The aftermarket for cruiser motorcycle fairings has become a pivotal sector in the motorcycle industry, highlighting the nuanced balance between performance, comfort, and aesthetics. As business owners in the motorcycle industry, understanding this niche market is crucial for maximizing customer satisfaction and driving sales. This article delves into the depth of aftermarket fairings, exploring their technology, benefits, market trends, and reliable sources for procurement. By equipping yourself with this knowledge, you can better meet the needs of riders seeking to enhance their cruising experience.

Riding the Edge: Crafting Comfort and Character with Aftermarket Cruiser Fairings

Every cruiser rider knows that the road is part stage, part partner, and part test. The aftermarket fairing scene for cruisers sits at the intersection of style, ergonomics, and endurance. It is not merely about changing the bike’s silhouette; it is about shaping a riding experience that can sustain hours on the highway, spaces between towns, and long stretches of open road where wind and weather become a dialogue with the rider. In this chapter, we walk through how aftermarket fairings for cruisers are designed, chosen, and refined to deliver more than a visual upgrade. The goal is not to convert a classic into a race machine, but to tune the bike to better carry a rider’s posture, balance, and presence as miles accumulate. The result is a cohesive blend where form mirrors function and the bike’s new face tells a story as much as it shields the rider from gusts and fatigue.

The landscape of cruiser fairings is distinguished by three broad approaches, each with its own ethos and set of practical considerations. Full fairings sweep across the front and upper regions of the bike, wrapping around the headlight and instruments to create a seamless, almost sculptural profile. The promise here is wind protection that feels deliberate and generous. The price, weight, and installation complexity rise in tandem with the coverage, as more surface area means more mounting points to reinforce and more contours to match. Semi-fairings—or clip-on styles—offer a more balanced proposition. They provide meaningful wind deflection without fully enclosing the bike. This makes for a lighter, more maintainable package, while preserving the iconic silhouette that many cruisers cultivate. Then there is the realm of custom bodywork, where individuality becomes a core feature. Chopper-inspired, vintage-inspired, or bespoke panels are not unusual in this space. Builders and riders alike use custom bodywork to conjure a visual identity that aligns with a specific riding persona—whether that persona favors nostalgia, modern minimalism, or a bold, urban stance. Platforms that cater to customize, including larger marketplaces, reflect a growing appetite for personalization that continues to shape what aftermarket fairings can be.

Material choice is a practical artist’s palette. ABS plastic remains a workhorse—affordable, impact-resistant, and relatively simple to shape and repair. Fiberglass sits in a similar pragmatic space but can be molded into more complex curves with a tougher surface. Expensive but eye-catching carbon fiber is the premium path for riders who want maximum stiffness-to-weight performance and a distinctive weave that announces sophistication. Each material interacts with the bike’s original architecture in its own way. Heftier full-fairing assemblies demand sturdier mounting points and careful integration with the bike’s framework, while lighter semi-fairings invite straightforward installation and easier maintenance. The developmental edge in modern aftermarket kits is the attention paid to fitment precision. Many kits now leverage 3D-scanned data from the original panels to capture the exact geometry of a given cruiser model. This scan-based workflow helps ensure that the aftermarket skin aligns with factory tolerances, reducing gaps, misalignments, and the need for improvisation during installation. It is a reminder that the best-looking fairing is the one that sits as if it had grown from the bike rather than been bolted onto it.

Yet a fairing is more than a frame with cosmetic skin. The engineering mindset is increasingly about airflow management, even in a genre that prioritizes comfort and a relaxed ride rather than raw top speed. Subtle channels and ducts can guide air toward engine cooling paths or around the rider’s torso to smoothen the air boundary layer. The result can be a more settled ride at highway speeds and a more stable visual field, which matters after a long day on the road. The ergonomic payoff sits at the core of the rider’s satisfaction. A well-designed fairing can position the rider into a posture that distributes weight through the hips and spine, easing shoulder strain and reducing fatigue during long sessions. The right windscreen height, the contours that cradle the chest, and the shape that funnels air around shoulder and arm lines all translate into a riding experience that feels less like bracing against the wind and more like gliding with it.

Aesthetics can be as consequential as comfort, because cruiser riders often seek a look that announces intent before the bike is even rolled out of the garage. The fairing’s line, its paint-ready surface, and its interaction with chrome, leather, and metal details all contribute to a cohesive narrative. In practice, this means choosing a fairing that harmonizes with the bike’s existing design language—whether that language is retro, modern, or a hybrid that nods to multiple eras. This alignment matters because the best aftermarket fairings don’t just alter a bike’s wind profile; they alter its perceived character. Riders report that a kit which respects the bike’s proportions and maintains clean, respectful proportions with the fuel tank, handlebars, and seat tends to feel more integrated—more like a curated evolution rather than a bolt-on modification.

When it comes to selecting a kit, the rider’s priorities guide the decision more than any single spec sheet. Material composition is a primary driver of weight, durability, and finish quality. ABS and fiberglass are common, redolent of a practical approach that values availability and repairability. Carbon fiber, on the other hand, signals a performance and premium aesthetic choice, often accompanied by higher cost and specialized finishing. Fitment precision is non-negotiable. The aftermarket landscape has matured to include compatibility guides and verified installation tutorials, with reputable suppliers offering after-sales support and replacement parts. The best-sellers in this segment won’t just ship a shell; they ship peace of mind, with mounting hardware calibrated to the bike’s frame and a paint-ready surface that reduces the need for heavy prep work on arrival.

In the broader ecosystem of aftermarket cruiser parts, there is a growing awareness of how a fairing interacts with other critical components. A versatile windscreen that is tall enough to shield the chest yet clear enough to preserve visibility can dramatically alter the daily riding experience. Storage integrations—like optional pockets or compartments that fit behind or within the fairing—can unlock a practical dimension for long trips. Integrated points for reflectors or auxiliary lights also reflect how modern fairing kits try to balance safety, necessity, and style in one package. This holistic perspective means riders increasingly evaluate fairings not as isolated shells but as part of a broader system that includes the seat, the exhaust note, the handling geometry, and the touring potential of the bike.

