Introduction

Decals for motorcycle fairings represent a dynamic intersection of style, protection, and personalization—key elements fueling demand across the motorcycle aftermarket industry. For business owners, understanding the underlying materials and durability factors, the expansive customization options, and the practical installation and retail frameworks creates pathways to enhance product offerings and customer satisfaction. This comprehensive exploration unpacks these three critical aspects, highlighting how they collectively offer opportunities to differentiate products, engage discerning riders, and expand market reach with reliable, attractive, and easy-to-apply decals.

Tables of Contents

Chapter 1: Materials and Durability of Decals for Motorcycle Fairing

- PVC Adhesive Vinyl: The Backbone of Durable and Flexible Motorcycle Fairing Decals

- Shielding Your Ride: How UV Resistance and Environment Shape Decal Longevity

- Cutting-Edge UV Printing and Adhesive Innovations Driving Decal Longevity and Performance

- How ABS Plastic and Multi-Layer Paint Coatings Amplify Decal Longevity on Motorcycle Fairings

- Effective Care Strategies to Maximize the Lifespan of Motorcycle Fairing Decals

Chapter 2: Customization Options for Decals on Motorcycle Fairing

- Unlocking Design Freedom: Tailoring Motorcycle Fairing Decals to Your Style

- Balancing Material Integrity and Lasting Impact: Durability Factors in Fairing Decal Customization

- Cutting-Edge Technologies Shaping the Future of Motorcycle Fairing Decal Customization

- Riding the Economic Wave: Market Growth and Trends Driving Motorcycle Fairing Decal Customization

- Streamlined Ordering and Support: Enhancing Custom Decal Experiences for Motorcycle Fairings

Chapter 3: Installation and Retail Availability of Decals for Motorcycle Fairing

- Exploring Online Retail Options and Custom Design Flexibility for Motorcycle Fairing Decals

- Navigating Availability and Customer Support: Where and How to Buy Motorcycle Fairing Decals

- Essential Steps for Smooth Fairing Removal and Preparation Before Decal Application

- Mastering Decal Installation: Surface Prep and Application for Long-Lasting Motorcycle Fairing Graphics

- Navigating DIY and Professional Installation: Making the Right Choice for Motorcycle Fairing Decals

Chapter 1: Materials and Durability of Decals for Motorcycle Fairing

1. PVC Adhesive Vinyl: The Backbone of Durable and Flexible Motorcycle Fairing Decals

Decals applied to motorcycle fairings require materials that can withstand constant exposure to harsh environmental elements while conforming precisely to complex surface curves. PVC adhesive vinyl stands out as the preferred material for these applications due to its exceptional balance of durability, flexibility, and ease of installation. This material’s inherent resistance to ultraviolet rays, rain, and abrasion helps maintain decal vibrancy and adhesion through changing weather and high-speed riding conditions.

The flexibility of PVC vinyl is particularly important because motorcycle fairings often feature curved and contoured shapes that demand a decal capable of stretching and conforming without wrinkling or peeling. By flexing with the fairing’s surface, PVC adhesive vinyl ensures a smooth, professional finish even on the most challenging geometries. Adhesives programmed to firmly bond yet allow careful removal without damaging the paint layer beneath are commonly used to enhance both application and long-term maintenance.

Finishes available in either glossy or matte textures allow riders to match or enhance their bike’s aesthetic preferences, often combined with UV-resistant clear coats that further protect colors from fading over time. Advanced PVC variants incorporate air-release layers to minimize micro bubbles during installation, yielding a seamless surface and simplifying the application process for riders and professionals alike.

Furthermore, the compatibility between PVC adhesive vinyl and the common injection-molded ABS plastic of motorcycle fairings supports this material’s effectiveness. Both materials demonstrate strong durability and flexibility, contributing to the decal’s longevity under rigorous riding conditions.

To explore tailored fairing solutions and the role vinyl materials play in customizing your bike’s appearance, visiting an expert hub like Summit Fairings provides valuable insights and options.

For more detailed technical perspectives on PVC adhesive vinyl’s properties in decal applications, consult specialized sources such as those found in industry reports 1[4]5.

