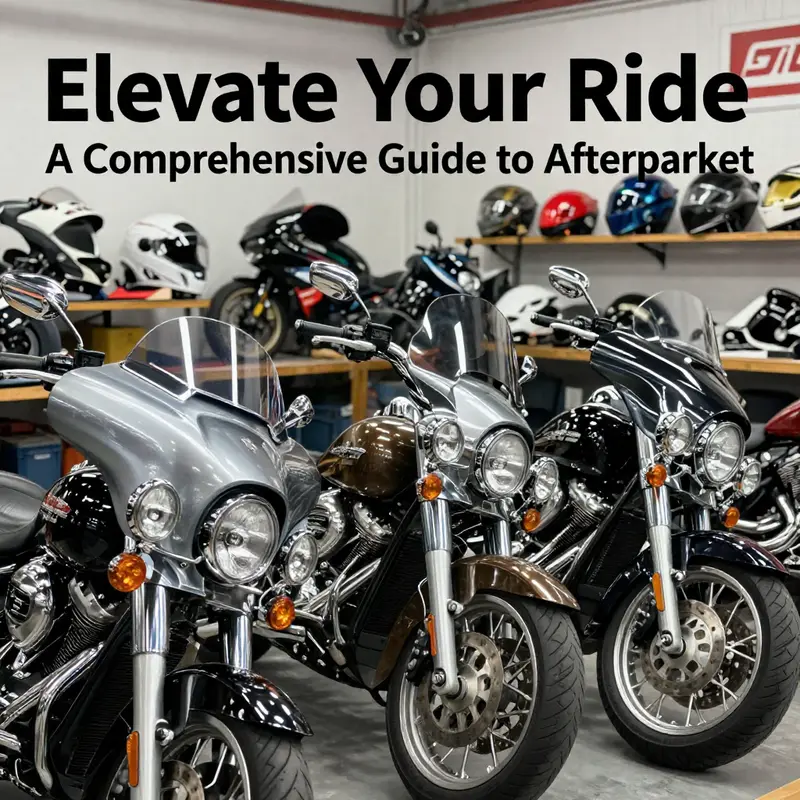

Aftermarket cruiser motorcycle fairings play a pivotal role in both aesthetics and functionality, tailored to meet the unique needs of cruiser riders. As motorcycle enthusiasts embrace customization, understanding the types, materials, compatibility, and available brands of fairings becomes essential for business owners in this thriving market. This article delves into these crucial aspects, empowering business owners to make informed decisions in their offerings and enhancing the cruising experience for customers. Each chapter will uncover valuable information about fairing types and functions, durable materials, installation compatibility, and reputable brands, providing a comprehensive toolkit for those involved in the motorcycle aftermarket industry.

Riding with a Purpose: The Types and Functions of Aftermarket Cruiser Windshields and Fairings

The aftermarket world for cruiser windshields and fairings is more than a cosmetic upgrade. It is a practical space where comfort, weather protection, and style converge in a single component. In cruising, the windscreen shapes the ride as a partner on open roads and city streets. When you look beyond the finish, the choices come down to core dimensions: how the piece integrates with the bike silhouette, how it redirects wind and noise, and how it resists the elements over time. This is a narrative of those choices, guided by practical insights drawn from current practice and safety considerations, while honoring the classic lines of cruiser motorcycles. The landscape of aftermarket fairings is about balancing rider comfort with the machine’s iconic stance, and keeping installation feasible for a wide range of models and riders.

The most recognizable categories in the cruiser segment are the half fairing and the short front fairing. Unlike full cockpit shields found on sport touring machines, these designs stay within a restrained footprint. They cover the front where air meets the rider but do not enclose the entire front end. The half fairing covers the head area and a portion of the tank line, providing a shield against direct wind while preserving the bike’s muscular profile. The short front fairing follows a similar philosophy but with a lower vertical silhouette that tucks into the cockpit without overpowering the handlebars or instrument cluster. Both configurations can reduce facial fatigue and upper body strain at cruising speeds, improving rider endurance on long rides and in urban commutes.

