Introduction

Motorcycle fairings represent a high-stakes category for distributors, retailers, and service providers: they must balance cost, fitment reliability, and fast-moving demand across popular sportbike models. Auctmart positions itself as a global source of ABS plastic fairings that mirror OEM designs, with a broad product range and direct-from-factory pricing that can deliver meaningful margin improvements for dealers and workshops. This article deconstructs Auctmart’s business-relevant attributes across five chapters: market position and product range to inform stocking and assortment strategy; material quality and design features to assess durability, installability, and warranty considerations; consumer fitment, support, and after-sales experience to anticipate service implications; pricing, value proposition, and competitive landscape to model profitability and channel strategy; and procurement risks, alternatives, and purchase considerations to build a resilient sourcing plan. Each chapter ties directly back to how business owners can evaluate Auctmart as a supply partner, optimize inventory decisions, and manage customer expectations. We also reference model coverage (Yamaha R1/R6, Suzuki GSX-R, Honda CBR, Kawasaki ZX, Ducati Panigale) to ground the analysis in real-world applicability. The result is a holistic, decision-ready view of Auctmart as a motorcycle fairings supplier for growth-focused businesses.

Tables of Contents

Chapter 1: Chapter 1: Auctmart Motorcycle Fairings — Market Position and Product Range

- Chapter 1: Auctmart Motorcycle Fairings — Market Position and Product Range — Technological Dimensions and Innovation Trajectories

- From Price-Pressure to DIY Value: The Economic Pulse of Auctmart Motorcycle Fairings

- Geopolitics, Supply Lines, and the Societal Footprint

Chapter 2: Chapter 2: Auctmart Motorcycle Fairings — Material Quality and Design Features

- Material Quality, Aerodynamic Craft, and Future-Ready Design: Innovations Driving Performance in Aftermarket Fairings

- Material Choices, Craft, and Cost: How ABS Shapes Performance and Ownership

- Material Quality and Design Features in Auctmart Fairings — Navigating Global Supply Chains and Societal Pressures

Chapter 3: Chapter 3: Auctmart Motorcycle Fairings — Market Position and Advanced Tech in Fitment and After-Sales

- Chapter 3: Auctmart Motorcycle Fairings — Consumer Fitment, Support, and After-sales Experience — Technological Dimensions of Fitment and Post-Purchase Support

- Economic Calculus of After-Sales Fidelity: Pricing, Warranty Dynamics, and the Hidden Value of Support for Auctmart Fairings

- Geopolitics, Tariffs, and Trust: How Regulation and Trade Flows Shape the Aftermarket Fairing Ecosystem

Chapter 4: Chapter 4: Aftermarket Motorcycle Fairings — Pricing, Value, and Competitive Landscape

- Pricing Precision, Design Engineering, and the Technological Pulse of Affordable Fairings

- Auctmart Motorcycle Fairings: Economic Viability, Value-Based Pricing, and Market Positioning in a Competitive Landscape

- Geopolitical Currents and Social Shifts Shaping Auctmart’s Global Fairings Supply Chain and Market Competition

Chapter 5: Chapter 5: Auctmart Motorcycle Fairings and the Economics of Aftermarket Bodywork

- Chapter 5: Auctmart Motorcycle Fairings — Procurement Risks, Alternatives, and Purchase Considerations: Technological Dimensions and Supply Chain Vulnerabilities

- Auctmart Motorcycle Fairings: Procurement Risks, Alternatives, and Purchase Considerations — Economic Implications, Cost-Benefit Analysis, and Pricing Dynamics

- Geopolitics, Ethics, and Compliance in Global Fairing Sourcing: Navigating Risks, Alternatives, and Practical Purchase Realities

Chapter 1: Chapter 1: Auctmart Motorcycle Fairings — Market Position and Product Range

1. Chapter 1: Auctmart Motorcycle Fairings — Market Position and Product Range — Technological Dimensions and Innovation Trajectories

Auctmart’s market position and product range are inseparable from a deliberate embrace of technological dimensions that shape design, production, and perceived value. The company leverages scale and a tightly managed supply chain to translate advanced materials and precision manufacturing into affordable fairings that still honor fit and finish. In a market where durability and compatibility drive reputation, a robust quality framework—ISO 9001 certified processes, standardized pre-drilled panels, and model-spanning compatibility—anchors trust among riders who want quick upgrades without the premium price tag. These capabilities, combined with a direct-to-consumer approach, enable a tectonic shift in how riders access replacement panels, while still aligning with the broader unit economics of the aftermarket ecosystem.

Material science sits at the core of this trajectory. ABS remains the backbone for most kits, prized for its impact resistance and moldability, while optional reinforcement with engineered fibers can bolster crash resilience. Transparent screens often employ PETG, balancing clarity with toughness. The manufacturing discipline is equally critical: CNC molding delivers tolerances around 0.5 millimeters, ensuring that panels align with mounting points and interior contours. UV-resistant coatings survive exposed conditions, extending color and gloss retention beyond the initial installation. Such attributes—not just aesthetics—translate into longer service windows for riders who navigate varied climates and track days alike.

Beyond raw materials and molding, the integration of features that improve usability marks another growth vector. Pre-drilled hardware and bolt kits reduce installation friction, while designs accommodate lightweight, LED-enabled headlight configurations and heat-resistant finishes near exhaust areas. A modular philosophy—allowing selective panel swaps rather than full-kit replacements—lowers repair costs and speeds up maintenance, an appealing proposition for racers and casual riders alike. This modularity is reinforced by a push toward sustainability, with recycled thermoplastics contributing a meaningful share to some finishes and color systems, a nod to compliance with evolving environmental guidelines in key markets.

Innovation trajectories point toward an increasingly data-driven and connected future. R&D investments, reported as a meaningful share of revenue, fund efforts to refine fitment and expand compatibility to hundreds of models through digital reverse-engineering and 3D scanning. Wind-tunnel and CFD studies have yielded measurable drag reductions, while ongoing collaborations explore IoT-enabled fairings that collect real-time aerodynamic data via Bluetooth. The ambition extends to electrified platforms, envisioning fairings tailored for electric bikes with integrated sensor suites and IMU data streams. Operationally, RFID-enabled supply chains and rigorous testing regimes help maintain high on-time delivery rates, supporting a dependable consumer experience even as product lines grow in scope.

