Introduction

Custom fiberglass motorcycle fairings represent a dynamic avenue in motorcycle customization that merges artistic design with functional performance improvements. For business owners in the motorcycle aftermarket industry, understanding the nuances of these fairings—from materials and manufacturing processes to design, installation, and market availability—is essential for making informed decisions that enhance product offerings and customer satisfaction. This guide walks through the fundamental aspects of custom fiberglass fairings, outlining key material properties and production techniques, aerodynamic design principles, fitment specifics for popular models like Harley-Davidson, as well as avenues for artistic customization. A comparative analysis with other materials highlights why fiberglass retains a niche appeal among enthusiasts. Finally, by examining current market providers and kit availability, businesses can better strategize sourcing and inventory management. Together, these chapters build a thorough framework that supports enhanced expertise and growth within the custom fiberglass motorcycle fairing sector.

Tables of Contents

Chapter 1: Custom Fiberglass Motorcycle Fairing: Materials and Manufacturing Processes

- Core Materials of Custom Fiberglass Motorcycle Fairings: The Vital Role of Fiberglass Cloth and Resin

- Crafting Custom Fiberglass Motorcycle Fairings: Mold Preparation, Lamination, and Curing Techniques Unveiled

- Achieving Flawless Finishes on Custom Fiberglass Motorcycle Fairings: Expert Sanding, Priming, and Painting Techniques

- Navigating the Technological and Economic Trade-Offs in Custom Fiberglass Fairing Fabrication

Chapter 2: Design and Aerodynamics in Custom Fiberglass Motorcycle Fairing

- Crafting Streamlined Performance: Aerodynamic Shaping in Custom Fiberglass Fairings

- Balancing Strength and Streamlined Style: Material Advantages Shaping Custom Fiberglass Fairing Performance

- Mastering Fitment Precision and Component Integration for Aerodynamic Excellence

- Balancing Visual Flair and Functional Protection in Custom Fiberglass Fairings

Chapter 3: Installation and Fitment of Custom Fiberglass Motorcycle Fairing on Harley-Davidson Motorcycles

- Mastering Fit and Compatibility: Key Considerations for Harley-Davidson Custom Fiberglass Fairing Installation

- Meticulous Preparation and Seamless Mounting: Installing Custom Fiberglass Fairings on Harley-Davidson Bikes

- Seamless Integration of Windshields, Headlight Covers, and Audio Systems in Harley-Davidson Fiberglass Fairing Installation

- Mastering the Complexities of Professional Fabrication and Fitment for Harley-Davidson Fiberglass Fairings

Chapter 4: Customization Options and Artistic Expression in Custom Fiberglass Motorcycle Fairing

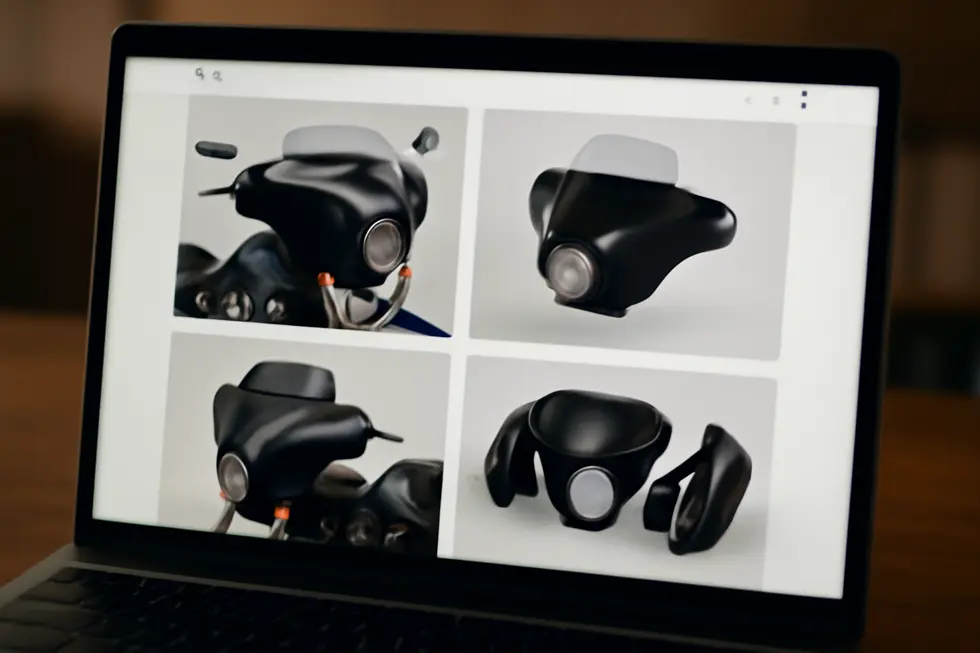

- Innovative Technologies Shaping Aerodynamics and Personal Style in Fiberglass Motorcycle Fairings