The market’s design language has moved toward versatility and adaptability. Adjustable windshields have become common and for good reason. A flexible screen can be tuned to rider height, posture, and preferred wind line. A rider at 5 foot 8 or 5 foot 11 will experience a different flow of air across the torso and head; the ability to adjust height, angle, tilt, and sometimes curvature, makes a tangible difference in comfort and control. The practical utility of adjustable windshields is magnified on longer journeys, where weather, riding posture, or load shifts the wind’s impact on the rider. A well chosen adjustable unit can hit a sweet spot where the air pressure on the chest is balanced with forward vision while delivering effective deflection of gusts. Such considerations explain why adjustable designs are common for riders who value customization without sacrificing practicality.

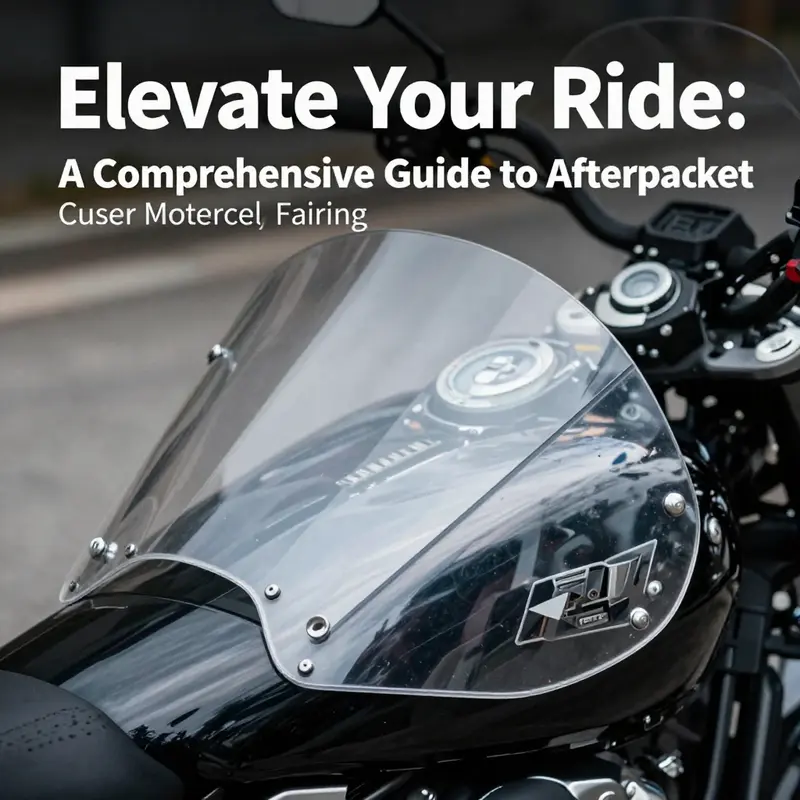

Beyond adjustability, the shape and material of the windscreen contribute to the riding experience. A larger shield can offer more complete front end protection. A large transparent shield often made from polycarbonate extends upward and outward to block wind over a broader range of speeds. The payoff is reduced air pressure on the upper body at highway velocity, less helmet wind noise, and a more stable helmet line. The trade-off is weight and the bike’s aesthetics when the shield dominates the silhouette. On many cruisers riders may accept a taller profile if it preserves the machine’s look while delivering comfort on long stretches.

A more sophisticated design path includes flow management features. Some aftermarket options add venting or deflection strategies such as shaped side fins or top edge grooves that disrupt turbulent air around the rider. These features can cut wind noise by reducing eddies and smoothing the air path at cruising angles. In wet conditions the same logic helps water flow away from helmets and glasses, preserving visibility and reducing damp mist on the face shield. With a shield that guides wind rather than pushes against it the experience shifts toward ease and speed without sacrificing the sense of freedom that cruising embodies.

In parallel with design, materials play a key role in durability and clarity. The most common substrates are polymers such as polypropylene or ABS for affordability and ease of shaping. They suit value oriented riders but may show vulnerability to UV exposure and hazing if not treated. For longevity and high impact resistance polycarbonate is a standout choice. It offers robust protection against stone impacts and clear visibility, albeit at a higher upfront cost. A growing middle ground is composite constructions based on PC mixed with ABS to balance rigidity and cost. In all cases riders should seek UV protective coatings and scratch resistant finishes. The visual clarity of the shield is as vital as its physical integrity because glare or distortion erodes safety and confidence on the road.