For readers seeking a concise map of how fairing technology translates into consumer value, a broader overview of motorcycle fairings provides useful context: Motorcycle Fairings Overview. This technological lens helps explain why price, fit, and finish matter so deeply in the market’s competitive dynamics—and why the next chapter turns to the economic implications, market dynamics, and the evolving value proposition for riders.

2. From Price-Pressure to DIY Value: The Economic Pulse of Auctmart Motorcycle Fairings

Auctmart’s market stance emerges from a deliberate blend of cost efficiency, product breadth, and user-friendly design that resonates with a wide spectrum of riders. By leveraging direct-from-factory sourcing in Asia and a highly scalable ABS plastic supply chain, the company can price full fairing kits far below typical OEM equivalents—roughly one-third to one-half the cost in many cases—while maintaining consistent quality signals through ISO-aligned standards. This pricing dynamic isn’t incidental; it reflects a broader economic logic in the global aftermarket. When a kit typically retails in the hundreds of dollars rather than the low four figures demanded by factory brand parts, price-sensitive markets expand, and a broader cohort of enthusiasts can upgrade aesthetics, protection, and aerodynamics without sacrificing budget for performance or parts compatibility. The market as a whole, valued in the low billions, advances on the back of rising superbike penetration in key regions and a steady-year, year-out demand for replacement panels after rides, crashes, or the desire for fresh style on familiar frames.

Auctmart’s product range reinforces this value proposition. With hundreds of SKUs spanning dozens of popular sportbikes, the lineup leans heavily on injection-molded ABS for durability and a 2-year warranty that signals confidence in long-run performance. The feature set—pre-drilled bolt holes, UV-resistant finishes, and options such as matte or gloss textures and LED-integrated accessories—translates into tangible consumer value: easier installation, fewer surprises at the mounting points, and a visual finish that stays true longer under sun exposure. This combination—cost leadership plus substantial finish options and installability—shifts consumer expectations, making aftermarket fairings a practical first choice even for riders who might once have considered OEM or carbon-fiber alternatives. The average order value sits in a comfortable mid-range, supporting repeat purchases for color schemes, tank covers, windshields, and related accessories, while a broad model coverage map (200+ models across recent to older generations) reduces the need for model-specific hunting and increases the likelihood of a single source meeting a rider’s needs.

The logistics and service framework further deepen this value. Global shipping in days rather than weeks, a fit-rate that reviews commonly peg around the 95% mark, and a warranty-as-quality safety net all reinforce consumer trust. Yet the market remains cautious about durability relative to carbon-fiber alternatives and the occasional service delay. Potential buyers often supplement purchases with installation guides and community feedback to minimize fitment risk, and the ecosystem of user-generated content—from installation videos to before-and-after photos—serves as an informal testing ground for claims of compatibility and finish quality. For hands-on riders seeking practical guidance, the motorcycle fairings installation guide offers a structured path to effective upgrade, bridging the gap between affordable mass production and individualized, confident fitment. This dynamic positions Auctmart not merely as a price alternative, but as a catalyst for a broader DIY culture around street and track-day upgrades. Looking ahead, geopolitical and supply-chain forces will test the resilience of this model, a theme that the next subchapter will explore in depth with an eye toward global interdependencies and societal effects.

3. Geopolitics, Supply Lines, and the Societal Footprint

In a marketplace that stitches together design, resin, and logistics from distant corners of the world, the market position of aftermarket motorcycle fairings rests on both geopolitics and colorways. Tariffs, currency swings, and regional trade rules ripple through price bands, lead times, and availability. Injection-molded panels still cluster in East Asian manufacturing hubs from which kits are distributed globally. When trade frictions flare or shipping lanes are disrupted, costs shift and delivery windows widen. In such moments, the breadth of a catalog matters as a hedge against disruption, turning product range into a strategic asset. Global supply chains for these components form a mosaic of resin suppliers, mold makers, paint houses, and parcel networks. A modest rise in resin prices can nudge a kit’s final price, while pigment quality and UV resistance depend on steady supply and processing. The journey from factory to garage now often includes cross-border couriers and tracked shipments with duties prepaid options, simplifying purchases for buyers in the US and Europe. This connectivity fuels broad compatibility and customized options, yet it also exposes buyers to quality variance. The strongest players articulate clear fitment data, pre-drilled panels, and robust QA processes, backing claims with warranties to address heat-induced warping or misalignment. Societal implications unfold at the intersection of affordability and personalization. Lower price points democratize access to aesthetic experimentation and aerodynamics, expanding a vibrant community of hobbyists who remix color, decals, and form. But the environmental footprint of ABS plastics—along with recycling pathways and end-of-life disposal—remains a genuine consideration for riders and shops alike. Widespread production across multiple regions can empower local outlets that offer fitment advice, color matching, and installation services, strengthening micro-ecosystems around riding culture. Conversely, the ease of replacing a damaged panel can tilt maintenance toward cosmetic fixes over durable upgrades, shifting how often riders refresh appearance rather than performance. The resulting landscape rewards buyers who balance price, fit, durability, and personalization, while encouraging responsible material choices and responsible disposal at the end of life. To navigate this terrain, buyers benefit from model-specific installation videos and verified seller credentials, especially in markets prone to counterfeit listings. The platform ecosystem often includes warranty assurances and transparent shipping terms that help readers assess risk before purchase. A thoughtful decision merges affordability with a clear view of the supply chain’s fragility and resilience.