- How Economic Forces and Market Trends Shape Customization and Artistic Design in Fiberglass Fairings

- Navigating Geopolitical Challenges: How Global Supply Dynamics Shape Creativity in Fiberglass Motorcycle Fairings

- Cultural Currents Shaping Artistic Identity in Fiberglass Motorcycle Fairings

Chapter 5: Comparative Analysis of Custom Fiberglass Motorcycle Fairing vs. Other Materials

- Innovations Elevating Fiberglass Motorcycle Fairings Above Plastic and Carbon Alternatives

- Balancing Cost and Performance: Economic Insights into Custom Fiberglass Motorcycle Fairings

- How Geopolitical Factors Shape Material Choices for Custom Fiberglass Motorcycle Fairings

- Balancing Environmental Impact and Societal Value in Custom Fiberglass Motorcycle Fairings

Chapter 6: Market Providers and Availability of Custom Fiberglass Motorcycle Fairing Kits

- Innovations Driving Availability and Fitment Precision in Custom Fiberglass Motorcycle Fairing Kits

- Economic Dynamics Shaping the Supply and Demand of Custom Fiberglass Motorcycle Fairings

- How Geopolitical Dynamics Shape the Supply and Reach of Custom Fiberglass Motorcycle Fairings

- Consumer Customization Trends and Material Innovations Shaping Fairing Kit Markets

Chapter 1: Custom Fiberglass Motorcycle Fairing: Materials and Manufacturing Processes

1. Core Materials of Custom Fiberglass Motorcycle Fairings: The Vital Role of Fiberglass Cloth and Resin

Custom fiberglass motorcycle fairings rely on a precise combination of fiberglass cloth and resin to achieve their strength and unique styling. The fiberglass cloth, woven from fine glass fibers, serves as the primary structural reinforcement, available in various weaves and weights tailored to balance durability and finish quality. This fabric is laid into molds shaped to the fairing design before being saturated with resin—a critical matrix that binds the fibers and hardens to form a solid composite. Polyester resin is the common choice due to its cost-effectiveness and ease of use, providing adequate mechanical properties for most custom applications. Epoxy resin, while pricier, is selected for projects that demand superior adhesion, toughness, and chemical resistance. Once cured, this composite presents a lightweight yet robust surface ideal for sanding and painting, allowing riders to customize their motorcycles both functionally and aesthetically. Compared to mass-produced fairings made from ABS plastic, fiberglass composites offer greater flexibility in design complexity and artistic expression without sacrificing weight or strength. This material synergy underpins the craftsmanship behind custom fiberglass fairings, enabling bespoke shapes and finishes suited to rider preferences. For further insights on motorcycle fairing options, explore detailed resources on custom motorcycle fairings.

2. Crafting Custom Fiberglass Motorcycle Fairings: Mold Preparation, Lamination, and Curing Techniques Unveiled

Creating custom fiberglass motorcycle fairings involves a meticulous manufacturing process beginning with mold preparation. The mold, typically made from metal or composite materials, must be cleaned and coated with a release agent to ensure the cured fairing separates easily. Sometimes, a gel coat is applied to the mold first to give the finished fairing a smooth, glossy exterior.

Once the mold is ready, layers of fiberglass cloth or mat are precisely cut and laid onto the resin-coated mold surface. Polyester or epoxy resin mixed with a hardener saturates the fiberglass, ensuring full impregnation and eliminating air bubbles through careful rolling or brushing. Multiple layers are applied to achieve the desired thickness and structural strength, tailored to the fairing’s performance needs.

The assembly then undergoes curing, which can occur at room temperature or in a controlled heated environment to accelerate hardening and enhance durability. After curing, the fairing is carefully demolded, trimmed, and sanded to refine edges and prepare for finishing touches.

This hands-on lamination and curing technique allows for complex shapes and lightweight, durable parts tailored to individual motorcycle styles. For further insights into fiberglass fairing options and customization, explore the comprehensive resources available at Summit Fairings.

3. Achieving Flawless Finishes on Custom Fiberglass Motorcycle Fairings: Expert Sanding, Priming, and Painting Techniques

Custom fiberglass motorcycle fairings require meticulous finishing to ensure a smooth, durable, and visually striking surface. Once the fiberglass curing is complete, sanding begins with coarse grit paper to eliminate rough patches and gradually moves to finer grits to blend surfaces seamlessly. Imperfections like pinholes or dents are addressed using specialized body fillers or glazing putty, which must be perfectly sanded to match the fairing’s contours before priming. Priming seals the fiberglass and establishes an ideal base for paint adhesion, also revealing any hidden flaws needing correction. Professional painting follows with multiple layers—color base coats provide depth, while clear coats enhance gloss and protect from UV and environmental damage. Various finishes, from matte to metallic, allow riders to customize aesthetics according to taste. After painting, ongoing care such as gentle washing and waxing helps maintain brilliance and longevity. This systematic approach blends craftsmanship with durability, delivering custom fiberglass fairings that not only look exceptional but endure riding conditions gracefully. For detailed guidance, expert spray painting resources provide valuable insights into achieving perfect results. Explore expert techniques and comprehensive guides here.

