The motorcycle industry is witnessing a dynamic shift towards customization, with motorcycle fairings at the forefront. These aftermarket body panels not only enhance the aesthetic appeal of motorcycles but also impact performance, safety, and rider experience. For business owners in the motorcycle parts industry, understanding the multifaceted nature of custom motorcycle fairings is crucial. This article delves into essential components, including design and aesthetics, performance impacts, material comparisons, market trends, and sourcing strategies. Each chapter aims to equip you with insights to navigate this competitive segment and optimize your offerings effectively.

Contours of Wind and Style: Designing Custom Motorcycle Fairings for Performance and Personal Expression

The fairing is where wind, weight, and whimsy meet on two wheels. It is more than a protective shell; it is a canvas for a rider’s aspirations and a pragmatic instrument that can shape a bike’s character and its behavior on the road. In the realm of motorcycle fairing customization, the best designs emerge from a continuous negotiation between aerodynamics and aesthetics, between what the rider wants to see and how the machine behaves at speed. A well-conceived fairing does more than shield a rider from the elements; it aligns with the bike’s silhouette, enhances stability in the rider’s line of sight, and supports a design language that communicates the rider’s intent before the bike is even in motion. The craft rests on a simple truth: form follows function only when the function is chosen with intention, and the form is allowed to speak with restraint and clarity.

From the first sketch to the final paint, a custom fairing begins as a conversation about line and mass. Designers think in terms of how curves sweep along the chassis, where a radial bend can guide the air to minimize lift, and where a crisp edge can shed turbulence without creating buffeting against the rider’s helmet. The front contour typically dictates the bike’s head-on stability: a broad, smoothly rounded nose can distribute air pressure evenly across the surface, reducing abrupt pressure changes that might otherwise translate into steering input. The side panels and the fairing’s midsection carry their own aerodynamic duties, shaping the wake that trails behind the rider. When lines sweep back toward the tail with a progressive rhythm, they help to keep the flow attached to the surface longer, smoothing the transition from nose to tail and contributing to a stable ride at highway speeds and a decisive feel on the track.

The aesthetic dimension begins where engineering ends, or at least where it becomes a matter of taste. Color, texture, and finish do not merely decorate the skin; they interact with light, depth, and the bike’s proportions. A high-gloss finish can amplify the curvature of a half fairing, making a leaner silhouette appear even more dynamic. A matte or satin surface may emphasize the sculptural planes and reduce glare, which can be preferable for riders who spend long hours in the saddle. Surface texture—whether a smooth mirror, a brushed effect, or a subtle grain—affects how light plays across the curves, and in turn, how aggressively the eye perceives the machine’s speed. The choice of color schemes matters as well: two-tone schemes can accentuate the bike’s geometry, while a single, carefully tuned tone can unify a complex form into a single expressive line.

Designers often think in terms of integration, not isolation. The fairing must speak with the tank, the seat, the headlights, and even the mirrors. A harmonious relationship across these elements makes the bike read as a single organism rather than a collection of separate parts. In practical terms, this means paying attention to the joint lines where panels meet. The transitions should feel inevitable, not chosen by accident. Mounting points must be precisely placed so that the fairing aligns with stock brackets and hardware, allowing for easy service access while maintaining the clean look that defines a well-cut shell. This is where the craft moves from art to engineering: precise mold-making, accurate fitment, and careful surface preparation ensure the final paint looks even and the seams stay tight after weeks of weather exposure and vibration on rough pavement.