For those who crave a sense of direction when navigating the marketplace, it helps to see how the ecosystem supports a rider’s journey from choice to installation. The process often begins with precise data capture—3D scans from the original panels to ensure the aftermarket panel aligns with the bike’s natural lines. This data is then translated into a kit that respects the bike’s original geometry while offering incremental improvements—reinforced installation points, optimized air channels, and, in some cases, integrated engine-cooling paths. The result is a kit that not only looks right but performs in a way that reduces the friction riders experience when they push the bike toward and through highway speeds. The choice to invest in this class of accessory is, at its core, a decision to invest in comfort, control, and character for the long-haul.

For readers who want a concrete sense of how aftermarket providers express these principles, a careful look at representative catalogs shows how different cruiser archetypes translate into available kits. A full fairing might be chosen by a rider who values maximum wind protection for extended highway runs and for who the extra weight is a practical trade-off for a cleaner silhouette. A semi-fairing could fit a rider who wants a balanced blend of protection and maneuverability, particularly when urban riding and weekend cruising define the use pattern. A custom route invites the rider to tell a personal story through a unique shape and finish, where the fairing becomes a canvas as much as a shield. In every scenario, the underlying thread remains: aftermarket fairings are about enabling a riding life that aligns with the rider’s comfort, aesthetics, and travel goals, all while preserving the relational balance with the bike’s chassis, controls, and ergonomics.

Within this evolving field, it is also prudent to stay grounded in sourcing and quality assurance. Reputable manufacturers and suppliers provide detailed specifications, compatibility guides, and clear after-sales support, including spare parts and installation guidance. While some platforms emphasize breadth and customization potential, discerning riders look for evidence of consistent fitment data, reliable finish quality, and a track record of accurate product descriptions. In this context, it is reasonable to approach aftermarket fairings with the same analytical lens often applied to OEM components: assess the fit, verify the materials, confirm the finish, and consider the broader implications for comfort and maintenance across miles of riding. The patchwork of options—full, semi, and custom—invites riders to craft a narrative that respects the bike’s lineage while expanding its present and future capabilities.

To explore a concrete path for those who want to see how a well-curated catalog can translate into a tangible upgrade, consider visiting a dedicated repository that curates cruiser fairings and related accessories. For riders curious about a wide range of model-specific options under a trusted collection, the Yamaha fairings section offers a clear, organized window into how aftermarket design language adapts to a familiar platform. The collection demonstrates how a reputable supplier frames compatibility and style, guiding the rider toward a choice that feels like a natural evolution of the bike rather than a radical departure. The approach—emphasizing fit, finish, and ease of installation—resonates across brands and styles, reinforcing the idea that the best aftermarket kits respect the original bike’s proportions and the rider’s expectations for long days in the saddle. In the end, the best fairing for a cruiser is the one that harmonizes three threads: comfort on the move, a look that travels well, and a system that integrates without forcing the bike to become something it is not.

For readers who want to explore a spectrum of aftermarket options beyond the immediate catalog, a broader market is visible in global platforms that emphasize customization and scale. These marketplaces present an invitation to imagine a bike that wears its owner’s story in its lines, its color, and its silhouette—yet still rides with the calm certainty that a well-designed fairing can provide. The right choice makes the road feel a touch friendlier, a little more predictable, and a lot more personal. It is this balance—between the rider’s comfort, the bike’s character, and the road’s demands—that makes cruiser fairings more than accessories. They become part of the craft of riding and the ongoing conversation between man, machine, and open asphalt.

External resource for broader exploration: https://www.alibaba.com/showroom/aftermarket-motorcycle-bodywork.html

Internal link example for model-specific exploration: To see how aftermarket specialists adapt popular models, explore the Yamaha fairings collection on Summit Fairings, which provides a curated view of compatibility and finish options across generations and styles. This resource helps translate the general principles discussed here into concrete choices you can evaluate in your own garage.

Riding Beyond Stock: The Real Benefits of Upgrading to Aftermarket Cruiser Fairings

