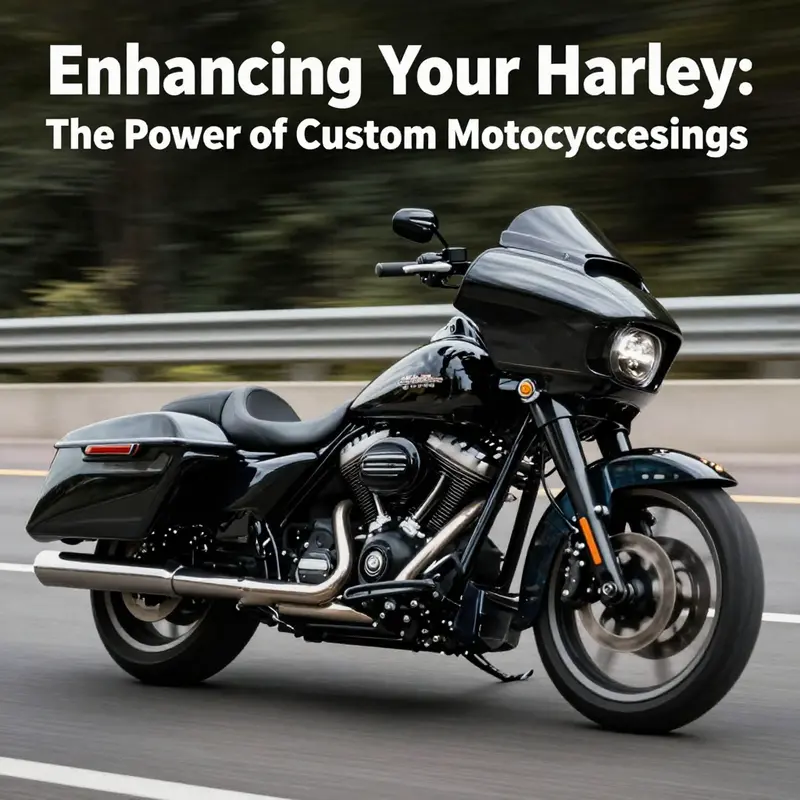

Custom motorcycle fairings have become an essential upgrade for Harley-Davidson owners, enhancing both aesthetics and performance. These tailored components not only improve the bike’s aerodynamic profile but also allow for personal expression through unique designs. In this exploration, we will delve into the intricate interplay between design and aesthetics, performance enhancements, installation processes, and the evolving market trends in the custom fairings industry. Through understanding these elements, business owners can better cater to the growing demands of Harley riders seeking to elevate their biking experience.

Contours of Control: Designing Harley-Davidson Custom Fairings That Merge Heritage with Modern Aerodynamics

Riders who turn to custom fairings for a Harley-Davidson understand that the choice is never merely cosmetic. It is a careful negotiation between a bike’s storied silhouette and the practical demands of wind, weight, and rider comfort. The art of designing Harley fairings sits at the intersection of heritage and innovation, where the past’s broad, muscular lines meet contemporary considerations of aerodynamics, materials science, and personal expression. The result is not a single formula but a spectrum of possibilities that allow each rider to write a chapter of their own riding identity onto the bike. What emerges from this spectrum is a coherent philosophy: fairings should honor the bike’s core character while subtly refining its behavior at speed, and they should do so without erasing the rider’s sense of place within the machine.

From the outset, the guiding principle is integration. Harley-Davidson’s factory approach to fairings has long emphasized a seamless relationship between the fairing and the motorcycle’s frame, electrical systems, and chassis geometry. A well-designed fairing kit is not an add-on but a continuation of the bike’s lines. It respects the rake and trail that influence steering feel, it accommodates the headlight and instrument cluster with proportion and clarity, and it slots into mounting points with precision so that vibration and misalignment are minimized. When such harmony is achieved, the fairing becomes a natural extension of the bike rather than a protruding aftermarket afterthought. It preserves structural integrity and reliability while elevating the machine’s presence on the road.

The visual language of Harley fairings is deeply tied to the brand’s identity. A sculpted exterior can emphasize the bike’s broad shoulders and a stance that communicates power even when the machine is stationary. The aesthetics are not just about a sharper edge or a cooler silhouette; they are about rhythm—the way the fairing curves sweep toward the rider and how a well-chosen windscreen height interacts with the rider’s line of sight. The design seeks to reduce buffeting without shutting out the wind entirely, especially for riders who relish long cruises where comfort matters as much as speed. In practical terms, this means a balance between a sleek profile and enough curvature to tame the air. The goal is to shape air around the rider as an ally, guiding it to create a cocoon of stability rather than a throbbing, fatigue-inducing pressure.

Color, finish, and texture are not afterthoughts but central to the rider’s sense of ownership. The fairing’s surface can be finished in a glossy, factory-like shine or in a more tactile, matte, or satin presentation that reduces glare and reflects light in a way that flatters the bike’s lines. Color choices become a dialogue with the bike’s existing palette and chrome accents, allowing for a cohesive look that extends across fenders, exhaust shields, and accents along the tank and subframe. Surface texture can also play a role in durability and maintenance. A lightly textured or woven finish can hide micro-scratches that appear with time, while high-gloss surfaces demand careful maintenance to preserve depth and clarity. For riders who prize a one-of-a-kind presence, finishes can incorporate subtle color-shifts or pearlescent effects that catch the sun at different angles, turning a simple ride into a moving sculpture.