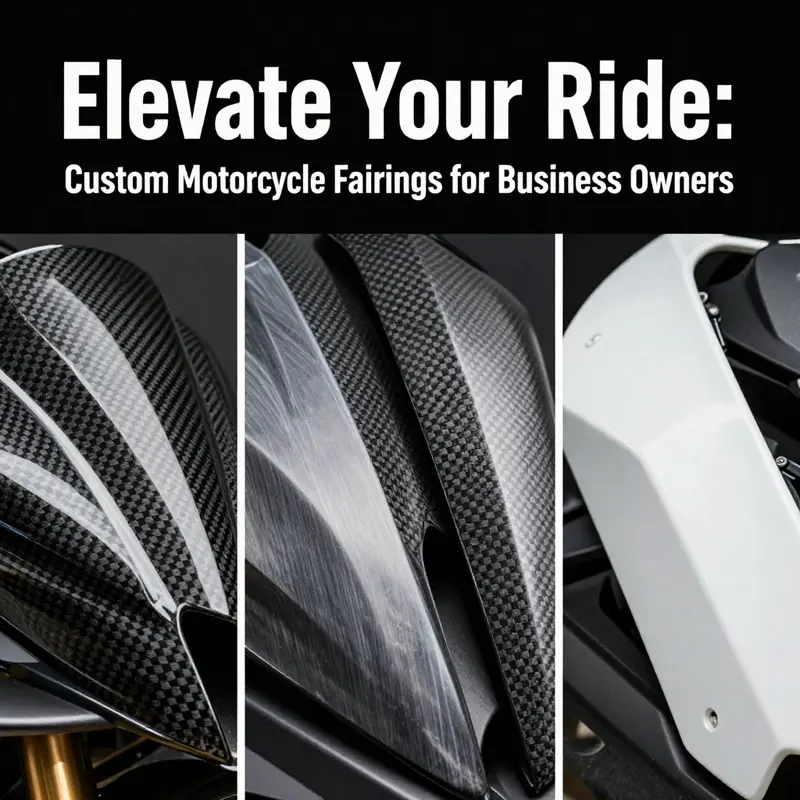

In the world of materials, the decision often crystallizes around three paths: fiberglass, carbon fiber, and reinforced composites. Fiberglass offers versatility and lower entry costs; it is forgiving in the hands of a custom shop and can be shaped with relative ease. It can, however, be more prone to cracking under high-stress impacts or if it is overworked by aggressive riding styles. Carbon fiber, by contrast, provides exceptional stiffness and a premium, high-tech look, with a lighter weight that contributes to the bike’s handling and feel. The trade-off is higher cost and a more demanding manufacturing process. Reinforced composites seek a balance, combining layers of fiber with resin systems that can deliver improved impact resistance and fatigue performance without the expense of full carbon fiber. Each option carries a different aesthetic: carbon fiber’s weave can read as a design feature in itself, a subtle reminder of engineering precision, while fiberglass surfaces invite bold custom graphics that ride close to the edge of artistic risk.

The surface finish plays a crucial role in how the final product is perceived. Clear coats must be hard enough to resist UV degradation and chemical exposure, yet flexible enough to tolerate small panel movements without cracking. A well-prepared substrate—meticulous sanding, careful filling, and controlled primer applications—forms the foundation for a flawless paint job. Painterly finishes, graphics, and protective clear layers add depth and longevity, but they also demand respect for the underlying geometry. Graphics should enhance the lines, not obscure them. A common strategy is to use graphics to draw the eye along a desired path, guiding attention toward the bike’s strongest features. It is the designer’s job to keep the visual cadence in harmony with the machine’s geometry, so the rider’s gaze travels along the fairing in a way that reads as speed rather than a static surface.

An important but sometimes overlooked element is proportionality. A fairing must scale with the bike’s overall silhouette. A misfit panel can produce a “stretched” or “squashed” look that unsettles the eye and, more importantly, perturbs the bike’s aerodynamics. Proportion also influences rider comfort. If a panel protrudes too aggressively around the knee or collides with the rider’s leg, it can create chafing or heat buildup. Conversely, a fairing that wraps too tightly can feel claustrophobic and impede access for maintenance. Modern practice recognizes these nuances: fairings are designed with generous tolerances for fitment, then fine-tuned in real-world tests to balance radical aesthetics with practical ergonomics and serviceability.

Inspiration travels through mood boards, sketchbooks, and digital libraries. Rider communities often converge on certain design cues that feel timeless—the way a tapering chin point can imply speed or how a broad shoulder line can project confidence. Pinterest and similar platforms serve as wellsprings of ideas, where curated images help riders articulate a personal language that they want to imprint on their machine. The most enduring designs, however, translate those moods into a language that respects the bike’s architecture. The result is a fairing that reads as a single, coherent idea: “this is a machine made for speed and a rider who values precision in both form and function.”

From a procurement perspective, the decision to pursue a custom fairing should start with fitment realities and the rider’s goals. Compatibility with the motorcycle’s structure is non-negotiable; the panels must align with mounting points, fuel tank geometry, and the rider’s stance. Material choice intersects with budget and durability expectations. The manufacturing process—from mold-making and layup techniques to curing cycles and surface finishing—must adhere to strict standards to ensure consistency across production runs. When a shop demonstrates reliable fitment guides and transparent workmanship, it signals a level of craftsmanship that reduces the risk of misalignment, paint defects, or awkward panel gaps. For businesses sourcing such components, capacity, responsiveness, and cost-efficiency become as important as aesthetics, because the supply chain ultimately governs whether a design can be realized on time and within budget.

Those exploring a path toward professional-grade customization should consider how their aesthetic decisions will withstand the realities of regular riding. Aerodynamic gains are meaningful only if the design remains robust under vibration, heat, and the occasional impact. The right balance of stiffness and flexibility—achieved through the chosen materials and construction technique—helps ensure the fairing remains stable through high-speed wind and hard braking, while still providing a forgiving surface for inevitable road contact. In this sense, the art of fairing design is not simply about achieving a dramatic silhouette; it is about achieving a silhouette that behaves predictably and safely as speed, wind, and rider input interact.

For riders who want to start the journey with a concrete reference, a curated catalog of fairing shapes can offer a practical springboard. For example, a collection focusing on production-ready shapes can help align a design concept with real-world fitment and finishing expectations. The aim is to move from a mood-board fantasy to a reliable, positionally sound skin that enhances both performance and personality. When the fairing finally leaves the workshop, the rider experiences the moment of truth: the bike looks back with a confident, tailored presence, while the wind is kept at bay and the ride is, in every sense, more engaging.