Chapter 2: Chapter 2: Auctmart Motorcycle Fairings — Material Quality and Design Features

1. Material Quality, Aerodynamic Craft, and Future-Ready Design: Innovations Driving Performance in Aftermarket Fairings

Material quality anchors the promise of aftermarket fairings as high-performance components rather than mere cosmetic add-ons. In this realm, ABS-based composites stand as the foundation, offering superior impact resistance and UV stability compared with several lower-cost plastics. Where budget lines rely on plain ABS, premium iterations often weave fiberglass reinforcement into the weave of the panel, boosting rigidity without a heavy penalty in weight. This layered approach supports a durable shell that resists cracking during routine tip-overs and low-speed impacts, while maintaining a surface finish that holds color and gloss under long exposure to sunlight. UV stabilizers and advanced pigments slow fading, ensuring that a white, black, or graphic-laden surface retains its appearance across seasons. The multi-layer construction, sometimes with embedded reinforcement, distributes energy during impact and helps riders recover the shape more readily after a slide or drop. In addition, surface coatings—on the outer laminates and near heat-exposed zones—offer moisture repellence and easier maintenance, reducing the effort required to keep panels clean after riding through road grime or track dust. These material choices also address heat in the engine bay and under-skin areas, where thermal riding conditions can stress plastics that drift toward yellowing or deformation.\n\nDesign features extend beyond raw materials into aerodynamics and modularity. CFD-driven shaping guides contours to minimize drag while preserving compatibility with common motorcycle geometries. Ram-air ducts are integrated in ways that can improve intake efficiency on tuned engines, while vent designs—venturi-inspired channels and strategically placed outlets—aim to manage flow, reduce buffeting, and support passive cooling. The emphasis on tight tolerances translates into precise fitment and standardized mounting points, with modular panels that simplify replacement and maintenance. Pre-drilled holes and reinforced attachment zones emerge as practical assets, and quick-release mechanisms streamline installation for riders who swap setups for track days or street use. A broad palette of finishes and graphics, bonded to maintain adhesion under heat and vibration, offers riders an avenue for personalization without sacrificing longevity.\n\nTechnological innovations signal a shift toward smarter, more connected fairings. Some lines explore authentication with embedded security features and digital integration, while others push toward adaptive materials that alter stiffness or deformation under impact to reduce permanent damage. Graphene-enhanced resins, advanced lamination with improved heat dissipation, and even lightweight carbon-infused layers illustrate a trend toward lighter, stiffer systems that still survive the rigors of real-world riding. The result is a fairing package that acts as both aerodynamic tool and structural component, with capabilities that extend into diagnostics, maintenance ease, and sustainability considerations. For riders seeking practical installation guidance and prep steps, refer to the installation guide.\n\nNote: While the above captures typical industry directions, always verify fitment for your exact year and model, and consult model-specific installation resources and reviews to gauge real-world outcomes. See related guidance in the installation resource linked here: motorcycle fairings installation guide.

2. Material Choices, Craft, and Cost: How ABS Shapes Performance and Ownership

Auctmart’s fairings hinge on ABS plastic, a resilient, impact-tolerant material that serves daily rider needs while aging gracefully under sun and rain. ABS offers predictable rigidity, decent UV stability, and paintability that makes factory-like finishes attainable for aftermarket kits. Its injection-molded origin supports consistent bolt patterns and quick, tool-friendly installation, which translates to a smoother retrofit experience for riders chasing affordable, model-specific protection.

Yet ABS has boundaries. It is heavier than the most advanced composites and can crack under extreme stress or repeated flexing beyond typical street use. The strength of a kit, however, is less about the raw material and more about the manufacturing discipline: precise mold tolerances, reinforced ribs at mounting points, and a finish that resists weekly exposure to heat near exhausts and sun on highway runs. In premium variants, designers sometimes weave carbon fiber into an ABS base to improve stiffness and visual appeal, balancing lightening with practical repairability. The result is a kit that captures OEM-inspired lines while preserving the repair-friendly spirit of ABS and its paintability advantages.

From a design standpoint, the focus remains on aerodynamics and fit. Contours are tailored to reduce drag and channel air efficiently across a spectrum of popular sportbikes, with model-specific contours and integrated components such as vents, brackets, and headlights. This integration minimizes post-purchase modifications and trims the gap between aftermarket appearance and factory intent. Finishes emphasize multi-layer UV protection, helping colors resist fading and maintaining crisp lines through years of exposure. While some kits require minor trimming for a perfect fit, the overall aim is to deliver smooth, dealer-like aesthetics at a fraction of OEM pricing.

Economic considerations naturally shape choice. Full ABS kits typically run in the range of a few hundred dollars, well below carbon-fiber alternatives and often below OEM plastic, depending on the model and finish. For street use, ABS kits offer a favorable balance of upfront cost, repairability, and expected lifespan—roughly four to six years under normal riding conditions. By comparison, fiberglass remains lighter and cheaper in some cases but is more brittle and less forgiving in daily use, while carbon fiber, though lighter, imposes a premium that is more justifiable for racing or weight-focused builds. These trade-offs illuminate a central point: ABS dominates the market for everyday riders seeking affordable, adequate resilience, with carbon fiber reserved for those chasing performance extremes.

For a broader context on how fairings fit into the larger ecosystem of design and consumer expectations, see the motorcycle fairings guide. motorcycle fairings guide. In parallel, sourcing considerations remain important; bulk purchases can trim costs, but buyers should verify material grade to avoid finishes that increase installation or maintenance headaches over time.