4. Navigating the Technological and Economic Trade-Offs in Custom Fiberglass Fairing Fabrication

Custom fiberglass motorcycle fairings offer unparalleled flexibility in design due to fiberglass’s moldability and finish options, allowing riders to achieve highly personalized aesthetics and functional enhancements. This bespoke approach supports unique aerodynamic profiles and features tailored specifically to rider preferences, such as adjustable windshields or integrated accessories. However, these technological advantages come with notable economic implications. The labor-intensive, often manual manufacturing process drives up costs and extends production schedules compared to mass-produced fairings. In contrast, mass-produced alternatives, typically crafted from ABS plastic or fiberglass composites, benefit from automation, economies of scale, and consistent fitment, delivering affordability and quicker availability. While mass production suits riders prioritizing cost and ease, custom fiberglass fairings appeal to those valuing exclusivity and precision fit, despite higher expenses. Ultimately, the decision balances the desire for individuality and advanced customization against practical considerations of price and production efficiency. This dynamic shapes the motorcycle bodywork market, with custom shops catering to those seeking artistic expression and larger manufacturers focusing on scalable solutions. For further insight into available options and customization possibilities, explore unmatched motorcycle fairings at Summit Fairings. Custom Fiberglass Motorcycle Fairings – TMF Cycles

Chapter 2: Design and Aerodynamics in Custom Fiberglass Motorcycle Fairing

1. Crafting Streamlined Performance: Aerodynamic Shaping in Custom Fiberglass Fairings

Aerodynamics in custom fiberglass motorcycle fairings focus on shaping surfaces to reduce drag and enhance stability. Fiberglass enables intricate molding that forms smooth, continuous contours, allowing air to flow efficiently around the bike and rider. This streamlined design minimizes turbulence and wind resistance, which is essential for better high-speed control and rider comfort.

Incorporating aerodynamic elements such as integrated winglets or panels can generate downforce, improving tire grip and cornering precision. Inspired by racing technologies, these features help the motorcycle maintain stability, especially during aggressive maneuvers. Technologies like computational fluid dynamics (CFD) guide designers in refining fairing shapes to balance aerodynamic benefits with practical functionality.

Custom fiberglass fairings also protect engine components while maintaining smooth airflow, thanks to their adaptable material properties. The combination of reduced drag and added downforce results in enhanced performance and rider experience. For riders seeking distinctive aesthetics without compromising efficiency, these aerodynamic advantages position fiberglass fairings as a versatile choice.

Explore more on achieving optimal motorcycle fairing design at Summit Fairings’ blog.

Additional insights on aerodynamic innovations in motorcycle design can be found here.

2. Balancing Strength and Streamlined Style: Material Advantages Shaping Custom Fiberglass Fairing Performance

Custom fiberglass motorcycle fairings excel by combining vital material properties with design flexibility that directly boost aerodynamic efficiency. The composite nature of fiberglass—glass fibers embedded in resin—creates a structure that is lightweight yet remarkably strong, providing resilience against impacts and weather exposure. This durability is essential for safeguarding riders while allowing fairings to maintain smooth, aerodynamic contours crucial for reducing drag and lift.

Its moldability supports handcrafted curves and shapes tailored to specific motorcycle models or bold custom visions, enabling fairings to streamline airflow seamlessly around the bike. These smooth surfaces minimize turbulence and wind noise, which enhances rider comfort and stability at high speeds. Unlike mass-produced ABS plastic fairings, fiberglass offers superior repairability and artistic freedom without sacrificing structural integrity.

By marrying strength with the ability to sculpt distinctive, flowing forms, fiberglass fairings optimize both aesthetic appeal and aerodynamic function. This balance makes them a preferred choice for riders seeking unique, performance-enhancing bodywork. For deeper insights into varied motorcycle fairing options, explore this resource on affordable motorcycle fairings.

3. Mastering Fitment Precision and Component Integration for Aerodynamic Excellence

Achieving an impeccable fit and seamless integration of custom fiberglass fairings presents intricate challenges that directly impact aerodynamic efficiency and rider comfort. Fiberglass’s rigidity demands exact measurements and expert craftsmanship to align panels perfectly with a motorcycle’s frame and components. Even slight misalignments can cause vibrations, increased drag, or damage both the fairing and the bike. Beyond physical fit, aerodynamic considerations require smooth transitions and continuous curves that minimize turbulence and wind noise. This smoothness supports improved stability by reducing drag and unwanted lift at speed.