Materials lie at the heart of how a fairing behaves in real-world conditions. ABS plastic remains common for many factory-style kits due to its balance of rigidity, impact resistance, and cost. Fiberglass offers a lighter weight and a forgiving layup for bespoke shapes, though it often requires more precise finishing and sealing. Carbon fiber brings an impressive strength-to-weight ratio and a distinctive weave that many riders associate with performance, but it raises cost and demands meticulous care against UV exposure and solvents. The choice of material influences not only weight and performance but also how the finish takes hold. A fairing built from a more rigid substrate can exhibit crisper lines, while a more compliant layup might better absorb road shocks and vibrations, subtly affecting the bike’s handling at highway speeds. In either case, the goal is to preserve the frame’s integrity and the steering’s feel while delivering a fully realized exterior that stands up to road debris, weather, and the daily wear of riding life.

Aerodynamics is another essential layer in the design conversation. A well-shaped fairing can reduce drag, improve stability at speed, and alter the rider’s air experience for comfort and focus. The process begins with a clear understanding of the bike’s existing aerodynamics, including the rider’s posture and typical riding speeds. Designers experiment with contouring and sweep angles to guide air smoothly around the rider’s torso and shoulders, while ensuring that the windscreen remains legible for instrumentation and line of sight. The introduction of clever features, such as integrated vents, can assist with ventilation and heat management, especially on longer rides or in warmer climates. A fairing that breathes well for the rider translates into less fatigue, a sharper sense of control, and more confidence when riding through gusty sections or open highways. The result is not merely a more aggressive look but a more composed, composed-on-demand experience that remains comfortable as the ride evolves from city streets to backcountry highways.

Aesthetics also have to reckon with personalization. The modern rider values a design that can be tailored to reflect temperament, not just model-year alignment. Therefore, aftermarket options open the door to a broader spectrum of shapes, lines, and finishes. Riders can explore variations in the fairing’s silhouette—perhaps a more pronounced chin for aggressive styling, or a softer curvature that echoes a vintage vibe while delivering modern protective capabilities. The color story can be tuned to match a rider’s helmet, gloves, or leather accents. The finish can be adjusted to complement or contrast with the bike’s chrome or matte components, creating a visual hierarchy that guides the eye along the bike’s length. In short, customization becomes a storytelling tool. The fairing speaks the rider’s language and casts the bike in a light that communicates both pride and purpose.

Within this broader design conversation, the installation narrative matters as much as the artwork itself. A fairing kit, regardless of its beauty, must be practical to mount and service. The best options offer a precise fit with hardware and gaskets that ensure weatherproof seals, minimal bolt holes, and clean cable routing. The rider who undertakes a fairing project benefits from clear alignment references and a straightforward path to reconnecting turn signals, headlamps, and dash components. The installation process is a test of the design’s integrity—whether the fairing remains true after the first highway miles, whether it resists vibration and flex, and whether the rider can re-create the intended alignment after removing and reattaching the unit for service or customization. When the process is smooth, the rider gains more than a new look; they gain the confidence that the machine carries its part with the same care with which it was built.

The conversation about design and aesthetics cannot ignore the social dimension of customization. Harley owners who assemble a personal fairing ensemble join a community that treats the motorcycle as a canvas for shared values—craft, history, and a certain swagger that comes from riding something unmistakably theirs. The bike’s external voice—its lines, its stance, the way light slants across its contours—becomes a public language. A well-done fairing communicates attention to detail and a respect for the machine’s origins. It doesn’t shout; it invites a conversation about the rider’s preferences, riding purpose, and the road’s ever-changing textures. This is why some riders prefer to blend a contemporary, aerodynamic profile with nods to the brand’s traditional cues, keeping the silhouette familiar enough to be recognizable while still signaling forward momentum and personal vision.

For readers who crave a broader sense of how fairing design has evolved across brands—and how those lessons can inform a Harley-focused project—there is value in cross-pollination. Even as this chapter emphasizes Harley’s specific design logic, it’s instructive to observe how other manufacturers approach wind protection, line quality, and surface finish. The broader fairing ecosystem highlights recurring themes: the necessity of an integrated approach that treats the fairing as part of the bike’s overall mechanical and aesthetic system, the importance of a finish that resists weathering and fading, and the value of selecting a material that balances strength, weight, and cost. It also underscores the practical reality that every rider’s climate, road profile, and comfort priorities shape the final choice. A fairing that works beautifully in a dry, temperate environment might need different venting or sealing considerations in a coastal climate with salt air or in a region that experiences heavy rain and temperature swings. The best designs anticipate these realities and provide flexible solutions that can be tailored to individual riding conditions.

In the end, the most compelling Harley fairing projects achieve a synthesis of form and function, where aesthetics do not overshadow performance but rather enhance it. The rider’s pride in the machine grows as the fairing becomes a tangible manifestation of personal taste, technical awareness, and a sense of responsibility to preserve and advance a storied riding heritage. The journey from concept to finished ride is an exercise in restraint and refinement: selecting lines that flatter the bike while mitigating wind pressure; choosing finishes that endure yet still feel alive when the sun crosses the chrome; and ensuring that all elements—mounts, seals, and wiring—converge into a seamless, lasting installation. For those who wish to explore further, the broader ecosystem of aftermarket fairings offers a wealth of references and options that can inspire a Harley-focused project while highlighting the common threads that unite all quality fairing designs. As with any customization, the invitation remains open to push the boundaries where tradition meets innovation, to honor the rider’s spirit, and to ride with a silhouette that feels as right as it looks.