To explore introductory options that emphasize broad compatibility and design versatility, consider visiting sources that curate fairing collections and provide guidance on fitment and customization. The right starting point can ease the transition from idea to execution, ensuring the final piece respects the bike’s core geometry while inviting a personal stamp that remains elegant under scrutiny. For riders seeking a concrete reference point online, a representative collection of fairings can serve as a practical gateway to understanding how a well-executed panel can harmonize with a machine’s lines and a rider’s ambitions. And as the design of a fairing progresses, the relationship between wind, weight, and visual impact becomes clearer: the contours that curve with the wind can also curve toward a rider’s sense of identity, making the motorcycle not just a machine, but a moving expression of self.

Internal link reference for further exploration: Honda fairings collection

External resource for broader context on design and fabrication practices: https://www.bikeradar.com/uk/motorcycles/guides/motorcycle-fairing-design-customization/

Shaping Speed: The Performance Cascade of Custom Motorcycle Fairings on Ride Quality

Every rider knows the first impression of a well-crafted fairing isn’t just how it looks, but how it behaves when the road fades from sight and the wind takes center stage. Custom motorcycle fairings are aerodynamic instruments, ergonomic refinements, and structural statements all at once. They shape the air that meets the bike, the wind that hits the rider, and the balance that determines how confidently the machine behaves at speed. In this chapter, we trace how the decisions behind a custom fairing—from its profile and materials to its mounting and integration with the bike’s geometry—set off a cascade of effects that reach the heart of ride quality. The aim is not to chase a single metric but to harmonize several dimensions of performance so a rider feels less turbulence, less fatigue, and more control, whether skimming the highway at 70 mph or carving a twisty mountain road at a settled pace.

The most immediate way a fairing influences ride quality is through aerodynamics. At higher speeds, air resistance grows, and the fairing becomes the primary gatekeeper of drag. A clean, well-designed front profile streamlines the flow around the motorcycle, reducing wake turbulence that can buffet the rider. This translates into steadier straight-line stability and a smoother ride on long stretches. The front fairing acts as the initial sculptor of airflow, guiding air toward the sides and under the bike in a way that minimizes separation and vortices. When airflow remains attached longer and separates later, the boundary layer stays coherent, and the overall drag coefficient drops. Even small adjustments to the leading edge radius, edge chamfers, and lower knee/leg cutouts can shift the way air reattaches around the rider’s torso. The result is not only speed potential but a more predictable ride feel, a sense that the bike does not fight you when the wind gusts or when you lean into a curve at speed.

This is where the material choice matters as much as the shape. A properly engineered composite or thermoformed shell can maintain its geometry under heat and vibration, ensuring the intended contour remains true as speeds climb. Inexpensive plastic kits, if ill-fitting or undersized, can sag or warp, changing the intended flow paths and causing unstable air pockets. On the other hand, higher-grade materials with precise molding preserve the intended surface finish and edge geometry through heat cycles and road stress. The reliability of the panel’s fitment to the bike’s subframe and the tank area is essential because gaps and misalignments create unintended drag channels and turbulent wakes that degrade performance and feel. The rider experiences this as a subtle but persistent drag increase and a sense that the bike is less willing to accept input from the handlebars at speed.

From a rider’s seat, the wind is more than a drag coefficient; it is a direct corridor of force. A well-executed fairing closes the cockpit around the rider, reducing wind blast and smoothing the airflow the helmet experiences. The effect is fatigue reduction, especially on extended rides, and a marked improvement in comfort when riding into crosswinds. The aerodynamic benefits often co-exist with a more refined sense of stability: the rider experiences less vertical oscillation and a more linear response when transitioning from a straight line to a curve. That feeling of being kept inside a controlled air environment translates into longer ranges, more precise steering input, and better control of torso posture. It is this synergy between drag reduction and wind management that makes the front-end experience a cornerstone of ride quality.

The second dimension in the ride-quality cascade is how fairing design interacts with the bike’s handling characteristics. A motorcycle’s balance is a relationship between mass distribution, wheelbase, steering geometry, and the added mass of any external bodywork. When a fairing is designed and mounted with attention to the bike’s existing geometry, it can preserve or even enhance governing dynamics like turn-in behavior and mid-corner stability. Conversely, a poorly integrated fairing can alter the motorcycle’s center of gravity or add unsprung mass in ways that dull the steering and invite understeer or oversteer characteristics in mid-corner scenarios. In this sense, the fairing is not merely an aerodynamic shell; it is a contributor to the vehicle’s dynamic fingerprint. The mount points, the rigidity of the attachment, and the distribution of load across the structure all influence how vibrations travel through the chassis and how the rider perceives the bike’s response to throttle, brake, and lean angle changes. The best outcomes come from fairings engineered to preserve or even complement the bike’s native handling cues, rather than overpower them with weight or drag increases in the wrong places.