2. Shielding Your Ride: How UV Resistance and Environment Shape Decal Longevity

The endurance of decals on motorcycle fairings is largely determined by their ability to resist ultraviolet (UV) rays and withstand harsh environmental conditions. UV exposure is a primary agent of fading and material breakdown, causing decals to lose vibrancy and become brittle. High-quality decals incorporate special UV-resistant vinyl films paired with protective clear coats or laminates. These layers act as a barrier that preserves the decal’s color intensity and structural integrity despite prolonged sun exposure.

Beyond UV rays, the decal’s durability also depends on its resilience to environmental challenges such as dirt accumulation, moisture, temperature fluctuations, and physical abrasions like scratches or rock chips. Premium vinyl materials designed for fairings often boast a robust thickness and lamination that shield both the decal and underlying paint from these elements, effectively extending the lifespan of the graphics. Improper exposure to these hazards without protective coatings typically results in premature peeling, cracking, or discoloration.

Successful long-term adhesion is closely linked to proper installation on a clean, undamaged surface, which prevents edge lifting and ensures the decal moves with the fairing’s contours. Routine maintenance further supports durability; gentle washing with mild soap, avoidance of harsh chemicals and pressure washers, and the application of wax or sealants can reinforce protection against grime and wear.

By prioritizing decals crafted from premium vinyl films with advanced UV protection and laminates, alongside mindful upkeep, riders can secure both the aesthetic appeal and longevity of their motorcycle fairing graphics. For in-depth guidance on choosing and caring for durable decal materials tailored to real-world riding conditions, informative resources such as those provided by specialist fairing suppliers offer valuable insights.

Explore more about the selection and care of motorcycle fairings in this guide to discover affordable motorcycle fairings at Summit Fairings.

3. Cutting-Edge UV Printing and Adhesive Innovations Driving Decal Longevity and Performance

The durability and visual appeal of decals on motorcycle fairings have been significantly boosted by advances in UV printing and adhesive technologies. UV printing employs ultraviolet light to cure inks instantly, resulting in decals with vivid colors and exceptional resistance to fading, scratches, fuel, and chemical exposure. This curing process produces a finish that not only showcases detailed and custom designs with precise color fidelity but also maintains a glossy, durable surface even under harsh outdoor conditions.

Protection is often enhanced by laminated layers applied over the printed decals. These layers add an extra shield against UV rays and physical abrasion, preserving the decal’s vibrancy and integrity over long periods. This technology is especially valuable for motorcycle fairings, which face continuous exposure to sunlight, road debris, and environmental chemicals.

On the adhesive front, modern formulations deliver strong, flexible bonds tailored for the unique surfaces of motorcycle fairings, including ABS plastic and carbon fiber composites. These adhesives accommodate the fairing’s curves, textures, and vibrations encountered in riding without peeling or bubbling. Their resistance to heat, moisture, and mechanical stress ensures the decals remain securely affixed even in demanding environments.

Together, these innovations facilitate decals that not only elevate a motorcycle’s style but also withstand the functional challenges of street and track use. The seamless combination of UV-cured inks and advanced adhesives results in long-lasting customization options that retain their gloss and adherence amid the rigors of riding.

For riders and customizers seeking reliable and visually striking decal solutions, understanding these technologies is key to selecting products designed for optimum durability and aesthetic appeal. More detailed insights into these developments and their applications can be found at MadMotoGraphics. Additionally, exploring versatile options at Discover Affordable Motorcycle Fairings at Summit Fairings may help integrate high-quality decals with matching fairings.

4. How ABS Plastic and Multi-Layer Paint Coatings Amplify Decal Longevity on Motorcycle Fairings

The lasting durability and optimal adhesion of decals on motorcycle fairings depend heavily on the synergy between the underlying fairing materials and their surface treatments. At the heart of many aftermarket and OEM fairings lies ABS plastic, a robust thermoplastic chosen for its exceptional balance of strength, flexibility, and impact resistance. This base layer effectively absorbs environmental stresses such as road vibrations and minor collisions without cracking or deforming, providing a stable and resilient foundation for decal application.