For readers seeking official design details and contemporary options aligned with the brand’s current direction, exploring Harley-Davidson’s official fairing options can provide a grounded point of reference. This external resource offers the latest insights into how the brand approaches fairing integration, lighting, and accessory alignment in a way that preserves the machine’s core identity while embracing modern aerodynamics and rider comfort. Harley-Davidson Official Fairing Kits Page

Internal link note: while the Harley ecosystem remains the focus, learning from the broader world of fairings can sharpen design intuition. For readers curious about non-Harley-fairing options and how different silhouettes influence aerodynamics and aesthetics, consider exploring the available Honda fairings collection on Summit Fairings, which offers a variety of shapes and finishes that illuminate the versatility of form in contemporary aftermarket kits. Honda fairings

Wind-Shaped Identity: Crafting Performance and Persona with Harley-Davidson Custom Fairings

Wind has a way of telling you what your bike wants to become. On a Harley-Davidson, the fairing does more than push air around the machine; it shapes the rider’s relationship with the road. A well conceived fairing is a bridge between sculpture and aerodynamics, between the long memories of a road trip and the precise geometry of a machine tuned for speed, stability, and control. Custom fairings are not simply add-ons; they are a design statement that aligns form with function. They respond to the rider’s desire for character while insisting that performance should be tangible, felt in the seat, in the shoulder line, and in the quiet certainty of high-speed steadiness. The result is a motorcycle that looks like it was built to go farther and stay fresher longer, without sacrificing the soul that makes a Harley feel alive.

Aerodynamics is where design meets physics in a clean, practical dialogue. A properly shaped fairing reduces drag by guiding air smoothly around the bike rather than letting it buffet the rider. This matters more on long-haul journeys than on quick sprints. The cumulative effect is lower fatigue, a modest bump to fuel efficiency, and the ability to maintain a confident posture at sustained highway speeds. When air flows efficiently, wind noise drops, and the rider’s helmet can sit in a more comfortable wind envelope. The rider’s shoulders and upper back stay steadier, which translates into less muscular strain after hours in the saddle. The rider can think about the road ahead rather than bracing against the wind, and that mental clarity becomes a part of the journey itself.

A custom fairing invites a conversation with the bike’s silhouette. Harley-Davidson models have a lineage of bold lines, and a well-fitted fairing respects those lines while extending them. The goal is not to impose a new shape but to harmonize the bike’s natural geometry with the rider’s preferences. Integrated styling—where the fairing flows into the fenders, side panels, and tank covers—creates a cohesive look that reads as a single design language rather than a patchwork of aftermarket pieces. This coherence is essential for riders who treat their machines as more than a mode of transport; they treat them as companions with a shared history and a future to sculpt. When the fairing complements the bike’s stance and wheelbase, it also contributes to a calmer front end at speed. The wind’s bite is not erased but redirected with precision, reducing turbulence behind the fork and around the rider’s torso.

The sophistication of a modern riding experience often hinges on how the cockpit feels in relation to the fairing. A thoughtfully designed fairing recognizes that the rider’s field of vision, reach to the controls, and access to essential gauges are part of the motorcycle’s choreography. In a contemporary setup, a fairing may be engineered to provide clean mounting surfaces for accessories, integrated lighting that follows the bike’s line rather than breaking it, and smart routing for cables and wires that keeps the cockpit uncluttered. The outcome is a cockpit that feels assembled rather than cobbled. Readability of displays, ease of reach to controls, and a wind-friendly environment work together to reduce cognitive load. The rider’s attention stays on the road and the experience of riding rather than on contending with a cockpit that fights against the wind or a jumble of loose wiring.

This is where customization becomes a practical craft. Carving a fairing to the rider’s tastes involves a careful balance between aesthetics and physics. Finishes can range from smooth, high-gloss surfaces to textured or matte treatments that catch the light differently along each contour. The choice of materials—whether fiberglass, composite, or lightweight carbon fiber—affects weight, rigidity, and the way paint adheres to the surface. Fiberglass and composites offer latitude in shaping, which is why many builders start here for a bespoke fit. Carbon fiber, when used, brings a premium look with superior stiffness and a light touch overall, but it also demands careful protection from road debris and clear-coat maintenance. The right balance of weight and strength is essential; a heavier fairing can dampen the bike’s nimble character, while too light a piece might compromise stability at higher speeds. A skilled craftsman will design around the bike’s existing balance, ensuring that the added mass contributes to steadiness rather than altering steering feel.

Beyond materials and forms, the color story and texture choices allow riders to translate personality into metal and paint. Some builders offer finishes that echo traditional Harley aesthetics—warm metal tones, hand-polished textures, and subtle weathering that speaks to a century of road-built ethos. Others push toward modern minimalism—smooth, stealthy surfaces with restrained graphics that let the bike’s silhouette do the talking. The payoff is a fairing that reads as a natural extension of the rider’s style rather than a costume added on top. It is this unification of look and feel that makes a custom fairing feel inevitable, as if it were always part of the bike’s design backstory—an integral chapter rather than a footnote.