The choice of materials shapes both aero performance and tactile interactions. Carbon fiber, while costly, offers high stiffness with relatively low weight, enabling a more predictable response in rapid direction changes and at higher speeds where the rider relies on precise feedback through the handlebars. Fiberglass and advanced resins strike a balance between stiffness, impact resistance, and cost, allowing bespoke shapes to be realized while preserving structural integrity. ABS plastics provide durability and resistance to impact but can be heavier and less stiff, which might limit the fine-tuning of airflow and the quality of edge finishes. The critical factor is not simply choosing a material on price or prestige, but understanding how the material behaves under load at speed, how it reacts to temperature changes, and how it interacts with the other weight-bearing elements of the bike, including fasteners and mounting brackets. When the fairing is engineered with a consistent thickness, uniform fiber orientation, and proper layering, its wind-reduction capabilities remain stable; this stability translates into less rider fatigue and more consistent steering feel at speed or in gusty conditions. It also reduces the likelihood of flutter or resonance at highway rpm, which, over hours of riding, can become a source of discomfort if not addressed in the design phase.

A key, often underappreciated, aspect of ride quality is how a fairing affects airflow around the rider’s helmet. The helmet’s own aerodynamics is a conversation between rider and machine. If the fairing directs air smoothly over the rider’s line of sight and into the side of the helmet—avoiding sudden pressure differentials that cause flutter or buffeting—the rider experiences a calmer field of air. That calm translates into less need to brace the neck or lean into the wind to maintain a steady head position. This is especially important on longer rides where fatigue compounds and small discomforts coalesce into a broader sense of fatigue and reduced endurance. The design challenge remains to tailor the fairing to the rider’s posture: a sport-oriented position often demands tighter, more enclosed air channels around the upper chest and helmet; a more upright riding posture may benefit from a slightly wider aperture that reduces wind shadow along the chest but maintains a protective barrier for the neck. The art lies in harmonizing these nuances with the bike’s geometry to create a coherent, predictable wind environment.

A practical thread weaves through the technical tapestry: fitment quality. In a world where a fairing is a modular addition to a complex machine, precise alignment with the fuel tank, the radiator inlets, the instrument cluster, and the fairing’s own internal mounting points matters more than sheer contour beauty. Consistent gaps and flush joints minimize flow disruption, reducing knock-on drag and ensuring stable airflow around the sides and the bottom of the bike. The finish cannot be overlooked either. Surface smoothness, the absence of micro-scratches, and the accurate alignment of mounting bosses all contribute to predictable airflow patterns. A matte or high-gloss finish, while aesthetically distinct, can influence boundary layer behavior and heat absorption in different ways; the smoother, uniform surface reduces the chances of micro-turbulence that would otherwise degrade aero performance and comfort. It is here that the artistry of the craft meets the science of performance in a way that touches both the eyes and the hands of the rider.

When riders or builders evaluate a custom fairing, the conversation often centers on a few practical questions: how will the shape influence fuel economy at my typical cruising speed, how much weight will this add, will it alter braking or suspension feel, and how will it look in motion? Answering these questions requires a holistic view. Aerodynamics, weight distribution, and mount rigidity must all be considered in concert, not in isolation. A well-conceived fairing not only reduces drag and wind fatigue but also preserves or enhances the motorcycle’s stability and steering feel. In some cases, it may even unlock improved fuel efficiency through reduced drag at highway speeds, especially for riders who spend long hours on the road. The true value lies in achieving a balanced package where airflow, rider comfort, and handling work together in a synergistic way. The rider experiences a more composed ride, with less wind noise and pressure fluctuations, and a bike that feels as confident on the highway as it does in the twisty backroads. The lasting impression is a sense of connection: the machine disappears behind the wind, and control feels effortless rather than contested.

For readers seeking a practical path to this outcome, the journey begins with fitment research that respects the motorcycle’s original geometry while acknowledging the unique requirements of a custom shell. Compatibility with specific models, the chosen material, and the level of craftsmanship all frame the decision. The path moves toward a design process that prioritizes aerodynamics while preserving the bike’s balance and rider comfort. It includes thoughtful mounting strategies, attention to seal gaps, and careful alignment with the rider’s riding posture. The result is a fairing that does not just cover the bike; it completes a controlled flow around the rider and the machine. As you move toward the day you ride with a new shell, your bike becomes a more coherent instrument, a partner that responds with steadiness at speed, comfort on long stints, and confidence in the corners.

For readers who want to explore model-specific options in a practical context, a catalog that aggregates fairing options can offer a sense of available contours and mounting concepts. A fairings collection page provides a sense of how different geometries align with common model families and how the edges and joints are treated to maintain consistent airflow. Engaging with such a catalog helps gauge compatibility and material choices before committing to a build. When considering a custom fairing, the emphasis should be on harmonizing air, weight, and geometry with the rider’s goals, rather than chasing a single performance metric. By embracing this integrated approach, riders can achieve a ride that feels smoother, more controlled, and reliably efficient across a wide range of speeds and conditions.