Overlaying this base, manufacturers often apply multi-layer paint coatings encompassing primer, base color, clear coats, and additional protective finishes. This multi-stage painting process not only delivers vibrant, fade-resistant colors but also creates an ultra-smooth surface crucial for decal adhesion. The smoothness prevents imperfections such as air bubbles or peeling and ensures the decal bonds evenly across the fairing’s contours. Moreover, clear coat layers approach a dual function, enhancing overall gloss while shielding the decals from UV damage and abrasion, which extends their visual sharpness and prevents early brittleness.

Many modern kits also incorporate heat shield elements that moderate temperature fluctuations around decal zones, preventing adhesive breakdown caused by excessive heat. This control over thermal stress is essential for maintaining decal integrity in varying environmental conditions.

Proper interaction between ABS plastic’s physical properties and finely crafted paint finishes ultimately supports decals that look authentic and endure real-world use. Riders benefit from graphics that sustain their vibrancy and adhesion without compromising the fairings’ structural strength. These features elevate aftermarket fairings beyond mere cosmetic parts, becoming durable platforms for expressive customization.

To maximize decal longevity, routine maintenance should avoid abrasive cleaners and excessive sun exposure, preserving both paint and decal layers. More on maintaining these surfaces can be found in guides dedicated to preserving premium finishes, such as those at Summit Fairings’ blog.

Leveraging these carefully engineered materials and coatings is the foundation for durable decal customization, balancing style with function in motorcycle fairing upgrades. For further technical specifications on OEM-grade ABS and paint processes, detailed insights are available from experts in aftermarket fairings production here.

5. Effective Care Strategies to Maximize the Lifespan of Motorcycle Fairing Decals

Maintaining the vibrancy and adhesion of decals on motorcycle fairings requires intentional care habits that protect them from environmental and physical stressors. UV exposure is a primary threat, as prolonged sunlight gradually fades colors and weakens adhesive bonds. Parking in shaded areas or indoors greatly reduces this risk, while when outdoor parking is unavoidable, a UV-protective motorcycle cover shields decals from damaging rays and reduces heat buildup.

Cleaning methods also play a critical role in decal longevity. Using mild soaps and soft cloths prevents abrasion or chemical damage to the decal surface, unlike harsh detergents or scrubbing pads that can cause premature deterioration or lifting. Washing should be gentle yet thorough to remove dirt without disturbing the decal’s edges.

Applying a protective wax layer designed for motorcycles further fortifies decals by creating a barrier against moisture, ultraviolet light, and road grime. This treatment helps maintain decal adhesion and preserve their original sheen, keeping graphics sharp and vibrant over time.

Underlying materials influence decal performance as well. High-quality ABS plastic fairings with UV-resistant paint and clear coats provide an optimal base for decals to bond securely and endure outdoor conditions. When decals need removal or replacement, controlled application of heat softens the adhesive, allowing safe lifting without damaging the fairing’s surface.

Adopting these care practices enhances decal durability while maintaining the customized appearance of the motorcycle. For riders seeking deeper insights on proper washing and waxing techniques, detailed advice is available via maintenance tips on washing and waxing for fairings and decals.

Additionally, exploring the best methods to protect and care for your motorcycle’s external components can be further supported by resources such as the Summit Fairings blog, which offers comprehensive guides on motorcycle fairings and their upkeep.

Chapter 2: Customization Options for Decals on Motorcycle Fairing

1. Unlocking Design Freedom: Tailoring Motorcycle Fairing Decals to Your Style

Customization of motorcycle fairing decals offers riders a dynamic canvas for personal expression through extensive design flexibility. This flexibility encompasses everything from the choice of materials and finishes to intricate graphic designs and precise decal placements, all crafted to harmonize with the bike’s contours and rider preferences. High-end custom kits typically feature premium materials such as durable ABS plastic and high-performance vinyl that not only ensure a perfect OEM-level fit but also withstand the rigors of road use and weather exposure.