Additionally, integrating essential elements like headlights, mirrors, and instrumentation without compromising structural integrity or airflow complicates the design process. The necessity for durable layering and flawless finishes ensures the material withstands road vibrations and weather exposure without warping or degradation. Builders often prefer modular fairings, which enhance customization and repairability but add complexity to initial fitment. These demanding factors highlight the delicate balance between creative freedom and functional precision that defines successful custom fiberglass fairing design.

For in-depth examples and strategies addressing these challenges, resources such as Monster Fairings offer valuable insights.

4. Balancing Visual Flair and Functional Protection in Custom Fiberglass Fairings

Custom fiberglass motorcycle fairings excel at merging style with practical performance, creating bodywork that is as visually striking as it is functional. The inherent flexibility of fiberglass allows artisans to sculpt sleek, aerodynamic shapes tailored to rider preferences and specific bike models. This smooth surface not only enhances aesthetics but also facilitates detailed paintwork and clear coatings that preserve color vibrancy and shield against UV exposure and road debris. Beyond their artistic appeal, these fairings play a crucial role in improving aerodynamics by streamlining airflow around key areas, cutting drag and enhancing stability at higher speeds. Features such as integrated windshields expertly redirect air, reducing rider fatigue without compromising sight lines. Moreover, fiberglass’s toughness offers protection against minor impacts and environmental elements, safeguarding vital mechanical components. This durability also supports adding functional mounts for accessories like headlights and audio systems without detracting from aerodynamic efficiency. By combining elegant styling with finish quality and robust defense, custom fiberglass fairings transform motorcycles into personalized machines optimized for both appearance and ride performance.

For a deeper dive into the variety and craftsmanship behind custom motorcycle fairings, explore discover unmatched choices in motorcycle fairings at Summit Fairings.

External reference: https://www.revzilla.com/motorcycle/klock-werks-fxrp-style-fairing-kit-for-indian-springfield-2016-2024

Chapter 3: Installation and Fitment of Custom Fiberglass Motorcycle Fairing on Harley-Davidson Motorcycles

1. Mastering Fit and Compatibility: Key Considerations for Harley-Davidson Custom Fiberglass Fairing Installation

Selecting the right custom fiberglass fairing for your Harley-Davidson demands careful attention to fit and compatibility to ensure seamless integration. Each Harley model—from Sportster to Touring—features unique frame geometries and mounting points, making model-specific fairings essential to avoid alignment issues or forced modifications. High-grade fiberglass with proper finishing, such as gel-coating or polyester priming, not only enhances durability but also eases customization like painting. Complete mounting kits benefit installers by offering tailored brackets and hardware, ensuring secure and vibration-resistant fitment.

Compatibility goes beyond physical fit: the mounting system must align perfectly with the bike’s frame or existing mounts, sometimes necessitating specialized brackets or adapters. Windshield size plays a crucial role, influencing aerodynamic efficiency and rider comfort; selecting screen dimensions compatible with both the fairing design and personal riding style is vital. Additionally, fairings designed to accommodate accessories like audio systems ensure functional integration without clutter or interference.

Preparation steps, including surface cleaning, light sanding, and test fitting, are critical before final installation to guarantee alignment and structural soundness. Employing all supplied hardware with appropriate torque prevents loosening during rides. For those encountering complex fitment challenges, professional assistance preserves the integrity of both fairing and motorcycle. More detailed installation guidance and product options can be explored at reliable motorcycle fairing sources such as Summit Fairings.

2. Meticulous Preparation and Seamless Mounting: Installing Custom Fiberglass Fairings on Harley-Davidson Bikes

Installing a custom fiberglass fairing on a Harley-Davidson demands careful preparation and precise execution. Begin by thoroughly cleaning the bike’s front areas to eliminate dirt, grease, or old adhesives that could interfere with mounting. Inspect the fairing for imperfections, sanding any rough edges to ensure a smooth fit. Conduct a dry test fit without securing bolts to verify alignment with the motorcycle’s forks, handlebars, and frame brackets. Next, gather essential tools such as screwdrivers, wrenches, drill, sandpaper, and mounting hardware often provided in kits.

If your model requires mounting brackets, install them securely onto the fork tubes or frame sections to create stable anchor points. Some fairings might need minor drilling or modification to align perfectly with the bike and accommodate personal angle preferences. Before final mounting, attach the windscreen and headlight covers carefully, securing them with supplied fasteners. Position the fairing, avoiding pinching cables or brake lines, and hand-tighten all bolts evenly to prevent fiberglass cracking. Adjust angles as needed, using thread locker on bolts to resist vibration loosening. Optional features, like integrated audio systems, are installed last with neat wiring to preserve steering clearance.