External resource: How Do Motorcycle Fairings Improve Aerodynamics and Fuel Efficiency? https://www.bikeride.com/motorcycle-fairings-aerodynamics/

Material Mastery for Custom Motorcycle Fairings: Balancing Performance, Durability, and Design

Material choices for custom motorcycle fairings are more than weight, stiffness, or cost. They shape a rider’s experience every time they twist the throttle and lean into a corner. The decision sits at the intersection of engineering, artistry, and practicality. The three primary options ABS plastic, fiberglass (GRP), and carbon fiber each bring distinct properties, and the best choice depends on how a rider uses the bike, what it will face on the road, and how much time and money they are willing to invest in craftsmanship and maintenance. In the broader context of motorcycle fairing customization, these materials define the canvas upon which design, aerodynamics, and integrated features come to life. They influence compatibility with a bike model, the ease of painting and finishing, and the long term resilience of the bodywork under real world conditions. For anyone considering a custom fairing, imagine the bike not just as a surface to be shaped, but as a system where every layer from the core material to the paint and clear coat affects handling, heat management, and durability.

ABS plastic stands as the workhorse of the aftermarket. Its advantages are most visible in everyday riding where reliability and cost efficiency matter most. ABS offers robust impact resistance that reduces cracking from knocks – think road debris, minor tip overs, and daily commutes. The surface accepts paint, decals, and graphics with relative ease, making personalization straightforward and predictable. Price is also a practical factor; ABS typically sits at the lower end of the cost spectrum among fairing materials, enabling panel refreshes or replacements without a heavy financial hit.

Yet ABS has limits. It does not match the stiffness or impact resistance of heavier composites under sustained impacts or high stress loading. In high speed riding or racing, ABS can flex more than fiberglass or carbon fiber, potentially altering aero shape over time. Temperature sensitivity is another concern; prolonged exposure to high heat can soften ABS and influence edge lines and welds. For riders who push their machines toward the track or intensive street use, these trade offs matter. Still, for most street bikes, ABS remains a dependable baseline that blends affordability with straightforward maintenance and customization options.

Fiberglass or GRP sits between ABS and carbon fiber in formability, weight, and repairability. Its moldability enables intricate shapes that would be harder with ABS without adding weight or cost. This makes fiberglass attractive for bespoke fairing concepts and features that must wrap around the frame with curvature that demands attention to geometry. GRP panels are also relatively repairable; small cracks or delaminations can often be addressed with epoxy repair, keeping maintenance accessible for DIY fixes. When used wisely, fiberglass becomes a potent ally in achieving elaborate contours and sculpted fairing features that demand precision in the design phase. However, fiberglass can be more brittle than ABS under sharp impacts and may be less forgiving under repeated stress. Moisture absorption if unchecked can affect dimensional stability and fitment over time. For riders pursuing extreme customization where form dominates function, fiberglass is an excellent choice with a trade off of higher maintenance overhead and careful inspection after heavy rides or off road use.

Carbon fiber represents the pinnacle of performance oriented materials for fairings. The main appeal is weight reduction: a carbon fiber panel can weigh roughly 30 percent less than a comparable ABS panel, improving handling, throttle response, and aero efficiency. The weave texture, sealed with a clear coat, conveys a high tech, race inspired look. For track focused riders, carbon fiber is ideal for load bearing areas and panels demanding structural efficiency, often enabling tighter aero packages.

Yet carbon fiber brings constraints. The cost is high, driven by raw materials and manufacturing processes such as prepregs and resin infusion. Repairs can be more complex and costly, and certain impacts may damage the weave and require professional repair. Material compatibility with paints, electronics, and coatings also deserves careful planning to avoid surface imperfections. A practical path is multi material configurations: carbon fiber for high stress zones, with ABS or fiberglass for non load bearing sections. This blends weight savings with affordability and design flexibility. The surface finish matters as much as the core; a high quality clear coat, UV protection, and a robust paint system can extend panel life and preserve color integrity.

Choosing the right material should flow from intended use, bike model, and budget. ABS offers a solid, low maintenance upgrade with broad compatibility. Fiberglass enables complex shapes and custom aesthetics, with trade offs in weight and maintenance. Carbon fiber offers maximum weight savings and aero potential, typically paired with careful repair planning. Many builds use hybrid strategies to balance cost, weight, and design intent. It helps to map the bike’s operating envelope and align material selection with heat, exposure, and anticipated impacts. In doing so, riders preserve design language while keeping the fairing’s function aligned with handling and comfort.

As the design unfolds, finish and fit influence the final impression. Carbon fiber’s surface is highly dependent on resin, weave, and curing; ABS and fiberglass finishes are more forgiving in the finishing shop. Trial fittings, geometric checks, and real world tests shape the final choice. For buyers seeking guidance to suppliers and decision frameworks, supplier guides emphasize fitment accuracy, production capability, and cost efficiency. This perspective helps buyers navigate sourcing and validation to ensure consistent results. For readers exploring a starting point within the broader ecosystem, the Honda fairings collection offers a microcosm of how materials and design converge in practice, illustrating how platform geometry shapes molding strategies, tolerances, and integration of features without compromising fit or aesthetics.

External resource for further context: https://www.sciencedirect.com/science/article/pii/S235271102300469X

Internal link reference: Honda fairings collection (https://www.summitfairings.com/collections/honda-fairings) provides a sense of how platforms accommodate varied material strategies while preserving fitment integrity.