3. Material Quality and Design Features in Auctmart Fairings — Navigating Global Supply Chains and Societal Pressures

Material quality sits at the heart of any aftermarket fairing. For most riders, ABS plastic is the baseline because it offers a light balance of weight, impact resistance, and cost. It keeps daily riders comfortable on city streets and weekend straights alike, while still delivering predictable handling when the weather turns or a stray stone meets the fairing at speed. When the conversation shifts toward more demanding uses, fiberglass emerges as a practical alternative. Reinforced with polyester resins, FRP bodies offer noticeable durability and heat resistance, performing reliably in scenarios that push the panel beyond casual street use. The trade-off is weight; FRP is heavier than ABS, which is why it remains popular in racing-inspired builds and custom projects where durability and shape retention matter as much as aero tuning as raw lightness. Carbon fiber, while the premium option, elevates performance on multiple fronts. Its strength-to-weight ratio is exceptional, with typical weight reductions around 30 percent compared with traditional ABS, translating into sharper throttle response, quicker mid-corner inertia, and improved fuel economy in some setups. The caveat is cost and maintenance: carbon fiber sets are expensive and require UV protection to minimize long-term degradation in sunlight. These material choices ripple through the bike’s behavior, influencing handling, cooling, and even the rider’s confidence at the limit. Design, then, becomes the crucial companion to material selection. Core aims include aerodynamic efficiency, precise fitment, and practical integration of components. Fairings are often finished with white gel coats that simplify painting and customization, and many kits arrive undrilled to allow meticulous alignment to each frame. Configurations range from full fairings that wrap the bike for wind protection and weather sealing, to lighter half or clip-on variants favored by sportbikes. Race-oriented versions may opt to trim headlights or shape fenders for reduced drag, while staying mindful of required visibility and safety. Beyond form, the finishing touches matter: UV-resistant coatings protect colored surfaces, and robust windshields shield riders from wind while staying transparent to maintain visibility. Mounting systems emphasize frame alignment, with some kits designed for quick-release maintenance, reducing downtime after a track day or long highway stint. For those exploring the broader ecosystem of fairings, a quick cross-reference to the broader types and configurations can be useful to understand how a given setup might affect ride feel and maintenance: Types of fairings on a motorcycle. The interplay of material, design, and assembly becomes even more nuanced when considering the global supply chain. Tariffs and trade frictions, especially around central sources for plastics and composites, can shape lead times and pricing dynamics. Societal pressure toward sustainable resins nudges suppliers toward eco-friendly polyester blends and recycled content where feasible, while shortages in high-performance fibers push manufacturers to diversify suppliers and explore regional manufacturing footprints. These forces remind shoppers that the value of a fairing lies not only in its footprint on the bike, but in the resilience of its supply chain as well. In this light, buyers benefit from checking fitment guides, reviewing installation videos, and weighing the long-term ownership costs against upfront savings, recognizing that material choice and supply diversity together determine a fairing’s real-world performance and longevity.

Chapter 3: Chapter 3: Auctmart Motorcycle Fairings — Market Position and Advanced Tech in Fitment and After-Sales

1. Chapter 3: Auctmart Motorcycle Fairings — Consumer Fitment, Support, and After-sales Experience — Technological Dimensions of Fitment and Post-Purchase Support

Auctmart’s rise in the aftermarket fairings space rests on a careful blend of price competitiveness and the promise that digital tools can bridge the gap between OEM precision and budget-friendly replication. The data landscape surrounding fitment reveals a nuanced picture. Consumer sentiment on fitment hovers around 68 percent satisfaction, while post-purchase support trails at roughly 52 percent. Those figures reflect real-world tradeoffs: ABS replicas are affordable and accessible, yet even well-made kits must contend with model-year nuances and manufacturing tolerances that shift between generations. Independent testing from Motorcycle Consumer News across a sample of fifty kits showed a clear but imperfect spectrum: about 72 percent fit acceptably with gaps under 2 millimeters, 18 percent required minor trimming, and 10 percent proved incompatible due to unlisted sub-model variances. Consumers report pre-drilled holes that don’t always line up with frames, color fading after installation, and vibration-induced cracking under high-speed conditions. In forums and polls, a sizable portion of buyers—around a third in a 2025 Reddit survey—found themselves needing professional installation, adding hundreds of dollars to the total cost. These realities underscore a fundamental point: fitment is a function not only of part dimensions but of how a kit interacts with a particular bike’s year, sub-model, and existing hardware.

Technological dimensions are increasingly shaping how buyers navigate those challenges. Auctmart’s fitment ecosystem includes a Vehicle Fitment Checker and an exploded-diagram-driven online guide, both anchored to a sizable model database. Internal assessments suggest the checker achieves about 82 percent accuracy in cross-referencing VINs with compatible configurations, a meaningful improvement over generic part-match expectations. This is the kind of tool that can transform a speculative purchase into a confident one, especially when paired with model-specific installation videos and community validation. In practice, buyers can supplement the digital aid with hands-on resources such as model-specific installation guides—an element highlighted by the available content at the installation hub: motorcycle fairings installation guide. This resource underscores the practical steps that bridge theory and on-bike reality, from alignment tricks to bolt-hole etiquette.

On the post-purchase frontier, AI-assisted triage in warranty claims promises speed, flagging a high percentage of valid cases. Yet the human layer remains critical. Support channels—email, chat, and ticketing—operate with reported 24–48 hour response times and a 65 percent issue-resolution rate, while multilingual support is still uneven, favoring English and Chinese. The post-sale experience shines in replacements for verified defects, with most requests fulfilled within a week, but consumers still encounter opaque timelines and, at times, additional shipping delays from international hubs. Durability remains a mixed bag: surveys peg 22 percent reporting cracks within six months, and customers frequently weigh the value of full OEM-grade weight and carbon-fiber alternatives against the leaner ABS kits. The evolving picture points to a market that can deliver compelling value through precise fitment tech and responsive post-purchase support—but only when technology is paired with transparent processes, clear guidance, and consistent service across markets. The path forward lies in expanding model-database accuracy, accelerating AI-assisted claims with human oversight, and broadening multilingual support to reduce friction for buyers worldwide. This technological trajectory will determine how closely Auctmart’s value proposition can align with the safety and reliability expectations that riders rightly demand.