For comprehensive guidance specific to your Harley model or kit, consult detailed manufacturer instructions. This meticulous method ensures a secure, aesthetically pleasing installation that respects the delicate fiberglass structure and enhances both function and style. For more insights on tailored fairings, explore this versatile selection of motorcycle fairings.

More details on kits and installation can be found here: https://www.rwdvtwin.com/products/fxr-fairing-fairing-only

3. Seamless Integration of Windshields, Headlight Covers, and Audio Systems in Harley-Davidson Fiberglass Fairing Installation

Integrating windshields, headlight covers, and audio systems into custom fiberglass fairings on Harley-Davidson motorcycles requires precise alignment and thoughtful design to balance aesthetics with functionality. Windshields, often adjustable or fixed, must complement the fairing’s contours and mounting points, offering wind protection without compromising the bike’s iconic profile. Headlight covers are typically molded into the fairing, featuring clear, gasketed designs that fit standard 7-inch headlights snugly to prevent moisture intrusion while enhancing the overall look. Audio systems are increasingly incorporated via specially designed inner fairings that house speakers and wiring discreetly, maintaining structural integrity and visual appeal. During installation, attention to proper fitment minimizes vibrations and gaps, while reinforcing mounting areas guards against stress on the fiberglass. Careful routing of audio wiring ensures a clean appearance and durability, supported by hardware compatibility with fasteners and brackets. This comprehensive approach guarantees that custom fiberglass fairings on Harley-Davidsons not only elevate styling but also enhance protection and entertainment seamlessly. For more details on audio integration options, explore specialized inner fairing solutions here. Additionally, techniques on fiberglass reinforcement can be found in this resource. To further understand fairing options and compatibility, visit the Summit Fairings blog.

4. Mastering the Complexities of Professional Fabrication and Fitment for Harley-Davidson Fiberglass Fairings

The professional fabrication and installation of custom fiberglass fairings for Harley-Davidson motorcycles require meticulous precision and expert craftsmanship. Achieving an exact fit means adapting the fairing to the bike’s unique frame contours while ensuring seamless alignment and sturdy attachment points. Improper mounting compromises safety and durability, demanding secure hardware rather than temporary fixes to withstand road vibrations and stresses. Fiberglass handling is equally critical; the material’s strength and finish depend on skillful layering and curing to prevent cracks or warping. Designs must harmonize with Harley components—such as handlebars, lighting, and instrumentation—often necessitating modifications for visibility and rider access without impairing electrical systems. Balancing aesthetic customization with functional requirements like airflow and wind management involves iterative adjustments and sometimes modifying the motorcycle itself. Additionally, fairings must comply with regulatory standards, especially for racing or street legality, which influences material choices and mounting methods. This multifaceted process calls for advanced expertise to deliver a durable, visually striking, and fully integrated fairing. For insights into precise fitment and alignment techniques, see Alibaba Harley-Davidson Fairing Listings.

Chapter 4: Customization Options and Artistic Expression in Custom Fiberglass Motorcycle Fairing

1. Innovative Technologies Shaping Aerodynamics and Personal Style in Fiberglass Motorcycle Fairings

The fusion of technological advancements has revolutionized customization and artistic expression in fiberglass motorcycle fairings. Leveraging computational fluid dynamics (CFD) and wind tunnel testing, designers craft fairings that not only enhance aerodynamic efficiency but also encourage bold, sculptural forms that reflect individual style. This synergy of form and function is evident in the latest Harley-Davidson models, where aerodynamically optimized fairings improve rider comfort without compromising unique aesthetics.

Material innovations further expand creative possibilities. The integration of lightweight carbon fiber composites and advanced prepregs offers enhanced durability and intricate surface textures. Cutting-edge manufacturing processes, driven by sensor feedback and machine learning, ensure precision in fiber placement and surface finish, facilitating custom patterns and textures that elevate artistic expression.

Precision molding techniques complement these advances by enabling easy installation and versatile customization options. Kits incorporating color variations, vinyl graphics, and faux textures provide riders a broad palette to personalize their motorcycles while maintaining quality fitments. These integrated technological innovations empower enthusiasts to achieve a balanced blend of performance, function, and unique artistic identity.

Explore how these advances shape the landscape of motorcycle customization at Summit Fairings.