Fitment is where imagination meets shop-floor reality. A custom fairing must align precisely with the bike’s mounting points, fenders, and bodywork. It requires careful measurement, knowledge of the frame geometry, and a plan for how the piece will be mounted, sealed, and painted. The installation is more than a bolt-on process; it is an exercise in preserving the bike’s structural integrity, maintaining ground clearance, and ensuring that the fairing does not impede steering or suspension travel. The goal is a flush, seamless appearance with consistent gaps and a finish that looks like factory work rather than aftermarket improvisation. Proper fitment also takes into account heat management, especially around the engine and exhaust areas, to avoid warping or discoloration over time. In other words, success hinges on attention to tolerances, alignment, and the subtle, almost invisible work of smoothing seams so they vanish as the bike is ridden.

Such precision work has a direct impact on long-term performance. A fairing that breathes with the bike’s airflow helps the rider tolerate higher speeds for longer periods. It supports stable handling during gusty crosswinds and keeps the front end planted in the kind of high-speed corridors where confidence matters more than raw horsepower. The rider feels less need to compensate with body English, and that translates into more consistent lap times on a track or more predictable behavior on a road that changes texture from asphalt to gravel. The psychology of stability should not be underestimated: when a rider feels in control, their focus becomes strategic instead of reactive, which is a lasting performance advantage across hundreds of miles.

This sense of integrated performance extends to electronics and display arrangements in the cockpit. A contemporary Harley-Davidson model may offer an integrated display environment that encourages a clean, ergonomic layout. A well conceived fairing helps keep these elements within easy sightlines and reachable range, reducing the need to tilt the head or shift position to read gauges or consult navigation. This is not about cramming features into a tight space but about organizing space so that technology serves the rider with minimal disruption. The fairing becomes the backbone of a cockpit that feels coordinated and intuitive, where the rider can navigate with confidence and comfort, even when the road becomes busy or the weather turns unfavorable. The result is a riding experience that is as much about serenity as speed, a sense that the bike is listening to the rider as closely as the rider listens to the road.

For riders craving individuality, customization options are not limited to color and texture. Functional upgrades can be incorporated in ways that respect the bike’s geometry and maintain weight balance. Built-in mounting points for accessories, discreet storage opportunities, and even subtle protective elements in the right places can add utility without breaking the line. The trick is to keep the overall profile harmonious while adding elements that enhance everyday riding. The fairing becomes a canvas for practical, well-considered additions that do not shout but speak in a confident, purposeful tone. In this sense, customization is not indulgence but an investment in daily comfort and long-term enjoyment. A well-designed fairing supports the rider’s routine, from the first start of the day’s ride to the final stretch home when fatigue begins to set in and the road demands more of the rider’s focus.

From a practical standpoint, maintenance and care are integral to preserving both appearance and function. Protective coatings, UV-resistant finishes, and periodic wax or sealant regimes help keep the fairing’s color and gloss stable. Fasteners and mounting hardware require routine checks to prevent any looseness that could degrade alignment or cause rattling over time. The climate in which a rider travels—whether humid coastal air, dry desert routes, or snow season seas—affects how a fairing ages. A conscientious owner treats upkeep as part of a broader stewardship of the bike’s condition. A clean, well-cared-for fairing not only looks better; it remains a reliable, consistent performer across seasons and miles. The maintenance routine becomes a quiet ritual that reinforces pride of ownership and reiterates the rider’s commitment to excellence.

Ultimately, choosing a custom fairing is a decision about cadence and character. It asks what the rider wants the bike to do beyond simply moving from point A to point B. It invites a dialogue between the rider and the machine about speed in a wind-controlled environment, about quiet focus at highway tempo, and about the way a machine carries its own legacy forward with every mile traveled. The fairing is the instrument that tunes that dialogue, shaping how air, light, heat, and perception combine to produce a single, coherent riding experience. It is a tangible expression of who the rider is and how they want to engage with the road that lies ahead.

For readers who wish to explore the possibilities in more concrete terms, consider consulting official resources from the manufacturer for model-specific fitment guidance, compatibility notes, and customization tools that align with a rider’s year and tier of bike. These references offer detailed specifications and practical steps for achieving a professional, factory-inspired finish while preserving the character that makes a Harley-Davidson so distinct on the open road. While the language of customization can be aspirational, the best outcomes come from thoughtful planning, honest collaboration with experienced builders, and a shared commitment to doing the work with care and attention to detail. When pursued with care, a custom fairing does more than alter a bike’s profile; it reshapes the rider’s everyday experience, turning each ride into a balanced conversation between rider, machine, and the wind that carries them forward.