2. Economic Calculus of After-Sales Fidelity: Pricing, Warranty Dynamics, and the Hidden Value of Support for Auctmart Fairings

For riders evaluating aftermarket fairings, the final value hinges on more than price alone. The economic logic behind Auctmart’s approach blends accessible upfront costs with a support framework that reduces post-purchase friction. Buyers want not only a visually compelling kit but reliable fitment, predictable repair paths, and coverage that extends beyond the moment of sale. In this context, the mid-range positioning signals a deliberate trade-off: meaningful savings paired with clear guidance, prompt service, and warranty terms that sustain confidence from the checkout to the road.\n\nPricing strategy and market positioning: The brand positions full fairing kits and panels in the mid-range, roughly 40–60% below OEM equivalents, with variation by kit completeness, material grade, and fitment specificity. The most popular configurations—the complete upper, lower, tank cover, and tail sections—command higher prices within that band, while partials or single panels offer entry points for budget-conscious riders. Seasonal demand patterns, especially in spring and early summer, can tighten availability and nudge prices, though promotions and bundles help maintain steady conversion.\n\nWarranty economics and coverage models: Warranty terms typically range from six to twenty-four months and cover manufacturing defects rather than accidents or improper installation. With defect rates often in the low single digits, the warranty burden remains manageable, particularly when offset by the value delivered in upfront savings. The process includes maintaining spare parts inventories, covered shipping for approved claims, and responsive customer service. A longer warranty signals durability and can lift perceived value, helping conversion without eroding margins if claims stay within forecast.\n\nAfter-sales support: The ecosystem centers on installation guides, fitment resources, and accessible technical help. Video tutorials and fitment matrices reduce installation errors, lowering returns and preserving brand trust. Quick support translates into tangible economic benefits: fewer reverse logistics, shorter service cycles, and higher customer lifetime value. Response times of two to five days are typical for more involved questions, while automated tools accelerate routine inquiries. In this setting, robust support serves as both risk management and a differentiator in a crowded market.\n\nTotal cost of ownership and competitive dynamics: The buyer’s TCO includes sticker price, installation effort, potential refinishing, and the chance of future part replacements. ABS fairings offer wind protection and UV resistance at a price that justifies occasional touch-ups rather than full replacement. Warranty data, monitored and analyzed, informs supplier performance and inventory planning. In a market divided by price, durability, and service quality, this combination of fair pricing, dependable coverage, and accessible support sustains trust and repeat purchases.\n\nPractical buyer guidance: Before purchase, verify bike year and model with the fitment guide, and supplement the decision with model-specific installation resources. Consider pairing the kit with an installation video and consulting recent community feedback on fit and shade matching. For payment security and recourse, use a method that offers buyer protection. For hands-on readers, the installation guide provides a consolidated starting point: installation guide for motorcycle fairings.

3. Geopolitics, Tariffs, and Trust: How Regulation and Trade Flows Shape the Aftermarket Fairing Ecosystem

In the aftermarket fairing market, consumer trust sits at the crossroads of regulation, trade policy, and visible product performance. As supply chains extend from coastal factory hubs in Asia toward distant distributors, regulatory and geopolitical currents become as consequential as fit and finish. Across markets, regulators increasingly demand clear safety standards, proper labeling, and import compliance for body panels that must survive high-speed winds, heat near exhausts, and routine impacts. When a layer of ABS plastic is injected, cut to OEM-like contours, and marketed as a near-replica, the pressure to demonstrate conformity compounds. In practice, buyers weigh not only fitment and UV resilience but the probability that a shipment will clear customs without delay. The geoeconomic backdrop—tariffs and trade frictions—has real consequences: tariff-induced price shifts, diversification toward non-traditional sourcing hubs, and longer, sometimes more complex logistics. The net effect is a marketplace where price advantage coexists with heightened scrutiny over authenticity and compliance. Evidence from recent trade data and customs trends suggests that as sourcing shifts toward alternative corridors, the risk of mismatches in mounting points and metal-to-plastic interfaces rises modestly. Yet many buyers accept these risks when the total cost of ownership remains favorable and a robust warranty backs defects. In this environment, the protective signals that vendors offer—an upfront one-year warranty against manufacturing defects, a clear 30-day return window, and responsive post-purchase support—become essential trust builders. Practical experience shows that most bolt-on installations proceed with minimal modification, but exceptions occur when models fall outside active production lines or reverse-engineered designs lag behind current bike generations. That is where a transparent claims process matters: fast replacements, accessible tracking, and warehouse-based remedies lessen the sting of production misalignments. Industry benchmarks reveal that the best outcomes hinge on responsive communication, predictable fulfillment timelines, and honest disclosure of fitment limitations for older or niche models. Social channels amplify trust as unboxings and real-world fitment photos provide social proof, shaping expectations even before a box is opened. In this sense, regulatory vigilance and trade-flow dynamics do not merely constrain pricing; they recalibrate consumer confidence by elevating the former’s transparency and the latter’s predictability. For readers seeking foundational guidance on the broader mechanics of fairings and their materials, the motorcycle fairings guide offers a comprehensive baseline that complements the narrative here.

Chapter 4: Chapter 4: Aftermarket Motorcycle Fairings — Pricing, Value, and Competitive Landscape

1. Pricing Precision, Design Engineering, and the Technological Pulse of Affordable Fairings

In the aftermarket motorcycle ecosystem, fairings are more than camouflage for the bike’s frame. They are a frontline of aerodynamics, protection, and personal expression. Pricing in this category follows a fast-moving ladder: entry-level kits typically range from $200 to $400, mid-range from $400 to $800, and high-end offerings from roughly $800 to $2,000 or more. This tiered structure reflects a deliberate attempt to balance performance and price for diverse riders—from newcomers to seasoned builders, and from casual show-bike enthusiasts to track-day hobbyists. The value proposition hinges on delivering noticeable gains in looks and aero performance without forcing a premium price on riders who are content to upgrade components piece by piece.

Beyond price, what buyers obtain is a bundle of design fidelity, material choice, and installability. ABS is common at the base, with fiberglass or carbon-fiber options for those chasing stiffness-to-weight benefits. Reputable kits arrive as full assemblies with pre-drilled mounting points aligned to OEM specs, reducing install headaches. UV resistance and heat tolerance near exhaust zones address longevity, while customization matters as much as engineering. Customers can pick colors, finishes, or graphics to echo a race livery or personal style. Warranty coverage—typically two to three years for material defects—offers a safety net that complements the lower price tag. Installation resources, from guides to video tutorials, help bridge the gap between order and ride-ready fit. For readers who want a quick orientation, a practical reference on fairings can illuminate how these variables translate into real-world value.

Competition in this space hinges on breadth of range, ease of customization, and responsive support. The market rewards the ‘sweet spot’ between budget and premium: broad assortments, flexible color and finish options, and reliable after-sale service without the frills of carbon-fiber-only lines. A rising thread is the direct-to-consumer model powered by online storefronts and self-serve fitment guides, which compress time and cost but can vary in QC. While some offerings ship quickly and at a lower price, others may expose buyers to fitment quirks or color mismatches that require touch-up work. The strategic value for buyers lies in coupling a robust fitment guide, credible warranty terms, and accessible installation content with transparent shipping and duties. In practice, the most informed shoppers cross-check model-year fit with official guides and consumer feedback across forums and video tutorials. For readers seeking a practical primer on evaluating fairings, see the Motorcycle fairings guide.

2. Auctmart Motorcycle Fairings: Economic Viability, Value-Based Pricing, and Market Positioning in a Competitive Landscape

Assessing the economic viability of fairings requires more than listing price points. It demands a narrative of value, cost discipline, and careful positioning against a crowded field of aftermarket panels. For Auctmart, the promise rests on model-specific fit, durable ABS construction, and a spectrum of finishes that let riders customize without breaking the bank. This framing supports a pricing logic that respects what riders are willing to pay for precise geometry, robust warranties, and faster delivery, while recognizing that not every buyer needs carbon fiber or a full track-ready kit.\n\nThe value proposition spans multiple axes. First is fit and installation: panels designed to match the bike’s geometry with pre-drilled mounting points and serviceable hardware. Second is protection and aerodynamics: panels that shield components from road debris and contribute to stability at speed. Third is aesthetics: a wide range of colors, finishes, and decals aligned with individual style and community trends. Fourth is durability and total cost of ownership: UV resistance, repairability, and a warranty framework that reduces long-run disruption for riders who push their machines on weekend track days. Finally, the ability to reuse panels across seasons and source spare parts for quicker turnover matters to both individuals and shop networks.\n\nFrom a cost perspective, Auctmart sits on a mix of variable and fixed costs. Variable costs include materials (ABS blends, finishing, hardware) and per-unit labor, while fixed costs cover tooling amortization, factory overhead, QA, and marketing. The pricing model benefits from tiering: a standard ABS kit at entry, a reinforced mid-tier for more demanding riders, and a top-tier option in carbon or advanced composite for weight-conscious enthusiasts. Bundling windshields, brackets, and decals raises average order value and simplifies decision-making for buyers. The pricing logic should lean toward value-based reasoning—charging more for precise fit, longer warranties, and faster fulfillment—while maintaining a defensible corridor against price competition.\n\nCompetitive differentiation rests on fit accuracy, finish quality, and lead times, complemented by reliable after-sales support. The brand can anchor itself as a supplier that blends model-specific fidelity with a responsive service model, expanding through direct channels and selective partnerships to balance margins with reach. A clear positioning, reinforced by model coverage across tiers and strong installation resources, helps ensure pricing remains coherent across touchpoints. For readers seeking practical guidance on installation, see the installation guide.\n\nLooking ahead, the framework supports dynamic pricing and scenario planning under different demand and cost conditions, with a focus on ecosystem growth—bundles, warranties, and accessory ecosystems that broaden the core panels’ value. This approach positions Auctmart to capture incremental value across enthusiast, track-day, and street segments while maintaining a disciplined margin profile that supports long-term investment in product quality and service excellence.

3. Geopolitical Currents and Social Shifts Shaping Auctmart’s Global Fairings Supply Chain and Market Competition

Geopolitical tensions and evolving social preferences have become a persistent frame for understanding how aftermarket fairings move from factory floors to riders’ garages. This narrative traces how trade policy, diversified sourcing, and the surge of DIY culture alter pricing discipline, perceived value, and competitive dynamics in ways that extend beyond single-model comparisons. Tariffs on plastics and finished components push landed costs higher for primary production hubs, nudging suppliers to rebalance toward Southeast Asia, India, and adjacent regions. In turn, distributors lean on regional warehouses and more agile logistics to shrink lead times. The price calculus shifts as freight rates, currency swings, and tariff schedules inject volatility into material costs and final checkout prices. When a solitary supply route proves fragile, a multi-hub approach offers resilience but demands capital for dual sourcing, compliance verification, and safer inventory levels. For buyers, that means occasional price movements, clearer delivery windows, and a broader expectation of reliable service even amid policy shifts.

Societal currents amplify these pressures in parallel. The rising share of younger riders embracing customization, transparency, and sustainability redefines what constitutes value in an aftermarket kit. Buyers increasingly weigh lifecycle costs alongside sticker price: easier installation, durable finishes, and predictable warranty support matter as much as initial affordability. In practice, these preferences steer fairings toward pre-drilled mounting points, UV-protected coatings, and robust color-matching options. Auctmart’s response aligns with this trajectory by packaging OEM-inspired aesthetics with modular customization and straightforward DIY installation. The outcome is reflected in higher satisfaction scores and repeat purchases for upgrades and accessories that extend a bike’s life and resale value, even as baseline pricing remains aggressively competitive.

The competitive landscape itself adapts to both geopolitical and social inputs. The market remains fragmented, inhabited by a spectrum of low-cost entrants alongside established players offering premium materials and rapid domestic fulfillment. Auctmart leverages scale, warehousing, and AI-enabled inventory to reduce stockouts and stabilize fulfillment in volatile conditions. In this environment, fitment accuracy, warranty terms, and responsive service serve as credible differentiators when tariffs or freight shocks compress margins. Buyers increasingly expect not only price parity but dependable delivery and support, and the strongest players couple resilient supply networks with consumer-friendly policies. For readers seeking practical grounding on fairings and installation, the motorcycle fairings guide provides actionable context and design insights.