Sculpting Speed: Market Currents Driving the Evolution of Custom Motorcycle Fairings

The market for custom motorcycle fairings is no longer a small atelier affair but a dynamic ecosystem where personal expression, performance optimization, and advanced manufacturing intersect. Riders increasingly view fairings not merely as protective shells but as canvases for identity and as functional platforms that influence how a machine feels at speed. This shift from purely aesthetic concerns toward integrated performance and digital craftsmanship has broadened the demand beyond hobbyists to small-scale teams, veteran builders, and OEMs seeking flexible, high-value customization channels. The result is a marketplace where design language is as important as fitment accuracy, and where the path from imagination to finished part is paved by a set of converging trends that redefine what it means to commission a fairing in the modern era. The ripples of this transformation are felt across the supply chain, from material selection and production methods to distribution, aftercare, and the way buyers evaluate potential partners.

One of the most consequential forces shaping demand is the surge in personalization and artistic expression. The rider as designer has gained prominence, and custom fairings have become a storytelling vehicle as much as a performance upgrade. Instead of choosing between a handful of factory options, customers increasingly seek bespoke color schemes, hand-crafted graphics, and tailored geometry that reflect a rider’s unique narrative. This impulse toward originality is strongest among enthusiasts who treat their machines as living portfolios, where every panel, hue, and contour speaks to a lineage, a taste, or a moment in time. In practice, this translates into longer design cycles and more iterative prototyping, but it also expands the market by attracting collectors and newer riders who previously considered customization out of reach. The vendors who thrive in this environment are the ones who blend technical mastery with a willingness to experiment, balancing art and engineering so that bespoke aesthetics do not compromise fit, strength, or durability.

Material science and manufacturing technique are central to this balancing act. A broader set of materials—carbon fiber, advanced fiberglass composites, and lightweight resins—now sits alongside traditional plastics, offering superior strength-to-weight ratios and expanding the design envelope. The accelerated adoption of CNC machining for precise jigs and fixtures, 3D printing for rapid prototyping and complex internal geometries, and vacuum bagging or resin infusion processes for consistent, high-quality layups has flattened many of the cost and lead-time barriers that once separated bespoke projects from mass production. The practical upshot is more ambitious forms that can accommodate integrated features without adding unsustainable weight. For the buyer, the implication is clearer fitment guidance, shorter iteration cycles, and the ability to push design boundaries with a clearer sense of manufacturability. For the fabricator, these advances enable more repeatable processes, tighter tolerances, and the possibility of small-batch runs that preserve the bespoke ethos while delivering reliable performance.

Technology in the fairing itself is no longer optional. Fairings are becoming platforms for electronics and connectivity, with lines designed to host integrated lighting, sensor routing paths, and cable channels that disappear into sleek seams. Integrated lighting patterns and accent LEDs are not just flashy add-ons; they are part of the aerodynamic package, influencing visibility, emphasis, and rider orientation. Smart features extend beyond cosmetics: channels and housings for GPS, action cams, and mobile mounts reduce installation friction and improve reliability in vibration-rich environments. Designers increasingly use computational fluid dynamics (CFD) to refine shapes for stability and reduced wind noise at highway speeds, ensuring that aesthetic choices do not compromise aerodynamics. In practice, this means a fairing can be sculpted to improve rider comfort, reduce fatigue, and preserve precise handling without forcing riders to sacrifice looks for performance.

But the story remains incomplete without considering sustainability. The shift toward eco-conscious production practices mirrors broader consumer expectations and regulatory pressures. Manufacturers are exploring recycled materials in composite layups, alternative resins that lower volatile organic compounds, and strategies to minimize waste through design for manufacturability and modularity. For many builders, sustainable practice is increasingly a market differentiator and a credential that resonates with a growing cohort of buyers who want gear that aligns with broader environmental values. The conversation moves beyond material choice to include end-of-life considerations, repairability, and the potential for refurbishing or reconditioning panels to extend their useful life. This sustainability thrust also aligns with cost efficiencies. When waste is reduced and production becomes more predictable, unit costs decline over time, enabling smarter pricing for custom work and the ability to offer higher-end finishes without ballooning the total cost of ownership.

A more transformative element of current trends is the rise of collaborative digital design and “one-stop-shop” ecosystems. Online platforms allow customers to collaborate directly with designers and fabricators, visualize options in real time, and source all necessary components from a single network. This model lowers barriers to entry for new builders and accelerates ordering cycles for established shops. The ability to route tweaks—whether a slimline fairing silhouette, a more aggressive winglet integration, or a reworked belly panel—through a shared, multi-disciplinary workflow reduces miscommunication and speeds up decision-making. It also widens access to design talent, enabling hobbyists and pros alike to participate in the early stages of product development without geographic constraints. A mature ecosystem leverages robust data on fitment, customer preferences, and performance outcomes to inform future designs, creating a feedback loop that continually elevates quality and consistency.