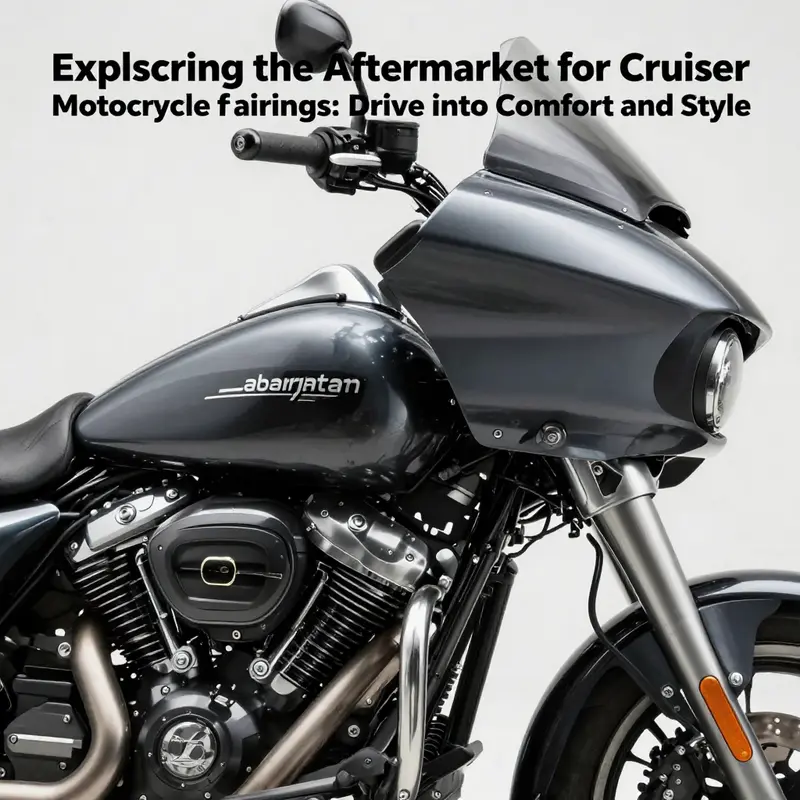

The pursuit of a cruiser motorcycle that feels tailored to the rider’s body and ambitions often begins long before the engine is started. It starts with the shell the rider interacts with every mile: the fairing. In the aftermarket, the fairing is not merely a cosmetic upgrade; it is a carefully engineered system that reshapes how a bike carries wind, how the cockpit feels after hours on the road, and how the overall character of the machine translates into a rider’s daily routine or weekend adventure. The batwing silhouette, one of the most recognizable forms in cruiser culture, stands as a case in point. It is as much about presence as it is about function. A well-chosen aftermarket fairing can transform a stock model into a platform that better supports long-distance comfort, smoother airflow, and a more confident stance. The modern aftermarket scene has matured to a point where data-driven design and practical fit are the baseline, which means riders can upgrade without sacrificing the integrity of the bike’s original geometry or its reliability.

At the heart of these upgrades lies a practical truth: wind is a constant companion on highway miles. A stock fairing is often adequate for casual, short hops, but long trips reveal a different calculus. Riders encounter a broad spectrum of riding conditions—from air pockets and gusts to relentless highway noise and the fatigue that follows. The aftermarket windscreen, the fairing’s sweep, and the shape of its surface work together to create a calmer microclimate around the rider. This is especially true for touring-minded cruisers that carry a passenger or gear. By deflecting the most direct wind, aftermarket fairings reduce the wind pressure on the chest, shoulders, and neck. The effect is not just comfort; it translates into sharper focus, which is a critical safety attribute when the road demands sustained attention over long hours. The result is a smoother ride that feels less like a battle with the air and more like a controlled conversation with the bike.

The batwing, in particular, embodies a philosophy of integration. It is designed to envelop the rider in a curated airflow, rather than simply sitting as a solitary shell on the bike’s front end. This integration is often aided by modern manufacturing approaches that include 3D scanning of the original bodywork data. By capturing the exact contours of the OEM panels, aftermarket suppliers can ensure a near-perfect match when the fairing morphs from a design concept into a physical component. The payoff is visible in every ride: the fairing lines up with the bike’s frame and fuel tank with minimal gap, and the fit is consistent across the entire surface. A precise fit reduces the likelihood of rattles, shielded engine cooling ducts, or misalignment that would otherwise require improvisation during installation. In some cases, brands take this data even further, refining reinforcing points where fasteners are placed, improving airflow channels, or adding integrated cooling conduits that help manage engine temperatures when ambient heat or sustained engine load tests the cooling system.

What this means on the road is immediate and tangible. First, the rider experiences increased wind protection. The overall drag felt on the upper body diminishes, and with that comes a reduction in fatigue. The arms and torso breathe a little easier because the wind’s direct impact is redirected around the rider rather than blasting against the chest. For a passenger, the effect is even more pronounced; the companion sits in a more stable airflow envelope, which can make extended trips more comfortable and less exhausting for both people on board. The moral is simple: better wind management improves endurance, which in turn expands the doable distance of a single ride and the frequency of weekend escapes. The design language behind this benefit is not purely aesthetic; it is an aerodynamic philosophy expressed through curves, radii, and surface finishes chosen to guide air in a controlled manner.

Second, the aesthetic payoff is far from decorative. The aftermarket market has embraced customization as a form of self-expression. From the finish—gloss, matte, metallic, or textured—to the silhouette’s sweep and the width of the side panels, riders can sculpt a machine that communicates a unique personality. A cruiser with a bold fairing creates a stronger first impression, and that impression is not merely about looking aggressive; it signals a rider who values presence and purpose. The visual upgrade often aligns with the practical upgrade: a fairing that looks substantial usually betrays a system built to endure. The materials chosen—fiberglass, ABS plastic, or composite blends—affect not only weight and stiffness but also finish resilience and repairability. Whether the rider seeks a clean, factory-like line or a more muscular, statement-making arc, the aftermarket ecosystem offers an array of textures and color options that invite experimentation without the risk of altering core mechanical systems.

Third, installation and integration remain a practical frontier where the benefits pay off quickly for many riders. A well-made aftermarket kit typically requires little or no modification to the bike’s fundamental structure. This non-invasive nature is essential for riders who value retainability of resale value or who prefer to preserve the bike’s original condition as much as possible. The common approach is to anchor the new fairing to existing mounting points, using hardware sized and placed to distribute load evenly. In some cases, the kit is designed to reuse the stock hardware and adds a few purpose-built brackets that accommodate the fairing’s shape. The result is a swap that can be completed in a weekend with basic tools, routine protective measures, and careful alignment. The best kits guide the installer through a clear sequence—from detaching the old unit to aligning the new panels and finally guiding the fasteners into their reinforced points. This careful choreography minimizes misalignment and ensures a secure, wind-tight seal once the screws are snugged. It is not just about plugging pieces together; it is about respecting tolerances and the bike’s intended dynamics. This care matters because a fairing that feels loose or leaks air will undermine both comfort and aerodynamics, potentially inviting vibration and noise that counteracts the very benefits the upgrade seeks to deliver.

The practical implications for daily riders extend beyond the highway’s edge. A well-chosen fairing can influence the riding posture in subtle but meaningful ways. The cockpit becomes a more open but still enclosed zone where hands, wrists, and shoulders sit in positions that reduce strain. For someone who spends long hours in the saddle, this can translate into less back fatigue and more consistent control. Even the seat, which often earns praise or blame for long-haul comfort, can work in concert with the fairing to create a more ergonomic seating triangle. In some builds, manufacturers or skilled shops add integrated wind deflectors that guide air away from the rider’s hands and forearms, diminishing the wind chill on cooler days. These additions might also contribute to quieter cockpit conditions by dampening the turbulent eddies that travel along the fairing’s edges.