For in-depth insight on materials, see Hexcel’s work in advanced composite manufacturing: https://www.hexcel.com/

2. How Economic Forces and Market Trends Shape Customization and Artistic Design in Fiberglass Fairings

Custom fiberglass motorcycle fairings are deeply influenced by shifting economic forces and evolving market trends, which directly shape available customization options and artistic expression. Material costs and global supply chain fluctuations impact fiberglass availability and pricing, prompting manufacturers to balance cost with quality and craftsmanship. This often leads to production being localized in North America and Europe, enhancing design flexibility despite higher costs. Meanwhile, riders’ growing demand for personalized fairings fosters niche markets where bespoke creations command premium pricing due to their labor-intensive nature and unique aesthetics. As technology advances, new materials and manufacturing methods like 3D printing enable more intricate, lightweight designs, expanding creative possibilities. Simultaneously, integration of aerodynamic optimization and smart features caters to both functional performance and stylistic expression. Market platforms that facilitate custom orders across diverse motorcycle models increase accessibility, empowering enthusiasts to take active roles in design. Together, these economic and market dynamics transform custom fiberglass fairings into highly personalized, performance-driven works of art. For further insights into market dynamics and customization options, explore this comprehensive resource on motorcycle fairings. External data on material supply and industry trends can be found at Hexcel composites market updates.

3. Navigating Geopolitical Challenges: How Global Supply Dynamics Shape Creativity in Fiberglass Motorcycle Fairings

Geopolitical factors exert considerable influence over the customization and artistic expression possible in fiberglass motorcycle fairings. The global sourcing of key materials like fiberglass composites and resins exposes manufacturers to price volatility and supply disruptions triggered by trade tensions, tariffs, or conflicts. For smaller custom shops, even minor delays or cost hikes can severely restrict their capacity to experiment with intricate designs or innovative finishes. Moreover, fluctuating energy costs driven by geopolitical instability raise production expenses, narrowing budgets available for creative ventures. Increasing demands for sustainability and corporate social responsibility further shape supplier choices, indirectly steering the range of materials and methods used. These intertwined geopolitical dynamics limit both the variety and feasibility of bespoke customization, narrowing artistic freedom even in a craft that thrives on individuality. Understanding these external pressures clarifies why some design ambitions may face practical constraints, highlighting the delicate balance between creative expression and global supply chain realities. For deeper insight, explore the global material cost impacts in motorcycle supply chains. External context on trade policy effects can be found in the advanced materials market analysis from related industry reports.

4. Cultural Currents Shaping Artistic Identity in Fiberglass Motorcycle Fairings

The artistic expression found in custom fiberglass motorcycle fairings is deeply rooted in societal and cultural contexts, influencing how riders personalize their machines. Motorcycle communities, like those shaped by the 1960s chopper culture, celebrate individuality through elaborate designs that reflect personal identity and craftsmanship. These cultural identities inform stylistic choices—from bold graphics to distinctive shapes—that transform fairings into more than protection; they become moving canvases showcasing personal stories and regional art influences. Technological advances in fiberglass molding enable artisans to realize innovative forms that respond to these cultural demands for uniqueness. Meanwhile, community preferences and national styles dictate what customization is embraced, making some designs popular in one region and rare in another. Economic factors and social trends also steer choices, with riders balancing sustainability, luxury, and accessibility in finishes and materials. This complex interplay ensures that custom fiberglass fairings serve as both functional components and cultural artifacts, embodying the rider’s social narrative and aesthetic values. For further insights on the cultural significance of custom builds, explore this insightful resource on motorcycle fairings. For a deeper understanding of material innovation supporting these designs, Hexcel’s composites innovations offer valuable context.

Chapter 5: Comparative Analysis of Custom Fiberglass Motorcycle Fairing vs. Other Materials

1. Innovations Elevating Fiberglass Motorcycle Fairings Above Plastic and Carbon Alternatives

Custom fiberglass motorcycle fairings have evolved significantly due to technological advancements that emphasize aerodynamic precision, durability, and customizable design. Unlike ABS plastic, which is prized for its cost-efficiency and mass production ease, fiberglass offers superior strength and flexibility, enabling the creation of complex shapes that enhance wind flow and reduce rider fatigue. Although carbon fiber surpasses fiberglass in weight and stiffness, it demands costly and intricate manufacturing techniques unavailable to most custom builders. Fiberglass strikes a balance—light enough to improve handling while lending itself to artistic expression through versatile finishing options and UV-resistant coatings. Aerodynamic testing methods, including computational fluid dynamics (CFD) and wind tunnel analyses, now shape fiberglass fairings with features that lower drag and wind buffeting, elevating both performance and rider comfort. This blend of design innovation and practical material benefits positions fiberglass as a preferred choice for riders seeking personalized, high-function motorcycle bodywork without the premium investment of carbon fiber. For more insights on leveraging these innovations, explore a comprehensive selection of styles and finishes in custom motorcycle fairings at Summit Fairings.

More about advancements in composite manufacturing can be found through Hexcel’s developments.