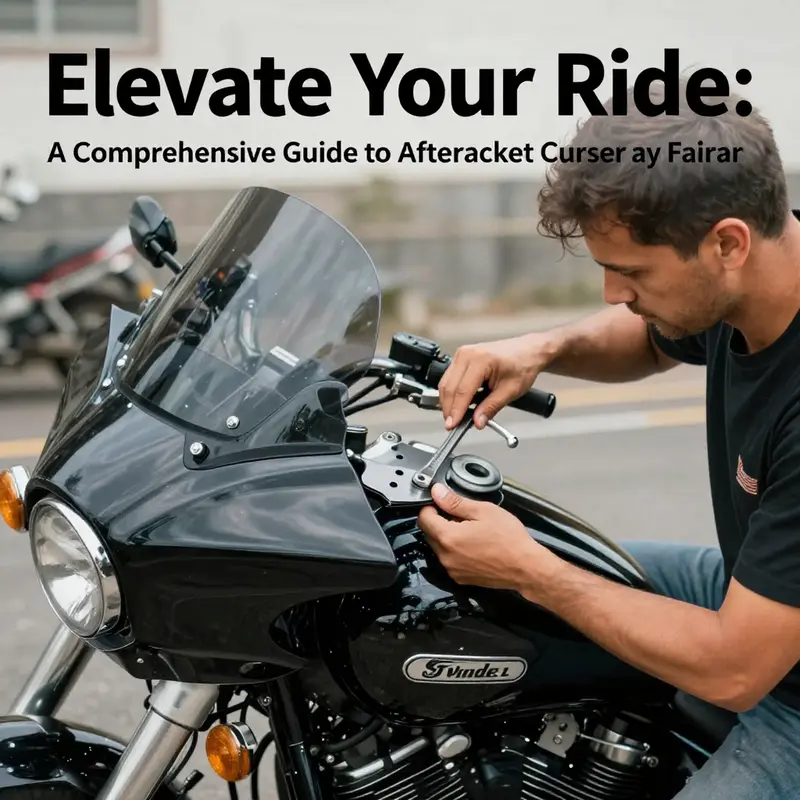

Compatibility and installation are the practical bedrock of any aftermarket windscreen or fairing. The cruiser ecosystem is diverse, with many models featuring different mounting points, bolt patterns, and instrument layouts. The path to a successful upgrade begins with a model-specific compatibility map from the vendor showing model years, brackets, and whether extra hardware is required. The risks of a poor fit are not merely cosmetic. A mismatch in mounting holes or shield geometry can misalign the wind line, alter the front end profile, or compromise protection by shifting center of pressure. Some lower-cost options may differ slightly or require modifications. While such adjustments can be feasible, they demand careful measurement, the right tools, and a patient approach. The rider’s safety hinges on a secure, stable installation, not just a visually appealing component.

To navigate compatibility with confidence, a disciplined checklist can be indispensable. Start with a model-specific compatibility list from the manufacturer or distributor. Confirm whether the windscreen requires extra brackets or specific fasteners, and verify that it does not interfere with the instrument cluster, fuel tank cap, or bar controls. Consider your usual riding posture; are you a rider who leans slightly forward, or upright with a tall windscreen? The geometry of the fairing must harmonize with your stance so that it guides air without obstructing your field of vision or control inputs. This is where installation meets aerodynamics: a well-mounted shield protects and preserves front wheel handling under wind loading.

From a safety and standardization perspective the aftermarket sector emphasizes durability, impact resistance, and optical clarity under stress. Certification programs and testing protocols give reassurance that a shield can withstand highway riding and occasional mishaps without fogging or fragmenting. In practice this translates to a preference for products bearing explicit safety certifications even when the look is strong. The investment in a certified windscreen is an investment in long-term visibility and a safer riding experience over years of use.

The conversation about cruiser windshields and fairings would be incomplete without noting the trend toward functional styling. Riders increasingly seek pieces that accentuate the bike’s lines while delivering measurable gains in quiet, weather protection, and comfort. The best options acknowledge the triad of bike lines, rider posture, and road conditions, presenting a solution that respects the machine’s character, augments riding ease, and remains feasible for a broad range of owners.

For readers seeking practical paths toward options, a catalog organized by model compatibility and wind management helps identify a good fit. While lists do not replace precise measurements, they provide a map of fitment and function. As a guideline, seek adjustable, mid- to high-visibility shields with UV-protected finishes, a robust scratch-resisting surface, and a mounting system that minimizes frame alterations. Reading installation guides and user reviews helps translate how a shield performs in rain, cold glare at sunset, and highway speeds.

From the standpoint of brand breadth and product quality the market hosts makers that emphasize different priorities. Some focus vintage aesthetics, others highlight high-strength materials and lightweight construction, and a few blend both into versatile multi-model solutions. The fairing is not a single piece but part of an integrated system with brackets, hardware, and sometimes flow features. The best outcomes come when riders align choices with riding goals whether quiet long-distance comfort, strong visual presence, or a subtle nod to a timeless cruiser silhouette.

To broaden practical context internal references can support informed decisions: a catalog of cruiser windshields and fairings organized by model compatibility serves as a reliable first stop and a curated fitment guide can demystify the process. A safety notes section highlighting certification marks, coatings, and service life helps buyers translate aesthetics into durable performance. The rider who approaches this upgrade with balance sees the windscreen as a well-sorted interface between rider, machine, and terrain.

If you are seeking concrete pathways consider Summit Fairings or other catalogs that offer a range of cruiser configurations. This resource helps compare features, materials, and mounting requirements in a structured way. Core criteria include compatibility, material strength, UV resistance, adjustable fit, and safety certification. Thoughtful comparison across these axes reveals the shield that best complements your bike lines and comfort thresholds.

In closing the aftermarket cruiser windshields and half fairings are best understood as a blend of design intent, material science, and practical fitment. The types—from adjustable half fairings to larger shield profiles and flow enhanced designs—carry a set of benefits and compromises. The right choice depends on how you ride, where you ride, and how much you value quiet, protected airflow at highway speeds versus the bike’s unadorned, muscular stance when parked. The materials chosen underpin long-term value dictating how the shield ages, resists UV damage, and withstands road debris. The installation pathway establishes compatibility checks, bracket choices, and fine tuning of tilt and height, ensuring the shield feels right and behaves predictably when the road demands precision. In this sense aftermarket cruiser windshields and half fairings are best understood not as single accessories but as integrated parts of a riding identity, a balance of comfort, safety, and classic silhouette on the road.

External reference for technical context: https://www.motorcycle.com/motorcycle-accessories/choosing-the-right-motorcycle-windshield/.

Choosing Durable Materials for Aftermarket Cruiser Fairings: Balancing Strength, Weight, and Longevity

When choosing an aftermarket fairing for a cruiser motorcycle, the material defines almost everything. It sets the tone for ride comfort, visual appeal, and long-term durability. For cruiser riders who prize relaxed ergonomics and classic style, the material choice must support that ethos. Fairings should protect from wind and debris while preserving the bike’s silhouette. They must also withstand sun, vibration, and road grit without becoming brittle, warped, or discolored.

A clear way to approach this decision is to think in three practical dimensions: impact resistance, environmental resistance, and weight versus stiffness. Impact resistance matters for safety and long-term integrity. Environmental resistance covers UV, chemical exposure, and temperature. Weight and stiffness affect handling and mounting reliability. Within those dimensions, four materials dominate the aftermarket market: polycarbonate (PC), fiberglass (often called glass-reinforced plastic or FRP), acrylic (PMMA), and common thermoplastics such as PVC and PET. Each brings a different balance of properties, costs, and trade-offs.

Polycarbonate is the most well-rounded option for most cruiser fairing buyers. It offers exceptional impact resistance, which reduces the risk of catastrophic failure if debris hits the screen at speed. The material absorbs shocks rather than shattering, keeping fragments from becoming projectiles. Polycarbonate is also relatively light, which helps keep the front end responsive. Many high-quality polycarbonate fairings include factory-applied UV inhibitors and scratch-resistant coatings. Those surface treatments extend clarity and reduce yellowing over years of sun exposure. For riders who want reliable protection with minimal compromise to handling, polycarbonate is a pragmatic choice. It also accepts bending and shaping well during manufacturing, which allows designers to maintain classic cruiser lines without adding unnecessary bulk.

Fiberglass offers a different, often subtler value. It is prized where structural strength and longevity under sustained stress are paramount. A fiberglass fairing can endure the sustained buffeting of long highway miles without permanent distortion. The material’s stiffness provides a reassuring, substantial feel and can carry complex shapes with crisp edges. For riders planning heavy use, loaded touring, or frequent long-distance trips, fiberglass can be the most durable structural choice. The trade-off is weight. Heavier components can alter steering feel and require stronger mounts. Properly finished fiberglass resists UV and chemical attack well, but repairs often require more workshop skill than thermoplastic fixes. Fiberglass remains a top pick for riders who value solidity and a classic handcrafted look.

Acrylic, or PMMA, shines where optical clarity is the primary goal. Its transparency rivals glass, offering a pristine view with minimal distortion. That makes acrylic attractive when aesthetic clarity matters most. However, acrylic is less impact-resistant than polycarbonate. It can crack or chip under a sudden high-energy impact. It also scratches more readily, so surface abrasion from cleaning or road grit can compromise the look over time. For riders focused on show-quality appearance and moderate-speed cruising rather than heavy touring, acrylic can be the preferred option. When chosen, acrylic fairings benefit from careful handling, soft cleaning materials, and protective storage to maintain clarity.

Basic thermoplastics like PVC and PET are common in entry-level fairings and budget replacements. They are inexpensive and light, which suits short commutes and casual city riding. But they age faster. Prolonged UV exposure leads to embrittlement and color shifts. Scratches and small cracks appear sooner than with premium materials. These plastics often lack specialized coatings, so their lifecycle is shorter. For riders on a tight budget or for temporary use, these plastics have a place. For long-term installations on a cherished cruiser, they usually fall short of expectations.

Modern manufacturers also use blends and composites to tune properties. A common approach is to alloy polycarbonate with ABS, creating a material that balances toughness and cost. These blends aim to retain impact performance while improving surface hardness and molding consistency. Such composite approaches can deliver the best of multiple worlds, but they demand careful specification. Not all blended sheets are created equal; the ratio, processing method, and coatings matter. Look for clear claims about UV stabilization and anti-scratch treatment on product documentation.

Beyond raw material choice, surface treatment and manufacturing quality are decisive for longevity. Fairings that carry a UV-resistant top coat will remain clearer and retain color longer. Anti-scratch hardcoats protect against the daily micro-abrasion of wind-borne particulates. In polycarbonate parts, these coatings prevent the surface from crazing and losing transparency. In acrylic, they reduce the visibility of fine scratches. For fiberglass, a high-quality gelcoat or paint system seals the fibers, blocks moisture ingress, and preserves the finish. Poorly finished parts—regardless of base material—will degrade faster than higher-quality counterparts.

Weight matters more than many riders expect. Cruiser geometry emphasizes stability, but added mass on the front end changes steering inertia and may increase fatigue during low-speed maneuvers. Lighter polycarbonate or composite fairings maintain more of the bike’s original feel. Heavier fiberglass units provide solidity but may mandate upgraded mounting hardware. Consider the entire system: fairing, brackets, and fasteners. If the material is heavier, make sure the mounting system is robust and designed to distribute load. Vibration over time can cause stress cracks at bolt holes, especially if the fairing flexes differently than the frame. Precision in hole placement and the use of rubber or composite bushings lengthen service life and reduce stress concentration.

Safety certification is a critical, yet sometimes overlooked, dimension of material selection. Certified materials and products undergo impact and clarity tests to verify their protective performance. Certification standards from recognized authorities demonstrate that a product will not shatter into dangerous shards and will remain clear enough for safe riding. When a fairing carries such certification, it often indicates better material quality and stricter production controls. Prioritize certified items when safety and durability are important to you.

Maintenance practices dramatically influence how long a fairing will look and perform like new. Cleaning with soft, non-abrasive cloths and mild cleaners helps preserve coatings. Avoid household glass cleaners with ammonia on polycarbonate and acrylic surfaces. Polishing compounds can remove fine scratches, but overuse thins protective coatings and eventually reduces clarity. For fiberglass, routine inspection of paint and gelcoat for hairline cracks prevents moisture intrusion. Small repairs applied quickly keep minor damage from becoming structural problems. Routine checks of mount hardware prevent the vibration-related failures that often cause the most expensive repairs.

Selecting a material means accepting trade-offs. If safety and longevity under impact are your priorities, choose polycarbonate with a robust hardcoat. If a substantial, lasting shape with a handcrafted look is more important, fiberglass is the natural path. If optical clarity and show-quality presentation are the top concern, acrylic fits best. If cost dictates, thermoplastics deliver short-term value. For many cruiser riders, a composite or polycarbonate option with UV and scratch protection hits the sweet spot: solid protection, reasonable weight, and lasting appearance.

Finally, compatibility with your bike matters as much as the material itself. The correct fit reduces stress and prevents wind-induced flutter, which can accelerate wear. Ensure the fairing’s mounting approach matches your machine’s geometry and mounting points. Look for products that specify fitment for your model or offer adjustable brackets. Some fairings also provide height or angle adjustability, which helps tune wind protection without adding unnecessary drag or stress.

Choosing a durable aftermarket fairing for a cruiser involves more than a single criterion. Material performance, coatings, manufacturing quality, weight, and mounting design all shape the outcome. Prioritize impact resistance, UV protection, and a finish appropriate for your riding style. Inspect product documentation for evidence of hardcoats and stabilization treatments. Consider the long-term maintenance you are willing to do. When these factors align, the fairing will enhance comfort and style while remaining durable for years of cruising.

For examples of how manufacturers present materials and fitment options across different motorcycle families, see the general collection of aftermarket fairings for a major brand as a reference: Yamaha fairings. For an independent perspective on material performance and durability testing, consult a technical resource with broad motorcycle coverage: https://www.motorcycle.com/

精准匹配与稳固守望:后市场巡航风挡的兼容性与安装之路

在巡航摩托车的改装世界里,后市场风挡不仅是外观件,更是直接影响骑行体验的核心部件。它的兼容性决定了风挡是否真正提升舒适性,是否会让车身轮廓失去本真的气质。与为运动型或旅行车设计的全挡风不同,巡航风挡多走简约路线,强调开放感与经典美学的平衡。这就要求设计师与改装者把握三个要点:车型设计、尺寸规格和安装方式。只有这三条线索在同一个系统中协同,后市场风挡才能既承载实用性,又不破坏整车的风格韵味。

对骑手而言,兼容性不仅是技术词汇,更关系到骑姿、风阻管理與视线稳定。一个合适的风挡,可以在高速巡航时降低面部疲劳,保持低速时的操控灵活性。相反,若风挡尺寸与姿势不匹配,风流会在胸腹区域产生更强冲击,仪表盘的可读性也可能被遮挡。这些差异背后,往往隐藏着细致的工程细节。

第一道门槛来自车型设计的多样性。巡航摩托车在前脸、车架与仪表布局方面差异显著。圆润复古前脸通常配合体积较小、弧度柔和的风挡;而线条更硬朗的前脸可能需要更大且更方正的风挡以实现空气动力学平衡。这种设计差异决定了风挡并非对所有车型通用。

为了达到理想贴合,风挡的曲线、高度与角度必须与具体车型的前叉、把手位置和仪表盘高度相匹配,才能形成稳定的空气动力屏障,避免高速共振或偏移。

第二道门槛来自尺寸规格。风挡的高度、宽度、角度及其与车体间的间隙决定了对迎面风的覆盖与视线的保留。不同身高段的骑手需要不同的视线保护和胸部区域的风阻覆盖。即便同一车型的不同年款,其前脸结构、仪表盘位置也会影响此前有效风挡的适配性。因此,选购时要对比前叉高度、把手宽度、仪表盘位置和油箱轮廓等参数,确保风挡在覆盖范围与视线之间达到平衡。尺寸偏差通常可通过可调风挡解决,但并非所有车型都能接受大幅度角度调整,因此应优先选择标注了明确适配车型与安装孔位的产品。

第三道门槛来自安装方式。后市场风挡的安装分为无损安装和有损安装。无损安装通过专用支架固定,不破坏漆面,调角度灵活但受支架结构与原厂接口限制;有损安装则需要在前脸或车架上开孔,使用螺栓固定,稳定性更高,角度和高度调节也更精准,但对原车结构有永久性影响。高端风挡通常提供专用安装件以减少不确定性。由于各品牌接口标准不一,即使标称同一类风挡,在不同年份或地区的产品也可能存在孔位错位、支架长度差异等问题。因此,购买前要核对适配清单,确认是否需要额外支架、螺栓或衔接件。

将这三要素串联起来,兼容性不再是模糊概念,而是一个可操作的决策框架。为了帮助在实际挑选时降低盲目性,可以把思考路径简化为三个问题:这款风挡是否标注了可适配的车型?它的尺寸参数是否与我的车身与骑行姿势匹配?安装配件是否已经包含在套件中,还是需要额外购买。

在对比不同风挡的功能性时,关注点应从能否装上扩展到装上后带来的风阻覆盖、视线保护和噪音水平。合适的风挡在高速巡航时会让胸部区域的风压更均匀,减少颈部疲劳,同时保持对头部的稳定支撑。

安装前的准备同样重要。清点工具与材料,确保螺栓、垫片、密封圈等配件齐全;仔细清理安装区域,避免油渍和灰尘干扰密封与涂层;按说明书顺序对齐孔位,采用对称的预紧力进行初步固定,防止单点受力导致变形。最后在静态、水平、安全的环境中微调风挡角度,使视线线条与骑手姿势保持一致,确保全幅面有均衡的风阻覆盖。

安全与美学同样重要。若风挡过大或角度过陡,虽在某些气候下或风况中能提高风阻,但可能影响前部视线与灯具可见性;若过小或角度过低,风阻提升效果会打折。最佳状态往往是在高度、角度与车架几何之间找到中间值,因此不要过度追求通用性。

信息来源与比照方法也很关键。可参考官方适配清单、经销商安装指南与用户社区反馈,建立稳固的决策库。若需要进一步挖掘车型与风挡之间的直接关系,可以参考厂商与经销商提供的适配页面,理解前脸设计如何改变风挡需求。

安全认证也应纳入考量。选择具备官方认证或符合国际标准的风挡,能在碰撞测试、雨天与高速行驶中提供更稳定的表现。

总结来说,后市场巡航风挡的兼容性是一门需要同时考虑车型设计、尺寸与安装的综合艺术。选购时把三大要素放在同一框架下评估,才能在保留经典外观的同时提升骑行舒适性与安全性。

在实际执行时,建议在购买前联系专业经销商,带上车型信息与典型骑行姿势数据,以获得更精确的适配建议。

最后,保持风挡的维护同样重要。关注材料耐久性、UV防护、抗刮涂层等因素,定期检查螺栓紧固力,以维持稳定性与安全性。

通过与专业渠道的交流与对比,建立属于自己的适配语言:选择可调性强、接口明确、材料耐用且经过认证的风挡,确保在不同路况与气候条件下都能保持稳定的风阻与清晰视野。

外部参考与扩展阅读:如需了解尺寸与安装细节的更多方法,可参考外部资源与教程,例如如何选择合适的风挡尺寸等资源。

null

null

Final thoughts

In summary, aftermarket cruiser motorcycle fairings are vital for enhancing not only the aesthetic appeal but also the rider’s experience on the road. Business owners should prioritize understanding the types of fairings available, the durable materials that contribute to their longevity, the importance of compatibility and installation, and the established brands that set quality benchmarks in the market. By equipping themselves with this knowledge, business owners can better serve their customers and elevate their offerings, ultimately leading to a more satisfying riding experience. The right fairing can make all the difference in comfort and style, fostering a deeper connection between riders and their motorcycles.