For riders who plan to travel with a passenger or carry gear, the fairing becomes part of a broader comfort strategy. It can free up valuable space by shaping the air in ways that reduce wind pressure on saddlebags and other storage solutions, allowing the rider to pack more confidently for a trip without sacrificing balance. In turn, this can influence choices about the seat design and the overall weight distribution on the bike. The greater sense of stability around highway speeds translates into a more predictable ride through sweeping turns and on long straightaways alike. The improved airflow can also complement other upgrades that a touring-minded rider often considers, such as a taller, adjustable windscreen or a tail section designed to reduce turbulence around the rider’s elbows.

To navigate the myriad options with confidence, riders frequently consult compatibility resources and design guides that emphasize precise data-driven fit. The advantages of 3D-scan-derived data cannot be overstated here. When a fairing is engineered from an exact replication of the bike’s original panels, the likelihood of misfit is dramatically reduced. Carving a perfect line around a tank seam or around the fork crown is not a matter of chance; it is a function of digital measurement and careful translation into a tangible part. The resulting interface feels seamless, and the installation experience becomes less of a test of improvisation and more of a straightforward assembly process. In practice, that means less time wrestling with brackets and more time enjoying the ride.

As a rider considers the trade-offs between stock and aftermarket, it is worth noting that the upgrade does not compel a wholesale rework of the bike’s structure. The essence of the machine remains intact—the frame and engine, the chassis geometry, and the fundamental lines that give the model its identity. What changes is the way air, sound, and line-of-sight interact with the rider. This is where the look, the feel, and the performance converge into a coherent experience. A fairing that integrates well with the windscreen, the instrument cluster, and the fuel tank creates a singular, confident pop when the ignition is first engaged. The rider is greeted by a cockpit that feels tailored, not tacked on.

For those who want to see examples of compatible options, a practical starting point is the Honda fairings collection at Summit Fairings. It offers a perspective on how a well-constructed kit aligns with a specific model family, including the kind of finish, mounting hardware, and contouring that track with the bike’s original aesthetics while enabling a distinct personal touch. That kind of alignment between form and function is a hallmark of quality aftermarket work, and it illustrates how the best upgrades carry forward the bike’s integrity rather than replacing it. If you’re exploring options, this is the type of resource that helps translate vision into a test ride rather than a shopping pile.

Ultimately, the decision to upgrade rests on the rider’s goals. If the aim is sustained comfort and a refined, road-tested silhouette, aftermarket fairings deliver a suite of advantages that go beyond immediate aesthetics. They offer measurable gains in wind management, ride feel, and overall enjoyment of longer trips. They also invite a level of customization that can reflect the rider’s preferences for color, texture, and even the sense of engineering craftsmanship that accompanies a well-fitted component. The aftermarket ecosystem, built on data-driven fit and iterative improvements, supports a growing culture of riders who view their bikes as co-authored instruments—each accessory shaping how the machine communicates with the road. For those moments when the road stretches ahead and the wind becomes a constant companion, upgrading to a well-chosen fairing can feel like choosing to ride with the wind rather than against it.

External guidance and practical details are always valuable. For riders who want structured advice on selecting the right aftermarket fairing, a detailed guide is worth consulting before purchasing. See the External resource: https://www.motorcyclefairingguide.com/aftermarket-motorcycle-fairing-guide-how-to-choose-right.

Engineering the Wind: Technologies Behind Aftermarket Cruiser Motorcycle Fairings

Cruiser motorcycles are defined by their laid-back ergonomics, long-haul comfort, and a presence that blends classic lines with modern capability. The aftermarket windshields and fairings that riders choose go far beyond mere aesthetics. They are active components in a system designed to tame the wind, fine-tune riding posture, and extend the machine’s versatility for relaxed cruising, spirited back-road jaunts, or extended touring. The technologies behind these aftermarket fairings weave together data-driven fitment, material science, precision manufacturing, and integrated design thinking to deliver products that feel almost tailor-made for each ride. The process begins with data—often 3D scans sourced from OEM panels—to capture the exact contours of the bike’s structure. This ensures a seamless fit that respects the bike’s lines and allows for subsequent refinements, such as reinforced mounting points, streamlined air channels, or the integration of cooling ducts that can improve engine efficiency without compromising the fairing’s silhouette. The result is a flow of parts that look purpose-built, yet are ready to be added to a wide range of models with minimal fuss. The rider, meanwhile, experiences a calmer cockpit during long days on the highway and a more confident posture when negotiating crosswinds on rural backroads. The wind no longer behaves like an adversary; it becomes a programmable element that riders can tune to their preference. In this sense, aftermarket cruiser fairings are not simply add-ons, but carefully engineered systems designed to harmonize with the bike’s existing architecture and the rider’s comfort envelope.

Technologies in this space flow from three core pillars: material selection, manufacturing precision, and integrated design that anticipates electronics and air management. Material choices drive weight, stiffness, and durability. Modern composites—most often fiberglass-reinforced plastics or carbon fiber—provide high strength with relatively low weight. These materials tolerate the flex and vibration inherent to cruising and touring while resisting impacts from stones and debris that inevitably meet the lower edges of the fairing at highway speeds. Carbon fiber, with its exceptional strength-to-weight ratio, offers a compelling performance edge. It can lower total system weight enough to feel tangible in handling and acceleration while delivering an upscale look. However, carbon’s higher cost and potentially brittle character under certain impacts mean many riders and manufacturers balance it with fiberglass-reinforced plastics to achieve a practical compromise: lightness and stiffness where it matters most, with ruggedness in areas prone to contact. Thermoplastics such as ABS remain a workhorse for many aftermarket kits because they combine impact resistance, formability, and ease of coating with color and finish. The material choice is seldom a single sentence—it’s a family of trade-offs that shapes the price, longevity, and the riding experience.

The means of turning raw material into a finished fairing hinge on advanced manufacturing methods. Injection molding for thermoplastics enables complex, repeatable geometries with tight tolerances that mimic OEM lines or push into bold, rider-customizable shapes. This process is favored for its efficiency and consistency across large production runs, supporting a uniform aesthetic and reliable mounting interfaces. When fibers or more exotic geometries are involved, CNC machining plays a critical role. Precision milling or routing creates high-accuracy components—mounting brackets, sample air channels, or vent housings—that align precisely with the bike’s frame. The combination of molding and machining unlocks fairings that respect factory geometry while offering an assortment of styling options. It becomes possible to craft modular pieces—interchangeable panels, removable windshields, and attachable LED housings—that can be swapped as the rider’s taste or riding conditions change without buying an entirely new system. The end result is a kit that integrates with the existing electrical and mounting infrastructure, reducing the potential for misalignment and uneven gaps around fairing seams.

A central design aim in these kits is effective integrated wind protection. The wind blast that riders encounter at mid-century speeds can be tiring when absorbed by the chest and shoulders over hundreds of miles. Aerodynamically optimized contours and deflectors work in concert with the rider’s posture to deflect wind away from the torso and head. This is not about turning a cruiser into a race bike; it is about making long days on the road feel like shorter excursions. The wind management strategy often includes carefully shaped side profiles, chin and upper deflection angles, and carefully positioned cutouts to reduce buffeting around the helmet. Even modest refinements in curvature or edge radii can yield meaningful reductions in rider fatigue, enabling longer stops between breaks and better overall stamina for the journey ahead.

Beyond passive shaping, modern aftermarket kits embrace modularity as a core feature. The most compelling kits offer a spectrum of configurations with minimal tools and time. Removable windshields, integrated light housings, and junction points compatible with a variety of handlebars and mounting hardware create a sense of freedom. This modular ethos extends to the interior of the fairing, where channels and mounting points are designed to accommodate electronics. GPS devices, intercoms, and auxiliary lighting can be integrated without breaking the visual coherence of the bike. The concept of a modular fairing reflects a broader design principle: the fairing should be adaptable to different riding styles, climates, and even model updates. Riders can tailor the level of wind protection, the look, and the functionality to match a single ride or a season-long project. A practical illustration of this approach appears in the way some kits offer a combination of fixed panels and interchangeable inserts, enabling changes to both aerodynamics and aesthetics as needs evolve. For riders who value the ability to swap looks without sacrificing performance, this modularity is a reassuring design feature. To gauge how such modularity can translate into real-world choices, one can explore the Yamaha fairings collection, which demonstrates how modular kits accommodate a spectrum of models and rider preferences. Yamaha fairings collection.

The interaction between fairings and electronics is another frontier where innovation matters. Contemporary aftermarket systems are designed with built-in channels and mounting points to host GPS units, Bluetooth communicators, and lighting, while preserving the aesthetic integrity of the primary structure. The intention is to make electronics nearly invisible when not in use, yet instantly accessible when needed. This requires multi-functional interior cavities that can route wiring in a clean, weather-resistant manner and connectors that resist vibration and moisture. In practice, this means fairings that can be updated with new features without requiring a complete replacement, a forward-looking approach that aligns with how riders often upgrade their bikes in incremental steps. The potential for integrated lighting and reflectivity also enhances safety, particularly for touring riders navigating at dusk or in mixed weather. Yet with every integration, the design team balances ingress protection, heat dissipation, and ease of maintenance, ensuring that components remain serviceable over time.

Fitment accuracy is more than a matter of aligning panels; it is a performance decision. When 3D scanning feeds the design phase, engineers can reproduce OEM geometry with high fidelity while offering targeted improvements. The result is a fairing that not only looks right on the bike but also interacts predictably with the bike’s aerodynamics and rider posture. The mounting system receives special attention, with reinforced points and purpose-built hardware that can cope with torque and vibration without loosening. In addition, finishing and coating processes must keep pace with functional needs. The fairing’s surface must accept paint and clear coats evenly, resist UV degradation, and maintain color stability in varying climates. For riders who crave a consistent, showroom-level finish after years of exposure to sun, rain, and road grit, these considerations matter as much as the structural attributes. The ability to maintain an unblemished appearance while standing up to the knocks of road debris is a hallmark of thoughtful engineering in aftermarket cruiser fairings.

Within this broader design landscape, material science, manufacturing precision, and modular architecture converge to deliver products that feel native to the bike and responsive to the rider. The choices and compromises that designers navigate reflect a philosophy: the fairing should enhance a rider’s experience without turning maintenance into a burden. That means selecting materials that withstand impact without being prohibitively heavy, choosing manufacturing methods that guarantee repeatable fit, and crafting shapes that balance wind reduction with the bike’s own aesthetic signature. In practice, this translates into a spectrum of solutions. Some kits lean toward the light-and-tight approach enabled by carbon fiber and high-tolerance CNC components, while others emphasize durability and value with reinforced fiberglass composites and robust mounting hardware. Either way, the end user gains a system that aligns with a touring rider’s priorities—comfort, reliability, and the visual language of a machine that travels well over long distances. The overarching message is clear: advanced materials and refined manufacturing unlock a new level of cohesion between rider, wind, and machine, transforming aftermarket fairings from cosmetic upgrades into performance-conscious, long-haul partners.

For readers curious about real-world fitment and model-specific possibilities, glance at the breadth of options within the aftermarket ecosystem. While specific SKUs are not the focus here, the underlying principle remains: data-driven fit, modularity, and integrated design enable a suite of products that can be adapted to a wide range of cruiser models while preserving the character of each bike. As riders explore their next upgrade, they can expect to encounter a carefully curated balance of lightness, strength, and stylistic versatility. These are not merely panels snapped onto a frame; they are engineered interfaces that translate wind, posture, and visibility into a tangible riding experience. The result is a smoother, more controlled encounter with air and road, where fatigue yields to endurance and the journey itself becomes part of the ride rather than a challenge to be endured.

External resources and broader guidance provide additional context for enthusiasts and professionals alike. For a comprehensive overview of material selection and fitment standards in aftermarket fairings, a widely cited guide offers practical considerations and comparison points. This external reference helps readers connect the technologies described here with concrete criteria for choosing the right kit, understanding how to assess compatibility, and recognizing the trade-offs between performance, price, and ease of installation. In particular, the guide underscores how integration with modern electronics, airflow management, and modularity shape the long-term value of aftermarket fairings. To extend your reading, visit the external resource linked at the end of this chapter.