For buyers and procurement professionals, the market presents an important calculus. The concentration of global manufacturing, especially in Asia, highlights the need for diligence in partner selection. Capacity, lead times, quality control, and price competitiveness all shape project viability. The best suppliers are those with transparent fitment guides, clear documentation of materials and manufacturing processes, and demonstrated capability to handle customization requests without compromising on reliability. The value proposition extends beyond a single order: scalable capacity, consistent quality, and responsive communication are the pillars of long-term partnerships. In navigating this landscape, professionals increasingly rely on structured references that help assess a supplier’s track record and production discipline. A strategic resource that many B2B buyers find useful outlines how to evaluate manufacturers and manage the sourcing process for premium aftermarket parts. guide to sourcing motorcycle fairings provides actionable insights into supplier identification, capability assessment, and long-term sourcing success. The guide emphasizes not just price but the reliability of delivery, the stability of production, and the ability to support intricate customization while maintaining fit, finish, and warranty standards.

Within this evolving framework, the role of a fairing becomes increasingly complex. It is no longer merely the outer shell; it is a structured component that interacts with the bike’s chassis, electronics, and rider interface. The best projects balance visual drama with functional precision. They optimize the rider’s stance, reduce fatigue through ergonomic refinements, and accommodate mounting points for sensors, cameras, and dash displays without clutter or interference. In this sense, design language and engineering discipline must move in lockstep. The most successful outcomes are born from cross-disciplinary teams that blend stylistic vision with mechanical know-how, materials science, and software-enabled design workflows. The result is a finished product that looks unmistakably bespoke yet fulfills the practical demands of real-world riding, including weather resilience, impact resistance, and serviceability.

This confluence of personalization, materials, technology, sustainability, and collaborative design also reframes how market players compete. Competition shifts from simply offering a broad catalog to delivering a coherent experience: a clear design philosophy, consistent quality across custom options, predictable production cycles, and transparent communication from concept through delivery. In practice, that means shops and brands invest in talent development, invest in robust inspection and post-production processes, and build relationships that extend beyond a single project. As consumer expectations rise, so too does the importance of documenting and communicating the value delivered—how a bespoke fairing enhances not just aesthetics but also performance, comfort, and long-term ownership experience.

Looking ahead, several macro threads promise to shape the next wave of innovation. Micro-factories and localized production capabilities are increasingly viable, enabling faster turnarounds and more sustainable logistics. The ability to prototype digitally, test with CFD, print or machine components on demand, and deliver finished panels with precise tolerances makes customization more accessible to a wider audience without sacrificing quality. Cross-border collaboration platforms will continue to evolve, dissolving traditional geographic barriers and enabling designers, engineers, and fabricators to co-create in shared virtual spaces. As consumer appetite for distinctive, intelligently engineered fairings grows, the market will reward those who marry bold, expressive design with disciplined manufacturing practices, eco-conscious choices, and a transparent, responsive purchasing journey. In this environment, a well-performed bespoke fairing project becomes both a signature achievement and a practical upgrade—proof that personalization and performance can grow hand in hand rather than stand apart.

For those looking to navigate this landscape with confidence, the emphasis should be on selecting partners who demonstrate a clear, repeatable process for translating art into durable parts. Look for evidence of sophisticated material choices, documented testing and quality assurance, and a track record of successful customization projects that reflect a balance between aesthetics and function. In the end, the market trends described here are not merely about trends; they describe a path toward a more connected, capable, and expressive form of motorcycling. The fairing that emerges from this path is not simply a cover—it’s a carefully engineered interface between rider, machine, and the road, crafted to elevate the experience at speed while preserving the integrity of the machine and the rider’s vision.

External resource: For broader market context, see the Statista Global Motorcycle Market Size. https://www.statista.com/statistics/1407868/global-motorcycle-market-size-by-region/

From Mold to Market: Strategic Sourcing for Custom Motorcycle Fairings

Getting a set of custom motorcycle fairings into production is rarely a single leap from sketch to showroom. It is a disciplined orchestration of design intent, material science, and supplier competency that stretches from the first CAD file to the last painted surface. For procurement teams, this means translating aesthetic ambition into a chain of verifiable capabilities, predictable performance, and long-term reliability. The demand for high-performance, aerodynamic, and visually distinct bodywork has grown, particularly for niche sport-bike platforms where every gram of weight, every angle of airflow, and every finish choice can influence handling, rider confidence, and brand perception. In this landscape, successful sourcing moves beyond simple price comparisons and instead relies on a data-driven, relationship-led approach that aligns technical fit with operational rhythm.

Relying on regional manufacturing hubs makes sense, but the choice of hub should be guided by the specific manufacturing recipe required. Guangdong offers scale, speed, and end-to-end capabilities. Factories here often handle CAD design, tooling, injection molding in ABS, surface finishing, and packaging, all in a tight loop. Proximity to major ports means faster transit times, which matters when turnarounds are measured in weeks rather than months. Zhejiang contributes precision engineering and advanced materials, with facilities adept at fiberglass and dry carbon fiber composites, sometimes using autoclave processes to achieve high strength and light weight. For performance-oriented projects, this combination of materials and processes can yield parts that cut wind resistance without inviting excessive stiffness, a balance that matters in on-road and track contexts alike. Fujian presents cost-efficient options for standardized or semi-custom designs, particularly for models requiring consistent ABS shells and predictable post-mold finishing. Its strength lies in budgets that demand reliable mass production without surprises, a constraint many distributors face when expanding into new market segments. Meanwhile, emerging centers in Chongqing and Tianjin bring stronger collaboration on engineered finishes, integrated systems, and modular kits, where design iterations can be tested against broader aerodynamic goals and rider ergonomics.

Knowing the hub is not enough. The best buyers measure capability through performance, not just paperwork. ISO 9001 certification is a reasonable baseline, but many top performers operate on the strength of demonstrated capability and a clear track record. Technical capability now means more than a certificate: CAD support, reverse engineering, rapid prototyping, and accurate data packs showing model compatibility. Production flexibility matters, too. A supplier with dual production lines that can switch between standard ABS and carbon-fiber variants is less exposed to market volatility and better able to serve both budget-focused distributors and premium boutique shops. Lead times are a practical metric: capable factories deliver bulk orders in 25–35 days, with rapid prototyping available in 7–14 days. Vertical integration reduces dependences on third parties and can shorten lead times by up to a third. A well-known metric is customer satisfaction and repeat business; a supplier with high reorder rates often signals that the parts meet field expectations and that the production system can scale with demand. Before placing a large order, buyers should seek verifiable performance data. A Guangdong-based supplier, for example, demonstrated a strong rating and the capacity to complete complex orders with tight tolerances. The story is not about a single project; it is about a pattern—consistent finishes, predictable color matching, and stable dimensional control across batches. This is where reorders become a practical shorthand for value: a reorder rate in the mid-to-high teens or higher, coupled with lead-time reliability, indicates a supplier that not only can build to spec but also sustain it under pressure. In many cases, reputable suppliers report reorder rates in the 20 percent range or higher for top lines, which translates to real-world reliability and a comfortable safety margin for procurement teams facing demand swings.

Procurement strategies must guard against quality deviations and supply risks. Pre-shipment inspections by independent third parties—think internationally recognized labs and inspectors—verify dimensional accuracy, material integrity, UV resistance, and paint adhesion. QA protocols should include test reports on thermal stability, vibration resistance, and impact strength, especially for critical wind-cheating pieces or panels that house electronics. Post-purchase support matters as well: responsive communication, clear revision policies, and documented escalation paths reduce the cost of design iterations and shorten the time to market. A vendor that offers timely feedback and structured amendment cycles can save months of back-and-forth by catching misalignments early in the process.

Platforms that connect buyers with verified factories play a helpful role in modern sourcing, but their value comes when used with discernment. A well-run program uses platform transparency as a screening tool, then applies direct engagement to qualify capabilities, validate samples, and confirm production readiness. The best buyers push for production galleries and sample availability to evaluate finish, fit, and textures under real-world conditions. The strongest relationships are built on hybrid models that blend traditional methods—on-site factory visits, in-person audits, and deep supplier interviews—with digital tools like live production tracking and AI-driven quality analytics. This blend delivers trust, visibility, and agility, even in volatile market conditions.

Internal knowledge resources and design libraries can accelerate decision-making for a given bike family. For instance, a documented Honda fairings collection may provide a direct reference to design language, mounting points, and fitments that recur across generations, enabling a smoother transition from one design cycle to the next. Explore the Honda fairings collection.

Ultimately procurement success rests on partnerships that endure. The most resilient supply chains combine fixed-price, long-term contracts for core platforms with flexible capacity for special editions or seasonal campaigns. By aligning production capacity with forecasted demand, buyers can secure favorable terms while ensuring that quality remains high even as volumes shift. The reorder rate remains a useful signal; a sustained rate in the teens or higher suggests a supplier that can weather fluctuations and keep the line moving without sacrificing tolerance or finish. The sentiment among seasoned buyers is clear: reliable partners are built on repeated performance, not sporadic wins.

Looking ahead, procurement teams should integrate supply chain visibility with design milestones, ensuring that every modification or option set remains compatible with the chosen manufacturing recipe and the rider’s expectations. The goal is not only to deliver parts on time but to deliver parts that perform. In this landscape, data becomes a compass: cadence of orders, rate of returns, and the precision of tolerances traded off against price all color the decision process. When teams align data, design intent, and supplier capability, the result is a pipeline that can adapt to evolving aesthetics, shifting regulations, and new aerodynamic insights while preserving the integrity of the rider experience. External resource: https://www.motorcyclepartsdirect.com/guide-to-sourcing-motorcycle-fairings

Final thoughts

Navigating the landscape of custom motorcycle fairings presents both challenges and opportunities for business owners. Understanding design, performance, material choices, market trends, and effective sourcing strategies equips you to better serve your customers and carve out a competitive edge. By embracing these insights, you can enhance your product offerings, optimize procurement processes, and ultimately drive sales in a thriving segment of the motorcycle industry. Stay ahead of the curve and ensure your business is well-positioned to meet the rising demand for customization.