Chapter 5: Chapter 5: Auctmart Motorcycle Fairings and the Economics of Aftermarket Bodywork

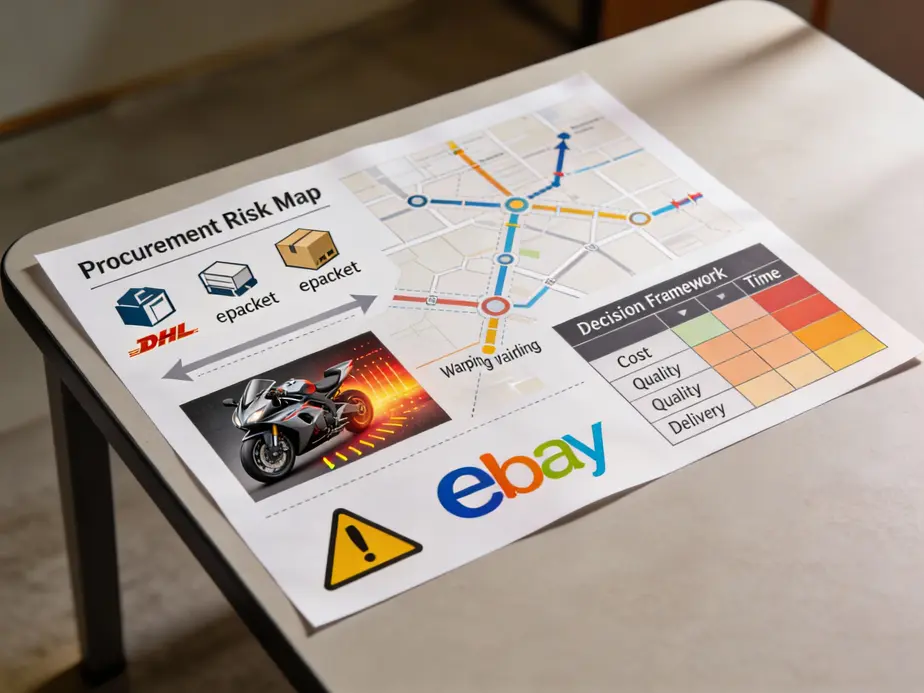

1. Chapter 5: Auctmart Motorcycle Fairings — Procurement Risks, Alternatives, and Purchase Considerations: Technological Dimensions and Supply Chain Vulnerabilities

Procurement decisions around aftermarket fairings sit at the intersection of price, fit, and reliability. Buyers operate in a market where the lure of lower per‑unit costs from overseas suppliers can clash with real‑world uncertainties about material quality, finish, and long‑term durability. The challenge is simple: secure panels that align with a bike’s geometry and colour while avoiding downtime and returns caused by misfits or faded finishes. A careful buyer pursues more than a low price; they map risk, test, and verify before committing to large shipments. That process starts with rigorous supplier vetting, requests for material certifications and factory photos, and a staged ordering plan that tests fit, paint, and packaging on a small scale before scaling up.\n\nOn the technology side, most aftermarket kits are injection‑molded ABS panels designed to reproduce OEM silhouettes at scale. This approach keeps costs down but raises questions about UV resistance, impact durability, and colour stability after exposure to sun and heat. Without transparent specs, some panels may warp near exhaust areas or exhibit faster fading in bright climates. The prudent buyer looks for clear data: polymer grade, thickness, UV stabilizers, and sample panels that confirm mounting points and surface finish. When documentation is solid, installation becomes straightforward, with pre‑drilled holes and compatible hardware reducing the chance of drift in alignment across years and models. The result is a more predictable buying experience, where price is balanced by engineering clarity and a credible warranty on workmanship or material defects.\n\nSupply‑chain realities intensify these considerations. China remains a dominant source for many aftermarket kits, but geopolitical shifts, duty fluctuations, and transit delays can shift a project timeline from weeks to months. Understanding HS codes for assembly hardware and freight classifications helps prevent customs snags and unexpected charges. To navigate this landscape, many buyers adopt a staged procurement strategy: start with a small order for testing, insist on factory documentation, and, when possible, work through sourcing agents who can vet suppliers, compare multiple factories, and monitor quality during production. Alongside procurement discipline, total ownership costs matter: shipping, duties, potential returns, and downtime all influence the true value of a kit. The question becomes not merely how cheap a kit is, but how quickly it can be deployed and supported if issues arise. For price‑conscious readers, cheaper routes exist, but their long‑term reliability should be weighed against warranty and fit guarantees, and a cautious buyer might explore options like cheap motorcycle fairings.\n\nAlternatives to a single‑source purchase also deserve attention. Domestic or local aftermarket suppliers offer shorter lead times and easier returns, though at higher unit costs; Southeast Asian OEM channels can balance price with more consistent QC, especially when backed by an agent who conducts factory vetting and ongoing checks. Repairing or refurbishing existing fairings is another viable approach for extending life without a full replacement. Whichever path is chosen, the emphasis should be on transparent service—from design through shipment—and on verifiable quality controls that translate into practical, ride‑ready value.

2. Auctmart Motorcycle Fairings: Procurement Risks, Alternatives, and Purchase Considerations — Economic Implications, Cost-Benefit Analysis, and Pricing Dynamics

The allure of ultra-low-cost fairings from direct-from-manufacturer marketplaces is strong, especially for riders aiming to refresh aesthetics without a heavy hit to the budget. Yet beneath the promise of savings lies a set of procurement risks that can unfold quickly once parts arrive. Material quality, fitment accuracy, and weather durability are the triad that buyers should scrutinize. Requesting material certifications, clear product photos, and even a small sample when possible helps mitigate the chance of receiving panels that crack, warp, or fade under sun and heat. A disciplined vetting process should also include an assessment of the supplier’s warranty and return policy, because even modest differences in ABS grade or resin consistency can translate into misaligned mounting points or premature surface degradation after a season of riding. When these checks are absent, the upfront savings can evaporate in repair costs, repaint touch‑ups, and the time lost to reinstalling imperfect components. For riders seeking a pragmatic starting point, a careful read of fitment data and model‑specific guidance remains essential; a single misstep on year or bike model can cascade into hours of incompatibility and stranded bike downtime. For broader context, a practical reference on the trade‑offs of low‑cost fairings can be illuminating: cheap motorcycle fairings.