Internal linking note: for readers interested in model-specific fit and customizable configurations, exploring a brand’s Yamaha fairings collection can illustrate how modular designs map to different cruiser models and riding preferences. See the collection here: Yamaha fairings collection.

External resource: For further exploration of material selection and fitment standards, refer to the aftermarket fairing guide provided by industry specialists: https://www.motorcycle.com/aftermarket-fairing-guide/.

Riding the Future: Market Trends Shaping Aftermarket Cruiser Motorcycle Fairings

The aftermarket cruiser motorcycle fairing market stands at a moment of profound convergence. On one hand, riders seek personal expression, a canvas for color, lines, and silhouette that captures a machine’s character as vividly as its chrome and leather seats. On the other hand, the demand for comfort, control, and efficiency continues to push technical improvements in materials, manufacturing, and modularity. Together, these forces are not simply expanding a product category; they are redefining what a fairing can be and how it should perform over the long arcs of touring and weekend rides. As of 2025, the broader motorcycle fairing market carried a substantial footprint, valued at around 15.3 billion dollars, with expectations of steady expansion that point toward a compound annual growth rate of about 10 percent through 2033. Those figures are more than a statistic; they map a consumer environment that rewards both design finesse and practical engineering, where every new panel must justify its place on a rider’s bike by delivering demonstrable gains in aerodynamics, weight, installability, and, importantly, visual impact. In this chapter, we move through the currents shaping demand, from materials and manufacturing to customization culture and modular configurations, and we explore what makes an aftermarket fairing not merely a cosmetic upgrade but a coherent extension of a cruiser’s riding experience.

A core driver behind the market’s momentum is material and manufacturing innovation. Manufacturers increasingly favor lightweight yet resilient composites and injection-molded plastics that offer strength with a gentler price tag than traditional alternatives. The shift toward composites, while preserving durability, translates into lower unsprung weight and, in some cases, improved vibration damping. For riders, the perceived and real benefits are tangible: less fatigue on long stretches, quicker handling through easier mass distribution, and steadier control at highway speeds. Even when the primary aim is aesthetic, the underlying physics cannot be ignored. A well-constructed fairing trims wind pressure in a way that reduces buffeting and concentrates airflow in an efficient path around the rider’s torso and helmet. The result is a riding experience that feels smoother, quieter, and more stable, especially on mixed roads where wind dynamics shift with weather, terrain, and speed.

Alongside material advances, the design workflow behind aftermarket fairings has become increasingly data-driven. Where once the fitment of a piece relied on manual measurements and trial fittings, today 3D scanning technologies capture the geometry of original body panels with astonishing accuracy. This data-rich foundation enables aftermarket teams to craft panels that align with factory lines while still allowing for stylistic deviations. The effect is twofold: first, installation becomes more straightforward, with fewer alignment surprises during mounting; second, the longevity of the fit improves as designers anticipate warp, heat expansion, and real-world handling. In practice, this means riders are less likely to confront misaligned gaps or rattles after a weekend at the car wash or a cross-country freeway sprint. The practical payoff is a more confident, enjoyable ownership experience.

Beyond fit and form, manufacturers are actively refining functional features that address the realities of cruising journeys. Enhanced mounting points, refined airflow channels, and integrated routing for cooling ducts are moving from optional extras into more standardized considerations. The logic is straightforward: a fairing that channels air effectively around the lungs and core engine area helps with engine temperatures during long climbs or sustained high-speed runs, while secure attachment points reduce maintenance intervals and increase durability against vibrations and occasional drops. These considerations matter less in showroom aesthetics and more in day-to-day reliability, which is a decisive factor for riders who view a fairing as part of the motorcycle’s core ergonomics, not simply as an add-on.

The evolving perception of what a fairing should deliver is closely tied to the growth of custom builds and the personalized culture that surrounds cruiser riding. Enthusiasts increasingly view fairings as a legitimate vessel for self-expression and for tailoring a machine to specific riding goals. The market responds with options that accommodate a spectrum—from fully faired configurations that optimize wind protection on long tours to modular, removable systems that let a rider adapt to weather or urban traffic. The modular trend, in particular, has gained strong traction. Riders appreciate the ability to swap between full fairings, partial fairings, or even a bare bike arrangement depending on conditions, mood, or travel plans. This flexibility broadens a bike’s usability across different environments, sustaining long-haul comfort while preserving the option to enjoy a leaner, lighter stance when the weather is favorable or the roads demand a sportier posture.

Within this ecosystem of customization, the conversation often turns toward compatibility and fit—questions that can make or break a purchase decision. The shift to scalable, modular designs does not simply sell ease of upgrade; it invites riders to conceive a fairing not as a fixed entity but as a evolving part of their cruising narrative. For those interested in brand-spanning compatibility and established aftermarket ecosystems, the reach of design standards becomes a cornerstone of trust. What matters is that the fairing integrates cleanly with the bike’s chassis, contributes to a balanced aerodynamics package, and offers predictable, repeatable installation. It is in this context that the industry’s attention to data-driven fitment, reinforced mounting geometry, and tested airflow behavior proves its worth. A well-engineered setup can transform a standard cruiser into a tour-ready machine that feels composed at speed, even when laden with luggage and a passenger.

The regional landscape of demand also shapes how manufacturers, retailers, and repair shops approach fairing projects. In North America and Europe, there is a strong appetite for high-quality, aesthetically distinctive pieces that also deliver meaningful comfort enhancements for long journeys. In Asia-Pacific, a growing culture of customization, supported by a broad base of rider communities, drives demand for versatile configurations and cost-effective options that still meet performance expectations. In all regions, the shift toward modular systems intersects with the broader supply chain realities of aftermarket parts: manufacturers pursue scalable production methods that can adapt to diverse model footprints and evolving rider preferences, while retailers emphasize clear compatibility information, robust installation support, and warranties that reassure buyers about long-term durability. This aligns with the wider market narrative, where a fairing is not a single purchase but the beginning of a longer relationship between rider, bike, and brand.

