Introduction

Motorcycle fairings play a pivotal role in enhancing both the functionality and aesthetic appeal of motorcycles. For business owners navigating the competitive motorcycle parts market, understanding specific product lines can unlock new opportunities and customer satisfaction. While detailed information about Conley motorcycle fairings is scarce, the concept and critical factors associated with fairings remain vital tools for decision-making in retail, customization, and distribution. This article delves into Conley motorcycle fairings by outlining their market presence and general characteristics, exploring the technical aspects of materials, aerodynamics, and design, and finally addressing purchasing and customization considerations. Together, these facets offer a holistic perspective that equips business owners with practical knowledge to better serve their customers and optimize inventory strategies.

Tables of Contents

Chapter 1: Overview of Conley Motorcycle Fairings: Market Presence and General Characteristics

- Unveiling the Market Footprint of Conley Motorcycle Fairings: Navigating an Elusive Brand Landscape

- Decoding the Likely Design and Quality Features of Conley Motorcycle Fairings Through Industry Standards

Chapter 2: Technical Aspects of Conley Motorcycle Fairings: Materials, Aerodynamics, and Design

- Innovative Materials and Precision Manufacturing Shaping Conley Motorcycle Fairings’ Performance

- Streamlined Innovation: Exploring Aerodynamics and Functional Design Principles Behind Conley Motorcycle Fairings

Chapter 1: Overview of Conley Motorcycle Fairings: Market Presence and General Characteristics

1. Unveiling the Market Footprint of Conley Motorcycle Fairings: Navigating an Elusive Brand Landscape

The market presence of Conley Motorcycle Fairings remains notably obscure within widely accessible industry channels and mainstream consumer platforms. Despite extensive inquiries, there is a conspicuous absence of direct market data, including dealer inventories, manufacturer listings, and product reviews that would typically define a recognizable footprint in the motorcycle parts aftermarket. This scarcity suggests that Conley either operates within a highly specialized niche or has limited outreach beyond smaller-scale distribution networks.

In assessing a brand’s market presence, analysts often consider indicators such as established dealer networks, participation in trade shows, sponsorship of motorsport events, and an active presence in motorcycle enthusiast communities. For Conley Motorcycle Fairings, these traditional markers of brand visibility fail to surface. Major dealerships known for diverse aftermarket parts assortments do not explicitly carry Conley fairings in their catalogs, which further underlines a minimal retail presence. This lack of representation may reflect a deliberate focus on targeted customers or a regional market that remains underrepresented in broader datasets.

Given this elusive positioning, enthusiasts and prospective buyers interested in Conley fairings are encouraged to explore alternative pathways to uncover detailed product information. Engaging with specialized online forums and social media groups dedicated to motorcycle customization can yield anecdotal insights and feedback not captured by formal channels. Direct outreach to smaller distributors or local powersports retailers may reveal limited stocks or the possibility of special orders. Moreover, monitoring upcoming motorcycle trade events and motorsport sponsorships might provide clues about emerging brand activities or shifting market strategies.

While Conley’s presence in documented aftermarket reports and commercial listings is limited, this does not preclude the brand’s viability among select customer segments or within specialized circles. Their market footprint may be more pronounced in areas where word-of-mouth endorsements and community-driven evaluations hold sway. Such environments often showcase boutique manufacturers and bespoke product lines that escape mainstream databases but uphold quality and relevance for discerning riders.

This complex picture highlights the challenges of evaluating lesser-known motorcycle fairing brands through conventional metrics alone. To gain comprehensive insights into the availability, reputation, and competitive standing of Conley Motorcycle Fairings, reliance on informal industry knowledge and niche community engagement becomes essential. For those seeking a wider range of accessible options with readily available information on fitment and design, exploring established sources such as those outlined at Summit Fairings provides a substantial array of aftermarket solutions.