External reference: https://www.harley-davidson.com/us/en.html

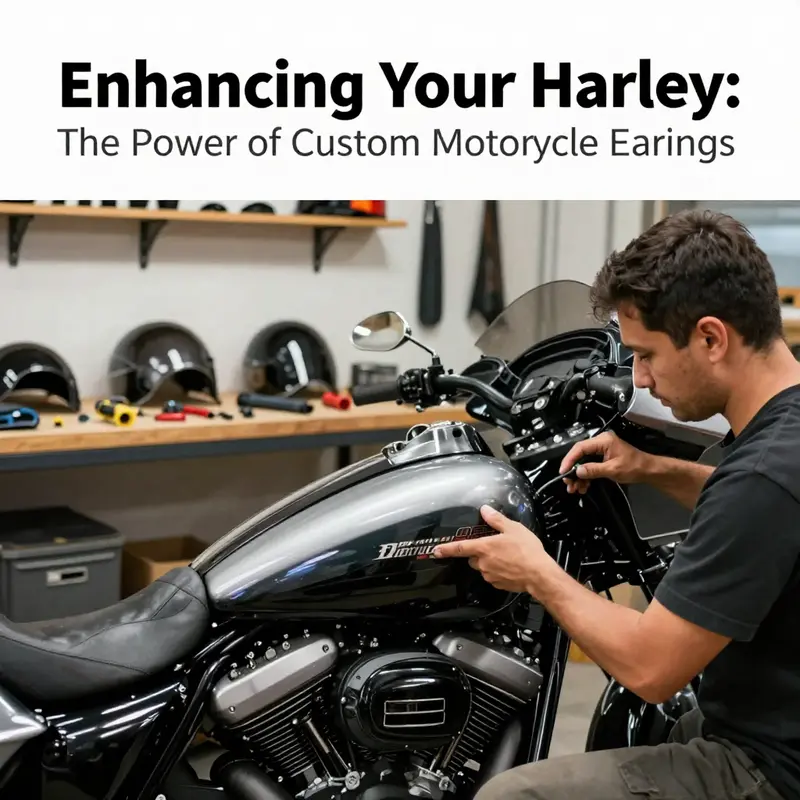

Engineering the Flow: Installing and Integrating Custom Fairings on a Harley-Davidson for Style, Safety, and Street-Ready Aerodynamics

Every rider who chooses a custom fairing for a Harley-Davidson knows it blends form and function. It is not merely cosmetic; it is a deliberate re-creation of how the bike meets wind, road, and rider. The decision begins with a thoughtful look at which fairing design best suits the rider’s ambitions. The answer comes down to understanding how a fairing integrates with the chassis, the steering geometry, and the rider’s posture. Only then does the adventure of installation begin in earnest. This project rewards patience, planning, and precision, because the goal is not only a striking facade but a harmonious interaction between air, weight, and the rider’s comfort at speed. A well-chosen fairing should reduce buffet at highway speeds, offer improved wind protection for the torso and hands, and still preserve the rider’s ability to maneuver, steer, and respond to road conditions with immediacy. The interplay between aesthetics and performance is where the art of this upgrade lives, and where a rider’s personal style can be married to practical engineering.

The first phase is meticulous fitment planning. Compatibility is more than a matter of aligning a single bolt hole with a frame tab; it involves a broader assessment of how the fairing’s mounting brackets will align with the bike’s backbone, its down tubes, and the handlebars. Because Harley-Davidson bikes have evolved with distinct frame architectures and control placements, the bracket system must sit true within the frame’s contour and the rider’s reach to essential controls. This means confirming that the selected fairing’s bracket pattern will sit true within the bike’s overall geometry, and that the mounting points are positioned so that the fairing’s weight distribution does not introduce unintended load into the fork or suspension travel. It also means ensuring that the fairing will clear every vital component during steering lock, full compression on rough pavement, and typical compression when the rider uses inputs for braking and gear selection. It is not uncommon for riders to perform a mock assembly with painter’s tape or light brackets before committing to hardware. A careful mock-up helps visualize how the fairing will sit in relation to the rider’s line of sight, the mirrors, and the lines of the tank and fender. That initial step is where many installing journeys either take a confident turn or require a return to the drawing board for adjustments.

Following this groundwork, the installation moves into the tangible realm of hardware and alignment. Reputable aftermarket kits aimed at Harley models typically include a complete hardware package: brackets tailored to the frame, fasteners in corrosion-resistant finishes, and a harness or wiring run designed to minimize interference with electrical or mechanical components. The practical reality is that even a complete kit cannot guarantee a flawless fit without careful alignment. The rider must verify that the fairing’s perimeter does not impede the movement of mirrors, the operation of hand controls, or the range of motion of the front forks. This is where the dialogue between design and reality becomes visible. The installer checks that the fairing’s lower edges sit above the engine bay contours without rubbing during engine heat expansion. They inspect the top edge for a consistent seam with the windshield or screen, ensuring that the transition from fairing to windscreen reads cleanly from the rider’s seating position. The process often includes shimming, fine-tuning, and, if needed, a measured adjustment of the mounting points. All of this is done with the rider’s posture in mind: a taller rider will have different wind protection needs than a shorter rider, and a fairing that looks perfect from the garage floor might feel intrusive or unstable when the rider is perched on the saddle.

Electrical routing is a dimension of installation that cannot be overlooked. The harness or wiring solution in a fairing kit is designed to integrate with the bike’s electrical system, but that integration requires thoughtful routing. Signal circuitry must avoid interference with mirrors, brake lines, throttle by wire controls, and the bike’s protective body hardware. The routing of lights, turn indicators, and any integrated indicators should be planned so that the power draw is balanced and that the circuits remain separate from critical safety systems. A common pitfall is letting wires cross moving parts or breathe near hot engine surfaces, which can degrade insulation over time. A careful installer organizes the loom into clean channels, uses grommets where the wires pass through metal, and secures bundles with compliant ties that do not bite into insulation as the bike vibrates on the road. The result is a clean, professional finish where the wiring is largely hidden yet accessible for any future maintenance. It is essential to maintain signal visibility and ensure that the addition of the fairing does not obscure or misalign the headlights, auxiliary lights, or turn signals. The goal is a wiring ecosystem that respects both regulatory requirements and everyday rider needs.

In this broader context of fitment, the integration of the fairing with the bike’s electronics remains a critical thread. Modern riding experiences on touring or cruiser platforms often reveal a deeper interconnection between bodywork and technology. If the goal is to preserve or emulate a high-tech cockpit experience, the install must accommodate not just lighting, but the prospects of future upgrades to navigation or display systems. While a custom fairing may not embed the latest digital interfaces, it should still provide a clean pathway for wires that could support future enhancements—things like power, data lines for a head-up display, or additional sensors placed in nearby fairing panels. The integration philosophy, then, is less about chasing the newest gadget and more about ensuring that, whichever route the rider takes, the bike remains a coherent whole: aerodynamics that work with the frame and rider, lighting and visibility that meet legal standards, and an appearance that resonates with the rider’s personal aesthetic without sacrificing safety or reliability.

Another layer of consideration is the qualitative alignment of the fairing’s lines with the bike’s existing silhouette. The process invites a design-minded approach: the fairing should extend the bike’s profile in a way that flatter curves or sharp edges reflect the rider’s taste. Achieving this balance often means pairing the fairing with complementary components–fenders, side panels, or tank covers–that echo the same visual language. When the aim is a cohesive, factory-inspired look, the integration tends to hinge on maintaining consistent panel gaps and a unity of surface texture. It is here that the craft of the installer shines: the subtle tolerance between fairing panels, the precision with which edges meet, and the way light plays along the surface. The result is a motorcycle that looks and feels like a single, engineered unit rather than a collection of add-ons. In practical terms, this means minding the transition points where metal meets plastic, where a glossy surface meets a matte finish, and where the fairing’s presence impacts the rider’s sense of wind flow and ride stability.

For riders who crave more than a static aesthetic, the realm of modern look with functional personality becomes a guiding compass. A fairing can serve as a canvas for refined detailing–paintwork that echoes the bike’s color story, or subtle air intakes sculpted into the fairing’s flanks to hint at improved aerodynamics. It is not always about making the bike faster in a straight line; often, it is about reducing wind fatigue on long rides, enabling a more relaxed grip on the bars, and letting the rider hear the road without a constant blast of air. This philosophy extends to the installation approach as well. Rather than forcing a dramatic change in riding position, the installer seeks to preserve or improve rider comfort by ensuring that the fairing’s height, width, and angle contribute to a natural wind boundary, reducing turbulence across the chest and shoulders. The tangible payoff is a ride that feels more controlled at speed, with less fatigue after miles on the highway, without sacrificing the bike’s iconic stance and personality.

Where a rider wants to explore the wide possibilities of design, the process becomes a collaborative dialogue with designers who offer a spectrum of styles–ranging from clean, understated lines to aggressive, forward-leaning sculptures. This is the moment when a rider can examine broader concepts, such as the fairing’s compatibility with a rider’s preferred riding posture, the synergy with crash bars or auxiliary protection, and the overall weight distribution that could influence steering at different speeds. Even in the absence of integrated electronics, a well-planned installation makes room for future upgrades, bracket modifications, or additional protective components. The installation’s clarity, especially the alignment and seam quality around the top edge and sides, speaks to a higher standard of craftsmanship. A finished fairing that sits squarely and breathes evenly with the bike’s lines is not just a proud DIY accomplishment; it is a tangible attribute of roadworthiness and long-term enjoyment.

Riders who want to keep exploring the conversation about fairings can look to a broader catalog of designs and structural concepts that different brands, builders, and workshops present. Some enthusiasts appreciate the chance to view universal or brand-agnostic brackets and shell shapes that emphasize customization, while others prefer a fully bespoke route that a design house might chart in collaboration with the rider. In either path, the learning curve is steep but immensely rewarding: the opportunity to tailor wind protection, aesthetically unify the bike’s lines, and craft a personal statement that stands up to the highway’s demands. This is a project that rewards patience, measurement, and precise workmanship, culminating in a Harley-Davidson that feels not only customized but also optimized for real-world riding. The result is a machine that marries the legend of the brand with a rider’s specific ambitions, a practical solution that respects both safety standards and the rider’s sense of identity on the road.

For readers seeking further practical guidance, it is wise to consult official technical resources and trusted technical literature that cover fitment, wiring, and alignment in depth. A precise guide can help confirm fitment tolerances and provide step-by-step procedures that minimize guesswork while protecting the bike’s electrical system and frame geometry. In any case, the journey from concept to road-ready installation should emphasize careful planning, deliberate measurement, and a restrained, methodical approach to modification. The payoffs are substantial: a fairing that not only flatters the bike’s lines but also adds to rider comfort and road confidence. The rider gains a streamlined look, improved wind management, and a sense of ownership over a machine that truly feels like their own. The road ahead becomes a canvas, with the fairing acting as both shield and sculpture, an embodiment of how a well-integrated modification can elevate a motorcycle from mere transportation to a personal statement of design and performance.

As you navigate this process, consider consulting live examples and guides from a variety of sources to understand the breadth of possible configurations and the practical quirks of different mounting schemes. One helpful path is to browse the broader ecosystem of fairing collections and hardware, which can offer insight into mounting strategies, bracket compatibility, and aesthetic options. Beyond the hardware, it is useful to study how other riders have approached the interplay between lighting, safety, and visual coherence. Attending a local workshop or connecting with experienced builders can also provide hands-on feedback, helping to translate general guidelines into a successful on-bike result. The objective is to arrive at a fairing configuration that feels integrated rather than added on, a design that speaks to the bike’s ethos while amplifying the rider’s personal style.

Internal link reference: for broader explorations of fairing styles and mounting concepts, see the Yamaha fairings collection as a representative reference to several design approaches and fitment considerations. Yamaha fairings

External resource: For official guidance on installation, fitment, and electrical integration relevant to Harley-Davidson models, consult the brand’s technical resources. https://www.harley-davidson.com/en_us/support/technical-resources.html

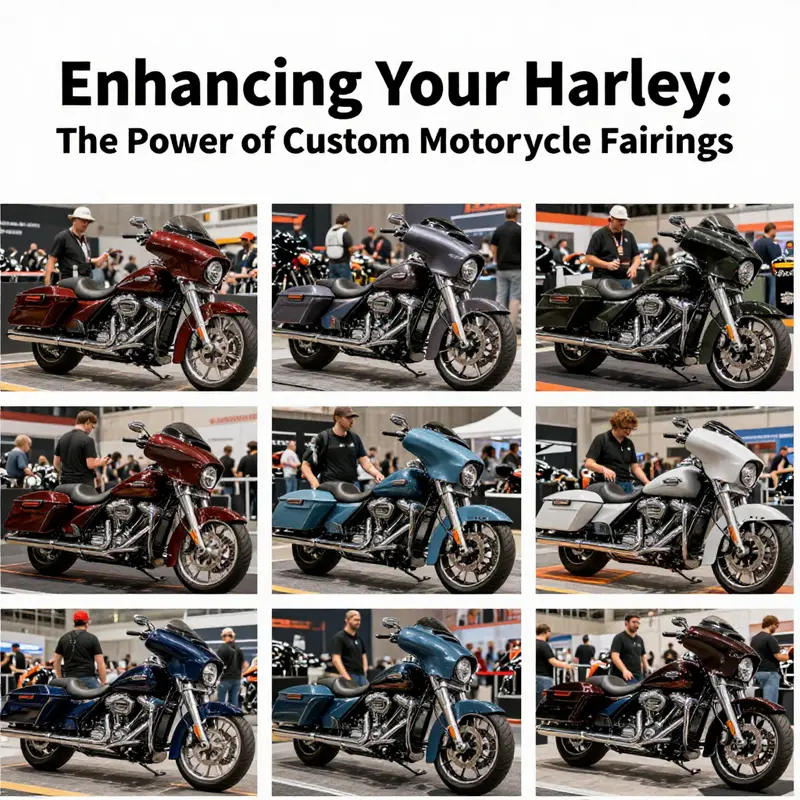

Winds of Change: Market Trends and the Personal Surge in Harley-Davidson Custom Fairings

The current landscape of motorcycle fairings sits at a crossroads of performance ambition and personal storytelling. The aftermarket scene is expanding rapidly, with a valuation that crosses the near record books and a steady rhythm of new designs that promise both better wind management and a more intimate connection between rider and machine. In 2025, the market crossed a notable threshold, reaching about 15.3 billion dollars in value, and the projection through the early 2030s shows a compound annual growth rate a little over 10 percent. Those figures are not merely numbers on a chart. They describe a durable shift in what riders expect when they look at a fairing kit: more control of air flow, more precise fitment, and a wider set of aesthetic options that let the motorcycle echo the rider’s mood, stance, and riding goals. For Harley-Davidson enthusiasts, this trend looks especially meaningful. It translates into a demand for fairing systems that can ride with the bike’s heritage—its long-hooded, upright stance or more aggressive lines—while delivering modern gains in aerodynamics and rider comfort.

The function of the fairing has evolved beyond the role of a stylish shell. It is increasingly treated as a performance accessory that must work in harmony with the bike’s power delivery, chassis geometry, and the rider’s posture. That means a fairing kit now requires careful attention to wind pressure at speed, turbulence reduction around the rider’s torso, and the way air interacts with the steering geometry during rapid lane changes or cornering. Materials matter. Manufacturers and custom shops alike are mixing composites with conventional plastics to strike a balance between stiffness, weight, and resilience to road debris and temperature cycles. In many cases, the choice of surface finish and trim is as important as the primary silhouette. A rider may want matte texture for a stealthy look, a glossy reveal to highlight color, or a translucent or metallic finish that catches light in a particular way as the bike moves down the long road. The result is that a modern fairing kit is a blend of engineering concern and artful expression, designed to survive miles of highway and years of evolving tastes.

From the rider’s seat, the difference in wind protection can be dramatic. A well-designed fairing reduces fatigue on longer rides, especially in crosswinds or at highway speeds. It can also stabilize the upper body, helping the rider maintain a steady grip and a comfortable posture when the machine is leaned into a curve. For many, this translates into longer days on the road without the interruption of back pain or shoulder strain. In addition to comfort, a properly tuned fairing enhances handling by guiding the air over and around the bike in a way that minimizes buffeting at mid- and high speeds. These outcomes matter not only in straight-line performance, but in the confidence a rider seeks when pushing through a challenging stretch of road or when crossing a canyon pass with a frequent gust. The net effect is a more precise instrument for the rider and an invitation to ride farther, faster, and with greater assurance.

The design language riding the wave of these market forces is varied yet cohesive. There is room for the classic cruiser look, with smooth curves that echo the bike’s historic silhouette, and there is room for a more modern, aggressive interpretation that whispers of aerodynamic efficiency. The challenge for designers is to deliver those effects without erasing the bike’s essential character. This is where modularity becomes a critical factor. A modular kit can be assembled to fit a range of sub-models within a brand’s lineup, sometimes swapping out panels, inner brackets, or mounting points to achieve a precise fit. It also invites color and texture customization, enabling riders to coordinate fairings with fenders, spoilers, and other bodywork to craft a cohesive, factory-inspired appearance that feels tailor-made. The result is not a single look, but a spectrum that allows riders to compose a visual narrative in harmony with their preferred riding tempo. Beyond images and colors, riders are paying attention to details such as anti-buffeting wind screens, air dams, venting patterns, and the logic behind airflow channels. Each choice affects comfort, stability, and the perception of the bike’s speed, making the fairing a central element in the overall riding experience.

In Harley’s ecosystem, as in the broader aftermarket space, riders show a strong preference for options that align with their personal riding style. Some favor a clean, old-school bobber vibe—minimalist fairings with restrained lines and a subtle sheen that nods to a simpler era—while others lean toward contemporary, performance-forward aesthetics that convey speed and edge the moment the bike rolls into the sunlight. The gap between these tastes is bridged by design strategies that emphasize modular parts, collaborative hardware ecosystems, and a palette of finishes that let the bike’s chrome, steel, or matte surfaces tell a consistent story. The result is not a single look, but a spectrum that allows riders to compose a visual narrative in harmony with their preferred riding tempo. Beyond images and colors, riders are paying attention to details such as anti-buffeting wind screens, air dams, venting patterns, and the logic behind airflow channels. Each choice affects comfort, stability, and the perception of the bike’s speed, making the fairing a central element in the overall riding experience.

Looking beyond Harley, the broader fairing ecosystem shows that the same forces shaping a rider’s tastes are at work across brands and models. The push toward personalization, combined with a desire for better wind management, has encouraged manufacturers to pursue modular kits that can be adapted to different frames without compromising fit or function. For enthusiasts who enjoy exploring options from outside their base marque, the variety of configurations and finishes is a welcome invitation to experiment with different looks and aerodynamic aims. See the Yamaha fairings collection for an illustration of how a similar design philosophy translates across platforms: Yamaha fairings. Watching how other brands approach integration, and how OEMs and aftermarket shops mirror these solutions, helps riders imagine what might be possible for their own Harley-Davidson.

The business implications of these shifts are equally compelling. A growing market means more competition, and competition tends to drive both price discipline and the pace of innovation. In practice, this translates to more transparent fitment guidelines, better documentation for installation, and wider availability of accessories that complement the fairing system. For riders, this often means shorter lead times, clearer expectations about what a kit can do, and a broader set of choices to tailor a bike to a particular ride profile—commuting, touring, canyon carving, or weekend cruising. For retailers and workshop specialists, the challenge is to maintain high standards of fit and finish across a wider array of model-year variations. This is where the importance of hardware compatibility and precise mounting solutions becomes evident. The modern rider does not want to compromise for the sake of ease; they want straightforward installation with predictable alignment, fasteners that resist vibration, and a finish that will hold up to weather, sun, and years of use.

The sustainability angle is another lens on the market dynamics. As riders seek longer lifecycles for their bikes and a reduced need to purchase new components as fashions change, manufacturers are investing in materials and processes that can endure the test of time. A fairing that maintains tensile strength and shape after repeated exposure to heat, cold, and road salt contributes to a lower overall environmental impact by extending the period of use before replacement. Even refined polymer blends and tougher coatings can slow the cycle of replacement and reduce waste. This attention to durability is not simply pragmatic; it is a statement about the rider’s relationship with the bike. If a fairing can weather years of adventures without visibly fading or warping, riders perceive greater value and are more likely to engage in ongoing customization rather than discarding older panels. That mindset further fuels demand for adaptable, modular systems that can be refreshed with new finishes or upgraded with more efficient airflow management without necessitating a full reconfiguration of the bike’s geometry.

From a design perspective, the emotional language of fairing choices mirrors the diversity of riding goals across the Harley-Davidson community. Some riders want the uninterrupted lines of a streamlined silhouette; others crave the dramatic profile that draws eyes at stoplights and on the highway. The fairing becomes an instrument of storytelling, a way to signal a rider’s preferences, experiences, and aspirations without saying a word. It is a visible expression of a rider’s approach to speed, comfort, and personal identity, all framed within a few carefully designed curves and edges. The interplay of light on a fairing’s surface, the precision of the panel gaps, and the quiet strength of the mounting hardware all contribute to a sense of pride in ownership. In this context, the topic moves from a purely functional upgrade to an act of self-expression that sits at the heart of the riding life.

As the next chapter approaches, it will examine how these market forces translate into practical considerations for riders choosing, budgeting, and installing a fairing kit. It will address fitment across model years, the role of professional installation versus home setups, and how riders can balance aesthetics with performance in a way that respects the bike’s original design language while pushing its capabilities forward. For now, the conversation centers on the way a market’s appetite for customization and refinement interacts with the rider’s hunger for a unique machine that feels tailor-made, even when it shares a road with many others. A fairing, after all, is a compact statement about what the rider wants from the bike and what the bike is willing to become in the hands of imagination and skill.

External resource: For further insights into the brand’s broader approach to customization and community, see the official Harley-Davidson site: https://www.harley-davidson.com

Final thoughts

Custom motorcycle fairings are more than just a cosmetic upgrade; they encapsulate the riders’ identity while boosting performance and creating a more enjoyable riding experience. As market trends evolve, understanding consumer preferences and effectively integrating these components becomes paramount for business owners targeting Harley-Davidson enthusiasts. By investing in knowledge and quality offerings, businesses can not only meet demands but also foster lasting customer relationships in this dynamic sector.