2. Balancing Cost and Performance: Economic Insights into Custom Fiberglass Motorcycle Fairings

Custom fiberglass motorcycle fairings strike a compelling balance between cost efficiency and performance, positioning themselves uniquely among competing materials like ABS plastic and carbon fiber. Fiberglass offers a mid-range price point—more affordable than carbon fiber but pricier than ABS plastic—reflecting its superior durability and strength. Unlike ABS fairings, which are mass-produced and lower in cost, fiberglass components are typically hand-laid, increasing labor expense yet extending their lifespan and reducing replacement frequency. Carbon fiber remains the premium choice, delivering up to 40% weight reductions and enhanced impact resistance, but its high raw material and manufacturing costs often restrict its use to racing or high-end custom builds. Economically, fiberglass minimizes long-term costs by balancing initial investment with product longevity and repairability. Its manufacturing process demands less specialized equipment than carbon fiber, reducing production overhead for manufacturers and ultimately benefiting riders seeking durable, customized options without exorbitant costs. For riders prioritizing personalized aesthetics alongside economic value, fiberglass fairings provide a versatile and cost-efficient alternative. For further insights on affordable and customizable options, readers can explore discover affordable motorcycle fairings at Summit Fairings. Detailed pricing data on other materials is available through resources such as Alibaba’s carbon fiber listings, Kings Motorcycle Fairings for ABS plastic, and the College of EMS for fiberglass fairings.

3. How Geopolitical Factors Shape Material Choices for Custom Fiberglass Motorcycle Fairings

Geopolitical realities significantly influence material selection in custom fiberglass motorcycle fairings compared to alternatives like carbon fiber or metal alloys. Supply chain stability is a prime concern as geopolitical tensions disrupt access to essential raw materials such as fiberglass resin or specialized composites. For example, resin components depend on petrochemical markets, which fluctuate with global political events and trade policies. Metals like aluminum alloys can face price spikes or scarcity due to tariffs or export restrictions tied to unstable mining regions or sanctions.

Unlike carbon fiber, which relies on limited producing countries for its precursor fibers, fiberglass benefits from broader and more politically stable sourcing. This diversity reduces risk and often translates into more cost-effective manufacturing with reliable availability. Manufacturers often strategically select materials based on regional production strengths and import/export regulations to mitigate risks.

Thus, geopolitical factors compel producers toward fiberglass in custom fairings as it offers an optimal balance of durability, design flexibility, and supply resilience. Understanding these dynamics is crucial when comparing materials on both performance and global sourcing grounds.

For more insights on innovative fairing options, visit Explore the Best Motorcycle Fairings at Summit Fairings.

4. Balancing Environmental Impact and Societal Value in Custom Fiberglass Motorcycle Fairings

Custom fiberglass motorcycle fairings present unique environmental and societal implications in comparison to materials like ABS plastic and carbon fiber. Fiberglass production demands significant energy and relies on petrochemical resins, contributing to carbon emissions and challenging disposal due to its non-biodegradable nature. While ABS plastic is also derived from fossil fuels, it offers recyclability, albeit limited by low recycling rates. Carbon fiber fairings excel in performance and weight reduction, potentially enhancing fuel efficiency, but their manufacturing is energy-intensive and recycling options remain costly and complex.

From a societal lens, fiberglass encourages artisanal craftsmanship, enabling riders to embrace personalized designs through easier shaping and repair. In contrast, ABS plastic’s mass production supports affordability and widespread availability, meeting the needs of consumers seeking durable, cost-effective options. Carbon fiber’s premium cost positions it primarily within high-performance niches, limiting accessibility for many enthusiasts.

Choosing between these materials involves weighing environmental sustainability against the cultural and economic dimensions of customization, with fiberglass standing out as a versatile yet environmentally complex option. For further insights on material options and performance, see Hexcel’s carbon fiber composites[2].

Chapter 6: Market Providers and Availability of Custom Fiberglass Motorcycle Fairing Kits

1. Innovations Driving Availability and Fitment Precision in Custom Fiberglass Motorcycle Fairing Kits

Market providers of custom fiberglass motorcycle fairing kits have embraced technological innovations that elevate material quality, fitment accuracy, and customization flexibility. While ABS plastic fairings remain popular for their OEM-like precision and ease of assembly, fiberglass kits offer unmatched design freedom, allowing for unique shapes and personalized finishes. Advances in molding techniques and multi-layer paint applications deliver durable, corrosion-resistant panels that retain lightweight strength. Many suppliers now include pre-drilled bolt kits and adjustable windshield options to simplify installation, catering to diverse motorcycle models and rider preferences.

The resurgence of fiberglass is driven by its cost-effective durability and versatility, especially for cruiser and Harley-Davidson-style bikes. Although carbon fiber is becoming more prevalent due to its superior strength-to-weight ratio, fiberglass continues to dominate the custom market for riders prioritizing style and affordability. Online platforms expand access, with a wide range of customization options and price points, ensuring riders find kits perfectly suited to their motorcycles and aesthetics. These market advancements support riders seeking artistic yet reliable fairing solutions.

For more on fairing options and customization, explore this comprehensive source on motorcycle fairings.

2. Economic Dynamics Shaping the Supply and Demand of Custom Fiberglass Motorcycle Fairings

The market for custom fiberglass motorcycle fairing kits thrives on a balance between cost efficiency and performance. Fiberglass offers an economical alternative to carbon fiber and ABS plastic, appealing especially to riders who value durability, repairability, and customization possibilities. Material costs remain a critical factor, with fiberglass being less expensive and easier to work with than composite rivals. This affordability attracts sportbike enthusiasts and racers who often require lightweight, aerodynamic parts at a competitive price point.

Globally, the market is expanding steadily, driven by increased motorcycle sales and a growing culture of personalization, notably among models like the Honda CBR1000RR. Asian manufacturers dominate production, providing competitive pricing and established supply chains, albeit sometimes requiring minimum order quantities that can challenge smaller buyers. Emerging trends toward reshoring composite manufacturing also hint at future shifts in availability and pricing.

Demand for customizable shapes and finishes underscores fiberglass’s advantage, as riders seek both aesthetic and performance upgrades. This creates a dynamic ecosystem where economic factors interlace with consumer tastes, supporting sustained growth. For those interested in exploring a wide variety of options, Summit Fairings offers valuable insights into affordable aftermarket choices.

More details on market growth can be found through industry forecasts highlighting a near 7% CAGR through 2028 source.

3. How Geopolitical Dynamics Shape the Supply and Reach of Custom Fiberglass Motorcycle Fairings

The availability and distribution of custom fiberglass motorcycle fairing kits are deeply impacted by geopolitical dynamics that govern global trade, raw material supply, and regulatory frameworks. Trade barriers like tariffs and sanctions can restrict manufacturers’ ability to export, limiting access to diverse markets and influencing pricing. Fragile supply chains, especially for critical inputs like fiberglass fibers and resin, frequently suffer delays due to political instability or restrictive trade policies, increasing costs and causing shortages. Additionally, government regulations and subsidies vary widely, where supportive policies foster local production and innovation, while restrictive measures can suppress both manufacturing and market entry. Regional manufacturing hubs in geopolitically stable countries provide more reliable supply flows, while instability in key resin or fiberglass-producing regions can ripple worldwide, affecting kit availability. These interconnected geopolitical factors dictate not only which providers can sustain market presence but also shape the range and cost of custom fiberglass fairings, balancing supply chain resilience with competitive access. For more insights on securing diverse motorcycle fairing selections, explore our ultimate source for motorcycle fairings. Detailed analyses in related industries highlight how international trade and government policy intricately influence raw material-dependent markets ([2]).

4. Consumer Customization Trends and Material Innovations Shaping Fairing Kit Markets

The custom fiberglass motorcycle fairing market is evolving, driven by riders’ growing appetite for personalization and enhanced performance. Enthusiasts prioritize fairings that blend aesthetic appeal with functional improvements, such as better aerodynamics and airflow management. This demand encourages providers to produce model-specific kits tailored to both style and riding dynamics. Alongside traditional fiberglass, advanced composites like carbon fiber are gaining traction for their superior lightness and strength, albeit at a higher cost. Such material innovations expand options but require manufacturers to balance quality, affordability, and production complexity. Market providers increasingly adopt bespoke production models, allowing customers to specify unique fitments and finishes, aligning with society’s broader inclination toward individualized products over mass-produced parts. Economic factors and supply chains add further complexity, as raw material costs and composite manufacturing challenges influence fairing availability and pricing. Ultimately, this interplay of consumer desires, material advances, and adaptive production methods shapes the accessibility and diversity of custom fiberglass fairing kits today. Learn more about these evolving options through Summit Fairings’ unmatched choices in motorcycle fairings.

For insights into high-performance composites relevant to this market, see Hexcel’s contributions to advanced materials across industries: https://www.hexcel.com/.

Final thoughts

Custom fiberglass motorcycle fairings offer a unique intersection of craftsmanship, design flexibility, and functional benefits that appeal distinctly to motorcycle enthusiasts, particularly in the cruiser segment. For business owners, understanding the intricate materials and manufacturing processes lays the foundation for maintaining quality and innovation. Appreciating aerodynamic design principles ensures products meet both aesthetic and performance needs. Knowledge of installation nuances, especially for popular brands like Harley-Davidson, delivers smoother customer experiences and fewer fitment issues. Embracing customization options unlocks vast creative potential that draws riders seeking individuality. Comparing fiberglass to other materials highlights why fiberglass remains a core selection for custom bodywork. Finally, staying informed about current market providers and kit availability facilitates strategic sourcing and competitive positioning. Harnessing this comprehensive perspective equips businesses to thrive within the custom fiberglass fairing market by delivering superior products and service tailored to evolving rider preferences.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined