Custom motorcycle fairings are more than just aesthetic upgrades; they represent a fusion of engineering, personal expression, and performance enhancement. As motorcycles become an extension of their riders’ identities, the demand for unique, high-quality fairings continues to rise, compelling business owners to recognize this growing market. This article will delve into the significance of custom fairings in personalizing motorcycle aesthetics, explore the technical innovations in materials and designs influencing the industry, and analyze the global supply chain dynamics that drive production and distribution. Together, these insights will equip you with a comprehensive understanding of the custom motorcycle fairing landscape, essential for tapping into this lucrative business opportunity.

Form as Identity: How Custom Motorcycle Fairings Shape Personal Style and Machine Performance

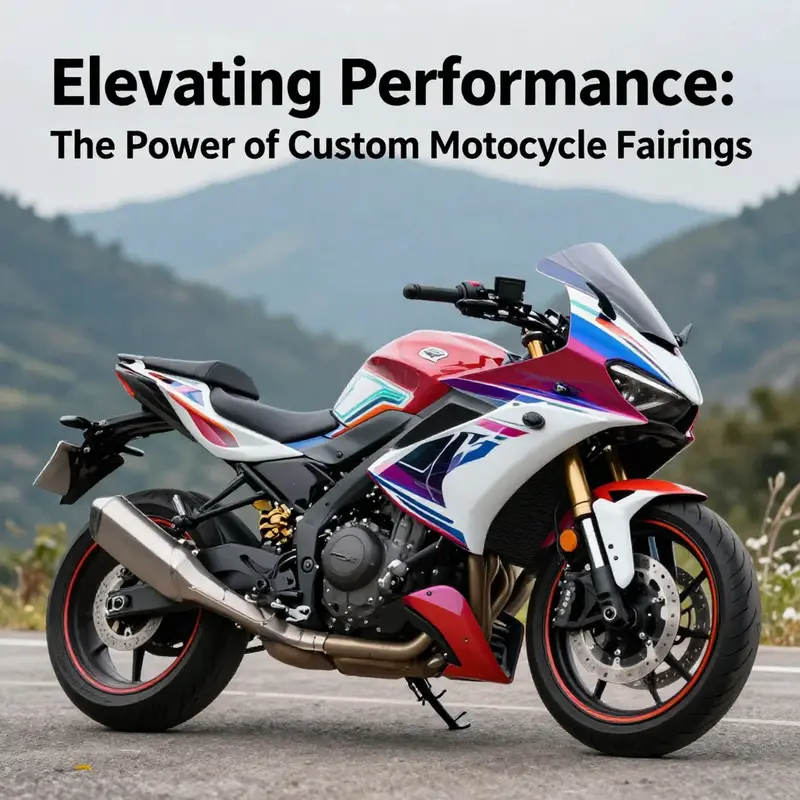

A motorcycle is more than a set of wheels and an engine; it is a moving canvas where a rider translates taste, philosophy, and ambition into metal, resin, and light. Custom motorcycle fairings sit at the intersection of artistry and engineering, offering a language through which a rider can claim ownership of a machine that would otherwise speak in factory tones. The fairing is the most visible expression of a rider’s persona—the first impression a passerby perceives as the bike comes toward them. But the impact of these body panels goes beyond aesthetics. The shape, the lines, and the way light falls on them influence wind flow, cockpit comfort, and even the feedback the rider receives at extreme lean angles. In this sense, the fairing becomes a kind of hybrid sculpture and aerodynamic aid, a piece that governs both appearance and performance, while inviting a conversation between rider and machine about purpose, identity, and craft.

The design philosophy behind custom fairings rests on a simple truth: surface is structure. The contours that seem to be decorative are frequently engineered to channel air more efficiently, reduce turbulent wake, and shield the rider from the wind. The more ambitious the project, the more the designer considers a spectrum of forces acting on the bike at speed—the pressure differential over surfaces, the boundary layer behavior along curves, and the way air can be diverted toward radiators and brake cooling ducts without compromising the rider’s line of sight or the bike’s balance. This is where the line between form and function blurs, and the rider begins to see a fairing not as a shell but as a living part of the motorcycle’s performance envelope. The resulting silhouette often signals a rider’s intention: whether they seek a streamlined, race-inspired presence or a more restrained, café-inspired stance. The transformation is not merely cosmetic; it is a redefinition of how the bike behaves when the throttle opens and the road stretches ahead.

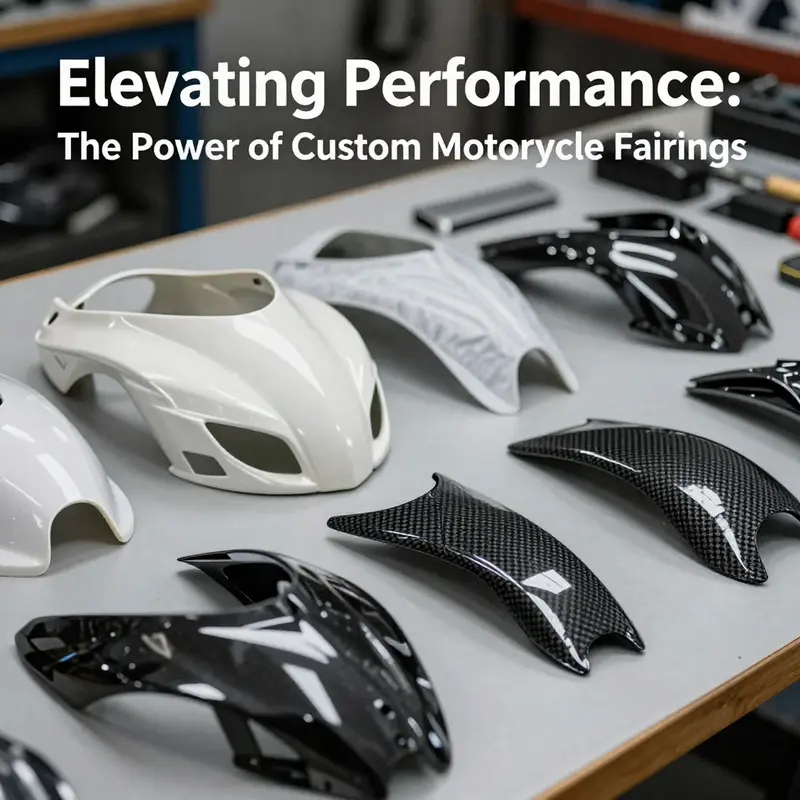

Material choices are the quiet architects of that transformation. ABS plastic offers a reliable, cost-conscious path to durable, impact-resistant panels that can be formed with precision and finished in a wide range of colors. Fiberglass remains a favorite for builders who want a good stiffness-to-weight ratio and easy repairability, especially when a project requires multiple iterations during the shaping and coating stages. Carbon fiber, while the most expensive option, delivers exceptional stiffness and a visual language of performance that many riders crave. The lightness and strength of carbon fiber align perfectly with a rider’s desire for an aggressive profile and high-speed handling, yet its cost demands careful budgeting and a clear plan for installation and maintenance. These materials also respond differently to finishing techniques. Water transfer printing, for example, can render complex graphics with a fidelity that rivals traditional paint, while powder coatings and clear coats can provide a durable, high-gloss, or matte finish depending on the rider’s aesthetic. The interdependence of material science and artistry becomes obvious when the design moves from concept to physical form, because every choice echoes in weight, fit, heat management, and the tactile feel of the bike under the rider’s hands.

The aesthetics of customization extend far beyond the face of the fairing. A well-considered design weaves in not just color and texture but also functional details that enhance the rider’s experience. Integrating lighting elements, whether as subtle accents or as primary visibility features, requires careful attention to electrical routing, heat dissipation, and compatibility with the motorcycle’s existing electronics. Graphics, too, are more than decoration; they act as a personal signature, a guide that can emphasize the bike’s line, highlight engineering features, or tell a story about the rider’s journey. The ability to tailor the graphics through techniques like water transfer printing enables complex motifs to wrap around curves and corners with a seamless continuity that hand-painted schemes seldom achieve. Even small decisions—such as the finish on fasteners, the visibility of mounting points, or the alignment of a badge with a flow line—contribute to a sense of cohesion that elevates the entire machine from a collection of parts to a unified narrative.

The cultural dimension of this practice is not incidental. A recent cultural appraisal from a major media outlet described custom bikes as a form of mechanical and artistic perfection, a lifestyle defined by personality and passion. The idea that a rider’s machine is a “piece that can run” speaks to a broader reverence for how function and artistry can coexist on two wheels. In this sense, the fairing becomes more than a protective enclosure or a surface to paint; it becomes a declaration of identity, a statement about how a rider relates to speed, to the road, and to a community of makers who see in metal and resin a shared language. This ethos invites riders to push the boundaries of what a production platform can offer, to reinterpret standard geometries, and to craft something that feels not borrowed from a catalog but earned through process, trial, and a personal vocabulary.

For riders who want to push the boundaries of style and efficiency, fairing design opens doors to a spectrum of configurations. A minimalist quarter fairing can evoke the clean lines of a café racer, stripping away extraneous mass to emphasize silhouette and rider posture. A full fairing kit can dominate a stance, turning the bike into a sculpture of speed with integrated ducts and aero wings that hint at wind tunnel refinement. Materials like carbon fiber grant a high-performance sheen, while the gloss of ABS or the rugged texture of fiberglass can be used to achieve a distinct tactile identity. The choices extend to how these panels meet other rider-driven elements, such as the integration of internal routing for cables, a design that preserves a clean outer edge while ensuring the mechanicals stay accessible for maintenance. The overall effect is to magnify the rider’s intent: a statement that distance itself is negotiable when the form of the machine is tuned to the rider’s grip, stance, and rhythm on the road.

For those exploring the practical path to customization, the process often begins with a concept and ends with a finished, road-ready fairing. Conceptual sketches or digital simulations provide a visual frame and a plan for how the fairing will wrap around the bike’s existing lines. The next steps typically involve 3D modeling or physical tracing to ensure an exact fit around essential components such as the throttle, brake, and clutch lines, as well as sensor housings and cooling inlets. The work then advances to shaping, trial fittings, and iterative refinements. It is here that the rider’s patience and precision become as important as the material and the aesthetic: the best outcomes arise when design, engineering, and practical testing are allowed to converge in a disciplined workflow. The result is a fairing that not only looks the part but also integrates with the bike’s mechanical and electronic systems in a way that feels intuitive to ride and robust under the demands of real-world use.

For riders and builders who prefer a direct, model-specific starting point, there are curated options that simplify the search. A dedicated Honda fairings collection, for example, offers ready-to-fit ABS kits and composite panels in a range of finishes. The collection serves as a practical bridge between a rider’s vision and a functional installation, providing a trusted baseline from which to customize further. This approach reduces the guesswork while preserving room for personal touches, whether that means adding a custom color accent, tweaking the airflow path, or selecting a particular surface texture that resonates with the rider’s sensibility. The ability to begin with a solid, compatible framework can empower a broader spectrum of enthusiasts to pursue ambitious aesthetics without sacrificing reliability or performance. For those who wish to explore this path, the Honda fairings collection stands as a useful waypoint—a starting point that invites experimentation while keeping the project anchored in tested fitment and finish.

From the perspective of the market, consumers now have access to an expansive ecosystem that supports both the artistry of customization and the pragmatics of living with the bike. The market for full body kits and individual components is diverse enough to accommodate both casual enthusiasts and serious builders, with materials ranging from inexpensive ABS to premium carbon fiber. The availability of ready-to-ship parts through e-commerce platforms makes it possible to begin a project with a clear sense of cost and lead time. At the same time, the option to commission bespoke work from skilled fabricators introduces a layer of personalization that stands apart from mass-produced, off-the-shelf solutions. The interplay between off-the-shelf convenience and bespoke craftsmanship creates a dynamic landscape in which riders can weave their personal preferences into the machine’s very skin. It is this adaptability that sustains the culture around custom fairings, enabling riders to align form with function as their skills mature and as their riding goals evolve.

Yet, alongside opportunity lies responsibility. The decision to modify a bike’s fairing implicates safety, legality, and reliability. Clearances around the wheels, chain, and steering must be maintained to avoid interference with motion or control systems. Airflow must support rather than obstruct engine cooling and brake performance, especially at high speeds or during sustained riding in warm climates. The installation process should account for the added weight and potential changes to the bike’s front-end geometry, which can alter handling characteristics if not calibrated properly. Warranties and service plans may also be affected when modifications involve non-original parts, so it pays to pursue fairings from reputable sources that offer fitment guarantees, documented mounting procedures, and quality control records. In short, the journey from concept to rideable, personalized fairing is a careful blend of design ambition, material science, practical engineering, and a respect for the machine’s core performance envelope.

On the supply side, the global ecosystem that supports custom fairings reflects specialization and scale. The manufacturing heartland centers in Asia have matured into hubs where quality, speed, and customization converge. Regions with distinct strengths offer buyers and builders different avenues to realize their visions. One cluster focuses on high-volume production with rapid turnaround, delivering standard lines and iterations of popular shapes quickly to the market. Another cluster emphasizes precision engineering and complex composite parts, supporting more intricate geometries and demanding tolerances. A third region provides cost-effective solutions for standardized designs that still require dependable fitment. This geographic specialization allows buyers—whether OEMs seeking consistent supply, distributors expanding their catalog, or boutique brands pursuing unique aesthetics—to align supplier capabilities with project requirements, lead times, and budget constraints. The result is a mature, globally integrated supply chain where a rider’s creative impulse can travel from concept to measurable performance with a reasonable degree of predictability.

The consumer-facing side of the market has likewise broadened. Ready-to-order fairings on large e-commerce platforms have democratized access to high-quality parts for riders around the world. A typical ABS plastic full fairing kit can be priced in the lower hundreds, offering a balance of affordability and appearance, while more specialized or carbon-fiber options rise in price in proportion to weight savings and thermal performance. The ranges reflect not only material choices but also the level of customization, the complexity of the design, and the precision of the finish. It is not uncommon for builders to start with a base kit and then layer in custom graphics, detachable panels, and integrated features such as artful air channels or light integrations. The accessibility of these parts empowers a wider audience to engage in customization as a form of personal expression, while still relying on the durability and consistency that come from established production methods and quality control protocols.

As riders pursue personalization, they often keep an eye on the long arc of ownership. A fairing’s appearance will age differently depending on the environment, exposure to UV light, and the heat cycles it experiences during riding. Carbon fiber, while aesthetically appealing and exceptionally stiff, can be more sensitive to certain environmental conditions and may require specialized finishing and protection. ABS surfaces can be repaired and refinished more readily but can scratch or ding more easily than carbon fiber. The design decision thus becomes a calculation about how much daily practicality a rider is willing to trade for an elevated visual statement. In many cases, riders seek a balanced approach: a striking silhouette that remains durable in daily use, with maintenance routines that keep the finish resilient and the fitment precise after years of riding. The result is a personal machine that wears its creator’s choices with a quiet confidence, a bike that tells its owner’s story every time it is rolled out of the garage.

For those who want to begin their journey with a structured, road-tested starting point, there are curated pathways to exploration that respect the rider’s desire for both individuality and reliability. A practical route is to explore collections that focus on a specific brand’s fairings, which can provide a coherent baseline in terms of geometry, mounting points, and serviceability. Such a starting point helps ensure that the initial investment yields a predictable upgrade path, reducing the risk of misalignment between the rider’s vision and the bike’s actual capability. The collection approach does not shut out experimentation; rather, it creates a stable framework within which the rider can introduce personal touches—whether that means a custom color story, a unique graphic vocabulary, or specialized airflow features that align with their riding style.

In the end, the choice of a fairing becomes synonymous with the rider’s approach to speed, craft, and identity. The fairing may be the first thing others notice, but it is what lies beneath—the fit, finish, and integration with the bike’s performance systems—that validates the investment and sustains the rider’s passion over time. The chapter that begins with a desire for self-expression through a sculpted shell gradually reveals itself as a dialogue about discipline, taste, and the shared culture of riders who see their machines as more than transportation: they are personalized, high-performance canvases that move, breathe, and endure the road’s demands. For those who want to learn more about how these choices translate into practical, installable configurations, a detailed technical overview of fairing kit specifications and applications offers a grounded framework to guide future work. This resource provides the technical underpinnings necessary to connect aesthetic ambition with mechanical reality, ensuring that style and safety remain in harmony as the project progresses.

For readers seeking a concrete starting point within this broader landscape, the Honda fairings collection provides a practical avenue to begin the journey. It offers a curated assortment of ABS and composite panels designed for straightforward fitment, finished in a variety of tones and textures that can be customized further. This pathway supports the idea that personalization can be both accessible and faithful to the bike’s original proportions, preserving handling geometry while enabling expressive detailing and color coordination. If you explore the collection, you will notice that the parts are designed to align with existing mounting points and contours, minimizing the need for invasive modifications and giving riders confidence as they plan their next upgrade. The goal is to empower enthusiasts to translate their aesthetic intent into tangible components that integrate cleanly with the machine’s core architecture, rather than forcing the machine to adapt to a difficult or fragile visual statement. The result is a coherent, expressive motorcycle that remains reliable on the road and compelling to the eye.

From a practical viewpoint, the decision to pursue customization should be grounded in a clear sense of the rider’s goals. Are you chasing a sharper, more aggressive stance for track days? Do you want a cleaner, minimalist profile that emphasizes rider posture and line? Or are you seeking a dramatic visual story that turns heads at every stoplight? Each objective correlates with different material choices, panel counts, and finishing techniques, yet all paths share a common thread: the fairing is a scalable project. It can be approached as a series of staged refinements—starting with a base kit, then adding targeted components like windshields or side covers, and finally layering in custom graphics or performance-oriented aero features. The pace and scope of the project should reflect the rider’s capabilities, budget, and risk tolerance, while maintaining a clear eye on safety and maintainability. If the journey is well planned, it can yield a motorcycle that not only looks like it is moving at speed but also feels more nimble, stable, and responsive at the helm.

As a final thought, it is worth recognizing the broader ecosystem that supports these transformations. The global supply chain, with its clusters of specialized production and a mature e-commerce marketplace, creates a fertile ground for riders to explore ideas and bring them to life. This ecosystem rewards thoughtful design by rewarding accuracy in fitment, finish, and compatibility with the bike’s existing systems. It also invites ongoing collaboration between riders, fabricators, designers, and technicians, an exchange that sharpens skills, extends the life of the customization, and sustains the cultural movement around custom fairings as a legitimate, aspirational form of personal artistry. In a world where motorcycles are increasingly seen as platforms for self-expression and technical ingenuity, the fairing stands as a powerful testament to the fusion of aesthetics, engineering, and identity. For readers who wish to dive deeper into the technical foundations of this practice, a comprehensive resource on fairing kit specifications and applications can provide a rigorous blueprint for translating creative ideas into reliable, road-ready hardware. This bridge between imagination and execution is where customization becomes a craft, and where a rider’s story truly takes shape on two wheels.

Shaped for Speed: Materials, Modularity, and Aerodynamics Driving Modern Custom Fairings

Shaped for Speed is no longer a slogan carved into the fairing’s silhouette. It is the converging point of material science, manufacture, and meticulous engineering that defines today’s pulse of the custom motorcycle fairing ecosystem. Across the spectrum of riders—from weekend enthusiasts chasing a cleaner wind profile to builders who want a distinct silhouette that matches a rider’s identity—the fairing has evolved from a simple shell to a carefully tuned system. The chapter that follows threads together three core innovations that now dominate the landscape: modularity, advanced materials, and aerodynamic refinement, all woven into a narrative that treats the fairing as a living component of the bike rather than a fixed cosmetic plate. The result is a more versatile, safer, and more aesthetically expressive platform that can be tailored with surprising precision to individual preferences and riding contexts.

At the heart of modern fairing design is modularity. The market has shifted toward adaptable systems that can be assembled, reconfigured, or upgraded without threatening the structural integrity or aerodynamic profile of the bike. Components that snap together, hinge open for maintenance, or interchange with other sections allow riders to experiment with front-end balance, weight distribution, and wind protection without needing a full fabrication from raw materials. This modular approach does more than ease customization; it also supports durability in the field. Riders who routinely swap track-focused pieces for street-legal panels can do so without a toolkit full of specialty fasteners or complex alignment procedures. The modular ethos has grown from a convenience to a principle, shaping how aftermarket suppliers and OEMs think about compatibility, repairability, and lifecycle value. As a result, designers are drawing on standardized interface geometries and resilient mounting strategies that maintain reliability while maximizing the range of personalization a rider can pursue.

The second pillar—advanced materials—has transformed what is possible in both form and function. Carbon fiber-reinforced polymers (CFRP) offer a compelling combination of lightness and strength, enabling fairings to carry more aggressive curves or sharper aero profiles without adding weight penalties. CFRP is often paired with carefully chosen resins and protective coatings to resist impact, UV exposure, and the inevitable wear from road grit. Yet CFRP is not the only high-performance material. Advanced thermoplastics, including impact-resistant blends of polycarbonate and ABS, bring a different set of advantages: skinnier gauge walls for tighter tolerances, easier repairability in some cases, and cost efficiencies in mass-produced shapes. These plastics also enable intricate geometry, allowing designers to push beyond traditional lamination processes into shapes that can support embedded channels for air and drainage or integrated light and sensor housings. The broader composite family—whether woven, stitched, or molded into sheets—has unlocked a spectrum of aerodynamically attuned forms that were difficult or time-consuming to realize with earlier technologies. This material mix is not simply about lighter weight; it is about shaping the air with a deliberate, repeatable fidelity that translates into measurable gains on the track and in street riding.

The third strand in this triad concerns aerodynamic innovations that make the most of these materials. Modern round universal headlight fairings and their successors are no longer generic shells; they are carefully engineered ensembles. Precision molds and surface treatments stabilize airflow under a wide range of speeds, temperatures, and riding positions. The aim is not just lower drag; it is steady, predictable airflow that reduces buffeting, minimizes lift at high speeds, and stabilizes the bike’s handling when the wind shifts or the rider changes posture. The integration of aerodynamics with aesthetics is particularly evident in the way curves, spoilers, and wind-deflectors are designed to work as a unified system. When a rider adds a small winglet or a refined tail piece, the aerodynamic effect is more than visual drama—it becomes a lever that can fine-tune cornering response, feedback through the handlebars, and the rider’s confidence at the limit. Designers increasingly use wind tunnel data and computational fluid dynamics to prototype shapes, but they also rely on empathetic, rider-centered testing. They watch how a wind gust interacts with the shoulder of a fairing, how turbulence forms behind a windscreen at different rider positions, and how the material’s stiffness influences the way the surface deflects under load. The result is a fairing that not only reduces drag but also returns a dose of tactile feedback that a rider can feel as a more composed ride at high speed.

As these threads intertwine, the fairing’s role in the rider’s experience becomes more nuanced. The aesthetic dimension—color matched finishes, glossy coatings, and crisp graphics—has grown in tandem with performance. Coating technologies now enable precise color matching so that inner and outer geometries appear seamless, even when riders opt for bold, high-gloss finishes or subtle, understated tones. The Alpine Green or similar tones once described as niche are increasingly accessible because the coating and preparation processes have become more controllable and repeatable across batches. This is not vanity alone; color and gloss contribute to psychological satisfaction, a rider’s sense of pride, and even the perceived perceived quality of the entire machine. The intersection of color, light, and curvature requires a disciplined approach to surface preparation, primer chemistry, and the flawless execution of transfer finishes. It is a discipline that sits at the crossroads of art and engineering, where the final look must withstand hot days, rain-soaked miles, and the abrasion of daily use while still conveying the intended mood of the rider’s creation.

In the broader context, these innovations do not exist in a vacuum. The market’s breadth—from global manufacturing clusters to local, hand-finished builds—reflects a supply chain that can deliver high-performance materials at scale. Regions with concentration in advanced composites, resin systems, and thermoplastic processing offer different advantages: some excel in high-volume production with short lead times; others specialize in precision, small-batch work that enables bespoke shapes and precise tolerances. This geographic specialization is not just a footnote; it informs how riders and builders select partners and plan projects. When a rider wants a fairing that perfectly mirrors a desired silhouette, the choice of material and process determines whether the look is achievable within a given budget and timeframe. The same decision also affects weight distribution, impact resistance, and repairability after a fall or collision. The result is a balancing act that demands a holistic view—from the choice of resin to the method of assembly and the final presentation of the surface.

The design philosophy supporting these innovations is stance-neutral: it does not privilege one riding environment over another. A well-tuned fairing should deliver wind protection and stability whether the rider is carving through mountain passes or cruising at highway speeds. It should be robust enough to endure gravel and rain, without requiring constant maintenance or overclocked repairs. It should also offer a path to personalization that remains compatible with the rider’s evolving taste and performance demands. In practical terms, modular components can be upgraded as new shapes and coatings become available, while the underlying materials provide a stable foundation that won’t crumble under daily use. This convergence of modularity, materials, and aerodynamics shapes a future where riders can express their identity without compromising ride quality or safety.

For readers who want a tangible sense of how these principles map onto real-world silhouettes, a curated Kawasaki fairings collection provides an illustrative guide to the kinds of shapes and interfaces that contemporary builders favor. The collection highlights how modular interfaces and composite panels translate into a coherent, upgradeable front end. Kawasaki fairings collection demonstrates the practical outcomes of this design language—how a rider can swap a front-panel configuration for a different windscreen angle, how a carbon-fiber stack can be replaced with a thermoplastic alternative without altering mounting points, and how the overall geometry maintains its aerodynamics across a range of configurations.

Beyond the bench and showroom floor, the conversation about fairing innovation is anchored in the daily realities of riders who push their machines to the edge. The combination of lighter materials, modularity, and aerodynamic refinement translates into tangible benefits: reduced fatigue from wind pressure, better stability in crosswinds, and more predictable handling through high-speed corners. Even when a rider is not racing, these improvements contribute to a more confident, enjoyable ride. The fairing ceases to be a mere shell and becomes a tuned feature that responds to the rider’s body position, the bike’s frame, and the road surface. When done well, the fairing reads as a single, coherent piece of engineering, yet the builder can disassemble it, upgrade it, or tailor it to a night ride with the same ease that a musician tunes an instrument for a studio session.

As the chapter closes on the present moment, the future remains full of possibility. Self-healing coatings could extend the life of surfaces exposed to road salts, debris, and UV exposure by repairing micro-scratches before they propagate. Shape-memory polymers could enable panels to adapt to different speeds and impacts, self-adjusting stiffness or contouring to minimize drag in certain wind regimes. These ideas are not speculative fantasies but logical extensions of current practice, rooted in ongoing research and collaborative development across material science and motorcycle engineering. The path ahead is likely to hinge on smarter materials that intelligently respond to conditions while preserving the ease of customization riders expect. For builders and riders alike, the result will be fairings that are not only lighter and stronger but also more adaptive, more expressive, and more capable of evolving with each ride. The fairing becomes a dynamic, upgradeable interface between rider intent and machine performance, a tool that amplifies human skill rather than merely dressing the bike in a new exterior.

In sum, the innovations reshaping custom motorcycle fairings are less about a single breakthrough and more about a new way of thinking. Modularity creates a flexible backbone that supports rapid iteration. Advanced materials unlock forms and weights that were once impractical. Aerodynamic finesse turns fancy shapes into practical performance tools. The chapter’s through line is clear: today’s fairing is a platform for experimentation and a canvas for personal expression that also respects the rider’s safety and the bike’s handling integrity. When these strands are harmonized, the result is a differentiated riding experience—one where the lines between engineering, art, and sport blur into a single, purposeful statement on the road.

External resource: For a deeper dive into real-world uses and case studies of fairing systems in action, see the external reference at https://www.motorcyclefairing.com/real-world-uses.

From Mold to Market: The Hidden Architecture of Custom Motorcycle Fairings

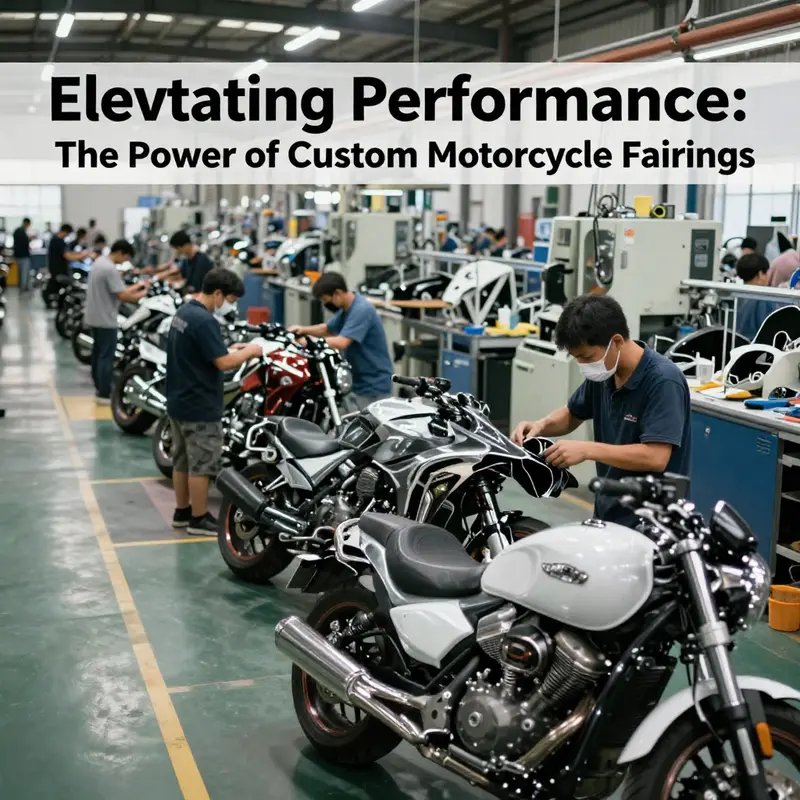

The global journey of a custom motorcycle fairing begins long before a rider ever straps on a helmet or wheels a bike into the sunlight. It starts in a tightly woven network of regional clusters that have grown into a seamless economy where design, materials, tooling, and finishing moves operate under one roof-spanning logic: speed, precision, and mass customization. The leading nodes of this network sit in coastal and near-coastal provinces where ports flank factories, warehouses, and finishing labs. In these hubs, the story of a fairing unfolds through a sequence of specialized steps, each tightly synchronized with the next, so that a concept born in a design studio translates into a physical shell that brings a rider’s vision to life. The scale of this operation is best understood not as a series of isolated shops, but as a vertically integrated ecosystem where mold engineering, composite fabrication, injection molding, CNC machining, surface finishing, and painting are all part of an end-to-end workflow that moves with the rhythm of demand and the precision demanded by performance riding.

The first piece of the puzzle is proximity to export ports. A fairing is typically one of the bigger, more fragile components in a bike’s assembly, and getting it to a customer in another country requires careful logistics. Ports that serve as conduits for fast, cost-efficient shipping reduce cycle times dramatically. In practice, this means that the largest engineering clusters have built shipping lanes and warehousing strategies around major gateways. The advantage is twofold: it shortens lead times for distributors and specialty brands that want to bring new shapes to market quickly, and it also enables smaller studios to participate in a globalization of style and function without carrying prohibitive inventory risk. What looks like a simple export line on a map is, in reality, a carefully tuned supply chain calculus, balancing air or ocean freight costs, batch sizes, and the reliability of carriers against the urgency of a rider’s project timeline.

Beneath the logistics surface lies the core of production strength: the material and process toolkit that lets a fairing do more than just clothe a motorcycle. ABS plastic injection molding remains the workhorse for high-volume, cost-conscious production runs. It offers predictable results, reasonable part-to-part consistency, and ample thickness control for impact resistance. It is not the only path, however. A tier of suppliers specializes in carbon fiber techniques, including both wet layups and more advanced dry carbon methods, such as 3K twill pre-preg with vacuum curing. These approaches yield parts that are lighter and stiffer, which can translate into marginal gains in handling at speed and improved acceleration response when smooth, clean aerodynamics are in play. A third stream—fiberglass reinforcement—often serves as a middle ground, delivering a blend of durability and affordability for riders who want a strong, visually striking shell without the premium price tag that carbon fiber can demand. The presence of multiple material pathways is not merely a diversification strategy; it is a risk management posture that allows manufacturers to tailor parts to different market segments, climates, and maintenance expectations.

In practice, the manufacturing ecosystem in these hubs emphasizes what researchers call vertical integration. Many suppliers manage design, prototyping, molding, priming, painting, and decal application in-house. This consolidation dramatically reduces lead times and blunts the risk of miscommunication between separate vendors, which can otherwise erode tolerances or alter surface finishes in ways that compromise aerodynamic performance or aesthetic fidelity. A fairing must not only fit its host model with exacting accuracy but also present a surface that accepts color, decals, and texture consistently across thousands of units and over the course of years. When a single facility handles measurement, molding, and surface treatment under a single quality system, the chances of deviation shrink to a narrow band, often measured in fractions of a millimeter for key contour lines. In a market that prizes aerodynamic alignment as much as visual impact, that precision matters. It matters especially when a rider pushes a machine toward the edge of its performance envelope, where even small irregularities can create flow separation, drag, and buffeting that degrade stability at high speed.

For buyers—whether they are regional distributors, specialty brands, or customization studios—the evaluation framework must move beyond price. The modern B2B purchasing decision for fairings rests on a handful of robust, data-driven indicators that illuminate a supplier’s reliability and capability. On-time delivery rates, for example, are not a vanity metric but a predictor of how well a supplier can synchronize with aggressive product launches and seasonal demand. A rate above 95 percent is often a baseline; anything lower signals gaps in planning or production capacity that could ripple through a distributor’s own commitments to customers, especially when a kit must arrive in time for a show or a custom build window. Reorder rates, a measure of repeat business, tell a story about customer satisfaction and post-sale performance. A rate above 30 percent indicates that the supplier is not merely a one-off partner but a consistent contributor to a brand’s ongoing catalog and customization workflow. Response time, typically under six hours for urgent inquiries, becomes a proxy for organizational discipline—an expectation that the supplier will engage quickly when a rider or a studio hits the brake on a design revision or a change in a material specification.

Material transparency is equally critical. OEM specifications demand certified resins and fibers, with traceable lot numbers and documented performance attributes. For buyers planning long-tail product lines or rev-share collaborations, this transparency is non-negotiable. The ability to scale—from the occasional one-off to large-batch production—defines a supplier’s appeal across the value chain. A vertically integrated supplier can navigate this scaling by applying a modular approach to design and production. They can start with a base fairing layup, then tailor variants through incremental changes in mold inserts, surface finishes, or decal layers, without destabilizing the core process. This flexibility is especially valuable for niche products, such as cafe racer-inspired fairings or sport-bike replicas, where the market demands both authenticity and the option for customization without initiating a new production line.

The market dynamics surrounding this supply chain are shaped by the demand for both highly specialized, model-specific kits and more broadly styled, retro-inspired bodies. The appetite for cafe racer aesthetics—clean lines, tapered tail sections, and a minimalist cockpit silhouette—has driven a significant portion of recent innovation. Yet the allure of model-specific kits remains a powerful driver as well, since riders who plan to keep or restore a machine for a prolonged period seek a fairing that aligns with the machine’s geometry and performance profile. This dual interest—the nostalgia-forged cafe racer look and the precision-forged fit of a modern sportbike—pushes suppliers to maintain a versatile toolkit. It encourages experimentation with different composites, finishes, and manufacturing tolerances while preserving the core standards that define safe, durable, and aesthetically compelling fairings.

In the production hubs themselves, the rhythm of work is organized around a set of interdependent capabilities. Mold engineering blends into precision tooling; CNC-machined aluminum molds ensure the reproducibility of complex aerodynamic curves with tolerances commonly quoted as within half a millimeter. The stories behind those measurements reveal a culture of meticulous validation: prototype parts are often tested in wind tunnel rigs or computational fluid dynamics simulations to verify that the intended aerodynamic benefits will manifest in real-world riding. The downstream finishing steps—priming, painting, and decal application—transform a blank composite into a market-ready component with a consistent color and gloss that remains stable through time and exposure to sun, rain, and abrasion. The best suppliers have built their own painting lines or partnered with trusted finishing houses that can reproduce color formulas with little drift across batches. For a customization studio, this means being able to offer a rider a palette and texture that stays faithful to the concept of the design, even after months of street use.

This intricate capability set explains why the geographic clustering of manufacturing matters. Guangdong’s strength lies in high-volume throughput and rapid shipping lanes that feed large distributors and OEM-adjacent networks. Zhejiang and Jiangsu excel in more technically demanding components and complex laminates, where precision matters as much as price. Fujian offers a cost-effective pathway for standardized designs, enabling studios to test new shapes at lower risk. The convergence of these regional strengths creates a dynamic ecosystem that can respond to shifting tastes in the aftermarket—the move toward sharper lines, more aggressive profiles, or more refined edge radii—without sacrificing reliability. And because these clusters host whole value chains under one roof, lead times shrink when a design moves from concept to tooling to finished part. A design intent, once validated, can evolve into multiple variants with only modest incremental changes to the mold or layup schedule, allowing studios to offer an array of options without overwhelming inventory risk.

The influence of global distribution channels on consumer access to fairings cannot be overstated. The lifecycle from design to door involves not only production planning but also the management of risk and the accommodation of diverse regulatory environments. While many buyers want to minimize upfront capital by leveraging ready-to-order kits, others seek a bespoke route—where fit, finish, and materials are aligned to the rider’s precise preferences and the bike’s unique geometry. In either case, the supply chain needs to accommodate small-batch custom orders alongside large-volume runs. The suppliers that succeed in this space are those who can apply a flexible manufacturing mindset to the discipline of mass production, maintaining tight tolerances and consistent finishes while offering customization options such as water transfer printing, color customization, and decal customization without sacrificing turn-around speed.

Within this context, the role of digital enablement becomes central. Modern suppliers rely on data to optimize production planning, monitor quality, and communicate with buyers in real time. A robust data backbone makes it possible to forecast demand with greater accuracy, track material usage against bill-of-materials, and identify bottlenecks before they translate into late deliveries. Buyers benefit from dashboards that reveal on-time performance, material certifications, and response times, empowering them to make decisions about supplier partnerships with clarity rather than conjecture. The result is a supply chain that not only delivers parts but also delivers confidence—confidence that a rival’s new design can be produced to the same tight standards and delivered on schedule to keep a rider’s project on track.

Against this backdrop, the everyday rider might encounter the realities of the market differently depending on how they source their parts. For some, the route is through large-scale online marketplaces that aggregate offerings from many suppliers, providing a catalog-like experience where price, lead time, and finish options are the primary selectors. For others, the path leads through customization studios that curate a more intimate collaboration with a single or a few trusted partners, enabling iterative design discussions and hands-on review of sample parts. In both cases, the end result is a fairing that carries not only the machine’s silhouette but also the trust of a system that has been stress-tested across thousands of units and thousands of miles of road. The long arc of development—mold design, material selection, surface finishing, and color stability—becomes visible in the ride itself, where a rider experiences the airflow flow patterns, the protection offered from wind and debris, and the way the surface contours reflect the sun as the bike accelerates toward a horizon both practical and aspirational.

For readers who want a tangible sense of where these parts come from, consider the practical implications of this ecosystem for a rider assembling a project from the ground up. They will find that the fairing is not merely a decorative shell; it is a complex, engineered assembly with a history rooted in specific material science and manufacturing practices. The choice of resin systems, the orientation of carbon fiber plies, the thickness variations at leading edges, and the surface texture all contribute to outcomes that matter on the road: front-end stability, reduced buffeting, and an appearance that remains faithful under sun exposure and ride wear. The market accommodates this complexity by offering both standardized kits that emphasize reliability and whole-program partnerships that enable highly customized, performance-driven builds. The end-to-end flow—from design intent to the first ride out of the workshop—rests on a shared commitment to precision and a willingness to adapt to evolving rider expectations.

Riders seeking to understand how a company arrives at a specific fairing shape may not see all the steps on a showroom floor, but the chain of decisions is built on predictable ground: tolerances, finish, and materials. Tolerances determine how well the piece aligns with the bike’s frame, the accuracy of mounting points, and the fit of fasteners and gaskets. Finish choices determine how color and gloss endure exposure to heat, rain, and road debris. Material choices determine weight, impact resistance, and cost, as well as the long-term behavior of the part under temperature cycles and UV exposure. Each of these dimensions is influenced by the supplier’s capacity to manage a spectrum of processes—from the cleanroom-like precision of CNC tooling to the artful handwork of a painter who can reproduce a color and finish with high fidelity. And because all of these decisions must be executed within a budget and a schedule, the best suppliers blend process rigor with creative problem-solving, creating options that meet the needs of riders who want to push boundaries without compromising reliability.

The ecosystem also sits within a broader narrative about accessibility and globalization. While the production clusters concentrate in a few regions, the result is a democratization of access to premium-looking, high-performance fairings. A rider anywhere in the world can browse a catalog, select a finish, and expect reasonable delivery times. The online ecosystem that supports this exchange—whether through direct-to-consumer channels, regional distributors, or customization studios—has become the final leg of the journey from concept to ride. This is where the supply chain’s design ethos meets consumer expectations: fast, predictable, and customizable. It is a story not of a single factory but of a coordinated system that scales, adapts, and evolves with the rider’s imagination.

In this continuous evolution, it helps to map a few concrete realities about how buyers assess partners in this space. Data-driven performance metrics guide ongoing supplier relationships, and material transparency is non-negotiable for long-term collaboration. The global demand for niche products—whether retro-styled fairings that echo past aesthetics or ultra-modern kits that enhance aerodynamics—drives a steady cadence of innovation, while the supply chain’s capacity to absorb these innovations without sacrificing quality keeps the market healthy. The result is a dynamic, resilient ecosystem where creative design and engineering excellence are not separate ambitions but intertwined strands of a single, coherent workflow. It is a system built to support riders who want their machines to look as they feel when the throttle opens: confident, fast, and unmistakably their own.

For readers exploring the practical implications of this supply chain architecture in their own purchasing or production decisions, a representative catalog of model-specific aftermarket options can offer a useful lens into how the ecosystem translates design intent into a physical product. Accessing a catalog that presents a range of shapes and finishes can illuminate what is possible when a supplier can align fit, surface finish, and material choice with the specific geometry of a bike. In such catalogs, riders and studios alike can observe how different regions apply unique strengths to common design challenges—how lighter carbon fiber variants balance weight with rigidity, or how ABS variants achieve reliable, cost-effective mass production without sacrificing surface smoothness. The comparative exercise helps illuminate why some partnerships endure: they deliver not just a single part but a reliable, repeatable performance platform that can be trusted across a portfolio of builds.

As the chapter closes on the current landscape, the central message remains clear: the modern custom motorcycle fairing is the product of a globalized yet regionally specialized supply chain that harmonizes design ambition with manufacturing discipline. It is a structure shaped by proximity to ports, by the precise science of materials, by the discipline of in-house finishing, and by the patience to align supplier capability with rider dreams. It is a market that rewards those who can combine speed with accuracy, who can blend high-volume efficiency with the flexibility required by niche tastes, and who can translate a concept into a part that both looks and performs as intended under the road’s real, unpredictable conditions. The chain’s strength lies not in a single point of contact but in the alignment of many moving parts around a shared goal: to deliver the right fairing, at the right time, in the right finish, at a scale that makes customization a practical expectation rather than a rare exception.

For those who want a glimpse into a representative catalog environment that embodies these principles, a curated collection exists online that mirrors the kind of model-specific options riders seek when turning a concept into a built reality. See the Kawasaki fairings collection for a practical sense of how a catalog translates into fit and finish across a range of models and years. This example illustrates how a cataloged approach can support both scale and specificity, providing a framework for decisions about fit, color, and finish across multiple builds. Kawasaki fairings collection.

As a closing reflection, the chapter’s gaze beyond the workshop floor focuses on the comparative intelligence of the supply chain: how data, process discipline, and regional strengths converge to deliver not just a part but a consistent riding experience. The fairing is a symptom of a larger industrial system that has learned to balance the unpredictable desires of riders with the precision required by engineering. That balance is what enables riders to push their machines to new edges while feeling safe in the knowledge that the shell protecting the rider is crafted from materials and processes that meet or exceed the highest standards of reliability. It is a chain that is constantly recalibrating to meet new aesthetics, new performance benchmarks, and new expectations for international delivery times. The result is a living, evolving ecosystem where every fairing tells a story of collaboration across borders, materials science, and the shared aspiration for speed and style on the open road.

External resource for further reading on supplier benchmarks and procurement metrics provides a complementary perspective to this chapter. It offers a window into how industry guides and data-driven practices shape supplier selection in high-fidelity fairing production: https://www.supplierinsights.com/2025/11/25/oem-ninja-400-fairings-supplier-guide/.

Final thoughts

Custom motorcycle fairings have emerged as essential components in the biking community, blending personal style with performance enhancements. Their ability to improve aerodynamics and safety further solidifies their importance in the motorcycle industry. As the market continues to grow, business owners must stay informed about innovations in materials and designs while navigating the complexities of global supply chains to thrive. By embracing the potential of custom fairings, businesses can cater to the diverse needs of motorcycle enthusiasts, ultimately enhancing both their product offerings and customer satisfaction.