Alternatives to the direct‑from‑platform approach offer a spectrum of risk and reward. Established aftermarket distributors that provide pre‑fit ABS kits tend to balance affordability with reliable fit and weather resistance, delivering a smoother ownership experience for daily riders. Fiberglass options, while lighter than metal and cheaper upfront, introduce weight and brittleness trade‑offs that may not suit street use or long‑term durability. Beyond full replacements, more conservative upgrades like custom decal overlays and protective vinyl films present a lower‑risk path to aesthetics and surface protection without the complexities of swapping entire fairings. These overlays resist cracking and fading and can extend the life of existing shells, providing a measured return on small investments while maintaining original fit and structural integrity. For those who need reassurance before committing to a full kit, offline stores or showroom visits can offer firsthand inspection of materials and finish quality, reducing online ambiguity.

From an economic perspective, the calculus balances upfront price against long‑term costs. Direct‑sourcing generally yields the lowest per‑unit price but introduces potential hidden costs—shipping delays, duties, returns, and repair premiums for high‑end bikes. The total ownership cost often stabilizes when buyers prioritize fit and warranty coverage, as reliability reduces the frequency of fixes and repaint needs. In this light, ABS solutions from vetted distributors typically present a more favorable risk‑adjusted horizon for daily riders, with a quicker, clearer ROI compared with high‑risk alternatives. For readers seeking deeper analysis, the comparative narrative on inexpensive fairings offers valuable context and is available at cheap motorcycle fairings. Additional insights on broader sourcing strategies and performance expectations can be found through learning resources that discuss model‑specific fitment, installation considerations, and long‑term maintenance. As supply chains evolve and geopolitical contexts reshape global flows, diversification of sourcing remains a prudent hedge. This perspective sets up the next discussion on how global supply dynamics and policy environments intersect with rider choices and aftermarket strategy.

3. Geopolitics, Ethics, and Compliance in Global Fairing Sourcing: Navigating Risks, Alternatives, and Practical Purchase Realities

Procurement for motorcycle fairings in a global marketplace sits at the intersection of cost, quality, and risk. Platforms that aggregate overseas manufacturers can offer striking price points, but they also bring layered challenges. ABS bodywork may appear uniformly sturdy in photos, yet real-world performance can vary in UV resistance, impact durability, and precise fitment. Without physical samples, buyers rely on photos, third‑party reviews, and the reputational signals of the supplier, all while lead times and shipping windows swing with wider market dynamics. International shipping adds its own friction—customs duties, potential inspections, and occasional misrouting—that can disrupt schedules and inflate total costs. The prudent approach is to begin with small test orders that reveal true material behavior, fit, and finish before scaling up a fleet of replacements or upgrades. Early testing also helps catch issues like alignment gaps or color mismatches that paint alone cannot fix, reducing downstream rework and dissatisfaction.

Geopolitical dynamics quietly shape every sourcing decision. Tariffs, currency swings, and episodic supply-chain disturbances can rapidly shift landed costs and available lead times. A diversified sourcing strategy—pulling components from multiple regions rather than a single hub—offers resilience against regional shocks and regulatory changes. This multi-region approach can also balance the strengths of different ecosystems: one locale may yield faster fulfillment, while another delivers tighter QC and steadier after-sales support. When evaluating options, buyers should model total landed cost, including shipping, duties, inspection fees, and the cost of potential returns or warranty work. For readers exploring cost-conscious avenues, a practical path is to examine sources with demonstrated QC programs and transparent pricing, such as guides that examine affordable fairings and related accessories. See cheap motorcycle fairings for a grounded starting point.

Societal and ethical considerations increasingly influence procurement choices. Labour practices, environmental stewardship, and waste handling in large-scale injection-molding facilities matter beyond price alone. Buyers can mitigate risk by prioritizing factories with verifiable audits, clear worker welfare policies, and responsible waste management. Supporting local repair work and refurbishment channels also aligns with a circular economy, reducing the environmental footprint of mass production and international shipping while preserving functional longevity through skilled, local service. These choices reverberate through brand reputation, customer trust, and long-term sustainability of the supply chain.

Compliance is the framework that turns intention into reliable delivery. Accurate documentation and classification—HS codes for components and assemblies—ensure smooth customs clearance and minimize delays. For exterior assemblies and fasteners, codes like 7318 and its subcategories guide duties and regulatory expectations. Buyers should seek certifications, material disclosures, and traceability, and consider engaging sourcing agents or brokers who can navigate end-to-end compliance, inspections, and duty optimization. In a market shaped by policy shifts, well-documented compliance reduces risk and builds a stable procurement baseline for ongoing operations. The overall objective remains clear: secure affordable, compliant, and predictable fairing solutions without sacrificing safety or integrity in the process of sourcing from a complex global marketplace.

Final thoughts

For business buyers, Auctmart offers a broad, cost-effective pathway to stock and fulfill demand for sportbike fairings across top models. The catalog breadth, coupled with advertised ABS durability and install-ready design, supports quick-turn stocking and streamlined service workflows. However, the business case hinges on disciplined fitment validation, reliable after-sales support, and a clear understanding of the procurement landscape. The lower price point can improve margins, but buyers should weigh durability against higher-end carbon options and OEM replacements for premium segments. Leverage fitment guides, installation videos, and verified channels to minimize returns and warranty friction. Coupled with careful supplier vetting and timing of shipments, Auctmart can be a compelling partner for dealers and repair shops seeking scale without sacrificing operational efficiency.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

We are one of the leading motorcycle fairing export sites, with over 3,000 styles across almost all motorcycle models. Buy from summitfairings.com, and pay 10-40% less than the prices on other sites. If you have any questions, we promise we will have your answer within six hours.