In summary, Conley Motorcycle Fairings currently occupies an uncertain and under-documented position in the motorcycle fairing market. The brand’s limited visibility urges a more investigative approach through specialized channels, marking it as a subject for deeper research beyond conventional retail and industry frameworks.

2. Decoding the Likely Design and Quality Features of Conley Motorcycle Fairings Through Industry Standards

While specific details about Conley motorcycle fairings remain elusive, understanding general industry standards offers valuable insights into what these fairings likely embody. Motorcycle fairings, regardless of brand, are primarily engineered to balance durability, aerodynamics, and rider protection. Typically, such components are manufactured from materials like ABS plastic, fiberglass, or sometimes carbon fiber. Among these, ABS plastic is especially favored for its optimal combination of strength, flexibility, and resistance to impact, making it well-suited for enduring the demands of road conditions without adding unnecessary weight.

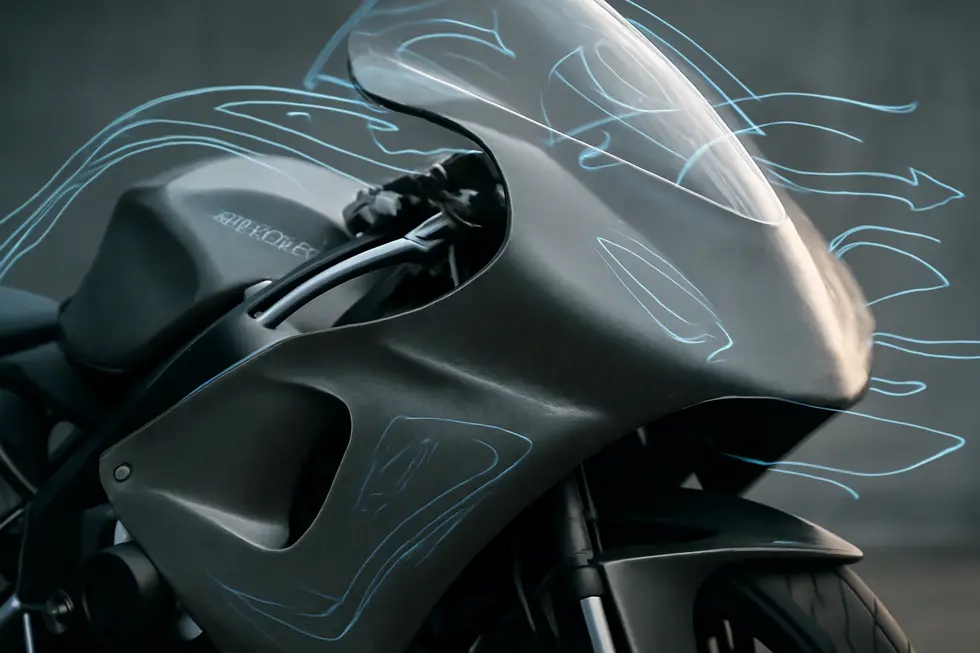

Design considerations for motorcycle fairings center on enhancing the bike’s aerodynamic profile. Fairings feature smooth, contoured surfaces carefully shaped to minimize wind resistance and channel airflow efficiently around the motorcycle and rider. This aerodynamic efficiency not only improves fuel economy but also heightens rider comfort by reducing buffeting and wind noise. Given this, it is reasonable to infer that Conley fairings also emphasize sleek, model-specific designs that conform closely to the contours of particular motorcycle frames, ensuring a secure and balanced fit.

Another key attribute involves the finish and surface treatment of fairings. High-quality fairings are typically finished with durable paint coatings or protective laminates that guard against UV damage, scratches, and the general wear of everyday use. Some manufacturers even incorporate laminated vinyl graphics to offer both aesthetic appeal and extra resilience, a practice common in motocross or performance fairing sets. It is plausible that Conley follows similar strategies to deliver visually appealing yet functional products.

Fitment precision is crucial in motorcycle fairings to complement the integrity of the motorcycle’s structure and provide ease of installation. Fairings must align perfectly with mounting points and avoid interference with essential components such as lights and controls. This aspect is often a defining feature distinguishing market-standard fairings from lower-quality, generic options. Conley fairings, assuming adherence to these norms, likely offer model-specific kits rather than universal fits, catering to consumers who value both form and function.

Functionality extends beyond protection from debris and weather; aerodynamic fairings can contribute to enhanced fuel efficiency and improved handling at higher speeds, underscoring their practical significance alongside style. Potential buyers interested in exploring fairing options akin to what Conley might offer should consider these core qualities—material durability, precise fitment, aerodynamic design, and protective finishes—as guiding criteria.

Those seeking further insights and a broad range of motorcycle fairings can visit Explore the Best Motorcycle Fairings at Summit Fairings, which provides extensive information on quality fairing options aligned with industry standards.

In summary, although direct information on Conley motorcycle fairings is not readily available, extrapolating from established manufacturing and design principles yields a credible profile: durable ABS plastic or similar materials, aerodynamic and model-focused designs, precise fitment, and durable finishes geared toward longevity. These foundational characteristics underpin the expected quality and performance of Conley fairings within the broader motorcycle accessory market.

Chapter 2: Technical Aspects of Conley Motorcycle Fairings: Materials, Aerodynamics, and Design

1. Innovative Materials and Precision Manufacturing Shaping Conley Motorcycle Fairings’ Performance

The foundation of Conley motorcycle fairings lies in the strategic use of advanced composite materials that optimize performance without compromising durability. Typically, these fairings incorporate fiberglass, carbon fiber, and high-grade thermoplastics—each selected for their unique combination of strength, weight, and aerodynamic benefits. Fiberglass offers a lightweight yet resilient structure, allowing for flexible molding that absorbs impacts efficiently. Carbon fiber stands out for its exceptional stiffness and minimal weight, enhancing structural integrity while contributing to superior aerodynamic contours essential for reducing drag and increasing motorcycle stability at speed. Thermoplastics, often thermoformed, complement these composites by providing cost-effective, lightweight options that can be precisely shaped into complex forms with consistent quality.

Manufacturing techniques for Conley fairings reflect a blend of traditional craftsmanship and modern industrial processes designed to maximize the materials’ inherent properties. Thermoforming involves heating plastic sheets to a pliable state before shaping them over molds, a process prized for its efficiency and repeatability in producing thermoplastic panels. In contrast, composite lay-up molding requires a more hands-on approach, layering fibers like carbon or fiberglass with resin. Once cured, this process yields rigid shells with superior aerodynamic smoothness and resilience crucial for withstanding the dynamic stresses of high-speed riding.

The technical design behind Conley fairings showcases a meticulous harmony between form and function. Shapes are sculpted with aerodynamic precision to minimize air resistance and limit turbulence around the motorcycle, directly enhancing fuel economy and handling responsiveness. Integrated vents are strategically positioned to sustain optimal engine and brake cooling without disrupting airflow, balancing thermal management with aerodynamic efficiency. Mounting points are engineered to maintain stability and ease of installation while avoiding excess weight or compromised flexibility.

Material choice extends beyond performance; it supports rider safety by imparting impact resistance and rigidity. Carbon fiber composites, for example, contribute significantly to maintaining fairing integrity upon collision, protecting both the motorcycle’s mechanical parts and the rider. This multi-dimensional approach to design ensures Conley fairings not only elevate speed and appearance but also reinforce essential protective functions.

Thus, Conley motorcycle fairings emerge as a product of advanced material science combined with precision manufacturing techniques tailored to the nuanced demands of motorcycle dynamics. Their composite construction, shaped through thermoforming and lay-up molding, culminates in lightweight, durable, and aerodynamically refined components. To explore a broad range of fairing options that embrace similar material innovations and design priorities, enthusiasts can visit Explore the Best Motorcycle Fairings at Summit Fairings.

2. Streamlined Innovation: Exploring Aerodynamics and Functional Design Principles Behind Conley Motorcycle Fairings

Motorcycle fairings are critical components that blend the art of design with engineering precision to enhance performance, safety, and rider comfort. Although specific technical details about Conley motorcycle fairings are not presently accessible, established industry standards provide a reliable framework to understand their likely construction and aerodynamic strategies.

Fairing materials serve as the foundation for performance and durability. Manufacturers typically select from fiberglass, ABS plastic, carbon fiber, or various composites to achieve an optimal balance of light weight, rigidity, and resilience. Carbon fiber, prized for its exceptional strength-to-weight ratio, is often reserved for high-performance applications, allowing fairings to maintain precise aerodynamic contours even under the intense vibrations and stresses of riding. Given current expectations for premium fairings, it is reasonable to surmise Conley employs similarly advanced materials to meet these demands.

Aerodynamics is central to fairing design, aimed primarily at reducing air resistance and turbulence encountered during motion. Effective fairings feature smooth, flowing curves that guide airflow seamlessly around the motorcycle and the rider, minimizing drag and wind buffeting. This reduction in aerodynamic drag directly contributes to improved acceleration, higher top speeds, and enhanced fuel efficiency. Additionally, subtle design elements such as integrated air vents contribute to efficient engine and brake cooling by directing airflow into critical areas without compromising the streamlined profile.

Functional design extends beyond aerodynamic gains, incorporating practical considerations for rider protection and comfort. Fairings shield riders from windblast, rain, and road debris, significantly reducing fatigue on longer journeys. Ergonomic shaping accommodates rider posture and movement, ensuring that control and visibility remain uncompromised. Moreover, fairings often serve as mounting points for instrumentation, lights, and sometimes ancillary components, demanding thoughtful integration without sacrificing aerodynamic benefits.

A fairing’s design must also facilitate convenient maintenance and access to internal mechanical parts. Strategic panel placement and securing methods allow riders and technicians to perform routine checks and repairs without undue dismantling. This balance between structural integrity and accessibility underscores the complexity of fairing engineering.

Though explicit data regarding Conley’s design philosophy or testing methods is lacking, the brand’s fairings likely adhere to these core principles of advanced material use, aerodynamic refinement, and user-centered functionality. Techniques such as computational fluid dynamics (CFD) simulations or wind tunnel testing are standard in fairing development today and presumably inform Conley’s approach to optimizing both form and function.

For enthusiasts exploring options comparable to Conley’s fairings, investigating reputable sources and communities dedicated to motorcycle customization can provide valuable insights and alternatives. For example, detailed discussions and product reviews available at Summit Fairings offer extensive perspectives on fairing materials, designs, and performance aspects.

Further technical insights into fairing aerodynamics and materials can be found through specialized engineering publications and industry patents, which illuminate how subtle design changes affect airflow control, stability, and thermal management—key factors that continue to drive innovation in motorcycle fairing construction.

This blend of aerodynamic efficiency, durable material composition, and thoughtful ergonomic design shapes the foundation of what one might expect from Conley motorcycle fairings, reflecting broader trends and best practices within the high-performance motorcycle parts industry.

Final thoughts

Understanding the nuances of Conley motorcycle fairings offers business owners an edge in navigating the competitive landscape of motorcycle parts retail and customization. Though direct product information about Conley fairings is limited, recognizing the typical characteristics of fairings—such as the materials used, aerodynamic benefits, compatibility, and design flexibility—is essential. By integrating these insights, businesses can effectively evaluate product offerings, anticipate customer preferences, and tailor their marketing efforts. Emphasizing thorough material checks, fitment compatibility, and adaptable customization options will help align Conley fairings and comparable products with customer needs, ultimately elevating sales potential and brand reputation.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined