confirm there are no new vibrations or handling quirks. Keep documentation with the bike in case of inspections.

For riders looking for compatible replacements, an example of where to begin browsing general options is the Honda fairings collection. This kind of resource can help you compare fitment and support documentation across multiple kits. Always pair online research with direct verification of test data before purchasing.

For further reading on regulatory context and safety testing processes, consult the appropriate national transportation safety authority resources: https://www.nhtsa.gov

Choosing an ABS injection fairing involves more than aesthetics. When materials, testing, and documentation align with regulatory standards, aftermarket fairings can protect your bike, preserve handling, and remain legal on public roads. Prioritize suppliers who provide clear evidence of compliance, and maintain an attentive approach to installation and upkeep to keep those safety benefits intact.

How ABS Injection Fairings Reshape the Motorcycle Aftermarket Economy

Market dynamics shift when a durable, cost-effective material becomes standard. ABS injection fairings have altered economics across design, production, distribution, and ownership. They create a ripple effect that touches independent garages, small manufacturers, global supply chains, and the everyday rider looking for an affordable upgrade. This chapter traces that ripple, showing how a single material technology can reshape an entire aftermarket ecosystem while preserving performance and safety.

ABS injection molding lowered barriers to entry for fairing production. Injection tooling demands upfront capital, but it yields high repeatability and low per-piece cost at scale. That combination favors manufacturers who can amortize molds across large runs and diverse model lines. As volumes grow, price per unit drops. Retailers and wholesalers pass those savings along, broadening access for riders who once could not afford custom bodywork. For many, the decision to repair or personalize a bike now hinges less on cost and more on taste or function. A broader customer base follows: hobby riders who want styling changes, commuters seeking wind protection, and track enthusiasts pursuing weight and aerodynamic improvements.

The pricing structure for ABS injection fairings exposes a clear economy of scale. Initial tooling represents the largest fixed cost; material and cycle time determine marginal cost. Once a mold produces hundreds or thousands of parts, the amortized tooling cost becomes negligible per kit. That math explains offers that list individual pieces for tens of dollars with minimums on bulk platforms, while full kits sold to resellers appear in the higher end of a range but still undercut traditional OEM pricing. These margins create a profitable model for suppliers and allow retailers to underprice OEM parts without sacrificing quality. The result is competitive pressure on legacy suppliers and a stronger aftermarket presence in replacement and customization markets.

Production efficiency is central to that competitiveness. Injection processes yield consistent wall thickness, integrated mounting points, and minimal finishing compared with hand-laid fiberglass or thermoformed parts. Consistency reduces returns and fitment issues, lowering warranty and installation labor costs for retailers and fit shops. Faster cycle times mean manufacturers can respond to market shifts, launching new colorways or slightly revised geometries to meet rider preferences. Lower scrap rates and more predictable inventories further strengthen supply chains, enabling smaller distributors to carry a wider range of SKUs with lower capital tied up in stock.

Those supply chain improvements have downstream economic effects. Local installers and paint shops see more work as riders buy inexpensive raw kits and choose professional finishing. Independent sellers gain options: they can sell unpainted units for DIYers or offer painted, bolt-on kits with installation markup. This diversification increases local employment and expands service revenue beyond part sales. At the same time, centralized factories optimize logistics, shipping unpainted kits in compact packaging to reduce freight costs. That division of labor—production at scale paired with local customization—creates a resilient, multi-tier market structure that benefits many actors.

Consumer segmentation broadens when price barriers fall. Lower-cost ABS fairings draw in new customers while satisfying existing segments. Riders who once deferred repairs now replace cracked panels instead of living with damaged parts. Enthusiasts choose aftermarket fairings to achieve aggressive looks without paying a premium. Sport riders seeking marginal aerodynamic gains find that molded ABS fairings can be engineered to reduce drag and improve stability at speed, offering an affordable path to performance upgrades. Long-distance riders appreciate durability and UV resistance, which points to reduced maintenance and replacement frequency—factors that influence lifetime ownership costs.

That lifetime cost perspective matters for both consumers and insurers. Durable ABS reduces the frequency of replacement, which can shift purchasing decisions from short-term savings to long-term value. Insurers and rental fleets also pay attention; lower replacement costs and predictable part availability reduce claims expenses and downtime. Fleets that maintain multiple units benefit from standardized parts and easier repairs, which lowers the total cost of ownership. These institutional purchasers bolster demand and provide steady order volumes that stabilize suppliers’ planning and investment decisions.

Competition intensifies as more manufacturers adopt molded ABS. Competition fosters innovation in design, fitment precision, and finishing techniques. Suppliers invest in better tooling, refined part tolerances, and pre-drilled mounting points to attract buyers who value quick, reliable installation. Brand differentiation shifts from raw material claims to service offerings: faster shipping, warranty terms, and finish quality. Retailers emphasize fitment guides and installation support to reduce buyer hesitation. That emphasis on service spurs ancillary business opportunities—installation kits, improved fasteners, and specialized paint services—that cumulatively enlarge the aftermarket economy.

The trade balance and global commerce picture also change. Injection molded ABS kits are compact and lightweight, improving shipping economics for international trade. Suppliers in manufacturing hubs can ship globally with lower freight costs than metal or fiberglass alternatives. That has enabled a global aftermarket where buyers source parts internationally with confidence. Economies of scale in certain regions concentrate production, while demand in other regions supports specialized finishing, distribution, and retailing. This geography of production and consumption allows smaller firms to access global markets without massive capital, democratizing participation in the aftermarket.

Regulatory and safety considerations shape economic outcomes. Reputable suppliers ensure compliance with road-legal standards and performance certifications. When aftermarket components meet recognized safety benchmarks, consumer trust rises. That trust reduces friction in purchase decisions and broadens market size. Conversely, poor-quality imports or noncompliant parts can erode confidence and increase warranty claims, raising costs for everyone. Clear standards and traceable manufacturing practices protect reputations and sustain long-term market growth.

Environmental economics also factor into this transformation. Injection molding produces less waste than many traditional fabrication methods. Scrap rates are lower and recyclable thermoplastic streams exist for ABS, which lowers disposal costs. Manufacturers increasingly optimize material use and consider recycled content. While plastics present environmental challenges, efficient production, longer part life, and the avoidance of frequent replacements can reduce overall material throughput over a bike’s lifetime. That reduction yields both cost benefits and potential regulatory goodwill, especially in markets sensitive to lifecycle impacts.

The OEM landscape responds in predictable ways. Faced with a robust aftermarket, OEMs can focus development resources on higher-margin innovations or complementary accessories. Some may offer factory-level bodywork options, while others form partnerships with aftermarket suppliers to co-brand or license designs. The presence of a healthy aftermarket can pressure OEM pricing but also expands the total available market by making repairs and personalization accessible. In many cases, the aftermarket and OEM channels coexist, with riders choosing between factory finish and lower-cost, quickly available alternatives.

Finally, the cultural and behavioral economics of riders influence demand. The lowered price of good-fit ABS fairings changes attitudes toward customization. Riders experiment more freely, and the visual diversity of bikes on the road increases. That diversity, in turn, fuels demand for paints, decals, and bespoke touches—services that create recurring revenue streams for shops and retailers. The aftermarket shifts from a replacement market to a broader personalization economy, and that shift multiplies the economic impact beyond the initial part sale.

Taken together, ABS injection fairings do more than cut costs. They reshape production models, broaden market access, stimulate local service economies, alter ownership calculations, and influence global trade patterns. Their influence is visible in the greater availability of model-specific kits and the rising sophistication of fit and finish. For riders and businesses alike, the result is a more dynamic, competitive, and resilient aftermarket—one in which affordable engineering and durable materials drive both access and innovation. For an example of how model-specific compatibility and fitment are presented in retail collections, see the CBR900RR (2002–2003) fairings collection.

For further details on material standards and industrial applications of ABS motorcycle fairings, consult this resource: https://www.hondamotorcycles.com/abs-fairing-kit-standards-composition-industrial-use

Final thoughts

Investing in ABS injection aftermarket fairings presents a unique opportunity for business owners in the motorcycle sector. With their strengthen material properties, enhanced performance features, customizable options, and compliance with safety standards, these fairings fulfill the needs of modern riders seeking both aesthetics and durability. By understanding how to effectively integrate these offerings into your business model, you can not only meet market demands but also drive growth in an increasingly competitive landscape. The benefits extend beyond mere appearance, providing a comprehensive solution that enhances the overall riding experience. As the motorcycle community continues to evolve, embracing high-quality ABS fairings could position your business for significant success.