One practical outcome of these trends is that buyers increasingly seek out options that explicitly balance aesthetics with utility. A visually striking panel matters, but its value is amplified when it complements wind management, reduces buffeting, and provides practical benefits such as telescoping or adjustable windshields, integrated pockets, or thoughtfully shaped storage recesses. The best offerings acknowledge that visibility and safety accompany comfort. A fairing that directs airflow toward the rider’s upper body in a controlled manner can lessen fatigue and improve concentration on the road. Equally important is the sense of durability that comes with credible mounting systems and robust seals against road spray. In practice, this means a rider benefits not just from a look that turns heads but from a design that stands up to repeated assembly and disassembly, the inevitable minor collisions, and the weather exposure that touring inevitably entails.

Shopping behavior mirrors these product realities. Consumers increasingly educate themselves about materials, fit, and performance and use this knowledge to guide decisions that are as much about ownership experience as about appearance. Sellers respond with more transparent information about weight, materials, thickness, and finish durability, along with installation guidance that helps riders avoid common pitfalls. The emphasis on compatibility also means that educational content—how to identify correct model-year matches, how to align mounting points, and how to assess the impact of a fairing on overall aerodynamics—becomes a core part of the purchasing journey. A well-supported buyer can confidently invest in a system that evolves with their bike, rather than a one-off cosmetic change that might be harder to maintain or upgrade later.

For readers interested in a concrete reference to a specific collection that illustrates the practical manifestation of these considerations, explore the Honda fairings collection, which exemplifies how an aftermarket ecosystem can be organized around clear fitment and quality expectations. The collection demonstrates how a streamlined catalog can help riders navigate compatibility while showcasing a range of styles that can suit both modern touring configurations and custom builds. See more at: Honda fairings collection.

In addition to the design and fitment logic, there is a strategic dimension to market trends that deserves attention. As the aftermarket fairing segment expands, competition disperses across a network of manufacturers, fabricators, and retailers who embrace a shared language of performance and aesthetics. This creates an ecosystem where iterative product development—driven by rider feedback, wind tunnel data, and real-world testing—accelerates the pace at which new features appear in the market. The result is a continuous cycle of refinement: panels becoming thinner without sacrificing impact resistance, mounting systems becoming easier to engage with, and color and texture finishes that endure climate exposure without fading. The cumulative effect is a market that rewards technical rigor and creative design equally, presenting riders with options that align with their budgets and ambitions, whether they are aiming to conquer multi-day routes or craft a distinctive city cruiser.

Of course, such a dynamic environment invites cautious consideration as well. The abundance of choice can overwhelm a first-time buyer, who often benefits from a guided approach that prioritizes core needs over flamboyance. For a long-distance cruiser, the emphasis typically lands on wind protection, noise reduction, seating comfort, and the ability to carry essentials without compromising handling. For urban riders, modularity, weight, and ease of installation may take precedence, along with the ability to switch to lighter configurations during the warmest months. This nuanced spectrum underscores a broader market truth: the most successful aftermarket fairings are those that offer a coherent value proposition across multiple riding contexts, rather than excelling in one scenario at the expense of another.

As the chapter closes on these market dynamics, the central takeaway is not merely a snapshot of growth figures or product features. It is an invitation to reimagine what it means to personalize a cruiser. Fairings are becoming instruments of control, comfort, and identity, designed to adapt to riders’ evolving needs while respecting the mechanical and thermal realities of the bike they adorn. The market’s momentum—from advanced materials to modular configurations, from data-driven fitment to custom-build culture—points toward a future where aftermarket fairings are judged not only by their appearance but by their holistic contribution to the riding experience. Riders will increasingly expect systems that are easy to install, reliable in long-haul life, and capable of growing with the bike as it migrates through seasons, miles, and memories. In that sense, the fairing market reflects a broader trend in motorcycling: customization without compromise, where form and function meet at the intersection of technology, craftsmanship, and a rider’s own story.

External resource for broader context: https://www.marketresearchfuture.com/reports/motorcycle-fairing-market-4829

Finding the Right Fit: Trusted Retailers and How They Shape Aftermarket Cruiser Fairings

The aftermarketscape for cruiser motorcycle fairings is more than a marketplace of shells and windshields; it is a careful negotiation between fit, function, and fatigue-free exploration of the open road. Riders who seek to extend their journeys beyond the showroom experience know that choosing a retailer is almost as important as choosing the fairing itself. A robust retailer network does more than stock multiple designs; it curates compatibility data, materials, and installation support that translate into longer rides, steadier lines of airflow, and a look that remains true to the bike’s lineage. In this sense, the right retailer becomes a partner in the journey, translating the hope of improved ergonomics and aesthetics into a concrete, rideable reality. The modern aftermarket ecosystem leverages advanced data collection—often through techniques like three-dimensional scanning of original panels—to ensure that every panel, every bulkhead, and every contour aligns with the bike’s exact geometry. When this data is well executed, the result is not a generic overlay but a tailored shell that integrates with the frame’s mounting points, gaps between panels, and the transitions where the fairing meets the handlebars, the seat, and the engine bay. Some manufacturers will go beyond the base data, refining installation points, enhancing airflow channels, and even weaving in engine cooling conduits to improve thermal behavior at highway speeds. The ride quality that emerges from such thoughtful engineering goes beyond mere wind protection. It reshapes riding posture, reduces fatigue on long stretches, and contributes to a sense of enclosure that makes cruising feel more deliberate and less taxing, especially in varied wind environments. It is important to be clear about expectations: aftermarket fairings are not primarily designed to shield a rider from impact; they are crafted to manage air, direct flow around sensitive components, and smooth the rider’s path through the air mass. For riders targeting long-haul comfort, a combination of a well-minded fairing, a supportive seat, and a windscreen with appropriate adjustability often yields the most satisfying balance between protection, visibility, and control. In practice, the fairing becomes part of a holistic approach to ergonomics: it positions the rider’s posture, influences where the air hits the torso and arms, and creates a quiet lane of air that reduces turbulence around the helmet. This integrated approach highlights why compatibility and professional guidance from reputable retailers matter so much. A well-matched kit reduces the risk of rattles, mismatched gaps, and misalignment over time, which can otherwise become sources of fatigue and distraction on longer trips. Riding a cruiser is as much about the sense of companionship with the road as it is about the machine’s visual language, and top-tier retailers understand this balance. They recognize that the appearance of a bike—its lines, its stance, its silhouette in the mirror—must harmonize with how it behaves at speed and how it feels to sit through hours of highway air. The best platforms provide robust filtering tools that help riders narrow choices by model year, frame type, and even engine layout. They also invest in detailed compatibility notes, installation guides, and visual aids that demystify the process for both first-time buyers and seasoned enthusiasts. In many cases, a well-documented set of installation steps is paired with video walkthroughs and threaded Q&A sections, where a rider can compare their bike’s geometry to a provided template and see where minor adjustments might be needed. This transparency is not just about convenience. It is about building confidence that the chosen fairing will align with the bike’s original design intent rather than forcing a compromise through fitment hacks. The practical implications of this are significant: when a fairing fits as intended, there is less hardware stress, safer wind shielding, and a reduction in vibration that could otherwise lead to faster wear of dovetail joints, mounting brackets, or edge seals. Materials selection also plays a decisive role in how a fairing performs on a cruiser. ABS plastics are common for their balance of cost and impact resistance, while fiberglass offers a stiffer, sometimes lighter alternative for more aggressive aerodynamic shaping. Carbon fiber or composite-reinforced panels tend to push the price point higher but can deliver a distinctive look with added rigidity. For the rider, that means choices driven by the desired blend of weight, durability, and surface quality—paint compatibility and clear-coat resilience being particularly important in the coastal or sun-drenched climates where UV exposure and road salt can challenge the finish. The best retailers acknowledge these material considerations and present clear guidance on how different options will behave in various riding conditions. They also provide practical details on fitment nuances—such as whether a kit is designed as a bolt-on replacement or if it requires the use of updated mounting hardware to accommodate new attachment points. This distinction matters, because some designs assume changes to the bike’s subframe or harness routing while others rely on existing mounts with slightly longer standoffs. Riders who are meticulous about installation appreciate suppliers that communicate these subtleties up front, because it reduces the risk of misalignment and the interminable loop of returns and exchanges that can sour an otherwise satisfying upgrade. When evaluating retailers, it is wise to weigh the breadth of their catalog against the depth of their technical support. A wide catalog is valuable, but only if it is paired with reliable advice on fitment, paint finishes, and post-purchase service. In practice, a trusted seller will combine a comprehensive selection with accessible customer care that can interpret model-year changes, regional variations, and even alternate fairing configurations that share a common family resemblance but differ in minor but critical ways. Returning to the rider’s experience, consider the practicalities that a good retailer emphasizes in its own ecosystem. Clear size and shape references, precise mounting bolt patterns, included hardware, and the provision of weather-sealed joints all contribute to a smoother installation and a more durable fit. The attention paid to edge contours and inter-panel gaps reduces the likelihood of paint cracking at high-stress points and minimizes air leaks that would otherwise undermine the desired wind management. For those who crave additional refinements, some kits offer adjustable windscreens, integrated vents, or hard-wearing seal gaskets that endure years of weather exposure. The ability to tailor the wind protection through adjustability, rather than adopting a one-size-fits-all approach, translates to a more personalized riding experience. It also expands the potential for autumn touring, coastal runs, or mountain passes where wind direction and density shift rapidly with terrain. In all these considerations, the retailer’s role is to translate the rider’s vision into a compatible, durable, and aesthetically coherent package. The best sources curate not only products but also community knowledge: user galleries, installation tips, and authentic ride reports that illuminate how a particular fairing behaves across miles of asphalt. A well-informed buyer can glean insight from these references—how a kit aligns with a bike’s natural lines, how installation time scales with the rider’s shop expertise, and how the finish holds up under salt spray or high heat. Finally, the decision to purchase from a specific retailer often hinges on a few practical pillars: clear return policies, transparent warranty language, and accessible customer support that can interpret your exact bike model and the kit’s fitment notes. While the allure of a glossy image or a bold colorway can be compelling, the real value comes from knowing that the kit will mount up with confidence and preserve the overall balance of the bike’s geometry. For riders who value a system-level upgrade, the retailer becomes a partner in the craft of shaping a machine that feels as if it were built with the new appearance in mind from the factory, even as it reflects a personal, expressive twist. As you explore the options, consider bookmarking a catalog that emphasizes the capability to filter by bike model and year and to view installation resources that align with your level of mechanical comfort. A helpful way to engage is to explore the cruiser fairings catalog, which offers a focused view into the kinds of shapes and profiles that tend to complement the cruiser silhouette while preserving the bike’s timeless stance. This careful approach to selection—combining data-backed compatibility, material awareness, practical installation guidance, and robust after-sales support—ensures that the fairing upgrade truly serves the rider’s comfort, control, and personal style. For readers who want to extend their search beyond a single platform, an external resource that aggregates reliability and accessory options can provide additional context about how fairings fit into the broader ecosystem of performance parts. External resource: https://www.performanceparts.com/motorcycle-fairings-accessories. In the end, the right retailer becomes more than a point of sale; it becomes a collaborator in shaping a motorcycle that embodies both the journey and the destination. For riders who crave long-range comfort and a refined aesthetic, choosing a trusted, technically capable retailer is the first decisive step toward a better ride.

Final thoughts

In the ever-evolving landscape of cruiser motorcycles, aftermarket fairings play an instrumental role in enhancing both performance and rider comfort. By understanding the intricacies of these products, their technological underpinnings, and the current market trends, business owners can tap into new revenue streams while adding value to the customer experience. Staying informed and connected with reputable retailers ensures that businesses can offer their customers exactly what they need to elevate their rides. The future of motorcycle cruising can be bright and comfortable, all thanks to these innovative aftermarket solutions.