Riders can choose from a variety of finishes including glossy, matte, pearlescent, or textured effects like carbon fiber patterns that amplify both style and the perceived sophistication of the motorcycle. Beyond standard color options, many decal providers enable integration of personal logos, racing numbers, or sponsor decals that infuse individuality and even brand identity directly onto the fairing surfaces. This level of customization extends to full graphic kit sets, covering components such as windscreens, fuel tanks, and seat cowls, all pre-drilled for seamless bolt-on installation without needing modifications.

Additionally, advanced vinyl technology used in these decals incorporates UV protection and reinforced adhesives, offering durability while maintaining vibrant visual appeal. Universal vinyl decal sets further broaden options by allowing size and design adjustments suitable for various motorcycle parts, accommodating diverse rider needs across different models. This wealth of customization choices ensures each rider can achieve a unique aesthetic while benefiting from professionally engineered fit and finish.

For those seeking comprehensive guidance or inspiration on selecting and applying custom decals, detailed resources and design services support riders throughout the process, ensuring their vision is realized with precision. To explore tailored possibilities for your motorcycle’s appearance, visit the Explore the Best Motorcycle Fairings at Summit Fairings blog.

2. Balancing Material Integrity and Lasting Impact: Durability Factors in Fairing Decal Customization

Customizing decals on motorcycle fairings requires careful attention to both the materials involved and their durability under diverse conditions. Most motorcycle fairings utilize high-grade ABS plastic as their base material, celebrated for its strength, flexibility, and resistance to impacts encountered on the road. This durable plastic provides a stable surface that supports decal adhesion while enduring environmental factors like heat and moisture. Decals designed for such surfaces predominantly employ high-quality vinyl films. These vinyl decals are specifically formulated to withstand outdoor exposure, resisting UV radiation, rain, and wear for over six years without significant degradation. To further protect the fairing and enhance decal longevity, factory-grade paint systems often include UV-resistant clear coats. These clear coats shield the underlying paint and the decal’s vibrant colors from fading due to sun exposure, maintaining visual appeal over time.

Achieving a durable and seamless decal application hinges on proper surface preparation. Cleaning the fairing with mild soap and water removes contaminants without damaging paint or plastic. This ensures optimal adhesion and prevents peeling or bubbling. Some advanced customization kits incorporate materials like carbon fiber composites to improve strength-to-weight ratios. While these enhance performance attributes, their delicate surfaces demand compatible adhesives that secure decals without compromising material integrity.

By integrating durable vinyl decals with robust fairing materials and protective coatings, riders can achieve vivid, long-lasting customization that endures the rigors of daily riding. Maintenance remains straightforward, requiring only gentle cleaning methods to preserve both decal vibrancy and fairing quality. This thoughtful balance of material choice and durability technologies exemplifies best practices in motorcycle fairing decal customization, ensuring that personalized graphics remain striking and structurally sound through varied weather and road conditions. For further insights into high-quality fairing materials and their customization compatibility, explore detailed resources like those available at Summit Fairings’ blog.

External reference: https://blog.summitfairings.com/explore-the-best-motorcycle-fairings-at-summit-fairings/

3. Cutting-Edge Technologies Shaping the Future of Motorcycle Fairing Decal Customization

The evolution of customization options for motorcycle fairing decals is marked by groundbreaking technological advances that blend precision engineering with creative freedom. Modern decals for fairings utilize high-grade vinyl materials engineered with reinforced adhesives and UV-resistant coatings to endure harsh weather and prolonged sun exposure without fading or peeling. These innovations guarantee that the decals retain vibrant colors and a flawless finish, enhancing both the look and longevity of the motorcycle.

Precision digital cutting techniques now allow decals to be tailored exactly to the unique curves and contours of specific motorcycle models. This meticulous fit achieves a seamless, factory-level appearance that complements the underlying structure of the fairing. Customized design platforms offer riders the ability to visualize and tweak graphics through digital proofs with unlimited revisions, ensuring that every element—from color gradients to intricate patterns—matches personal style and bike aesthetics.

Manufacturing processes have also progressed to integrate multi-step paint and decal application systems. These steps not only secure strong adhesion but also enhance durability and gloss, producing finishes that resist scratches and environmental wear. Some advanced kits even factor in aerodynamic principles through computational fluid dynamics (CFD) during fairing and decal design, optimizing airflow while elevating visual impact.

Fast, made-to-order production technologies support rapid turnaround without sacrificing quality, acknowledging the rider’s need for distinct, race-inspired, or brand-specific themes. The fusion of premium materials, exacting digital customization, and sophisticated manufacturing delivers highly resilient, captivating decals that maintain performance integrity.

For riders seeking a comprehensive guide on the customization and durability of motorcycle fairings, exploring expert insights at Summit Fairings blog provides valuable knowledge. Additional details on cutting-edge production processes and materials are also available through industry leaders specializing in precision paint and decal applications for motorcycle fairings. (Source: https://www.kingsmotorcyclefairings.com/pages/aboutus)

4. Riding the Economic Wave: Market Growth and Trends Driving Motorcycle Fairing Decal Customization

Customization of decals on motorcycle fairings has evolved into a significant economic force within the aftermarket motorcycle industry. This demand is largely fueled by riders’ desire to individualize their bikes not just visually but also functionally. Businesses specializing in custom fairing decal kits have developed premium, tailor-made solutions that combine aesthetic appeal with durability and ease of installation. Customers now expect not only attractive designs but also modular options that blend performance improvements with personalization.

Companies have capitalized on this by offering complete kits featuring multi-step paint and decal applications, including graphics that resonate with brand identity or racing heritage. This approach enhances the perceived value and supports premium pricing, beneficial in a competitive market. Meanwhile, emerging trends demonstrate a shift from purely decorative decals to integrated designs that complement aerodynamic and ergonomic advances seen in newer motorcycle models—an example being advanced fairing kits that marry graphic customization with performance enhancements.

Despite some challenges in traditional motorcycle retail sectors caused by market shifts and e-commerce pressures, the aftermarket customization segment thrives. Riders invest continuously in personalization, proving that decal customization is a resilient and profitable niche. This sustained interest provides a steady revenue stream for businesses and encourages innovation in materials, design software, and packaging options.

The expansion of customization options also broadens the consumer base—from novices seeking subtle personal touches to veteran enthusiasts keen on unique, race-inspired looks. This diversity fuels ongoing market growth and attracts a spectrum of suppliers offering everything from simple sticker sheets to comprehensive graphic kits.

For those interested in exploring a broad selection of high-quality and affordable options, discovering more at Summit Fairings provides a useful gateway to current market offerings.

These market dynamics highlight how decal customization on motorcycle fairings is driving economic vitality and innovation within the aftermarket ecosystem globally.

For more context on custom kit providers and market impact, visit Kings Motorcycle Fairings.

5. Streamlined Ordering and Support: Enhancing Custom Decal Experiences for Motorcycle Fairings

Securing custom decals for motorcycle fairings involves a meticulous ordering process paired with attentive customer support to ensure satisfaction at every step. Leading providers empower riders to personalize every detail, from color schemes to graphic elements, often through intuitive online design tools that enable unlimited revisions before finalizing the look. This tailored approach guarantees that the final product matches the rider’s vision precisely. Alongside design customization, customers typically receive detailed proofs or photos of their decals or full kits before production or shipment, allowing them to confirm accuracy and request adjustments if necessary.

Customer support plays a pivotal role in smoothing this experience by offering responsive communication channels, often operating around the clock. Whether assisting with design choices, clarifying order details, or addressing post-purchase concerns, this support ensures buyers feel confident and informed. Installation guidance is frequently provided as well, with step-by-step video tutorials or QR-code links helping riders apply decals correctly to protect their longevity and appearance.

Since customized decals are made to exact specifications, return policies tend to be strict, allowing exceptions mainly when manufacturing errors occur. Buyers ordering from international locations should anticipate upfront payment of taxes and shipping fees to prevent delivery delays or unexpected costs.

This comprehensive customer-centric model—from initial design through shipping and installation support—creates a seamless, enjoyable purchasing journey. It empowers riders of all levels to confidently enhance their motorcycles with decals that reflect their unique styles while minimizing order errors and installation frustrations.

For more insights on enhancing your bike’s look through quality fairings and decals, explore detailed selections and tips at Discover affordable motorcycle fairings at Summit Fairings.

In addition, one example of providers offering accessible online proofing and rapid global shipping with durable vinyl materials illustrates the growing ease of customizing motorcycle aesthetics with professional support and streamlined ordering.

Chapter 3: Installation and Retail Availability of Decals for Motorcycle Fairing

1. Exploring Online Retail Options and Custom Design Flexibility for Motorcycle Fairing Decals

Decals designed for motorcycle fairings are readily accessible through a variety of online retailers that cater to diverse customization needs and quality expectations. These online sources range from vendors offering complete fairing kits integrated with decals to those specializing in personalized graphic applications suited for distinct brands and styles. High-end providers typically deliver OEM-fit fairing sets made from durable materials like injection-molded ABS plastic, finished with UV-resistant paints to ensure longevity and appeal. Their offerings allow riders to select from factory-inspired color schemes, racing aesthetics, or entirely unique designs, blending both protection and style seamlessly.

For enthusiasts seeking tailored graphic decals without replacing fairings, several specialists offer extensive design freedom through intuitive online tools. These platforms support unlimited revisions, enabling customers to perfect fonts, colors, shapes, and patterns before printing. Their products emphasize durability, employing high-quality vinyl engineered to withstand various riding conditions including off-road environments. This adaptability is ideal for riders who require resilience alongside strong visual impact.

Additionally, smaller boutique shops and marketplaces often showcase distinctive reflective and artisanal vinyl stickers, giving riders the chance to stand out with unique, handmade touches that complement standard fairing decals. The broad selection of digital design services ensures fast turnaround times with worldwide shipping, meeting the needs of local and international customers alike.

Choosing between full kits or individual decal sheets, riders benefit from professional-grade products tailored to their specific model, riding style, and aesthetic vision. This spectrum of retail availability makes upgrading motorcycle fairings accessible and flexible, supporting both beginners and custom builders chasing personalized expression. Those interested in detailed options and expert insights may find valuable resources discussing comprehensive fairing choices at Summit Fairings.

Explore in-depth retail options and customization possibilities at this source.

2. Navigating Availability and Customer Support: Where and How to Buy Motorcycle Fairing Decals

Motorcycle fairing decals offer riders a dynamic way to personalize and protect their bikes, but accessing these decals involves a landscape dominated by online specialty vendors complemented by physical retail touchpoints. While most decals are purchased through online stores that provide a vast selection and convenient ordering, these sellers often extend their presence beyond digital platforms by attending motorcycle events and bike weeks. At these gatherings, riders can interact face-to-face with decal makers, examine products firsthand, and even receive on-site guidance.

Contrastingly, large motorcycle gear retailers maintain brick-and-mortar showrooms in various cities, allowing customers to see and choose fairing decals with direct assistance from knowledgeable staff. These stores foster rider communities through events like Bike Nights, supporting both product education and social networking. The availability of in-person customer service means shoppers can receive personalized advice and immediate answers to queries, enriching the purchasing experience beyond a simple transaction.

Local two-wheeler parts dealers occasionally stock decals or facilitate orders for specific motorcycle brands, offering a more regionalized option for riders. Their decal variety tends to be narrower compared to specialty sources, but their proximity can provide quicker access and community-oriented support.

Customer assistance across these channels varies with the retail format: online vendors typically support buyers via email and provide detailed video tutorials to guide installation, including replacement services if needed. Physical stores combine sales with hands-on help, product demonstrations, and a social atmosphere that encourages knowledge exchange among riders.

This dual approach bridges convenience and personalized service, empowering motorcyclists to select decals that suit their style and needs. For those seeking a wide range of options and custom designs, online platforms remain unparalleled, while physical locations cater to riders who value immediate assistance and tactile interaction. Riders interested in exploring superior choices in motorcycle fairings can visit this comprehensive resource on Summit Fairings to further enhance their customization journey.

For additional examples of vendor participation at events and the blend of online and personal customer support, see resources detailing vendor engagement at bike weeks and physical showroom events.

3. Essential Steps for Smooth Fairing Removal and Preparation Before Decal Application

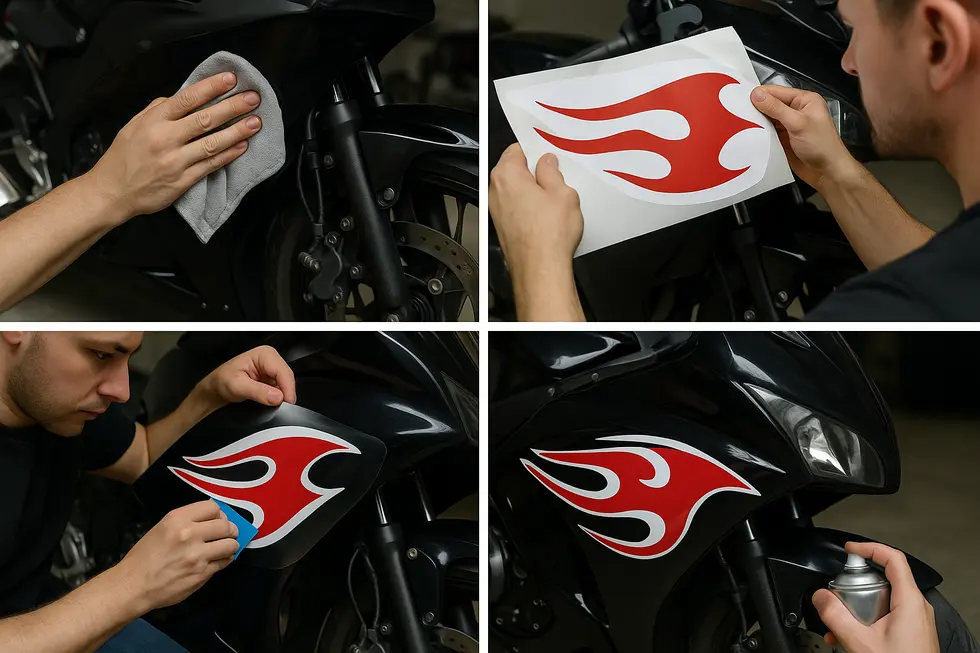

Achieving a flawless decal installation on motorcycle fairings begins well before applying the graphic itself. The process starts by carefully removing the fairings, which must be detached without damage to the panels or mounting hardware. This involves unscrewing all bolts and clips securing the fairings—such as the side rear panels on popular models, which often require a 4mm Allen key or similar tool. Organizing all the hardware during removal is crucial to ensure easy and accurate reassembly later. Once the fairings are off, the next step is meticulous surface preparation. Any dust, grease, or oils left behind can reduce decal adhesion and cause bubbling or peeling over time. Cleaning with mild detergents and soft cloths followed by complete drying ensures a pristine base for the vinyl to stick firmly. Some riders also choose to lightly scuff the surface to enhance bonding, depending on the decal manufacturer’s advice. After preparing the fairing panels, aligning decals precisely is vital. Many decals come with transfer tape to aid positioning; loosely reattaching the fairings can help verify alignment before sticking the graphic permanently. Using a squeegee or a flat tool while pressing down eliminates trapped air bubbles, delivering a smooth, professional look. Allowing proper curing time as recommended ensures the adhesive sets fully for durability. Finally, reinstallation of the fairings completes the process. Using the original bolts and clips, the panels are fastened back securely to maintain the motorcycle’s structural integrity and aesthetic. This careful sequence—from removal and cleaning to application and reassembly—forms the foundation for a long-lasting, visually striking decal upgrade. For detailed disassembly instructions tailored to specific models, consult specialized tutorials available online. Those seeking more information on acquiring quality motorcycle fairings and decals can explore Summit Fairings’ ultimate source for affordable motorcycle fairings.

4. Mastering Decal Installation: Surface Prep and Application for Long-Lasting Motorcycle Fairing Graphics

Achieving a durable and visually flawless decal application on motorcycle fairings hinges on meticulous surface preparation combined with skillful installation techniques. Before applying any decal, the fairing’s surface must be immaculately clean. Dirt, grease, wax, or residues pose a significant risk to adhesive strength, so using a mild detergent with a soft cloth is essential. Follow this by drying the surface thoroughly and wiping with isopropyl alcohol to remove any remaining oils. The fairing should be smooth and free of imperfections; unevenness can cause bubbles or peeling over time, undermining the decal’s longevity.

Environmental factors play a subtle but vital role; applying decals in a dust-free space with moderate temperature minimizes moisture and contaminant interference. This controlled environment supports a seamless bond between vinyl and fairing.

When ready to install, careful alignment prevents awkward distortion or misplacement. The use of a squeegee or similar tool to press out air bubbles is crucial, working outward from the center to the edges with firm, even pressure. Avoid stretching the vinyl to preserve graphic integrity and prevent warping. Once installed, it’s important to allow proper curing time before exposing the decal to water, sunlight, or harsh conditions, ensuring the adhesive fully bonds to the fairing’s surface.

Adopting these practical steps optimizes both the appearance and durability of motorcycle fairing decals, allowing riders to enjoy customized styles that withstand daily elements. For further insights on selecting and enhancing motorcycle fairings, explore affordable motorcycle fairings options that complement your decal customization journey.

5. Navigating DIY and Professional Installation: Making the Right Choice for Motorcycle Fairing Decals

Choosing between DIY and professional installation of motorcycle fairing decals involves weighing factors such as cost, skill level, and desired finish quality. Many retailers offer high-quality decal kits made from durable materials like ABS plastic, often accompanied by clear coat protection and all necessary mounting hardware. These kits typically include detailed instructions to support a successful DIY approach.

DIY installation demands careful surface preparation—cleaning to remove dirt and oils—and meticulous alignment to prevent air bubbles or misplacement. Tools like squeegees or soft cloths help smooth decals onto fairings, while precision trimming ensures a seamless edge. Although this method can be cost-effective and rewarding, it requires patience and steady hands to achieve a professional look.

On the other hand, professional installation offers expertise that minimizes risks of damage or imperfect placement. Skilled installers use specialized equipment to guarantee strong adhesion and long-lasting durability. This option is particularly worthwhile for complex full-body wraps or riders who prioritize a flawless finish, especially when warranty conditions require certified application.

Cost is a practical consideration: DIY installation mainly involves material expenses, while professional services add labor fees. However, the quality and longevity of the decal application often justify the higher price of expert services. For riders who prefer personal involvement and have reasonable skill, DIY can deliver satisfying results. Those seeking precision and convenience may lean toward professionals.

Retailers often provide support for either choice, ensuring that both DIY enthusiasts and those opting for professional help have a smooth installation experience. This reflects the broad appeal of decals as a versatile and accessible way to customize and protect motorcycle fairings.

For more guidance on selecting and installing fairings and decals, explore comprehensive resources available at Summit Fairings.

Additionally, tutorials for specific models highlight best practices in surface preparation and application, helping riders optimize durability and finish quality with their chosen installation method.

Final thoughts

Decals for motorcycle fairings offer business owners a compelling product category that balances durability, extensive customization, and user-friendly installation. Leveraging high-quality vinyl materials ensures end-user satisfaction through longevity and resistance, while diverse customization fuels creative expression and brand differentiation. Practical installation methods paired with wide retail availability facilitate accessibility and market growth. By focusing on these integrated elements, businesses can deliver value-packed solutions that appeal to a broad spectrum of riders—from novices to seasoned custom builders—maximizing sales potential and customer loyalty in the competitive motorcycle aftermarket.

Ready to elevate your ride? Summit Fairings delivers premium, custom-fit fairings that blend style and durability. Whether you’re chasing speed or turning heads, we’ve got your bike covered. Don’t wait—transform your machine today. Click, customize, and ride with confidence. Your perfect fairing is just a few clicks away. Act now!

About us

undefined